Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

see. control. automate.<br />

<strong>NELA</strong>Punch-<br />

and Bending Devices<br />

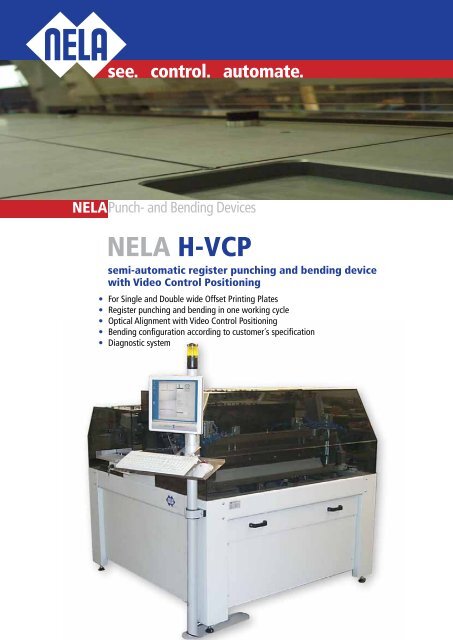

<strong>NELA</strong> H-<strong>VCP</strong><br />

semi-automatic register punching and bending device<br />

with Video Control Positioning<br />

• For Single and Double wide Offset Printing Plates<br />

• Register punching and bending in one working cycle<br />

• Optical Alignment with Video Control Positioning<br />

• Bending configuration according to customer´s specification<br />

• Diagnostic system

<strong>NELA</strong>Punch- and Bending Devices<br />

The fully automatic register punching and<br />

bending machine <strong>NELA</strong> H-<strong>VCP</strong>2002 realizes<br />

a maximum register accuracy by the<br />

systematic use of modern technologies and<br />

manufacturing processes. The flexibility<br />

allows the combination with a variety of<br />

modern and fast imaging equipment to an<br />

economical, high-precision printing plate<br />

processing line. The <strong>NELA</strong> H-<strong>VCP</strong>2002<br />

can be flexibly integrated into any automation<br />

solution.<br />

<strong>NELA</strong> H-<strong>VCP</strong> Semi-Automatic Register Punching and Bending<br />

machine with Video-Control-Positioning - as primary equipment<br />

or as back-up - for Newspaper and Commercial Printing<br />

Operation<br />

Printing plates are put into the <strong>NELA</strong> H-<br />

<strong>VCP</strong>2002 by hand and are pre-positioned<br />

against 3 alignment stops. After pushing the<br />

start button video cameras detect preexposed<br />

register marks on the printing plate.<br />

By means of top image processing and<br />

positioning the printing plates are placed<br />

into the correct position to ensure precise<br />

register between the image and the punch<br />

and bending every time. Register correction<br />

at the printing plate can be entered<br />

over keyboard. In one operation the plates<br />

are punched and bent at both ends. The<br />

processed printing plates can then be easily<br />

taken out of the machine.<br />

Reliability<br />

All parts in the <strong>NELA</strong> H-<strong>VCP</strong>2002 are<br />

developed and designed according to the<br />

latest state of technics and technology and<br />

manufactured with highest precision. <strong>NELA</strong><br />

quality is guaranteed for the manufacturing<br />

of the <strong>NELA</strong> H-<strong>VCP</strong>2002 , ensuring a<br />

trouble free operation for years to come.<br />

www.nela.de<br />

e-mail: sales@nela.de<br />

BRüDER NEuMEISTER GMBh<br />

Gottlieb-Daimler-Straße 15<br />

D-77933 Lahr<br />

Phone +49 (0) 78 21 - 58 08-0<br />

Fax +49 (0) 78 21 - 58 08-62<br />

Technical Features<br />

1. Mechanical:<br />

• Modern design<br />

• For single- and doublewide offset printing<br />

plates<br />

• Video-controlled register punching and<br />

bending in one cycle<br />

• Cleaning and lubrication of punching die<br />

before each punching stroke guarantee<br />

long life of punch tools and precise, burrfree<br />

punch holes<br />

• Register-true alignment of offset plates<br />

via:<br />

a) Video cameras by using imaged register<br />

targets<br />

b) Pin register<br />

c) Electronic edge register; adaptable for<br />

various requirements<br />

• 3-way alignment controlled by stepper<br />

motors<br />

• Integration of plate slitter is possible<br />

2. Electronics and Software:<br />

• <strong>NELA</strong><strong>VCP</strong>NET – intuitive operating software<br />

• Network capable via action channels<br />

• Open platform design allows for easy<br />

integration of new applications<br />

• JDF/JMF compatible tracking format<br />

• Integrated Java interface for creation of<br />

web-based applications<br />

• Priority-driven warning system: Errors,<br />

warning, information<br />

• Industrial PC-based operation<br />

• <strong>NELA</strong>Remote<br />

3. Options<br />

• <strong>NELA</strong>PQM + : Automatic measurement<br />

and evaluation of the image quality of<br />

printing plates for 100% control during<br />

plate production regarding precision of<br />

register, and quality of image and development<br />

process<br />

• Automatic register correction as well as<br />

software-driven Fan-Out-Compensation<br />

• Barcode Reader<br />

• Inkjet Printer<br />

• Multiple Stackers<br />

• PSM Plate Sorting Manager<br />

• Page Tracking<br />

• Status Centre<br />

<strong>NELA</strong> - Who we are:<br />

The <strong>NELA</strong> group, consisting of <strong>NELA</strong> Brüder Neumeister Gmbh, <strong>NELA</strong> uSA and <strong>NELA</strong> Asia, forms one<br />

of the largest manufacturer of high-quality optical control devices for industrial applications, process<br />

control and automation. <strong>NELA</strong> Register systems include inline punch-bending machines, both for<br />

newspaper and commercial printing and plate automation and transportation systems. With more<br />

than 1400 installations around the world, <strong>NELA</strong> is among market and technology leaders.<br />

As a leader in our industry in Europe, we are also represented on the markets of North and South<br />

America and Asia / Oceania. At our headquarters in Lahr/Germany 200 employees manufacture stateof-the-art<br />

precision equipment in modern and spacious production facilities.<br />

see. control. automate.<br />

Printed in Germany - 0911-001