SKS Brochure for web - Neptronic

SKS Brochure for web - Neptronic

SKS Brochure for web - Neptronic

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

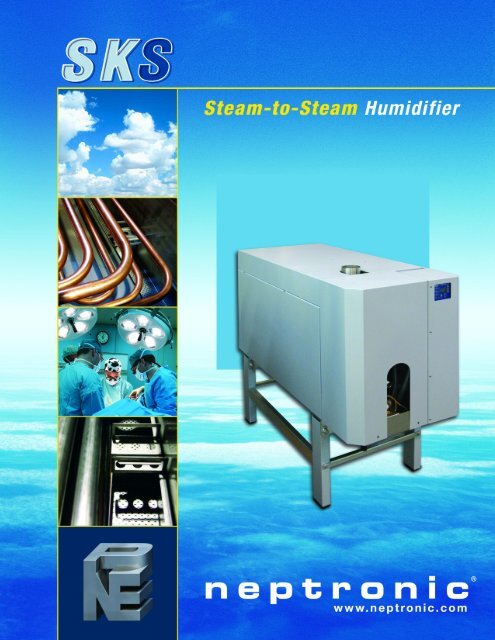

Each year, <strong>Neptronic</strong> ® produces thousands of humidifiers to meet<br />

a diverse and expanding worldwide demand. Great care has been<br />

taken to select materials which have proven themselves <strong>for</strong> their<br />

exceptional per<strong>for</strong>mance in very harsh conditions.<br />

The <strong>SKS</strong> series of steam-to-steam humidifiers offers an innovative<br />

design and trouble free operation. Chemical free steam is produced<br />

by using on-site boiler steam as a heat source. The wide modulation<br />

range, high capacities and ease of servicing makes it the most<br />

dependable and best humidifier on the market.<br />

The attractive and innovative design of the <strong>SKS</strong> has a scale management system that<br />

simplifies the maintenance of scale removal. The <strong>SKS</strong> also uses a patented water level<br />

control called the AFEC ® System which is energy efficient.<br />

Modulating Controls<br />

The <strong>SKS</strong> are supplied with a linear actuated globe valve giving full modulating<br />

control of low pressure steam.<br />

Principle of Operation<br />

The main energy source of<br />

the <strong>SKS</strong> is either raw steam<br />

under pressure or high temperature<br />

hot water (HTHW)<br />

from a central boiler.<br />

The raw steam or HTHW<br />

passes through the heat<br />

exchanger of the humidifier, thus<br />

providing the energy to produce<br />

clean sterilized steam to be distributed<br />

to the Air Handling Unit (AHU) system.

Features<br />

• Capacities from 100-1250lbs/hr (45-568kg/hr) of clean steam<br />

• Maximum boiler steam pressure 15 psi on standard unit<br />

to 100 psi on special applications<br />

• Plated copper and stainless steel heat exchangers are available<br />

• Uses either “Domestic”, “RO” or “DI” water<br />

• Comprehensive system of scale management<br />

• AFEC ® system, mass measuring water sensor<br />

• Temperature of the drain water is tempered below 140ºF (60ºC)<br />

• Ease of servicing: cleans and re-installs within minutes<br />

• BACnet remote communications protocol<br />

Simplicity of Operation<br />

and Service<br />

Check<br />

Unit indicates an abnormal<br />

condition of operation<br />

Fill<br />

Water supply valve is open<br />

Easy to remove<br />

scale trap trays<br />

Fan<br />

Indication that fan is on<br />

Steam<br />

Humidifier is on and there is<br />

a humidity demand<br />

The <strong>SKS</strong> offers built in “scale trap trays”<br />

located at the bottom of the evaporation<br />

chamber. These trays can be accessed from<br />

the top of the unit allowing <strong>for</strong> easy<br />

maintenance and scale removal.<br />

Self Cleaning System<br />

A comprehensive system of scale management<br />

where the supply of cold water at the sloped<br />

bottom of the evaporation chamber <strong>for</strong>ces<br />

the precipitated mineral deposits into the<br />

“scale trap trays”.

The AFEC ® - System<br />

The AFEC ® technology developed by the <strong>Neptronic</strong> ®<br />

engineering team offers a unique, safe and energy efficient<br />

control of boiling water and steam. The AFEC ® system consists<br />

of a mass measuring water sensor, antifoam sensor,<br />

electronic high temperature sensor, interactive LCD display<br />

and microprocessor controller.<br />

The AFEC ® system is unique because the water level<br />

sensor cannot be falsely triggered by foam <strong>for</strong>ming on the<br />

surface of the boiling water.<br />

The foam sensing probe which is unique to our design<br />

automatically initiates a drain cycle upon foam <strong>for</strong>mation.<br />

Unlike other humidifiers the drain can be initiated only<br />

when necessary without having a continuous skimming to<br />

drain off expensive boiling water.<br />

AFEC ® is designed to work equally well in deionized,<br />

reverse osmosis or potable water.<br />

Water and Temperature Probe<br />

LCD Display & Control Panel<br />

Power<br />

Unit is connected to<br />

power source<br />

Clean steam outlet(s)<br />

Drain<br />

Unit is in drain cycle<br />

Control panel<br />

Raw steam or HTHW<br />

Inlet(s)<br />

Condensate or return outlet(s)<br />

Power supply<br />

Electrical controls<br />

Main drain outlet<br />

Water supply inlet<br />

Exceptional Reliability<br />

Legs (Optional)<br />

Skirt Panels (Optional)<br />

The <strong>SKS</strong> was designed and built upon the <strong>Neptronic</strong> philosophy to provide high quality, safe, easily maintained and<br />

energy efficient units. The fully enclosed cabinet eliminates the possibility of accidental contact with hot surfaces<br />

and saves energy by virtue of the insulated panels. Adjustable legs (optional) can be provided in order to ensure<br />

proper level when installed directly on the floor. Skirt panels are also available (see illustration above).

Steam Distribution Systems<br />

In order to prevent the accumulation of condensation in air ducts, NEP has designed 2 basic configurations of A<br />

steam distribution to provide the most economical solution <strong>for</strong> any particular application.<br />

"Multi-Steam" System<br />

The multi-steam system is to<br />

be installed in critical locations,<br />

particularly where<br />

absorption distances are very<br />

short (less than 3 feet/900mm)<br />

or low air duct temperatures<br />

are in effect.<br />

"S.A.M.E2"<br />

(steam absorption manifold)<br />

The SAME2 is to be<br />

installed where absorption<br />

distances are short (less<br />

than 5 feet/1500mm) and/or<br />

low duct temperatures are in<br />

effect.<br />

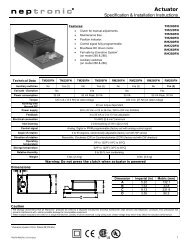

Technical In<strong>for</strong>mation<br />

Dimensions in. (cm)<br />

Weight lbs (kg)<br />

A<br />

B<br />

Model<br />

A B C D Empty<br />

4Ӓ In<br />

[10.1] Operation<br />

6Ӓ<br />

[15.2]<br />

12 í<br />

[30.5]<br />

“<br />

C<br />

D<br />

<strong>SKS</strong>-100<br />

<strong>SKS</strong>-130<br />

<strong>SKS</strong>-190<br />

<strong>SKS</strong>-290<br />

<strong>SKS</strong>-390<br />

<strong>SKS</strong>-500<br />

<strong>SKS</strong>-690<br />

<strong>SKS</strong>-950<br />

<strong>SKS</strong>-1250<br />

19.7<br />

(50.0)<br />

19.7<br />

(50.0)<br />

22.8<br />

(57.9)<br />

22.8<br />

(57.9)<br />

27.5<br />

(69.9)<br />

27.5<br />

(69.9)<br />

31.0<br />

(78.7)<br />

31.0<br />

(78.7)<br />

30.0<br />

(76.2)<br />

45.8<br />

(116.3)<br />

45.8<br />

(116.3)<br />

45.8<br />

(116.3)<br />

47.2<br />

(120.0)<br />

58.8<br />

(149.3)<br />

58.8<br />

(149.3)<br />

58.8<br />

(149.3)<br />

58.8<br />

(149.3)<br />

58.8<br />

(149.3)<br />

26.2<br />

(66.5)<br />

26.2<br />

(66.5)<br />

29.4<br />

(74.7)<br />

29.4<br />

(74.7)<br />

27.3<br />

(69.3)<br />

27.3<br />

(69.3)<br />

33.2<br />

(84.3)<br />

33.2<br />

(84.3)<br />

42.3<br />

(107.2)<br />

44.1<br />

(112.0)<br />

44.1<br />

(112.0)<br />

47.3<br />

(120.1)<br />

47.3<br />

(120.1)<br />

45.2<br />

(114.8)<br />

45.2<br />

(114.8)<br />

51.1<br />

(128.8)<br />

51.1<br />

(128.8)<br />

60.3<br />

(153.2)<br />

265<br />

(120)<br />

270<br />

(122)<br />

310<br />

(141)<br />

315<br />

(143)<br />

395<br />

(179)<br />

400<br />

(182)<br />

470<br />

(213)<br />

475<br />

(215)<br />

570<br />

(259)<br />

487<br />

(221)<br />

484<br />

(220)<br />

578<br />

(263)<br />

616<br />

(280)<br />

E 828<br />

F (376)<br />

822<br />

(373)<br />

1102<br />

2.6“í(501)<br />

[6.6] 1168<br />

(531)<br />

1574<br />

(715)<br />

G<br />

<strong>SKS</strong> <strong>Neptronic</strong><br />

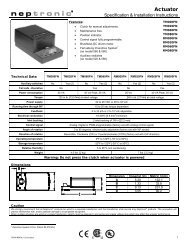

Heat Exchanger - SLP Stainless Steel 316 - Low Pressure (15 PSI Max.)<br />

Model<br />

Nb of<br />

heat<br />

exc.<br />

<strong>SKS</strong>-100-SLP 1<br />

<strong>SKS</strong>-130-SLP 1<br />

<strong>SKS</strong>-190-SLP 1<br />

<strong>SKS</strong>-290-SLP 1<br />

<strong>SKS</strong>-390-SLP 1<br />

<strong>SKS</strong>-500-SLP 1<br />

<strong>SKS</strong>-690-SLP 1<br />

<strong>SKS</strong>-950-SLP 1<br />

<strong>SKS</strong>-1250-SLP 2<br />

Output steam capacity lbs/hr (kg/h) <strong>for</strong> supply steam pressure<br />

5 PSI<br />

34.5kPa<br />

33<br />

(15)<br />

43<br />

(19)<br />

63<br />

(28)<br />

97<br />

(44)<br />

130<br />

(59)<br />

167<br />

(76)<br />

230<br />

(104)<br />

317<br />

(144)<br />

417<br />

(189)<br />

8 PSI<br />

55.1kPa<br />

53<br />

(24)<br />

69<br />

(31)<br />

101<br />

(46)<br />

155<br />

(70)<br />

208<br />

(94)<br />

267<br />

(121)<br />

368<br />

(167)<br />

507<br />

(230)<br />

667<br />

(303)<br />

10 PSI<br />

68.9kPa<br />

67<br />

(30)<br />

87<br />

(39)<br />

127<br />

(57)<br />

193<br />

(87)<br />

260<br />

(118)<br />

333<br />

(151)<br />

460<br />

(209)<br />

633<br />

(287)<br />

833<br />

(378)<br />

12 PSI<br />

82.7kPa<br />

80<br />

(36)<br />

104<br />

(47)<br />

152<br />

(69)<br />

232<br />

(105)<br />

312<br />

(142)<br />

400<br />

(182)<br />

552<br />

(251)<br />

760<br />

(345)<br />

1000<br />

(454)<br />

15 PSI<br />

103.4kPa<br />

100<br />

(45)<br />

130<br />

(59)<br />

190<br />

(86)<br />

290<br />

(132)<br />

390<br />

(177)<br />

500<br />

(230)<br />

690<br />

(314)<br />

950<br />

(432)<br />

1250<br />

(568)<br />

Steam outlet<br />

Qty & Ø<br />

in (mm)<br />

(1x) 3” (76)<br />

(1x) 3” (76)<br />

(1x) 3” (76)<br />

(1x) 4” (108)<br />

(1x) 4” (108)<br />

(1x) 5” (133)<br />

(1x) 5” (133)<br />

(2x) 4” (108)<br />

(2x) 5” (133)<br />

Heat Exchanger - CHP Plated Copper High Pressure (100 PSI Max.)<br />

Model<br />

<strong>SKS</strong>-200-CHP<br />

<strong>SKS</strong>-333-CHP<br />

<strong>SKS</strong>-667-CHP<br />

240˚F<br />

(116˚C)<br />

10 PSI<br />

(69kPa)<br />

40<br />

(18)<br />

65<br />

(29)<br />

130<br />

(59)<br />

Output steam capacity lbs/hr (kg/h) <strong>for</strong> supply steam pressure<br />

250˚F<br />

(121˚C)<br />

15 PSI<br />

(103kPa)<br />

65<br />

(30)<br />

110<br />

(50)<br />

220<br />

(100)<br />

260˚F<br />

(127˚C)<br />

20 PSI<br />

(137kPa)<br />

85<br />

(39)<br />

145<br />

(66)<br />

290<br />

(132)<br />

280˚F<br />

(138˚C)<br />

35 PSI<br />

(241kPa)<br />

150<br />

(69)<br />

255<br />

(116)<br />

510<br />

(231)<br />

300˚F<br />

(149˚C)<br />

50 PSI<br />

(344kPa)<br />

220<br />

(99)<br />

365<br />

(166)<br />

730<br />

(331)<br />

320˚F<br />

(160˚C)<br />

75 PSI<br />

(517kPa)<br />

330<br />

(150)<br />

550<br />

(249)<br />

1100<br />

(499)<br />

338˚F<br />

(170˚C)<br />

100 PSI<br />

(689kPa)<br />

440<br />

(200)<br />

730<br />

(333)<br />

1465<br />

(667)<br />

Steam<br />

outlet<br />

Qty & Ø<br />

in (mm)<br />

(1x) 4” (108)<br />

(2x) 4” (108)<br />

(2x) 5” (133)

distributed by:<br />

Manufacturer of actuators, actuated valves, controls, humidifiers and electric heaters.<br />

Head Office<br />

National Environmental Products Ltd<br />

400 Lebeau Blvd, Montreal, Quebec H4N 1R6<br />

Tel.: (514) 333-1433 Fax: (514) 333-3163<br />

Toll Free (Canada/USA): 1-800-361-2308<br />

U.S. Office<br />

NEP Inc.<br />

355 North Main Street, Suite 2<br />

Hiawassee, Georgia 30546<br />

Tel.: (954) 421-6216 Fax: (954) 421-8785<br />

Middle East & Asia<br />

NEP International<br />

P.O. Box 125687, Dubai, UAE<br />

Tel.: +97155 8825487 Fax: +9714 3426772<br />

email: shyam@neptronic.com<br />

Copyright 2012, <strong>Neptronic</strong> ® All Rights Reserved.<br />

090001 _KS 271212