NELASF-Bender 1100

NELASF-Bender 1100

NELASF-Bender 1100

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

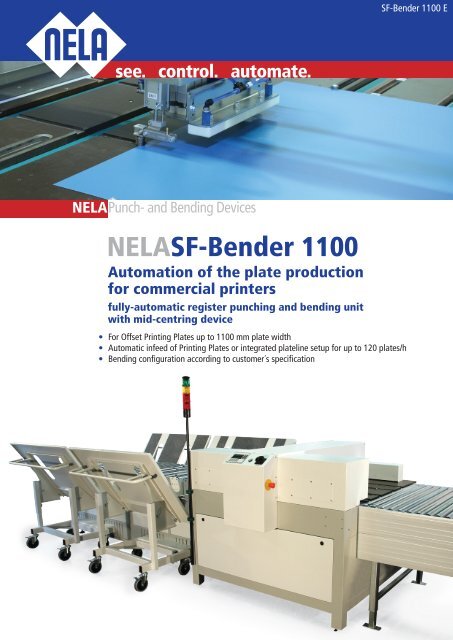

see. control. automate.<br />

NELAPunch-<br />

and Bending Devices<br />

<strong>NELASF</strong>-<strong>Bender</strong> <strong>1100</strong><br />

Automation of the plate production<br />

for commercial printers<br />

fully-automatic register punching and bending unit<br />

with mid-centring device<br />

• For Offset Printing Plates up to <strong>1100</strong> mm plate width<br />

• Automatic infeed of Printing Plates or integrated plateline setup for up to 120 plates/h<br />

• Bending configuration according to customer´s specification<br />

SF-<strong>Bender</strong> <strong>1100</strong> E

Product Profile<br />

The <strong>NELASF</strong>-<strong>Bender</strong> <strong>1100</strong> combines reliable<br />

technology designed in Germany with easy<br />

serviceability due to the use of brand name<br />

parts from suppliers with international support.<br />

With its basic floor layout configurations it offers<br />

all benefits of modern automated plate line<br />

at an affordable price and NELA technology<br />

which can be trust.<br />

Operation<br />

In the <strong>NELASF</strong>-<strong>Bender</strong> <strong>1100</strong> the offset<br />

plates are positioned automatically by register<br />

pins. Then the punching / bending is made.<br />

The processed printing plates are then safely<br />

loaded into a stacking station. An electronic<br />

monitoring system guarantees the register<br />

accuracy of the printing plates.<br />

Reliability<br />

All parts in the <strong>NELASF</strong>-<strong>Bender</strong> <strong>1100</strong> are<br />

developed and designed according to the latest<br />

www.nela.de<br />

e-mail: sales@nela.de<br />

NELAPunch- and Bending Devices<br />

state of technology and manufactured with<br />

highest precision. NELA quality is guaranteed<br />

for the manufacturing of the <strong>NELASF</strong>-<strong>Bender</strong><br />

<strong>1100</strong>, ensuring a trouble free operation for<br />

years to come.<br />

Technical Features<br />

BRÜDER NEUMEISTER GMBH<br />

Gottlieb-Daimler-Straße 15<br />

D-77933 Lahr<br />

Phone +49 (0) 78 21 - 58 08-0<br />

Fax +49 (0) 78 21 - 58 08-62<br />

• Register-true positioning of the plates by<br />

electronic controlled three point alignment<br />

• Three configurations possible: Punching only,<br />

bending only, punching and bending<br />

• Processing of several plate formats possible<br />

• Plate output: depending on plate layout up to<br />

120 offset plates per hour (depends to plate<br />

specification)<br />

• Standardized transport units from plate processor<br />

to <strong>NELASF</strong>-<strong>Bender</strong> <strong>1100</strong><br />

• Input height corresponding to the preceding<br />

plate processor<br />

• Operator display<br />

• Electronic process control<br />

• Register punching configuration according to<br />

customer’s specifications<br />

TECHNICAL DATA<br />

<strong>NELASF</strong>-<strong>Bender</strong> <strong>1100</strong><br />

• Compressed Air: 7-10 bar<br />

• Electrical supply: 400 V, 50 – 60 Hz, 1kW<br />

• Dimensions:<br />

length: approx. 1465 mm<br />

width: approx. 1450 mm<br />

height: approx. 1285 mm (+/- 100 mm)<br />

• Weight: approx. 850 kg net<br />

(depending on the technical design)<br />

<strong>NELASF</strong>-<strong>Bender</strong> <strong>1100</strong> is a fully inline capable <strong>Bender</strong> geared to Sheetfed printing houses,<br />

covering all sheetfed press configurations.<br />

• Support table with vacuum and air cushion<br />

• Integration of technological high quality<br />

electronically and mechanical components<br />

• Use of particular high-quality material for the<br />

manufacturing of punching and bending tools<br />

• Ultra fine lubrication of punching dies longer<br />

life cycles and burr-free register holes<br />

Our Service - Your Advantage<br />

• Responsive, expert consulting<br />

• Everything from NELA – from register bars<br />

to fully automatic plate processing lines and<br />

on-press register control.<br />

• Installation drawings and layouts (CAD)<br />

according to your requirements<br />

• Modern and reliable pneumatic and electronic<br />

components - the worlds leading<br />

manufacturers with service centres worldwide<br />

are our partners<br />

Automatic sorting and stacking<br />

• See our special leaflet<br />

NELA - Who we are:<br />

The NELA group, consisting of NELA Brüder Neumeister GmbH, NELA USA and NELA Asia, forms one<br />

of the largest manufacturer of high-quality optical control devices for industrial applications, process<br />

control and automation. NELA Register systems include inline punch-bending machines, both for<br />

newspaper and commercial printing and plate automation and transportation systems. With more than<br />

1400 installations around the world, NELA is among market and technology leaders.<br />

As a leader in our industry in Europe, we are also represented on the markets of North and South<br />

America and Asia / Oceania. At our headquarters in Lahr/Germany 200 employees manufacture stateof-the-art<br />

precision equipment in modern and spacious production facilities.<br />

see. control. automate.<br />

Printed in Germany - 1204-050