Passive versus Active Packaging

Passive versus Active Packaging

Passive versus Active Packaging

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

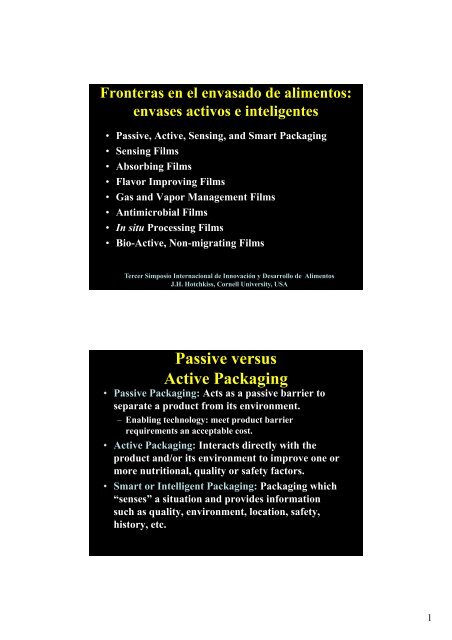

Fronteras en el envasado de alimentos:<br />

envases activos e inteligentes<br />

• <strong>Passive</strong>, <strong>Active</strong>, Sensing, and Smart <strong>Packaging</strong><br />

• Sensing Films<br />

• Absorbing Films<br />

• Flavor Improving Films<br />

• Gas and Vapor Management Films<br />

• Antimicrobial Films<br />

• In situ Processing Films<br />

• Bio-<strong>Active</strong>, Non-migrating Films<br />

Tercer Simposio Internacional de Innovación y Desarrollo de Alimentos<br />

J.H. Hotchkiss, Cornell University, USA<br />

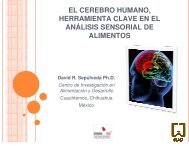

<strong>Passive</strong> <strong>versus</strong><br />

<strong>Active</strong> <strong>Packaging</strong><br />

• <strong>Passive</strong> <strong>Packaging</strong>: Acts as a passive barrier to<br />

separate a product from its environment.<br />

– Enabling technology: meet product barrier<br />

requirements an acceptable cost.<br />

• <strong>Active</strong> <strong>Packaging</strong>: Interacts directly with the<br />

product and/or its environment to improve one or<br />

more nutritional, quality or safety factors.<br />

• Smart or Intelligent <strong>Packaging</strong>: <strong>Packaging</strong> which<br />

“senses” a situation and provides information<br />

such as quality, environment, location, safety,<br />

history, etc.<br />

1

Microbial Sensing “Smart” Films<br />

LASER<br />

DIFFRACTION<br />

PATTERN<br />

ANTIBODY GRID<br />

Removal of Unwanted Food<br />

Components<br />

• Removal of aldehydes and amines from<br />

headspace<br />

• Immobilized Chelating Agents<br />

2

Example: <strong>Active</strong> Control of<br />

Lipid Oxidation in Foods<br />

Conventional control of lipid oxidation in foods:<br />

Additives<br />

Antioxidant<br />

Chelating agents<br />

Barrier packaging/Nitrogen flushing<br />

<strong>Active</strong> control<br />

Absorb products of oxidation<br />

Irreversible Removal of Amines<br />

and/or Aldehydes<br />

• Incorporation of activated sites onto films<br />

• Formation of Schiff’s bases (imines)<br />

• R-NH 2 + R’-C=O R-N=CH-R’<br />

3

Removal of Metals<br />

from Beverages<br />

Fe 2+<br />

Chelating agent<br />

Example: In situ Processing for<br />

Improved Flavor<br />

• Nature makes foods such as citrus bitter to<br />

as a df defense mechanism<br />

• Enzymes exist which degrade the bitter<br />

compounds<br />

4

Immobilization of Flavorenhancing<br />

Enzymes into<br />

Cellulose Ester Films<br />

• Debittering of citrus with naringinase<br />

5

Loss of naringin from grapefruit juice after exposure to CA<br />

film containing naringinase at 7°C<br />

Gas & Vapor Management<br />

• CO 2 ,O 2 , water vapor<br />

• Ethylene<br />

• 1-MCP as an inhibitor of ethylene<br />

receptors<br />

6

Equations for optimal<br />

permeability & atmosphere<br />

Al-Ati & Hotchkiss, 2004<br />

7

Permeabilities and Permselectivity for Selected<br />

Produce to Give Opt Atmosphere<br />

(1 mil, 4°C, mL·mil/cm 2 .hr.atm)<br />

P O2 P CO2 CO 2 /O 2<br />

Strberry 0.245 0.26 1.1<br />

Lettuce 0.049 0.47 9.5<br />

Broccoli 0.032 0.07 2.2<br />

Carrot 0.017 0.06 3.7<br />

Apple 0.017 0.10 6.3<br />

Celery 0.014 0.04 3.2<br />

Cabbage 0.008 0.03 3.0<br />

Grn Peppr 0.007 0.04 6.0<br />

Release of MCP from <strong>Packaging</strong><br />

Materials<br />

CH 2<br />

HC = C – CH 3<br />

8

Release of MCP from LDPE film<br />

containing sliced apples<br />

Antimicrobial Polymers:<br />

Potential Uses<br />

• <strong>Packaging</strong> (food contact films)<br />

• Non-packaging food contact tsurfaces<br />

– tables, filler nozzles, conveyer belts<br />

• Personal hygiene equipment<br />

– gloves, aprons, utensils<br />

• Machinery surfaces<br />

• Non-contact surfaces<br />

– refrigeration systems, walls, floors, drains<br />

9

Antimicrobial Polymers<br />

Migrating: Incorporation and generation<br />

of volatile & nonvolatile antimicrobials in<br />

films<br />

Non-migrating: Immobilization of<br />

antimicrobial agents to food packaging<br />

materials.<br />

Example: Antimicrobial<br />

Enzymes in Films<br />

• Immobilization of lysozyme in cellulosic<br />

ester films.<br />

10

Films Containing Antibiotics<br />

or Antimycotics: Hydrolysis of<br />

benzoic anhydride to benzoic acid<br />

11

Inhibition of Penicillium spp. on cheese by<br />

LDPE containing benzoic anhydride<br />

Nisin Impregnated Antimicrobial<br />

Film/Paper<br />

Hu et al 2000<br />

Scanell et al 2000<br />

12

Non-migrating “food additives”<br />

When is a food additive<br />

not a “food additive?”<br />

Potential Non-migrating<br />

Functional “Additives”<br />

• Anti-microbial<br />

• Enzymes<br />

• Chelating agents<br />

• Anti-oxidants<br />

• Selective aroma sorbents/reactants<br />

• Colors<br />

• Surface energy modifiers<br />

• Sanitizers<br />

• Indicators (chemical & biological)<br />

• Film physical and chemical modifiers<br />

13

Immobilized Functional Food<br />

Ingredients (Bio-active <strong>Packaging</strong>)<br />

Enzyme<br />

Antioxidant<br />

Antimicrobial<br />

Bulk<br />

Solution or<br />

Food<br />

Surface<br />

Bulk Polymer<br />

w modified<br />

surface<br />

Spacer<br />

Anchor<br />

<strong>Active</strong><br />

Agent<br />

Covalent attachment of Bioactive<br />

Molecules to Polymers<br />

Polymer surface<br />

Functionalized<br />

Polymer surface<br />

Functionalized<br />

Polymer surface<br />

Biofunctionalized<br />

Polymer surface<br />

Goddard et al 2006<br />

14

Surface Protein Content of PE Film Before<br />

and After Lactase Attachment<br />

8.00<br />

Avera age μg protein/ /cm 2<br />

7.00<br />

6.00<br />

5.00<br />

4.00<br />

3.00<br />

2.00<br />

1.00<br />

0.00<br />

a<br />

a<br />

a<br />

PE PE-COOH PE-NH2 PE-GL PE-LAC PE-LAC<br />

(SDS)<br />

a<br />

Film Sample<br />

b<br />

c<br />

Relative Activity of Free and Film-Attached Lactase<br />

Re elative Activ vity (%)<br />

100%<br />

90%<br />

80%<br />

70%<br />

60%<br />

50%<br />

40%<br />

30%<br />

20%<br />

10%<br />

0%<br />

4 5 6 7 8 9 10<br />

pH Value<br />

Free Lactase<br />

Film-Attached Lactase<br />

15

AFM view of modified<br />

surface of LDPE<br />

Antimicrobial Peptides<br />

• Occur widely in nature.<br />

• Typically 23 to 34 aa to 35-70 kDa proteins.<br />

• Amphipathic and highly basic (+ charge).<br />

• Helical structure.<br />

• Act at cell surface.<br />

• Permeabilize cell membrane.<br />

16

Synthetic antimicrobial peptide<br />

• 6K8L, leucine and lysine<br />

• low hemolytic activity, strong antimicrobial<br />

activity<br />

17

Changes in OD 600nm of E. coli 0157:H7 in TSB with ()<br />

or without () 50 μg/ml peptide 6K8L at 25°C<br />

(b)<br />

1.2<br />

1<br />

0.8<br />

OD 600nm<br />

0.6<br />

0.4<br />

0.2<br />

0<br />

0 20 40 60 80 100 120 140 160<br />

Time (min)<br />

18

Effect of peptide 6K8L on P. fluor., S. liquefac., S. typhy., E.<br />

coli survival in buffer at 25°C for 10 min.<br />

A.<br />

lo og 10<br />

CFU/ml<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

P.f luorescens<br />

S. liquef sciens<br />

S. t yphymurium<br />

E. coli O157:H7<br />

0 20 40 60<br />

Peptide (ug/ml)<br />

Effect of peptide 6K8L on S. aureus, L. mono., and B.<br />

subtilis, K. marxianus in buffer at 25°C for 10 min.<br />

B.<br />

log<br />

10<br />

CFU/ml<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

S. aureus<br />

L. monocytogenes<br />

B. subtilis<br />

K. marxianus<br />

0 20 40 60<br />

Peptide (ug/ml)<br />

19

Peptide Immobilization<br />

• PS resin bead---spacer molecule---peptide<br />

• 345 mg (0.2 mmol) peptide/g resin<br />

• Surface modified polystyrene (SMPS)<br />

Immobilization on PS Beads<br />

Peptide<br />

Spacer<br />

Molecule<br />

Polymer<br />

Bead<br />

20

Effect of 0, 6, 10, 20, 40 mg/ml of SMPS on E. coli 0157:H7<br />

growth in TBS at 25°C. () PS control<br />

12<br />

10<br />

Log10 CFU/ml<br />

L<br />

8<br />

6<br />

4<br />

2<br />

0<br />

0 5 10 15 20<br />

Time (h)<br />

21

Concentration (mg/ml) of SMPS required to give a 3 log<br />

reduction in counts in buffer in 10, 30, or 60 min at 25°C<br />

• ORGANISM 10 MIN 30 MIN 60 MIN.<br />

• E. coli 0157:H7 8 5 4<br />

• S. typhimurium 18 17 8<br />

• S. liquefasciens 8 5 ND<br />

• P. fluorescens 7 5 3<br />

• B. subtltis 3 3 2<br />

• L.monocytogenes 12 5 3<br />

• S. aureus >60 57 50<br />

• K. marxiamus 16 9 8<br />

Conclusions<br />

• Surfaces can be reasonably made bioactive<br />

with commercial chemistry.<br />

• Bioactive materials can be covalently<br />

attached to surfaces with acceptable loss of<br />

activity.<br />

• <strong>Active</strong>/smart packaging materials may be<br />

useful in foods and biomedicine.<br />

22

"Discovery is seeing what<br />

everyone has seen and<br />

thinking what<br />

nobody has thought"<br />

-- Albert Szent-Gyogyi<br />

23