steel - Nouvelle page 1 - Free

steel - Nouvelle page 1 - Free

steel - Nouvelle page 1 - Free

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

MMPDS-01<br />

31 January 2003<br />

2.4.3 9Ni-4Co-0.30C<br />

2.4.3.0 Comments and Properties — The 9Ni-4Co-0.30C alloy was developed specifically<br />

to have high hardenability and good fracture toughness when heat treated to 220 to 240 ksi ultimate tensile<br />

strength. The alloy is through hardening in section sizes up to 4 inches thick. The alloy may be exposed to<br />

temperatures up to 900EF (approximately 100EF below typical tempering temperature) without<br />

microstructural changes which degrade room temperature strength. This grade must be formed and welded<br />

in the annealed condition. Preheat and post-heat of the weldment is required. The <strong>steel</strong> is produced by<br />

consumable electrode vacuum melting.<br />

The heat treatment for this alloy consists of normalizing at 1650 ± 25EF for 1 hour per inch of cross<br />

section, cooling in air to room temperature, heating to 1550 ± 25EF for 1 hour per inch of cross section but<br />

not less than 1 hour, quenching in oil or water, subzero treating at -100EF for 1 to 2 hours, and double<br />

tempering at 975 ± 10EF (sheet, strip, and plate) or 1000 ± 10EF (bars, forgings, and tubings) for 2 hours.<br />

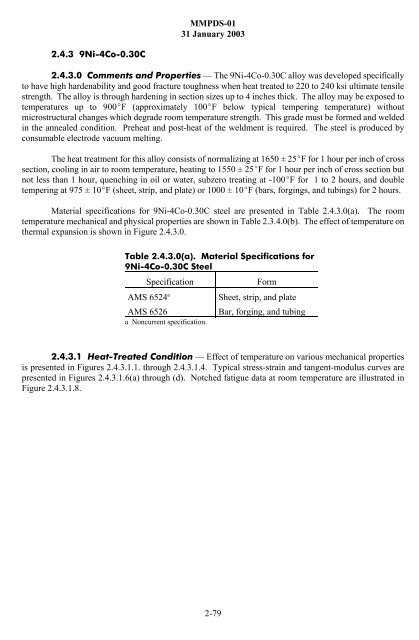

Material specifications for 9Ni-4Co-0.30C <strong>steel</strong> are presented in Table 2.4.3.0(a). The room<br />

temperature mechanical and physical properties are shown in Table 2.3.4.0(b). The effect of temperature on<br />

thermal expansion is shown in Figure 2.4.3.0.<br />

Table 2.4.3.0(a). Material Specifications for<br />

9Ni-4Co-0.30C Steel<br />

Specification<br />

AMS 6524 a<br />

AMS 6526<br />

a Noncurrent specification.<br />

Form<br />

Sheet, strip, and plate<br />

Bar, forging, and tubing<br />

2.4.3.1 Heat-Treated Condition — Effect of temperature on various mechanical properties<br />

is presented in Figures 2.4.3.1.1. through 2.4.3.1.4. Typical stress-strain and tangent-modulus curves are<br />

presented in Figures 2.4.3.1.6(a) through (d). Notched fatigue data at room temperature are illustrated in<br />

Figure 2.4.3.1.8.<br />

2-79