steel - Nouvelle page 1 - Free

steel - Nouvelle page 1 - Free

steel - Nouvelle page 1 - Free

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2.4 INTERMEDIATE ALLOY STEELS<br />

MMPDS-01<br />

31 January 2003<br />

2.4.0 COMMENTS ON INTERMEDIATE ALLOY STEELS — The intermediate alloy <strong>steel</strong>s in this section<br />

are those <strong>steel</strong>s that are substantially higher in alloy content than the alloy <strong>steel</strong>s described in Section 2.3, but<br />

lower in alloy content than the stainless <strong>steel</strong>s. Typical of the intermediate alloy <strong>steel</strong>s is the 5Cr-Mo-V<br />

aircraft <strong>steel</strong> and the 9Ni-4Co series of <strong>steel</strong>s.<br />

2.4.0.1 Metallurgical Considerations — The alloying elements added to these <strong>steel</strong>s are<br />

similar to those used in the lower alloy <strong>steel</strong>s and, in general, have the same effects. The difference lies in<br />

the quantity of alloying additions and the extent of these effects. Thus, higher chromium contents provide<br />

improved oxidation resistance. Additions of molybdenum, vanadium, and tungsten, together with the<br />

chromium, provide deep air-hardening properties and improve the elevated-temperature strength by retarding<br />

the rate of tempering at high temperatures. Additions of nickel to nonsecondary hardening <strong>steel</strong>s lower the<br />

transition temperature and improve low-temperature toughness.<br />

2.4.1 5CR-MO-V<br />

2.4.1.0 Comments and Properties — Alloy 5Cr-Mo-V aircraft <strong>steel</strong> exhibits high strength<br />

in the temperature range up to 1000EF. Its characteristics also include air hardenability in thick sections;<br />

consequently, little distortion is encountered in heat treatment. This <strong>steel</strong> is available either as air-melted or<br />

consumable electrode vacuum-melted quality although only consumable electrode vacuum-melted quality<br />

is recommended for aerospace applications.<br />

The heat treatment recommended for this <strong>steel</strong> consists of heating to 1850EF ± 50, holding 15 to<br />

25 minutes for sheet or 30 to 60 minutes for bars depending on section size, cooling in air to room<br />

temperature, tempering three times by heating to the temperature specified in Table 2.4.1.0(a) for the<br />

strength level desired, holding at temperature for 2 to 3 hours, and cooling in air.<br />

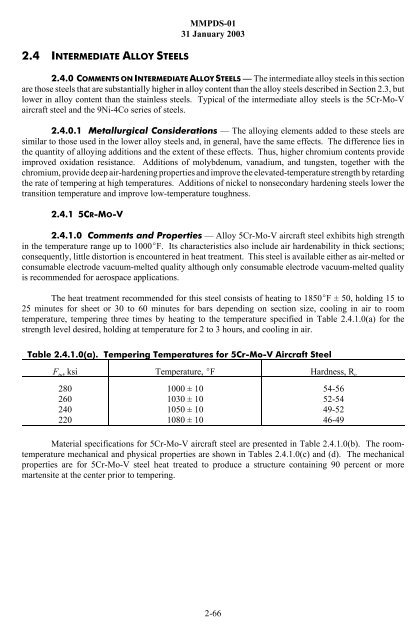

Table 2.4.1.0(a). Tempering Temperatures for 5Cr-Mo-V Aircraft Steel<br />

F tu , ksi Temperature, EF Hardness, R c<br />

280<br />

260<br />

240<br />

220<br />

1000 ± 10<br />

1030 ± 10<br />

1050 ± 10<br />

1080 ± 10<br />

54-56<br />

52-54<br />

49-52<br />

46-49<br />

Material specifications for 5Cr-Mo-V aircraft <strong>steel</strong> are presented in Table 2.4.1.0(b). The roomtemperature<br />

mechanical and physical properties are shown in Tables 2.4.1.0(c) and (d). The mechanical<br />

properties are for 5Cr-Mo-V <strong>steel</strong> heat treated to produce a structure containing 90 percent or more<br />

martensite at the center prior to tempering.<br />

2-66