VISA Steel Limited Annual Report 2010-11

VISA Steel Limited Annual Report 2010-11

VISA Steel Limited Annual Report 2010-11

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Annual</strong> <strong>Report</strong> <strong>2010</strong> -<strong>11</strong><br />

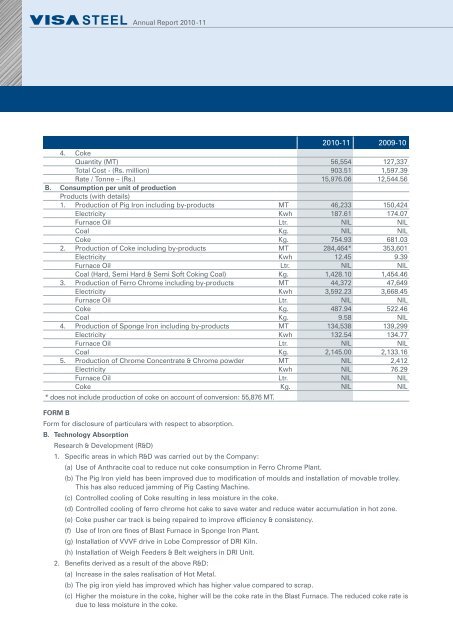

<strong>2010</strong>-<strong>11</strong> 2009-10<br />

4. Coke<br />

Quantity (MT) 56,554 127,337<br />

Total Cost - (Rs. million) 903.51 1,597.39<br />

Rate / Tonne – (Rs.) 15,976.06 12,544.56<br />

B. Consumption per unit of production<br />

Products (with details)<br />

1. Production of Pig Iron including by-products MT 46,233 150,424<br />

Electricity Kwh 187.61 174.07<br />

Furnace Oil Ltr. NIL NIL<br />

Coal Kg. NIL NIL<br />

Coke Kg. 754.93 681.03<br />

2. Production of Coke including by-products MT 284,464* 353,601<br />

Electricity Kwh 12.45 9.39<br />

Furnace Oil Ltr. NIL NIL<br />

Coal (Hard, Semi Hard & Semi Soft Coking Coal) Kg. 1,428.10 1,454.46<br />

3. Production of Ferro Chrome including by-products MT 44,372 47,649<br />

Electricity Kwh 3,592.23 3,668.45<br />

Furnace Oil Ltr. NIL NIL<br />

Coke Kg. 487.94 522.46<br />

Coal Kg. 9.58 NIL<br />

4. Production of Sponge Iron including by-products MT 134,538 139,299<br />

Electricity Kwh 132.54 134.77<br />

Furnace Oil Ltr. NIL NIL<br />

Coal Kg. 2,145.00 2,133.16<br />

5. Production of Chrome Concentrate & Chrome powder MT NIL 2,412<br />

Electricity Kwh NIL 76.29<br />

Furnace Oil Ltr. NIL NIL<br />

Coke Kg. NIL NIL<br />

* does not include production of coke on account of conversion: 55,876 MT.<br />

FORM B<br />

Form for disclosure of particulars with respect to absorption.<br />

B. Technology Absorption<br />

Research & Development (R&D)<br />

1. Specific areas in which R&D was carried out by the Company:<br />

(a) Use of Anthracite coal to reduce nut coke consumption in Ferro Chrome Plant.<br />

(b) The Pig Iron yield has been improved due to modification of moulds and installation of movable trolley.<br />

This has also reduced jamming of Pig Casting Machine.<br />

(c) Controlled cooling of Coke resulting in less moisture in the coke.<br />

(d) Controlled cooling of ferro chrome hot cake to save water and reduce water accumulation in hot zone.<br />

(e) Coke pusher car track is being repaired to improve efficiency & consistency.<br />

(f) Use of Iron ore fines of Blast Furnace in Sponge Iron Plant.<br />

(g) Installation of VVVF drive in Lobe Compressor of DRI Kiln.<br />

(h) Installation of Weigh Feeders & Belt weighers in DRI Unit.<br />

2. Benefits derived as a result of the above R&D:<br />

(a) Increase in the sales realisation of Hot Metal.<br />

(b) The pig iron yield has improved which has higher value compared to scrap.<br />

(c) Higher the moisture in the coke, higher will be the coke rate in the Blast Furnace. The reduced coke rate is<br />

due to less moisture in the coke.