ProductionWave⢠- Baker Hughes

ProductionWave⢠- Baker Hughes

ProductionWave⢠- Baker Hughes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ProductionWave <br />

ProductionWave <br />

FLEXible Production Solution<br />

for UNCONVENTIONAL OIL WELLS<br />

Rod lift systems have their place.<br />

But ESP systems can deliver the same<br />

benefits—with better economics<br />

and fewer HSE risks.

FLEXible Solution for Unconventional Oil Wells<br />

ProductionWave FLEXible Solution for Unconvetional Oil Wells: Products and Services Map<br />

CHARACTERISTIC CHALLENGE THE SOLUTION BAKER HUGHES OFFERING<br />

• Wide flow range<br />

• Keeping production online at<br />

every flow range in dynamic<br />

producing conditions<br />

• Choose ESP systems that work in ranges from<br />

50 BPD to 3500 BPD<br />

• Centrilift FLEX series pumps<br />

Choose a service provider that<br />

lets you get the most out of<br />

your well or asset.<br />

Choose <strong>Baker</strong> <strong>Hughes</strong>.<br />

• Reliability<br />

• Maximizing uptime and well<br />

drawdown in high-gas<br />

environments<br />

• Separate the gas from the liquid before it enters the pump<br />

with high-efficiency gas separators<br />

• Deploy pumps that provide the lowest drawdown possible<br />

in the well<br />

• Run pumps that allow continuous system operation in<br />

extreme gas conditions, and create a homogeneous<br />

fluid to reduce underload shutdowns<br />

• Engineer unique hydraulics for better gas and<br />

solids handling<br />

• Prevent gas from entering the pump when the system is<br />

landed in the horizontal<br />

• GM Performance series rotary and vortex<br />

gas separators and multiseparator systems<br />

• GI “gas insurance” charge pumps<br />

• MVP multiphase gas-handling pumps<br />

• FLEX series pumps<br />

• Gas Avoider series of intakes<br />

• Use real-time monitoring to alert you to unfavorable<br />

system operating conditions and software to<br />

maximize well uptime<br />

• Electrospeed Advantage variable-speed drive<br />

<strong>Baker</strong> <strong>Hughes</strong> has the only combination<br />

that performs reliably and helps you produce<br />

more economically and effectively in<br />

unconventional oil wells.<br />

• Minimizing damage from<br />

abrasives<br />

• Standing up to harsh conditions<br />

• Use coatings that prohibit abrasive wear in the pump<br />

• Deploy sand screens that resist plugging and erosion<br />

to ensure a long productive life<br />

• Select pump designs that mitigate abrasive wear<br />

and tear<br />

• Choose ESP systems that withstand harsh environments of<br />

thermal cycling<br />

• ARMOR pump coatings<br />

• EXCLUDER2000 screen<br />

• FLEX series pumps<br />

• FLEX pumps<br />

• MVP pumps<br />

• GM Performance series gas separator<br />

• Electrospeed Advantage VSD<br />

• Efficiency<br />

• Staying as close to the best<br />

efficiency point as possible<br />

• Deploy onsite real-time monitoring and control<br />

• Electrospeed Advantage variable-speed<br />

drive with MaxStart and MaxPoint software<br />

• Production<br />

optimization<br />

• Producing at targeted levels • Use a field management solution • Vision optimization service<br />

• Flow assurance • Keeping the well flowing • Treat your wells with chemicals that inhibit scale, paraffin,<br />

corrosion, and asphaltenes<br />

• SULFIX scavenger treatment, wax<br />

dispersants, scale inhibitors<br />

$<br />

Integrating ESP systems with talented people<br />

and flexible commercial models impacts your<br />

economics at even greater levels.<br />

www.bakerhughes.com<br />

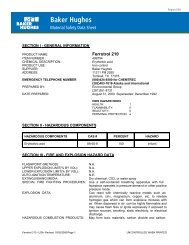

Disclaimer of Liability: This information is provided for general information purposes only and is believed to be accurate as of the date hereof; however, <strong>Baker</strong> <strong>Hughes</strong> Incorporated and its affiliates do not make any<br />

warranties or representations of any kind regarding the information and disclaim all express and implied warranties or representations to the fullest extent permissible by law, including those of merchantability, fitness<br />

for a particular purpose or use, title, non-infringement, accuracy, correctness or completeness of the information provided herein. All information is furnished “as is” and without any license to distribute. The user agrees<br />

to assume all liabilities related to the use of or reliance on such information. BAKER HUGHES INCORPORATED AND ITS AFFILIATES SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, PUNITIVE, EXEMPLARY OR<br />

CONSEQUENTIAL DAMAGES FROM ANY CAUSE WHATSOEVER INCLUDING BUT NOT LIMITED TO ITS NEGLIGENCE.<br />

© 2013 <strong>Baker</strong> <strong>Hughes</strong> Incorporated. All rights reserved. 39168 09/2013

Using rod lift systems in<br />

unconventional oil wells is<br />

a little too conventional<br />

ESP systems are an unconventional<br />

approach with stronger benefits<br />

Rod lift systems have their place. In conventional brownfield and stripper wells with<br />

low flow rates, they’ve been the standard for many years. They’re considered to be a long-term<br />

lift solution, and the equipment is familiar, proven, and typically readily available.<br />

But if you’re using rod lift systems to manage unconventional oil wells with flow ranges between<br />

50 and 4000 barrels of fluid per day, you’re missing an opportunity to improve your economics.<br />

Improve Economics<br />

ESP systems can be set deeper in a well, placing the pumping system closer to the producing zone,<br />

and they operate reliably in low-flow ranges—as low as 50 barrels of fluid per day—allowing<br />

you to dramatically improve your return on investment. These systems also are<br />

deviation tolerant, which eliminates the costly workovers often required due to the tubing wear.<br />

And ESP systems can reliably handle high levels of gas and abrasives in the fluid,<br />

increasing drawdown in applications with natural gas entrained in the fluid. New equipment design features<br />

also improve ESP system efficiency, driving down power costs to rates competitive with those of rod lift.<br />

In addition to the economic benefits, ESP system installation is less intrusive and requires a smaller, less<br />

unsightly surface footprint. ESP systems also eliminate potential emissions from the wellhead,<br />

and pose fewer HSE risks.<br />

X<br />

Did you know…because rod lift systems aren’t designed to yield<br />

high production rates from deep setting depths and have performance<br />

issues in highly deviated wells, they often have reliability issues.<br />

NO<br />

LIMITS<br />

<strong>Baker</strong> <strong>Hughes</strong> ESP systems specifically designed for unconventional<br />

oil wells can operate from 50 to 4000 barrels of fluid per day and<br />

have no setting-depth limitations.

The ProductionWave solution<br />

can lead to greater production levels<br />

Produce more economically<br />

with fewer HSE risks<br />

Breakthrough ESP Systems and Associated Technologies<br />

At the heart of the ProductionWave solution are the <strong>Baker</strong> <strong>Hughes</strong> Centrilift FLEX series pumps—ESPs that<br />

can produce from 50 to 4000 barrels of fluid per day—integrated with best-in-class capabilities for gas and<br />

abrasives handling, and unmatched monitoring and automation services.<br />

Experienced People…from Innovation to the Field<br />

<strong>Baker</strong> <strong>Hughes</strong> engineers will collaborate with you to determine the specific pumping requirements of your well and to<br />

design the optimal system that meets your economic drivers. Real-time optimization experts extend the effectiveness<br />

of the ESP system over the life of the field by ensuring optimal system performance that is in line with your production<br />

expectations. And <strong>Baker</strong> <strong>Hughes</strong> experienced field service professionals deliver the most reliable ESP system.<br />

Choose a production solution based on experience and successful execution<br />

in the field in more than 1000 wells.<br />

Choose the ProductionWave FLEXible production solution<br />

for unconventional oil wells.<br />

Commercial Models that Meet Your Business Requirements<br />

Economic requirements vary, so the best solution offers a choice of commercial models that can range from renting<br />

equipment, to sell/trade, to lease-to-own, to expanded warranties, to well testing. <strong>Baker</strong> <strong>Hughes</strong> can work with you<br />

to deploy the one that’s right for you.<br />

<strong>Baker</strong> <strong>Hughes</strong> has been the leader in new patents for ESP technology<br />

since 1960. In the last 10 years, the company has outpaced its nearest<br />

competitor by 47% in its number of patents.<br />

After experiencing reliability issues with rod lift systems, a Bakken operator<br />

increased oil production by 35%, improved uptime, and reduced workover<br />

expenditures—all by switching to a ProductionWave solution. Featuring<br />

the Centrilift FLEX TM 3.2 pump technology, the ESP system mitigated fluid<br />

turbulence, preventing cycling and gas locking, and effectively handled<br />

solids—both challenging conditions for rod lift systems.<br />

ESP<br />

system