SECAR® 70V - SECAR®, solutions for refractories

SECAR® 70V - SECAR®, solutions for refractories

SECAR® 70V - SECAR®, solutions for refractories

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

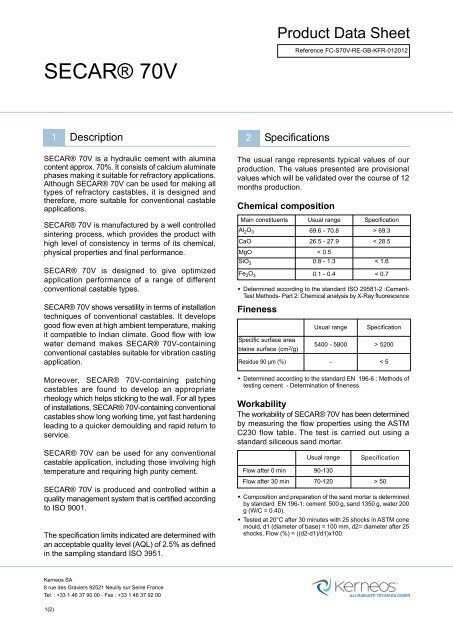

Product Data Sheet<br />

<strong>SECAR®</strong> <strong>70V</strong><br />

Reference FC-S<strong>70V</strong>-RE-GB-KFR-012012<br />

1 Description<br />

2 Specifications<br />

<strong>SECAR®</strong> <strong>70V</strong> is a hydraulic cement with alumina<br />

content approx. 70%. It consists of calcium aluminate<br />

phases making it suitable <strong>for</strong> refractory applications.<br />

Although <strong>SECAR®</strong> <strong>70V</strong> can be used <strong>for</strong> making all<br />

types of refractory castables, it is designed and<br />

there<strong>for</strong>e, more suitable <strong>for</strong> conventional castable<br />

applications.<br />

<strong>SECAR®</strong> <strong>70V</strong> is manufactured by a well controlled<br />

sintering process, which provides the product with<br />

high level of consistency in terms of its chemical,<br />

physical properties and final per<strong>for</strong>mance.<br />

<strong>SECAR®</strong> <strong>70V</strong> is designed to give optimized<br />

application per<strong>for</strong>mance of a range of different<br />

conventional castable types.<br />

<strong>SECAR®</strong> <strong>70V</strong> shows versatility in terms of installation<br />

techniques of conventional castables. It develops<br />

good flow even at high ambient temperature, making<br />

it compatible to Indian climate. Good flow with low<br />

water demand makes <strong>SECAR®</strong> <strong>70V</strong>-containing<br />

conventional castables suitable <strong>for</strong> vibration casting<br />

application.<br />

Moreover, <strong>SECAR®</strong> <strong>70V</strong>-containing patching<br />

castables are found to develop an appropriate<br />

rheology which helps sticking to the wall. For all types<br />

of installations, <strong>SECAR®</strong> <strong>70V</strong>-containing conventional<br />

castables show long working time, yet fast hardening<br />

leading to a quicker demoulding and rapid return to<br />

service.<br />

<strong>SECAR®</strong> <strong>70V</strong> can be used <strong>for</strong> any conventional<br />

castable application, including those involving high<br />

temperature and requiring high purity cement.<br />

<strong>SECAR®</strong> <strong>70V</strong> is produced and controlled within a<br />

quality management system that is certified according<br />

to ISO 9001.<br />

The specification limits indicated are determined with<br />

an acceptable quality level (AQL) of 2.5% as defined<br />

in the sampling standard ISO 3951.<br />

The usual range represents typical values of our<br />

production. The values presented are provisional<br />

values which will be validated over the course of 12<br />

months production.<br />

Chemical composition<br />

Main constituents Usual range Specification<br />

Al 2 O 3 69.6 - 70.8 > 69.3<br />

CaO 26.5 - 27.9 < 28.5<br />

MgO < 0.5<br />

SiO 2 0.8 - 1.3 < 1.6<br />

Fe 2 O 3 0.1 - 0.4 < 0.7<br />

w Determined according to the standard ISO 29581-2 :Cement-<br />

Test Methods- Part 2: Chemical analysis by X-Ray fluorescence<br />

Fineness<br />

Specific surface area<br />

blaine surface (cm 2 /g)<br />

Usual range<br />

Specification<br />

5400 - 5800 > 5200<br />

Residue 90 µm (%) - < 5<br />

w Determined according to the standard EN 196-6 : Methods of<br />

testing cement - Determination of fineness.<br />

Workability<br />

The workability of <strong>SECAR®</strong> <strong>70V</strong> has been determined<br />

by measuring the flow properties using the ASTM<br />

C230 flow table. The test is carried out using a<br />

standard siliceous sand mortar.<br />

Usual range<br />

Specification<br />

Flow after 0 min 90-130<br />

Flow after 30 min 70-120 > 50<br />

w Composition and preparation of the sand mortar is determined<br />

by standard EN 196-1: cement 500 g, sand 1350 g, water 200<br />

g (W/C = 0.40).<br />

w Tested at 20°C after 30 minutes with 25 shocks in ASTM cone<br />

mould, d1 (diameter of base) = 100 mm, d2= diameter after 25<br />

shocks, Flow (%) = ((d2-d1)/d1)x100.<br />

Kerneos SA<br />

8 rue des Graviers 92521 Neuilly sur Seine France<br />

Tel. : +33 1 46 37 90 00 - Fax : +33 1 46 37 92 00<br />

1(2)

Setting time<br />

Other physical characteristics<br />

Usual range<br />

Specification<br />

• Pyrometric cone equivalent:<br />

IS 1528 (Part 1), Orton Cone 26, 1605°C - 1620°C<br />

Initial set (min) 250 - 450 > 200<br />

Final set (min) 350 - 550 < 600<br />

4<br />

Storage and shelf life<br />

w Composition and preparation of the sand mortar is determined<br />

by standard EN 196-1: cement 500g, sand 1350g, water 200g<br />

(W/C = 0.4).<br />

w Setting time measurement according to NF P15-431: Vicat<br />

apparatus standard EN 196-3 but using a 1000 g test weight;<br />

temperature 30°C; samples immersed in water or cured at > 90%<br />

relative humidity.<br />

w Final setting time measured in accordance with NF P 15-330:<br />

the Vicat needle no longer penetrates the mortar.<br />

In common with all hydraulic binders, <strong>SECAR®</strong> <strong>70V</strong><br />

must be stored in shrink wrapped condition on pallet,<br />

as supplied, in dry conditions under a covered storage<br />

area. <strong>SECAR®</strong> <strong>70V</strong> when stored correctly will retain<br />

its properties <strong>for</strong> at least 6 months.<br />

Mechanical strengh<br />

Compressive strength (MPa)<br />

Age Usual range Specification<br />

24 h 40 - 50 > 40<br />

w Composition and preparation of the sand mortar according to<br />

EN 196-1: cement 500g, sand 1350g, water 200g (W/C = 0.4).<br />

w Test conditions according to EN 196-1; test prisms 40 x 40 x 160<br />

mm; temperature 20°C; prisms cured <strong>for</strong> 24 hours at > 90%<br />

relative humidity, followed by immersion in water.<br />

3<br />

Additional in<strong>for</strong>mation<br />

This in<strong>for</strong>mation is given <strong>for</strong> guidance only.<br />

Mineralogical composition<br />

• Principal phases*) : CA, CA 2<br />

•Secondary phases*): Aa, C 2 AS, C 12 A 7<br />

*)S = SiO 2 , C=CaO, A=Al 2 O 3<br />

Kerneos warrants that the product complies with the specifications stated herein to the exclusion of any other warranty, express or implied. Kerneos makes no representation or<br />

warranty of any kind, either expressed or implied, as to the suitability or fitness <strong>for</strong> a particular purpose or use of the product. The warranty shall be limited to the replacement of the<br />

non-con<strong>for</strong>ming products or, at Kerneos option, the refund of the purchase price.<br />

Any technical advice, recommendations or in<strong>for</strong>mation are given based on Kerneos current knowledge and experience of the products and are deemed to be accurate. However,<br />

Kerneos undertakes no liability or responsibility of any kind with respect thereof. Users are invited to check that they have the latest version of this document.<br />

Kerneos SA<br />

8 rue des Graviers 92521 Neuilly sur Seine France<br />

Tel. : +33 1 46 37 90 00 - Fax : +33 1 46 37 92 00<br />

2(2)