PETROSWEET HSW7336 Hydrogen Sulfide ... - Baker Hughes

PETROSWEET HSW7336 Hydrogen Sulfide ... - Baker Hughes

PETROSWEET HSW7336 Hydrogen Sulfide ... - Baker Hughes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Product Overview<br />

<strong>PETROSWEET</strong> <strong>HSW7336</strong> <strong>Hydrogen</strong> <strong>Sulfide</strong> Scavenger<br />

H 2<br />

S scavenger for H 2<br />

S tower applications<br />

Application<br />

The <strong>PETROSWEET</strong> <strong>HSW7336</strong> hydrogen<br />

sulfide (H 2<br />

S) scavenger is a fast-acting<br />

product for tower applications where<br />

traditional triazine H 2<br />

S scavengers typically<br />

form intractable solids and mineral scales.<br />

The <strong>PETROSWEET</strong> <strong>HSW7336</strong> H 2<br />

S scavenger<br />

is specifically designed to eliminate<br />

these solids resulting in fewer tower<br />

cleanouts, packing replacements and<br />

increased production.<br />

<strong>PETROSWEET</strong> <strong>HSW7336</strong> scavenger<br />

represents a step change alternative to<br />

high pH hydrogen sulfide scavengers such<br />

as triazine.<br />

<strong>PETROSWEET</strong> <strong>HSW7336</strong> H 2<br />

S scavenger is<br />

compatible with most brines, including<br />

brines with high total dissolved solids<br />

and calcium. The spent product is also<br />

compatible with most brines, eliminating<br />

the need for a separate holding tank<br />

for the spent H 2<br />

S scavenger. This means<br />

that the spent product will not cause<br />

mineral scales to form. While it does not<br />

form intractable solids like triazine-based<br />

products do, the spent product may<br />

produce small amounts of solids that are<br />

readily removed with a hot water wash.<br />

Typical Properties<br />

Specifi c gravity<br />

1.05<br />

at 60°F (15.6°C)<br />

Typical density<br />

at 60°F (15.6°C)<br />

Flash point, SFCC<br />

Pour point<br />

Viscosity, ASTM D-455<br />

at 60°F (15.6°C)<br />

at 40°F (4.4°C)<br />

8.8 lbm/US gal<br />

(1050 kg/m 3 )<br />

210.2°F (99°C)<br />

14°F (-10°C)<br />

1.7 cP<br />

2.4 cP<br />

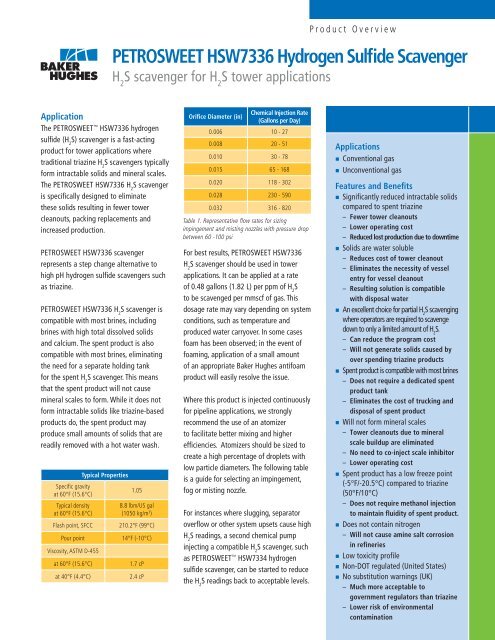

Orifice Diameter (in)<br />

Chemical Injection Rate<br />

(Gallons per Day)<br />

0.006 10 - 27<br />

0.008 20 - 51<br />

0.010 30 - 78<br />

0.015 65 - 168<br />

0.020 118 - 302<br />

0.028 230 - 590<br />

0.032 316 - 820<br />

Table 1. Representative flow rates for sizing<br />

impingement and misting nozzles with pressure drop<br />

between 60 -100 psi<br />

For best results, <strong>PETROSWEET</strong> <strong>HSW7336</strong><br />

H 2<br />

S scavenger should be used in tower<br />

applications. It can be applied at a rate<br />

of 0.48 gallons (1.82 L) per ppm of H 2<br />

S<br />

to be scavenged per mmscf of gas. This<br />

dosage rate may vary depending on system<br />

conditions, such as temperature and<br />

produced water carryover. In some cases<br />

foam has been observed; in the event of<br />

foaming, application of a small amount<br />

of an appropriate <strong>Baker</strong> <strong>Hughes</strong> antifoam<br />

product will easily resolve the issue.<br />

Where this product is injected continuously<br />

for pipeline applications, we strongly<br />

recommend the use of an atomizer<br />

to facilitate better mixing and higher<br />

efficiencies. Atomizers should be sized to<br />

create a high percentage of droplets with<br />

low particle diameters. The following table<br />

is a guide for selecting an impingement,<br />

fog or misting nozzle.<br />

For instances where slugging, separator<br />

overflow or other system upsets cause high<br />

H 2<br />

S readings, a second chemical pump<br />

injecting a compatible H 2<br />

S scavenger, such<br />

as <strong>PETROSWEET</strong> HSW7334 hydrogen<br />

sulfide scavenger, can be started to reduce<br />

the H 2<br />

S readings back to acceptable levels.<br />

Applications<br />

• Conventional gas<br />

• Unconventional gas<br />

Features and Benefits<br />

• Significantly reduced intractable solids<br />

compared to spent triazine<br />

– Fewer tower cleanouts<br />

– Lower operating cost<br />

– Reduced lost production due to downtime<br />

• Solids are water soluble<br />

– Reduces cost of tower cleanout<br />

– Eliminates the necessity of vessel<br />

entry for vessel cleanout<br />

– Resulting solution is compatible<br />

with disposal water<br />

• An excellent choice for partial H 2<br />

S scavenging<br />

where operators are required to scavenge<br />

down to only a limited amount of H 2<br />

S.<br />

– Can reduce the program cost<br />

– Will not generate solids caused by<br />

over spending triazine products<br />

• Spent product is compatible with most brines<br />

– Does not require a dedicated spent<br />

product tank<br />

– Eliminates the cost of trucking and<br />

disposal of spent product<br />

• Will not form mineral scales<br />

– Tower cleanouts due to mineral<br />

scale buildup are eliminated<br />

– No need to co-inject scale inhibitor<br />

– Lower operating cost<br />

• Spent product has a low freeze point<br />

(-5°F/-20.5°C) compared to triazine<br />

(50°F/10°C)<br />

– Does not require methanol injection<br />

to maintain fluidity of spent product.<br />

• Does not contain nitrogen<br />

– Will not cause amine salt corrosion<br />

in refineries<br />

• Low toxicity profile<br />

• Non-DOT regulated (United States)<br />

• No substitution warnings (UK)<br />

– Much more acceptable to<br />

government regulators than triazine<br />

– Lower risk of environmental<br />

contamination

Materials compatibility<br />

Suitable:<br />

Metals: 304 stainless steel, 316 stainless<br />

steel, admiralty brass, copper<br />

Plastics: HD polyethylene, HD<br />

polypropylene, linear<br />

polyethylene, PVC, TEFLON ®<br />

Elastomers: Buna N, EPDM, HYPALON ® ,<br />

neoprene, VITON ®<br />

Not suitable:<br />

Metals: Aluminum<br />

Materials suitability is based on analysis of test<br />

results obtained under specified laboratory conditions.<br />

All materials selection should be based on actual<br />

application. Testing results for materials will be made<br />

available on request.<br />

Safety and handling<br />

Before handling, storage or use, review the<br />

Safety Data Sheet (SDS) for guidance.<br />

<strong>PETROSWEET</strong> <strong>HSW7336</strong> H 2<br />

S scavenger<br />

should be transported and stored in stainless<br />

steel tanks with a vented cap. Neither drums<br />

nor pails should be used for storage or<br />

transport. Tanks should not be shipped in a<br />

closed container. The recommended shelf life<br />

of the product is 6 months.<br />

<strong>Baker</strong> <strong>Hughes</strong>/<strong>Baker</strong> Petrolite 24-Hour<br />

Emergency Hotline:<br />

1-800-424-9300 (CHEMTREC) US<br />

1-613-996-6666 (CANUTEC) Canada<br />

www.bakerhughes.com<br />

<strong>PETROSWEET</strong> is a trademark of <strong>Baker</strong> <strong>Hughes</strong> Incorporated. TEFLON is a registered trademark of E. I. Du Pont de Nemours and Company. HYPALON and VITON are registered trademarks<br />

of DuPont Performance Elastomers L.L.C.<br />

Disclaimer of Liability: This information is provided for general information purposes only and is believed to be accurate as of the date hereof; however, <strong>Baker</strong> <strong>Hughes</strong> Incorporated and<br />

its affiliates do not make any warranties or representations of any kind regarding the information and disclaim all express and implied warranties or representations to the fullest extent<br />

permissible by law, including those of merchantability, fitness for a particular purpose or use, title, non-infringement, accuracy, correctness or completeness of the information provided<br />

herein. All information is furnished “as is” and without any license to distribute. The user agrees to assume all liabilities related to the use of or reliance on such information. BAKER<br />

HUGHES INCORPORATED AND ITS AFFILIATES SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, PUNITIVE, EXEMPLARY OR CONSEQUENTIAL DAMAGES FROM ANY CAUSE<br />

WHATSOEVER INCLUDING BUT NOT LIMITED TO ITS NEGLIGENCE.<br />

© 2013 <strong>Baker</strong> <strong>Hughes</strong> Incorporated. All rights reserved. 38272. BPPO<strong>HSW7336</strong>. 03/2013