Tornos MultiDECO - Gibas

Tornos MultiDECO - Gibas

Tornos MultiDECO - Gibas

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

THINK PARTS THINK TORNOS<br />

MULTIDECO<br />

Multispindle automatic lathe with<br />

numerical control.

MULTIDECO<br />

Bar turning through the <strong>Tornos</strong> experience<br />

For more than 100 years <strong>Tornos</strong> has been producing<br />

automatic single spindle and multispindle<br />

lathes, which can machine small or large series of<br />

the most simple to the highly complex parts, in a<br />

way that is both highly accurate and economical.<br />

Whether this is for the car, medical and<br />

dental sector, the connector or even horology<br />

industry, <strong>Tornos</strong> is constantly developing<br />

innovative tailor-made solutions for its clients<br />

to meet market requirements.<br />

The company is now offering three product<br />

ranges : DECO loose tailstock single spindle machines,<br />

the CNC MULTIDECO and MultiAlpha<br />

numeric multispindle machines and the SAS 16.6<br />

cam operated multispindle machines.<br />

In order to provide on-going functional improvement,<br />

these machines may be complemented<br />

with various peripherals and tooling :<br />

■<br />

Built-in bar loader.<br />

■<br />

Chucker.<br />

■<br />

Universal swarf conveyor.<br />

■<br />

High-pressure drill.<br />

■<br />

Interchangeable tool holders.<br />

■<br />

Manipulating and palettising.<br />

■<br />

Various milling units.<br />

1959 First cam-operated multi-spindle.<br />

1984 Launch of SAS 16.6.<br />

1988 First CNC multispindle lathes.<br />

1996 <strong>Tornos</strong> created the DECO 2000 by joining the benefits of cam operated<br />

lathes with those of NC lathes.<br />

1997 <strong>Tornos</strong> combined the advantages of the DECO with the benefits offered by<br />

multi spindle lathes. Launch of MULTIDECO 20 / 6.<br />

1999 DECO Basic : new range dedicated to executing straightforward parts.<br />

2000 Complete range from Ø 1 to 32 (34) mm.<br />

2000 More than 3500 DECO machines sold.<br />

2001 A new stage has been reached towards larger diameters and an integral solution –<br />

the MULTIDECO 32 / 6i.<br />

2003 MULTIDECO 20 / 8b : more axes, more position, more possibilities.<br />

2004 MULTIDECO 20 / 6b : new version profiting from all the experience acquired with DECO<br />

and MULTIDECO.<br />

2005 More than 400 MULTIDECO sold.<br />

2006 Creation of a new platform for complex parts : MultiAlpha.<br />

2

PRESENTATION<br />

Multispindle automatic turning machine with parallel numerical control and<br />

integrated MULTIDECO bar feeder<br />

From simple to medium complexity parts<br />

Multispindle turning machines<br />

MultiAlpha<br />

Complexity of parts<br />

SAS<br />

MULTIDECO<br />

Diameter 20 32<br />

Summary<br />

2-3 The experience of <strong>Tornos</strong> in small parts<br />

turning<br />

4-5 The best of both worlds<br />

6-7 Your key benefits<br />

8-9 Standard units and possibility<br />

10-11 MULTIDECO 20 / 6b<br />

12-13 MULTIDECO 20 / 8b<br />

14-15 MULTIDECO 32 / 6i<br />

16-18 Dimensions in a glance<br />

3

THE BEST OF BOTH WORLDS<br />

MULTIDECO gets the most out of bringing CNC and mechanics together...<br />

DECO 2000 CONCEPT<br />

The DECO 2000 concept : A powerful tool at your service which will guarantee more just in time<br />

parts in the quality and quantity required – when small batches mean frequent changes.<br />

TB-DECO<br />

User-friendly programming software operating<br />

under Windows.<br />

PNC-DECO<br />

Parallel numerical control.<br />

– Program written on-line or on a<br />

portable PC.<br />

– Easy, versatile and rapid use of the<br />

system.<br />

– Real time calculation of machining times.<br />

– Instantaneous programme transfer to<br />

the NC.<br />

– Graphic simulation of tool paths.<br />

– ISO language.<br />

– No unproductive times (NC calculations).<br />

– No 360° limit.<br />

– All axes simultaneous.<br />

KINEMATICS<br />

Hybrid concept, absolute power at your service.<br />

PNC-DECO and TB-DECO<br />

The newest generation of modular numerical controls, adaptable to all automatic<br />

turning applications.<br />

PNC-DECO and TB-DECO<br />

Discover the real flexibility in multispindles.<br />

4

THE BEST OF BOTH WORLDS<br />

MULTIDECO gets the most out of bringing CNC and mechanics together...<br />

The production tool by excellence,<br />

the MULTIDECO comprises :<br />

■<br />

A MULTIDECO lathe with bar capacity up<br />

to 32 (34) mm.<br />

■<br />

An integrated barfeeder.<br />

■<br />

An universal swarf conveyor.<br />

■<br />

A global filtering unit.<br />

■<br />

A cooling system.<br />

Unproductive time<br />

Work end<br />

INDEXING<br />

STOCK FEEDING<br />

UNPRODUCTIVE TIME<br />

Work start<br />

Hybrid concept<br />

The mechanical part has been created around<br />

the hybrid concept already used on the 6 spindle<br />

and the 8 spindle version of the MULTIDECO<br />

family, for the features which must operate<br />

regardless of the component. E.g. spindle<br />

locking, collet open / closes, etc.<br />

This concept allows <strong>Tornos</strong> to propose with<br />

MULTIDECO a solution combining the productivity<br />

of cam operated machines with the flexibility of<br />

the numerical control.<br />

The programming system and unique kinematics<br />

create a new concept, which brings the same<br />

advantages of versatility and machining capacity<br />

that is found in the single spindle lathes, namely,<br />

movable tool slides, flexibility, programming.<br />

0 0.2 0.4<br />

second<br />

0.6 0.8<br />

5

YOUR KEY BENEFITS<br />

Stiffness, flexibility, suppleness, precision, optimized set-up, cost-effectiveness<br />

Strength<br />

The most reliable solutions, which have been in<br />

practice with <strong>Tornos</strong> for more than 50 years and<br />

used daily on more than 4500 multispindle machines<br />

throughout the world, such as Hirth coupling,<br />

spindles with pre-stressed bearings, as well<br />

as the base made from mineral cast iron, mean<br />

that the MULTIDECO can lay down new standards<br />

in terms of precision and finishing quality.<br />

Versatility<br />

The DECO 2000 concept applied to the multispindle<br />

world is versatility itself !<br />

■<br />

No cam machining.<br />

■<br />

No assembly of cam sets.<br />

■<br />

Programming real machining times on<br />

the TB-DECO.<br />

■<br />

Dimension correction during the course of<br />

machining, without stopping the machine.<br />

■<br />

Machining part families merely by program<br />

changes.<br />

Assessing the versatility of the MULTIDECO cannot<br />

be measured against conventional technology.<br />

Versatility is also synonymous with the term<br />

“adjustment facility” (correction) in real<br />

time, during the machining operation,<br />

without even having to stop the machine.<br />

Flexibility<br />

In order to enhance, the interest and universality<br />

of the MULTIDECO, the product offered by <strong>Tornos</strong><br />

is more a solution centred on a basic system than<br />

a mere machine.<br />

■<br />

Standard commercially available tooling.<br />

■<br />

Standard units.<br />

Change of the programme and<br />

of two tools in less than 5 minutes<br />

on MULTIDECO<br />

In two hours<br />

on a cam machine<br />

31,5 parts / min. 32 parts / min.<br />

■<br />

Position interchangeability.<br />

■<br />

Integrated “Mayfran” swarf management<br />

system.<br />

■<br />

High-pressure pump.<br />

■<br />

Cooler.<br />

■<br />

Oil mist extraction.<br />

An imposing list of options also completes this<br />

brief appraisal.<br />

The merit of this solution is that it has been<br />

incorporated since the basic design stage of the<br />

machine. Its completely integrated design ensures<br />

overall consistency and guarantees performance.<br />

The facility of interpolating shapes considerably<br />

increase the flexibility of the solution proposed.<br />

Production comparison according to batch size<br />

Series<br />

time in<br />

hours<br />

Total time<br />

for the<br />

series in<br />

Batch<br />

size<br />

Cam-operated 63.8<br />

11.2 10 000 82%<br />

MULTIDECO 20 / 6 hp<br />

multispindle m / c. 47.8<br />

setting up time 32 50 000 33%<br />

Startup time 24 hrs<br />

71.6<br />

6 hours + production<br />

+ production rate<br />

58.1 100 000 19%<br />

rate of 32 pts / min.<br />

of 35 pts / min. 262<br />

266 500 000 -2%<br />

NB : The more the series is broken down, the greater the difference in favour of the MULTIDECO.<br />

The price difference is compensated by the specific tooling required for cam-operated<br />

machine, even after a few series.<br />

Time<br />

saving<br />

6

YOUR KEY BENEFITS<br />

Stiffness, flexibility, suppleness, precision, optimized set-up, cost-effectiveness<br />

Optimised set-up time<br />

The MULTIDECO is flexible, accurate and productive.<br />

Its integral concept makes it a highly powerful<br />

and heavy-duty tool since it dispenses with :<br />

■<br />

Lost time because of setting operations.<br />

■<br />

Down times for tool readjustments.<br />

■<br />

Worn cams requiring replacement.<br />

■<br />

Feed clamps on the barfeeder.<br />

These items, which are associated with tooling<br />

pre-adjustment and programming in hidden<br />

time, make the MULTIDECO a remarkable tool<br />

with regard to productivity and return.<br />

Profitability<br />

All characteristics are combined to provide a substantial<br />

increase in the possibilities offered by<br />

the MULTIDECO, especially with respect to its rate<br />

of use, reduced setting times and stopping for<br />

chip clearing purposes, no cam reworking or<br />

machine shut-down to compensate for tool wear.<br />

All these features gua rantee that the high performance<br />

of the MULTIDECO is available to you<br />

for an absolute maximum period over the total<br />

time available.<br />

Precision<br />

SPC control and the ever growing demand for<br />

high precision coupled with the overall development<br />

of processes, make the MULTIDECO a tool,<br />

which is perfectly adapted to its environment.<br />

■<br />

The spindle cooling system.<br />

■<br />

Numerical correction of the barrel.<br />

■<br />

Fine adaptation of the parameters of the<br />

8 spindles.<br />

■<br />

Tool life management.<br />

■<br />

Numerical correction of all axes.<br />

■<br />

The large number of work stations for finishing<br />

as a “complete solution”.<br />

■<br />

Short part detection.<br />

The design of the oil tank, cooling and filtration<br />

system and of fluid distribution, guarantees optimum<br />

heat transfer and hence exemplary consistency<br />

of results.<br />

18.000<br />

17.995<br />

17.990<br />

17.985<br />

17.980<br />

17.975<br />

17.970<br />

17.965<br />

17.960<br />

17.955<br />

17.950<br />

1 3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39 41 43 45 47 49 51 53 55<br />

Condition of test :<br />

Warming-up time : 60 min.<br />

Productivity 5 parts / min.<br />

Material : AC INOX 303 Ø 20<br />

Sampling : 56 parts in a row<br />

7

MULTIDECO<br />

Standard equipment<br />

Possibilities<br />

As we have seen before, the MULTIDECO is an<br />

open system to meet all your requirements.<br />

What is more, all the ergonomic and convenience<br />

parameters for meeting the most varied requirements<br />

have been provided :<br />

■<br />

Chip evacuation directly to the outside of the<br />

Front and rotating milling<br />

attachment<br />

machine.<br />

■<br />

Ventilated and comfortable machining area.<br />

■<br />

Through tool coolant flow.<br />

■<br />

Spindle stop for cross milling (drilling, milling,<br />

eccentric end drilling).<br />

■<br />

Positioned stopping (axe c).<br />

■<br />

Chucker.<br />

■<br />

Independent motor for the counter-spindle<br />

Synchronised broaching<br />

attachment<br />

with controlled stopping and positioning option.<br />

The MULTIDECO represents the synthesis of<br />

<strong>Tornos</strong> multispindle know-how with the success<br />

of the DECO 2000 concept.<br />

Cross drilling unit<br />

Polygon milling unit<br />

Thread milling unit<br />

Pre-setters<br />

Modular tool holders<br />

8

MULTIDECO<br />

The world of the multispindle opens up to flexibility<br />

Open systems<br />

■<br />

Chucker entails machining rough and forged<br />

parts with special profiles.<br />

■<br />

The universal swarf conveyor independently<br />

evacuates all types of chips from production in<br />

the most varied of forms.<br />

■<br />

High pressure drilling saves on boring operations<br />

thanks to the surface finish quality and<br />

precision obtained.<br />

■<br />

All calibration, loading, positioning and barfeeding<br />

operations are automatic with the<br />

barfeeder.<br />

Chucker<br />

Integrated swarf conveyor<br />

With the <strong>Tornos</strong> MSF integrated bar loader, all<br />

calibration, loading, and positioning operations,<br />

as well as bar feed are automatic. Since control is<br />

via the machine, the entire barfeed unit is<br />

governed by the machine control. The interface<br />

used is quite clear and unique.<br />

The oil bath technology reduces drastically the<br />

vibrations, for example when using profiled bars<br />

of materials.<br />

Cooler<br />

Filtermist<br />

9

MULTIDECO 20/6b<br />

Technical specifications<br />

Z11<br />

X6 X7 Z15<br />

X1<br />

X5<br />

X4<br />

Z14<br />

Z26<br />

Z21<br />

Z13<br />

X3<br />

Z12<br />

X2<br />

Z22<br />

10

MULTIDECO 20/6b<br />

Technical specifications<br />

TECHNICAL CHARACTERISTIC<br />

Bar passage through the spindle (with MSF) 4-20 (24) mm<br />

Max. part length<br />

100 mm<br />

Max. spindle speed<br />

6000 rpm<br />

Max. spindle power<br />

11 kW<br />

Max. spindles torque<br />

70 Nm<br />

Max. drilling, tapping power<br />

2,2 kW<br />

Number of numerical axes 18<br />

Spindle stopping<br />

Yes<br />

C-axis in position 4, 5 Max. 2<br />

Spindles cooling<br />

Yes<br />

Cross slide (X, Z position 1 to 5) 6<br />

Cut off slide (X6) 1<br />

Counter operation slide (X7) 1<br />

End working (Z21-Z25) 5<br />

Counter spindle with c-axis (Z26) 1<br />

Max. counter spindle speed<br />

8000 rpm<br />

Max. counter spindle motor power<br />

1,1 kW<br />

PNC-DECO numerical control<br />

FANUC 16iTB<br />

Barrel lock<br />

Hirth teeth<br />

Integrated barfeeder MSF 522 / 6<br />

Capacity Ø<br />

5-22 (24) mm<br />

Loading of hexagon bars<br />

Yes<br />

DETAIL OF AXES<br />

Position 1 Cross slide X1, Z11<br />

End working<br />

Z21<br />

Position 2 Cross slide X2, Z12<br />

End working<br />

Z22<br />

Position 3 Cross slide X3, Z13<br />

End working<br />

Z23<br />

Position 4 Cross slide X4, Z14<br />

End working<br />

Z24<br />

Position 5 Cross slide X5, Z15<br />

End working<br />

Z25<br />

Position 6 Cutting slide X6<br />

Counter operation slide<br />

X7<br />

End working (counter spindle)<br />

Z26<br />

Main spindle<br />

S1<br />

Drilling<br />

S2<br />

Threading<br />

S3<br />

Counter spindle<br />

S4<br />

GENERAL CHARACTERISTICS<br />

Max. length (with integrated barfeeder) mm 5888 (8053)<br />

Max. width mm 1548<br />

Max. height mm 2210<br />

Height at spindle centre mm 1150<br />

Weight kg 6000<br />

Cutting oil tank capacity l 550<br />

Control pump fl ow rate l / min. 50<br />

Additional tank l 450<br />

Mayfran solution : Tank capacity l 1200<br />

Pump 3,5 bars l / min. 200<br />

Pump 35 bars l / min. 40<br />

Pump 80 bars l / min. 20<br />

Installed power kVA (32) 43<br />

Pneumatic group pressure bars 6<br />

Ambient working temperature degrees 10-35<br />

Colours : grey RAL 7035, blue RAL 5013<br />

CE / CEM certifi ed<br />

11

MULTIDECO 20/8b<br />

Technical specifications<br />

MULTIDECO 20 / 8b<br />

Bar passage through the spindle (with MSF) 4-20 (24) mm<br />

Max. part length<br />

100 mm<br />

Max. spindle speed<br />

6000 rpm<br />

Max. spindle motor power<br />

15 kW<br />

Max. spindles torque<br />

95 Nm<br />

Max. tapping, drilling motor power<br />

2,2 kW<br />

Number of linear axes 23<br />

Spindle and c-axis stopping<br />

Yes<br />

C-axis in position 4, 5 and 6 Max. 2<br />

Spindles cooling<br />

Yes<br />

Infeed slide (X1) 1<br />

Cross slides (X, Z, position 2-7) 6<br />

Cut off slide (X8) 1<br />

Counter operation slide (X9) 1<br />

End units (Z21-Z27) 7<br />

Max. counter spindle with c-axis (Z28) 1<br />

Max. counter spindle motor speed<br />

8000 rpm<br />

Counter spindle motor power<br />

1,1 kW<br />

PNC-DECO numerical control<br />

FANUC 16iTB<br />

Barrel lock<br />

Hirth teeth<br />

Integrated barfeeder MSF 522 / 8<br />

Capacity Ø<br />

4-22 (24) mm<br />

Loading of hexagon bars<br />

Yes<br />

Z26<br />

X8<br />

X7<br />

X9<br />

Z25<br />

Z17<br />

X6<br />

X5<br />

Z16<br />

Z15<br />

MULTIDECO 20 / 8b [2x4]<br />

Bar passage through the spindle (with MSF) 4-20 (24) mm<br />

Max. part length<br />

100 mm<br />

Max. spindle speed<br />

6000 rpm<br />

Max. spindle motor power<br />

15 kW<br />

Max. spindles torque<br />

95 Nm<br />

Max. tapping, drilling motor power<br />

2,2 kW<br />

Number of linear axes 22<br />

Spindles stopping<br />

Yes<br />

C-axis in position 4, 5 and 6<br />

No<br />

Spindles cooling<br />

Yes<br />

Infeed slide (X1, X5) 2<br />

Cross slides (X, Z, Pos. 2, 3, 6, 7) 4<br />

Cut off slide (X4, X8) 2<br />

Counter operation slide (X4’, X9) 2<br />

End units (Z21, Z22, Z23, Z25, Z26, Z27) 6<br />

Counter spindle with c-axis (Z24, Z28) 2<br />

Max. counter spindle motor speed<br />

8000 rpm<br />

Max. counter spindle motor power<br />

1,1 kW<br />

PNC-DECO numerical control<br />

FANUC 16iTB<br />

Barrel lock<br />

Hirth teeth<br />

Integrated barfeeder MSF 522 / 8<br />

Capacity Ø<br />

4-22 (24) mm<br />

Loading of hexagon bars<br />

Yes<br />

Z24<br />

Z13<br />

X3<br />

X4<br />

12

MULTIDECO 20/8b<br />

Technical specifications and MULTIDECO 20/8b [2x4]<br />

Z14<br />

DETAIL OF AXES<br />

Position 1 Cross slide X1 X1<br />

End working Z21 Z21<br />

Position 2 Cross slide X2, Z12 X2, Z12<br />

End working Z22 Z22<br />

Position 3 Cross slide X3, Z13 X3, Z13<br />

End working Z23 Z23<br />

Position 4 Cross slide X4, Z14 X4, X4’<br />

End working Z24 Z24<br />

Position 5 Cross slide X5, Z15 X5<br />

End working Z25 Z25<br />

Position 6 Cross slide X6, Z16 X6, Z16<br />

End working Z26 Z26<br />

Position 7 Cross slide X7, Z17 X7, Z17<br />

End working Z27 Z22<br />

Position 8 Cutting Slide X8 X8<br />

Counter operation slide X9 X9<br />

End working (counter spindle) Z28 Z28<br />

Main spindle S1 S1<br />

Drilling S2 S2<br />

Threading S3 S3<br />

Counter spindle S4 S4<br />

GENERAL CHARACTERISTICS<br />

Length (with integrated barfeeder) mm 5888 (8053)<br />

Width in protection mm 1700<br />

Max. height mm 2210<br />

Height at spindle centre mm 1150<br />

Weight kg 6000<br />

Cutting oil tank capacity l 550<br />

Control pump fl ow rate l / min. 150<br />

Additional tank l 450<br />

Mayfran solution : Tank capacity l 1200<br />

Pump 3,5 bars l / min. 200<br />

Pump 35 bars l / min. 40<br />

Pump 80 bars l / min. 20<br />

Installed power (with Mayfran) kVA 46 (80)<br />

Pneumatic group pressure bars 6<br />

Ambient working temperature degrees 10-35<br />

Colours : grey RAL 7035, blue RAL 5013<br />

CE / CEM certifi ed<br />

MULTIDECO 20 / 8b [2x4]<br />

High production<br />

The [2x4] spindle layout gives you the opportunity<br />

of producing at high production rates, parts<br />

that require only a few machining operations.<br />

It is an authentic configuration producing<br />

two separate parts per cycle ! The parts can be<br />

completely different from each other if needed.<br />

Second feeding<br />

Counter spindle<br />

Bar stop<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Bar stop<br />

Counter spindle<br />

First feeding<br />

Two machines in one<br />

Simply stated, we can say that the machine is like<br />

two four-spindle machines.<br />

Feed out in position one. First position has a single<br />

axis cross slide for forming and an independent<br />

end slide unit.<br />

Second & third positions have compound cross<br />

slides and independent end slide units.<br />

Fourth position we have a cut-off slide, a back<br />

operation slide with two tools and a counter<br />

spindle. Positions 5, 6, 7 and 8 have exactly the<br />

same configuration.<br />

13

MULTIDECO 32/6i<br />

Technical specifications<br />

Z11<br />

X6<br />

X7<br />

Z15<br />

X4<br />

X1<br />

X5<br />

Z14<br />

Z26<br />

Z21<br />

Z13<br />

X3<br />

Z22<br />

X2<br />

Z12<br />

14

MULTIDECO 32/6i<br />

Technical specifications<br />

TECHNICAL CHARACTERISTICS<br />

Bar passage through the spindle (with MSF) 8-32 (34) mm<br />

Max. part length<br />

120 mm<br />

Max. spindle speed<br />

5000 rpm<br />

Max. spindle power<br />

22 kW<br />

Max. spindles torque<br />

140 Nm<br />

Max. drilling, tapping power<br />

3,7 kW<br />

Number of numerical axes 18<br />

Counter operation slide (X7) 1<br />

Cross slide (X, Z, position 1 to 5) 5<br />

Cut off slide (X6) 1<br />

End working (Z21-Z25) 5<br />

Counter spindle with c-axis (Z26) 1<br />

Spindles cooling<br />

Yes<br />

Max. counter spindle rotation speed<br />

8000 rpm<br />

Max. counter spindle motor power<br />

1,1 kW<br />

PNC-DECO control management<br />

FANUC 16iTB<br />

Barrel lock<br />

Hirth teeth<br />

Integrated barfeeder<br />

Capacity Ø<br />

8-32 (34) mm<br />

Loading of hexagon bars<br />

Yes<br />

DETAIL OF AXES<br />

Position 1 Cross slide X1, Z11<br />

End working<br />

Z21<br />

Position 2 Cross slide X2, Z12<br />

End working<br />

Z22<br />

Position 3 Cross slide X3, Z13<br />

End working<br />

Z23<br />

Position 4 Cross slide X4, Z14<br />

End working<br />

Z24<br />

Position 5 Cross slide X5, Z15<br />

End working<br />

Z25<br />

Position 6 Cutting slide X6<br />

Counter operation slide<br />

X7<br />

End working (counter spindle)<br />

Z26<br />

Main spindle<br />

S1<br />

Drilling<br />

S2<br />

Threading<br />

S3<br />

Counter spindle<br />

S4<br />

GENERAL CHARACTERISTICS<br />

Max. length (bars 3 m) mm 8300<br />

Max. width mm 2790<br />

Max. height mm 2240<br />

Height at spindle centre mm 1200<br />

Weight kg ~10500<br />

Cutting oil tank capacity l 900-1200<br />

Control pump fl ow rate l / min. 200<br />

Mayfran solution : Tank capacity l 1200<br />

Pump 3,5 bars l / min. 200<br />

Pump 35 bars l / min. 40<br />

Pump 80 bars l / min. 20<br />

Installed power kVA 75<br />

Pneumatic group pressure bars 6<br />

Ambient working temperature degrees 10-35<br />

Colours : grey RAL 7035, blue RAL 5013<br />

CE / CEM certifi ed<br />

15

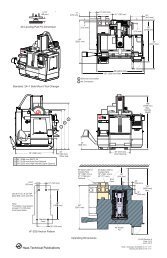

DIMENSIONS IN A GLANCE<br />

MACHINE MULTIDECO 20/6b MULTIDECO 20/8b MULTIDECO 32/6i<br />

Peripherals 3 m bar 3 m MSF 3 m bar 3 m MSF 3 m MSF<br />

guide barfeeder guide barfeeder barfeeder<br />

(1) 5888 8053 5888 8053 8300<br />

(2) 7638 9483 7638 9483 9731<br />

(3) 900 580 900 580 580<br />

(4) 850 850 850 850 851<br />

(5) 4065 4078 4065 4088 4341<br />

(6) 1823 3975 1823 3964 3959<br />

(7) 1762 1955 1762 1955 1955<br />

(8) – 570 – 570 630<br />

(9) 1420 1420 1420 1420 1530<br />

(10) 1435 1435 1435 1435 1464<br />

(11) 2210 2210 2210 2210 2240<br />

(12) 1314,5 1704 1393,5 1770 1770<br />

(13) 1548 1548 1700 1700 1720<br />

(14) 760 1156 760 1235 1335<br />

(15) – 2790 – 2790 2790<br />

(16) 2770 2770 2720 2920 3214<br />

(17) 760 760 760 760 827<br />

(18) 1650 1650 1650 1650 1650<br />

(19) 620 620 620 620 620<br />

(20) – 820 – 820 820<br />

(21) – 450 – 450 450<br />

(22) 500 500 575 575 610<br />

View with 3 m barfeeder and<br />

integrated swarf conveyor (Mayfran)<br />

<br />

<br />

<br />

<br />

<br />

<br />

Support plates<br />

<br />

<br />

<br />

<br />

<br />

16

DIMENSIONS IN A GLANCE<br />

<br />

<br />

View with 3 m tube<br />

and additional tank<br />

<br />

<br />

<br />

<br />

<br />

<br />

Support plates<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Cooler<br />

<br />

<br />

Additional tank<br />

<br />

<br />

<br />

<br />

<br />

<br />

View with 3 m barfeeder and<br />

integrated swarf conveyor (Mayfran)<br />

<br />

<br />

<br />

Control<br />

panel<br />

<br />

<br />

<br />

Cooler<br />

<br />

<br />

<br />

<br />

17

MACHINE KINEMATICS<br />

Technical specifications<br />

<br />

<br />

Counter spindle<br />

motor<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Drilling motor<br />

Main motor<br />

Threading motor<br />

TECHNICAL CHARACTERISTICS MULTIDECO 20/6b MULTIDECO 20/8b MULTIDECO 32/6i<br />

Bar passage through the spindle (with MSF) mm 4-20 (24) 4-20 (24) 8-32 (34)<br />

Max. part length without counter operation mm 100 100 120<br />

Max. part length with counter operations mm 80 80 100<br />

Max. spindle speed rpm 6000 6000 5000<br />

Max. spindle power Kw 11 15 21<br />

Max. spindles torque Nm 70 95 140<br />

Number of numerical linear axes 18 23 18<br />

Number of c-axis available 2 2 2<br />

Counter spindle and c-axis positioning Yes Yes Yes<br />

Spindles cooling Yes Yes Yes<br />

Cross slides 5 6 5<br />

Simple slides 2 3 2<br />

End working 5 7 5<br />

Barrel lock Hirth teeth Hirth teeth Hirth teeth<br />

Programming system TB-DECO TB-DECO TB-DECO<br />

Numerical control PNC Fanuc 16iTB PNC Fanuc 16iTB PNC Fanuc 16iTB<br />

18

TORNOS PROVIDES SOLUTIONS<br />

TO HIGH-TECHNOLOGY INDUSTRIES,<br />

IN THE FOLLOWING SECTORS IN PARTICULAR :<br />

Automotive<br />

Medical<br />

Electronics<br />

Watchmaking & Micromechanics

TORNOS S.A.<br />

Rue Industrielle 111<br />

CH-2740 Moutier<br />

Tel. +41 (0)32 494 44 44<br />

Fax +41 (0)32 494 49 03<br />

contact@tornos.com<br />

www.tornos.com<br />

TORNOS-TECHNOLOGIES<br />

DEUTSCHLAND GmbH<br />

Karlsruher Str. 38<br />

D-75179 Pforzheim<br />

Tel. +49 (0)7231 / 910 70<br />

Fax +49 (0)7231 / 910 750<br />

contact@tornos.de<br />

TORNOS TECHNOLOGIES<br />

ITALIA SRL<br />

Via Cesare Pavese 21<br />

I-20090 Opera / MI<br />

Tel. +39 02 57 68 15 01<br />

Fax +39 02 57 68 15 230<br />

contact@tornos.it<br />

TORNOS TECHNOLOGIES<br />

US CORPORATION<br />

840 Parkview Boulevard<br />

US - Lombard, IL 60148<br />

Tel. +1 203 775 4319<br />

Fax +1 203 775-4281<br />

info-us@tornos.com<br />

TORNOS TECHNOLOGIES<br />

ASIA LIMITED<br />

Unit 4, G/F, Transport City<br />

Building<br />

1-7 Shing Wan road<br />

Tai Wai, Shatin<br />

N.T., Hong Kong<br />

Tel. +852 2691 2633<br />

Fax +852 2691 2133<br />

asiapacific.contact@tornos.com<br />

TORNOS TECHNOLOGIES<br />

FRANCE<br />

Boîte postale 330<br />

St-Pierre en Faucigny<br />

F-74807 La Roche<br />

s / Foron Cedex<br />

Tel. +33 (0)4 50 038 333<br />

Fax +33 (0)4 50 038 907<br />

contact@tornos.fr<br />

TORNOS TECHNOLOGIES<br />

UK LTD<br />

<strong>Tornos</strong> House<br />

Whitwick Business Park<br />

Coalville<br />

UK-Leicestershire LE67 4JQ<br />

Tel. +44 (0) 1530 513100<br />

Fax +44 (0) 1530 814212<br />

sales@tornos.co.uk<br />

TORNOS TECHNOLOGIES<br />

IBERICA<br />

Pol. Ind. El Congost<br />

Avda. St Julia, 206 Nave 8<br />

E-08403 Granollers<br />

Tel. +34 93 846 59 43<br />

Fax +34 93 849 66 00<br />

commercial.tti@tornos.com<br />

TORNOS SHANGHAI<br />

REPRESENTATIVE OFFICE<br />

Tower B, Office 512-513<br />

Far East International Plaza<br />

No. 317 Xianxia Road<br />

CN-Shanghai 200335<br />

Tel. +86 (0)21-62351235<br />

Fax +86 (0)21-62351938<br />

china.contact@tornos.com<br />

Conforms to the European CE / CEM Safety Standards<br />

This document is based on information available at the time of publication. While every effort has been made to be accurate, the information contained herein<br />

does not purport to cover all details or variations in hardware and software, nor to provide for every possible contingency in connection with installation, operation<br />

and maintenance. TORNOS S.A. assumes no obligation of notice to holders of this document with respect to changes subsequently made. TORNOS S.A. makes no<br />

representation or warranty, expressed, implied, or statutory with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency or usefulness<br />

of the information contained herein. No warranties of merchantability nor fitness for purpose shall apply.<br />

Edition 8 / 2007