Chapter 26.indd - Automotive Electronics Services

Chapter 26.indd - Automotive Electronics Services

Chapter 26.indd - Automotive Electronics Services

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Chapter</strong> 26<br />

PC-Based Diagnostic Equipment<br />

Overview<br />

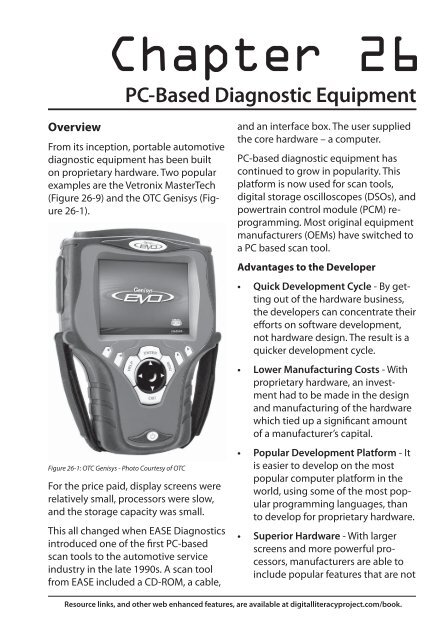

From its inception, portable automotive<br />

diagnostic equipment has been built<br />

on proprietary hardware. Two popular<br />

examples are the Vetronix MasterTech<br />

(Figure 26-9) and the OTC Genisys (Figure<br />

26-1).<br />

Figure 26-1: OTC Genisys - Photo Courtesy of OTC<br />

For the price paid, display screens were<br />

relatively small, processors were slow,<br />

and the storage capacity was small.<br />

This all changed when EASE Diagnostics<br />

introduced one of the first PC-based<br />

scan tools to the automotive service<br />

industry in the late 1990s. A scan tool<br />

from EASE included a CD-ROM, a cable,<br />

and an interface box. The user supplied<br />

the core hardware – a computer.<br />

PC-based diagnostic equipment has<br />

continued to grow in popularity. This<br />

platform is now used for scan tools,<br />

digital storage oscilloscopes (DSOs), and<br />

powertrain control module (PCM) reprogramming.<br />

Most original equipment<br />

manufacturers (OEMs) have switched to<br />

a PC based scan tool.<br />

Advantages to the Developer<br />

• Quick Development Cycle - By getting<br />

out of the hardware business,<br />

the developers can concentrate their<br />

efforts on software development,<br />

not hardware design. The result is a<br />

quicker development cycle.<br />

• Lower Manufacturing Costs - With<br />

proprietary hardware, an investment<br />

had to be made in the design<br />

and manufacturing of the hardware<br />

which tied up a significant amount<br />

of a manufacturer’s capital.<br />

• Popular Development Platform - It<br />

is easier to develop on the most<br />

popular computer platform in the<br />

world, using some of the most popular<br />

programming languages, than<br />

to develop for proprietary hardware.<br />

• Superior Hardware - With larger<br />

screens and more powerful processors,<br />

manufacturers are able to<br />

include popular features that are not<br />

Resource links, and other web enhanced features, are available at digitalliteracyproject.com/book.

358<br />

Part III: <strong>Automotive</strong> Applications of Technology<br />

practical on proprietary platforms.<br />

For example, the level of detail displayed<br />

on a EASE Diagnostics scan<br />

tool (Figure 36-25) is virtually impossible<br />

to deliver on a smaller screen<br />

size.<br />

The added storage capacity of a<br />

computer’s hard drive also allows for<br />

longer recordings of data. Recording<br />

time is now measured in hours,<br />

rather than minutes on proprietary<br />

equipment.<br />

Advantages to the User<br />

• Lower Cost - By allowing the enduser<br />

to supply a computer in lieu of<br />

expensive proprietary hardware, the<br />

total cost of the equipment is lower.<br />

• Easy Hardware Replacement - If<br />

there is a catastrophic failure of the<br />

hardware, moving the software and<br />

cabling over to a new computer is<br />

simple, fast, and easy.<br />

• Superior Platform - With large<br />

screen sizes, full keyboards, and<br />

large storage capabilities, PC-based<br />

diagnostic equipment offers a superior<br />

platform over the typical proprietary<br />

platform.<br />

Ruggedized Laptops<br />

A desktop computer can be used to<br />

connect to a vehicle using a relatively<br />

long cable or a wireless connection, but<br />

laptop computers are the most popular<br />

solution.<br />

Some technicians prefer to use a ruggedized<br />

laptop such as the Dell Latitude<br />

XFR (Figure 26-2) or the Panasonic<br />

Toughbook (Figure 26-3).<br />

The high cost of these models is their<br />

only disadvantage. With a ruggedized<br />

model costing three to four times more<br />

than a standard laptop, most technicians<br />

use standard laptops. Even if they<br />

broke a few, it would still be cheaper<br />

than buying a ruggedized model.<br />

Figure 26-2: Dell Latitude E6400 XFR - Image Courtesy of Dell<br />

Figure 26-3: Panasonic Toughbook CF-19<br />

© 2009 - All Rights Reserved | DLP Publishing | Grant Swaim

<strong>Chapter</strong> 26: PC-Based Diagnostic Equipment 359<br />

<br />

Dell XFR Series<br />

www.dell.com/xfr<br />

Panasonic Toughbook Series<br />

www.panasonic.com/business/Toughbook/fully-rugged-computers.asp<br />

Rugged Notebooks<br />

www.ruggednotebooks.com<br />

Diagnostic Tool Carts<br />

Any laptop used in an automotive shop<br />

environment, whether it is a standard<br />

or ruggedized model, needs protection.<br />

The most popular solution is to use a<br />

tool cart, (Figure 26-4).<br />

This diagnostic cart is in use at Guilford<br />

Technical Community College in Jamestown,<br />

NC. It is made up the following<br />

equipment.<br />

• Standard Dell Laptop Computer<br />

• AutoEnginuity Scan Tool<br />

• 4-Channel PicoScope DSO<br />

• CarDaq Plus J-2534 Gateway Box<br />

The computer is stored inside the top<br />

lid which protects it against the shop<br />

environment. All the other components<br />

and cables fit in the lower drawers.<br />

Figure 26-5: Custom Built <strong>Automotive</strong> Diagnostic Cart<br />

Some technicians have even set up<br />

diagnostic carts with a large LCD monitor<br />

mounted to the inside of the cart’s<br />

lid. The video out signal from the laptop<br />

is sent to the monitor for easy viewing.<br />

This would be a good setup in a school<br />

environment where many students are<br />

trying to view the small screen of a laptop<br />

at the same time.<br />

In the quest for the perfect automotive<br />

diagnostic cart, some automotive<br />

technicians modify existing tool carts or<br />

even custom-build carts (Figure 26-5).<br />

Figure 26-4: Diagnostic Tool Cart<br />

Resource links, and other web enhanced features, are available at digitalliteracyproject.com/book.

360<br />

Part III: <strong>Automotive</strong> Applications of Technology<br />

Figure 26-6: John Anello, of Auto Tech on Wheels, and his customized Hummer H2 mobile diagnostic rig<br />

PCs in Mobile Diagnostics<br />

Educational Applications<br />

PC-based information systems and diagnostic<br />

equipment deliver a lot of power<br />

and portability in a small package. This<br />

is a winning combination for those involved<br />

in mobile diagnostics and one of<br />

the most successful mobile diagnostic<br />

businesses is John Anello’s Auto Tech on<br />

Wheels located in New Jersey. John has<br />

equipped an H2 Hummer with an impressive<br />

array of diagnostic equipment,<br />

much of which is PC-based.<br />

If you want to get “up close and personal”<br />

with John’s rig (Figure 26-6), attend<br />

one of his week-long “Boot Camp”<br />

sessions.<br />

<br />

John Anello’s “Boot Camp”<br />

www.autotechonwheels.com/bootcamp.htm<br />

PC-based diagnostic equipment is also<br />

a favorite among automotive educators<br />

since anything on the screen can be<br />

projected to a large screen for the entire<br />

class to see.<br />

PDA-Based Equipment<br />

In the past, scan tool and DSO systems<br />

were available for hand-held personal<br />

digital assistants (PDAs). In most cases,<br />

both the PalmOS and the Pocket PC<br />

platform were supported. While some<br />

of these systems are still available,<br />

popularity seems to be quickly fading.<br />

This can be attributed to at least three<br />

reasons, including:<br />

• Limited Capabilities - The screen<br />

size and power of a PDA, in most<br />

© 2009 - All Rights Reserved | DLP Publishing | Grant Swaim

<strong>Chapter</strong> 26: PC-Based Diagnostic Equipment 361<br />

cases, is less than a standard scan<br />

tool or DSO. Choosing the PDA<br />

platform over a PC platform forfeits<br />

power and features.<br />

• Public Perception - The appeal to<br />

PDA-based diagnostics seemed to<br />

be its compactness. These “shirt<br />

pocket” sized tools were often used<br />

in the service drive, in the full view<br />

of the motoring public, for a quick<br />

diagnostic trouble code (DTC) read.<br />

Problems arose when most observers’<br />

perceived their cars were being<br />

diagnosed with “toys,” thus trivializing<br />

the complexity of operations in<br />

the service bay.<br />

• Availably of PDAs - Today’s smartphone<br />

can do more than a PDA, plus<br />

functions as a telephone; therefore,<br />

the PDA market is on life support<br />

and new PDAs are scarce. Most PDA<br />

users have moved to a smartphone<br />

for an all-in-one gadget solution.<br />

In February 2009, Palm announced<br />

they would not release any new<br />

products powered by the PalmOS,<br />

the operating system that established<br />

the PDA market.<br />

• Netbook Computers - The popular<br />

“netbook” laptop computer is a<br />

much better choice than a PDA for a<br />

low cost and portable platform. For<br />

details, see the next section.<br />

To learn more about PDAs see <strong>Chapter</strong><br />

14 - Other Digital Devices.<br />

Netbooks Are The New PDA<br />

When the first netbooks hit the market<br />

in 2007, their screens were just too<br />

small and their processing power was<br />

inadequate to be used with PC-based<br />

diagnostic equipment. However, some<br />

of the current netbook models are now<br />

approaching laptop specifications and<br />

meet the minimum requirements for<br />

PC-based scan tool and DSO programs.<br />

A netbook with a 10” screen, such as the<br />

Lenovo S10 shown in Figures 26-7 and<br />

26-8 is a viable platform. This netbook<br />

was tested with the AutoEnginuity scan<br />

tool and the PicoScope 4423 DSO and<br />

worked flawlessly with both pieces of<br />

equipment.<br />

Figure 26-7: Lenovo S10 Netbook Using AutoEnginuity<br />

Figure 26-8: Lenovo S10 Netbook Using PicoScope DSO<br />

Resource links, and other web enhanced features, are available at digitalliteracyproject.com/book.

362<br />

Part III: <strong>Automotive</strong> Applications of Technology<br />

If you are looking for a low cost hardware<br />

solution, a high end netbook is<br />

likely your best choice.<br />

PC-Based Scan Tools<br />

Scan Tool Overview<br />

Covering scan tools in depth is beyond<br />

the scope of this book, so this section<br />

will focus on scan tools that are based<br />

on the PC platform. To better understand<br />

the contemporary PC-based<br />

automotive scan tool, some core OBD-II<br />

information is needed.<br />

While scan tools first appeared in the<br />

mid-1980s, they were primarily used by<br />

the domestic OEMs to display very basic<br />

information from the powertrain control<br />

module (PCM). Each manufacturer used<br />

a different data link connector (DLC), a<br />

different communication protocol, and<br />

even a different diagnostic trouble code<br />

(DTC) set.<br />

Scan tools passed a major milestone in<br />

1996 when OBD-II regulations standardized<br />

many of these variables. From 1996<br />

forward, OEMs are required to provide<br />

certain emissions-related information<br />

on a standardized DLC using a standardized<br />

communication protocol. They<br />

were also required to use a standardized<br />

DTC set and use common terminology<br />

for all the fuel and emissions components.<br />

This level of standardization<br />

and functionality is often referred to as<br />

Global or Generic OBD-II.<br />

Functionality/Platform Classification<br />

Since 1996, all scan tools, regardless of<br />

their form factors (e.g. proprietary or<br />

PC-based hardware) have fallen into<br />

one of three classifications: OEM level,<br />

Global OBD-II Level, and Enhanced<br />

Global OBD-II Level.<br />

OEM Level Scan Tool<br />

As stated earlier, every car sold in the<br />

U. S. since 1996 must support Global<br />

OBD-II functionality. Yet, every OEM<br />

develops an OEM level scan tool that<br />

supports functionality far above the<br />

Global OBD-II level. For example, OBD-<br />

II regulations mandate that approximately<br />

25 specific parameters must be<br />

made available on the OBD-II DLC in the<br />

Global OBD-II protocol; however, most<br />

OEM level scan tools can retrieve well<br />

over 500 parameters. These additional<br />

parameters are not retrieved using<br />

the Global OBD-II protocol. They are<br />

supported by a protocol of the OEM’s<br />

choosing.<br />

The actual functionality supported by<br />

any scan tool is determined by two key<br />

factors:<br />

• Control Module Software - Every<br />

scan tool function available on<br />

a given car is supported by software<br />

code written by the OEM and<br />

embedded into the PCM’s processor.<br />

Literally, every single piece of<br />

information or bidirectional control<br />

made available on a scan tool<br />

requires corresponding embedded<br />

code on the processor.<br />

Scan Tool Software<br />

• - A scan tool’s<br />

ability to display information, and<br />

activate a bidirectional control, supported<br />

on the PCM is determined by<br />

its software.<br />

© 2009 - All Rights Reserved | DLP Publishing | Grant Swaim

<strong>Chapter</strong> 26: PC-Based Diagnostic Equipment 363<br />

Therefore, the highest level of functionality<br />

is achieved from an OEM developed<br />

scan tool since the OEM developed<br />

the software on both the scan tool<br />

and the car.<br />

Global OBD-II Level Scan Tool<br />

Some scan tools only support Global<br />

OBD-II functionality, retrieving information<br />

mandated by OBD-II regulations.<br />

These scan tools tend to be inexpensive<br />

($100 - $200) and are often targeted at<br />

the consumer market.<br />

Enhanced Global OBD-II Scan Tool<br />

Scan tools are available that exceed<br />

Global OBD-II functionality, but do not<br />

match the OEM level. This additional<br />

functionality is usually achieved by purchasing<br />

enhanced modules for specific<br />

car lines such as: GM, Ford, Honda, Toyota,<br />

BMW, and others. Some scan tool<br />

vendors also sell modules for bundled<br />

car lines such as: domestic, Asian, and<br />

European.<br />

The level of functionality supported by<br />

an enhanced module will vary among<br />

scan tool manufacturers. Regardless of<br />

what marketing material may imply, an<br />

enhanced module for a given car line<br />

does not support the same functionality<br />

level as the OEM’s scan tool.<br />

OEM Scan Tools<br />

Overview<br />

Early OEM scan tools were based on<br />

proprietary hardware; however, many<br />

OEMs have since moved to PC-based<br />

platforms. Even more are planning to<br />

move to PC-based scan tools for their<br />

next generation of diagnostic equipment.<br />

Information about each OEM’s scan tool<br />

program is always evolving and acquiring<br />

accurate information on the source,<br />

cost, and model coverage on a given<br />

OEM scan tool can be a bit of a challenge.<br />

One good resource to use to find<br />

this information is the National <strong>Automotive</strong><br />

Service Task Force (NASTF) web<br />

site, which maintains a matrix providing<br />

information about each OEM’s scan tool<br />

program.<br />

One of the best ways to get “real world”<br />

information on an OEM scan tool is<br />

through the “Tools and Equipment Forum”<br />

on the iATN website.<br />

<br />

NASTF Tool Matrix<br />

nastf.org<br />

iATN’s Tool & Equipment Forum<br />

members.iatn.net/forums/read/index.<br />

aspx?f=forum8<br />

OEM Aftermarket Support<br />

OBD-II legislation only regulates information<br />

that relates to emission<br />

control systems. OEMs may provide<br />

non-emissions related information via<br />

their service information websites and<br />

scan tool functions, at their discretion;<br />

therefore, the level of information made<br />

available to the aftermarket does vary<br />

significantly among the OEMs.<br />

Ultimately, a given OEM’s support for<br />

the aftermarket service industry is<br />

revealed in the implementation of their<br />

service information website and scan<br />

tool functionality. For a fair evaluation<br />

of an OEM’s support for the aftermarket,<br />

Resource links, and other web enhanced features, are available at digitalliteracyproject.com/book.

364<br />

Part III: <strong>Automotive</strong> Applications of Technology<br />

the factors to consider include:<br />

• Web Portal Content - How deep<br />

does the information go above and<br />

beyond the mandated emissions<br />

requirement? Does the information<br />

cover models older than 1996 (pre<br />

OBD-II models)?<br />

• Service Information Cost - Does the<br />

access cost seem reasonable, or is it<br />

prohibitive? In May 2010, OEM website<br />

access varied from $350 per year<br />

(very reasonable), to over $4,000 per<br />

year (very prohibitive).<br />

• OEM Scan Tool Functionality - What<br />

level of functionality does the OEM<br />

scan tool deliver to the aftermarket?<br />

Is it just like the one used by a dealership<br />

technicians or have some of<br />

the functions been crippled?<br />

• Reprogramming Program - What is<br />

the cost of the reprogramming software?<br />

How affordable is the OEM<br />

reprogramming hardware? How well<br />

does the OEM support the J2534<br />

reprogramming standard?<br />

The current trend in the aftermarket<br />

service industry is to specialize in one<br />

car line or a group of related car lines.<br />

When choosing which lines of cars to<br />

service, it would be prudent to include<br />

the OEM’s level of support to the aftermarket<br />

in the selection process.<br />

Evaluating each OEM’s support of the<br />

aftermarket goes beyond the scope of<br />

this book; however, Toyota deserves<br />

recognition based on a presentation<br />

delivered at the Congress of <strong>Automotive</strong><br />

Repair & Service (CARS) convention<br />

held during <strong>Automotive</strong> Industry Week<br />

in 2007.<br />

The Environmental Protection Agency<br />

(EPA) and <strong>Automotive</strong> Service Association<br />

(ASA) hosted an OEM Tool Forum.<br />

The purpose of the forum was to give<br />

OEMs an opportunity to present information<br />

about their aftermarket programs<br />

for diagnostic tools and service<br />

information systems. While BMW,<br />

Subaru and Toyota made presentations,<br />

it was Toyota’s program that “knocked<br />

it out of the ball park” for the independents.<br />

Mark Saxonberg, the Service Technology<br />

Department Manager for Toyota<br />

Motor Sales, made the presentation.<br />

Part of the presentation focused on<br />

Toyota’s philosophy towards the independent<br />

service industry. The title of the<br />

presentation, “Building Brand Loyalty<br />

Through Outstanding Service Support<br />

in the Aftermarket”, set the stage.<br />

The following quotes were taken from<br />

Mark’s PowerPoint presentation and<br />

used with his permission.<br />

On Toyota’s Philosophy Towards<br />

the Aftermarket:<br />

“A reputation for a positive lifetime<br />

ownership experience is one of the<br />

more important distinguishing attributes<br />

that can set an auto maker<br />

apart from its competitors. Positive<br />

ownership experiences sell cars! If<br />

auto makers expect independent<br />

shops to deliver positive ownership<br />

experiences, we have to create effective<br />

and affordable service support<br />

systems for you.”<br />

© 2009 - All Rights Reserved | DLP Publishing | Grant Swaim

<strong>Chapter</strong> 26: PC-Based Diagnostic Equipment 365<br />

Toyota’s Challenge to the Aftermarket<br />

“The industry is changing at an astonishingly<br />

fast pace – and if you haven’t<br />

already, it’s time to get on-board and<br />

start changing with it. Here are a few<br />

suggestions to help get you started:<br />

First, get yourself a broadband connection<br />

to the Internet in your shop<br />

and connect it by a secure wireless<br />

network to your service area so you<br />

can begin taking advantage of the<br />

wealth of service support resources<br />

available there.<br />

Use your third-party and OEM website<br />

service information resources regularly<br />

– the days of fixing cars without<br />

service information are gone.<br />

Come to grips with the fact that the<br />

increasing incremental costs of service<br />

information and diagnostic tools are<br />

eroding your bottom line – it is time to<br />

understand just how much and begin<br />

building these costs into your fee<br />

structures.<br />

And finally, become accustomed to<br />

using PCs in your service environment<br />

– a great deal of your service support<br />

will be delivered by them in the future.<br />

Toyota’s Glimpse at the Future<br />

“Assuming we maintain the cooperative<br />

working relationships between<br />

auto makers and the aftermarket, I<br />

foresee:<br />

I see a growing use of OEM websites<br />

as complete service support portals,<br />

providing access not only to service<br />

information, but also to subscription<br />

based diagnostic software, just in time<br />

training resources, and manufacturer<br />

specific technical assistance.<br />

Historically, auto makers have relied<br />

on aftermarket tool and equipment<br />

suppliers to create service support<br />

systems for the aftermarket. With the<br />

complexity of today’s vehicles and<br />

service support systems, this model is<br />

becoming more of a challenge.<br />

I see more collaboration on standardization<br />

in vehicle diagnostic interfaces,<br />

movement toward Windows<br />

based diagnostic applications and<br />

development of diagnostic appliances<br />

- capable of supporting all auto<br />

maker diagnostic systems - offer the<br />

best hope in realizing this vision for<br />

the future.<br />

Turn Key Vs Interface Solutions<br />

When an OEM moves to a PC-based<br />

scan tool program, it can follow one of<br />

two models:<br />

• Turn Key Solution - With this model,<br />

the OEM provides a fully-engineered<br />

package.<br />

• Interface Solution - With this model,<br />

the OEM provides an interface unit<br />

and software only. The end user is<br />

responsible for providing all other<br />

hardware.<br />

Honda and Toyota both used Vertronix’s<br />

Mastertech (Figure 26-9) to power their<br />

original OEM scan tools. Both OEM’s<br />

have since moved to a PC-based platform.<br />

This section will showcase the<br />

evolution of these two programs, which<br />

Resource links, and other web enhanced features, are available at digitalliteracyproject.com/book.

366<br />

Part III: <strong>Automotive</strong> Applications of Technology<br />

are representative of most other OEM<br />

PC-based scan tool programs.<br />

Honda’s Scan Tool Program<br />

Honda’s first<br />

scan tool, based<br />

on Vertonix’s<br />

Mastertech, was<br />

launched in 1992.<br />

Migration from<br />

this original platform<br />

to today’s<br />

PC-based system<br />

took a few twists<br />

and turns.<br />

The Mastertech<br />

was first replaced<br />

with the Honda<br />

Diagnostic System<br />

(HDS) tablet.<br />

This Windowspowered,<br />

rugge-<br />

Figure 26-9: Mastertech MTS3100<br />

dized tablet was<br />

custom built by Teradyne Inc. and was<br />

an impressive piece of equipment. The<br />

titanium case looked like it could survive<br />

anything that got thrown at it. This<br />

hardware option is no longer available,<br />

but it still works with Honda’s current<br />

scan tool software.<br />

Figure 26-10: Honda HIM Unit<br />

Sometime after<br />

the HDS Tablet<br />

was released, the<br />

Honda Interface<br />

Module (HIM)<br />

was offered<br />

(Figure 26-10).<br />

This hardware<br />

interface solution<br />

is no longer<br />

Figure 26-11: HDS Pocket Tester<br />

(Figure 26-11).<br />

available, but<br />

still works with<br />

Honda’s current<br />

scan tool software.<br />

Honda offered<br />

one more scan<br />

tool option – the<br />

Pocket Tester -<br />

that targeted the<br />

aftermarket and<br />

was based on<br />

the PDA platform<br />

This option was not particularly well-received<br />

due to its glitchy nature and less<br />

than stellar tech support from Teradyne,<br />

the manufacturer. This hardware option<br />

is no longer available, but it still works<br />

with Honda’s current scan tool software.<br />

The current Honda scan tool is based on<br />

the interface model. Honda’s gateway<br />

device (Figure 26-12), is manufactured<br />

by Teradyne and called the GNA600.<br />

This device has a USB cable on one end<br />

and a 16-pin OBD-II DLC connector on<br />

the other.<br />

The OEM Honda scan tool is made up of<br />

the following components:<br />

• Subscribe to Service Express - Subscribe<br />

to Honda’s service information<br />

website, Service Express. This<br />

subscription is required, before you<br />

can purchase the GNA600 or the<br />

HDS software. The cost of an annual<br />

subscription to Service Express is<br />

$350 which includes access to both<br />

Honda and Acura information.<br />

© 2009 - All Rights Reserved | DLP Publishing | Grant Swaim

<strong>Chapter</strong> 26: PC-Based Diagnostic Equipment 367<br />

Figure 26-12: Honda’s GNA600 Gateway Device<br />

• Purchase GNA600 - Purchase the<br />

GNA600 interface directly from Teradyne<br />

for $1,997.<br />

• Purchase HDS Software - Purchase<br />

the HDS software package from<br />

Helm, Inc. for $840 per year. When<br />

changes in the software are made,<br />

updated versions are available.<br />

This puts the initial cost of the Honda<br />

scan tool system at approximately<br />

$2,837, not including a computer and<br />

the annual Service Express subscription<br />

price of $350 per year. The HDS software<br />

will also cost $840 per year to renew.<br />

This system can also be used to perform<br />

PCM reprogramming at no additional<br />

cost.<br />

<br />

Honda’s Service Express<br />

techinfo.honda.com<br />

Teradyne GNA Website<br />

www.teradyne-ds.com/GNA600Sales/<br />

tabid/83/Default.aspx<br />

Toyota’s TIS Techstream<br />

Toyota’s first scan tool, based on Vetronix’s<br />

Mastertech, was launched in 1993<br />

and replaced with the TIS Techstream in<br />

the spring of 2007.<br />

As shown in Figure 26-13, the TIS Techstream<br />

is made of three main parts.<br />

The core is a Panasonic Toughbook<br />

Model 19 computer, an industry standard<br />

among ruggedized computers.<br />

Notable ruggedized features include:<br />

• Full magnesium alloy case<br />

• Moisture and dust resistant keyboard<br />

and touch pad<br />

• Sealed port and connector covers<br />

• Shock-mounted removable hard<br />

drive.<br />

The Backpack<br />

The ruggedized Toughbook is further<br />

toughened with a second frame (backback)<br />

that adds big, corner bumpers<br />

Resource links, and other web enhanced features, are available at digitalliteracyproject.com/book.

368<br />

Part III: <strong>Automotive</strong> Applications of Technology<br />

Service Information<br />

Service information from Toyota’s<br />

Technical Information System (TIS) is<br />

delivered to the scan tool using industry<br />

standard wireless network technology.<br />

Techstream will also notify the technician<br />

if a PCM update is available for the<br />

car being scanned. The technician is<br />

given the option of reading the technical<br />

service bulletin (TSB) that addresses<br />

the details of the PCM software update<br />

before updating the PCM’s software.<br />

The TIS Techstream integrates a robust<br />

OEM level scan tool, a service information<br />

system, and PCM reprogramming<br />

into one bay side tool!<br />

Currently this system is sold as a complete<br />

package for $7,995 and includes<br />

a two-year subscription to TIS with<br />

Techstream software updates and ECU<br />

Reprogramming Calibrations.<br />

Figure 26-13: Toyota’s TIS Techstream Courtesy of Toyota Motor<br />

Sales USA, Inc. and University of Toyota<br />

and additional padding. The backpack<br />

also holds the Vehicle Interface Module<br />

(VIM) and a charging module to provide<br />

power to the computer from the 12-volt<br />

source that is available from the OBD-II<br />

data link connector.<br />

The Docking Station<br />

When not in use, the computer/backpack<br />

unit is placed in the docking<br />

station to recharge. The backpack can<br />

also be locked to the docking station for<br />

security.<br />

<br />

Toyota TIS Website<br />

techinfo.toyota.com<br />

Toyota’s Techstream Lite<br />

In November 2009, Toyota became<br />

one of the first OEMs to use the J-2534<br />

platform to support vehicle diagnostics<br />

(scan tool operations). The J-2534 platform<br />

was initially developed to support<br />

PCM reprogramming across all car lines<br />

using a single gateway device. To learn<br />

more about J-2534 reprogramming, see<br />

<strong>Chapter</strong> 27.<br />

The system, Techstream Lite, is an inexpensive<br />

alternative to the full Toyota<br />

Information System (TIS) Techstream diagnostic<br />

tester which does not use the<br />

© 2009 - All Rights Reserved | DLP Publishing | Grant Swaim

<strong>Chapter</strong> 26: PC-Based Diagnostic Equipment 369<br />

J-2534 standard to communicate with<br />

the car. Techstream Lite provides factory<br />

level support for Toyota/Scion/Lexus<br />

vehicles with the following exceptions.<br />

• Techstream Lite supports OBD-II<br />

based diagnostic functions on 1996<br />

and later vehicles, while the full TIS<br />

Techstream supports diagnostics<br />

from 1989 using two pre-OBD-II<br />

data link connectors<br />

• Techstream Lite provides support<br />

for new vehicles nine months after<br />

launch, while TIS Techstream supports<br />

new vehicles at launch<br />

Toyota offers Techstream Lite as a package<br />

consisting of the following components:<br />

• Mongoose MFC VIM - This is a 6-foot<br />

long innovative cable that includes<br />

an integrated J-2534 gateway (Figure<br />

26-14.) The Mongoose cable was<br />

developed and is supplied by Drew<br />

Technologies.<br />

• 1 Year Pro Subscription to TIS - You<br />

must have an active professional<br />

level subscription to use the Techstream<br />

software. For each subscription<br />

you can use one installation of<br />

Techstream Lite on one computer.<br />

The professional TIS subscription<br />

includes access to the TIS Library (repair<br />

manuals, wiring diagrams, etc),<br />

Techstream Diagnostic Software,<br />

and ECU reprogramming calibration<br />

files.<br />

• IDENTIFIX Direct Hit - Access to<br />

the IDENTIFIX Direct Hit program<br />

for Toyota/Scion/Lexus models is<br />

Figure 26-14: Drew Technologies’ Mongoose Cable<br />

included.<br />

Based on information posted on Toyota’s<br />

website, as of May 2010, the price<br />

of this kit was $1,590. Toyota was offering<br />

the kit at an introductory price of<br />

$1,345; however, there was no indication<br />

about the length of this introductory<br />

offer.<br />

The Mongoose MFC cable can be purchased<br />

directly from Drew Technologies<br />

and other vendors, such as AES Wave.<br />

The Professional Subscription to TIS<br />

must be purchased directly from Toyota.<br />

In addition to performing scan tool<br />

diagnostics, Techstream Lite can be<br />

used for ECU reprogramming. Access to<br />

the reprogramming calibration files are<br />

included in the Professional TIS Subscription.<br />

The Techstream Lite diagnostic software<br />

is J-2534 compliant; however, Toyota<br />

is recommending it be used with the<br />

Mongoose MFC cable, since this is the<br />

only J2534 device that they have tested<br />

and will support. However, based on<br />

this statement taken from the Drew<br />

Technologies website, Techstream Lite<br />

Resource links, and other web enhanced features, are available at digitalliteracyproject.com/book.

370<br />

Part III: <strong>Automotive</strong> Applications of Technology<br />

will work with their CarDAQ-Plus J2534<br />

gateway device:<br />

If you service vehicles besides<br />

Toyota, you may want to Consider<br />

CarDAQ-Plus. CarDAQ-Plus is a universal<br />

J2534 reprogramming tool for<br />

all-makes. CarDAQ-Plus is also compatible<br />

with Toyota’s Techstream<br />

software.<br />

For additional information about Techstream<br />

Lite, including minimum computer<br />

requirements, visit Toyota’s TIS<br />

website.<br />

<br />

Toyota TIS Website<br />

techinfo.toyota.com<br />

Drew Technologies<br />

www.drewtech.com/products/Mongoose/mongoosemfc.html<br />

ASE Wave<br />

aeswave.com/Products/Product.<br />

asp?i=817<br />

Aftermarket Scan Tools<br />

Industry Wide Issues<br />

The aftermarket scan tool industry has<br />

brought several viable PC-based scan<br />

tools to market, with the two major<br />

players being AutoEnginuity and EASE<br />

Diagnostics.<br />

With many PC-based scan tool products,<br />

there seems to be a large group of supporters<br />

and a large group of disgruntled<br />

former users. Some of the issues consistently<br />

plaguing the aftermarket PCbased<br />

scan tool industry include:<br />

• Inconsistent OBD-II Connections -<br />

The scan tool may establish communication<br />

with the OBD-II system on<br />

a given car type on most occasions,<br />

and then, for no apparent reason, be<br />

unable to establish communication.<br />

The scan tools will typically perform<br />

well if communication is established.<br />

• Glitchy Software - The scan tool<br />

may stop working or hang up on<br />

a screen. This usually requires the<br />

computer to be rebooted.<br />

• Short of Expectations - Marketing<br />

departments tend to oversell PCbased<br />

scan tools’ capabilities. Some<br />

people buy them, believing these<br />

tools will deliver OEM level feature<br />

sets, when they won’t.<br />

Almost all of these industry-wide issues<br />

improve with each new software<br />

release, and disgruntled customers<br />

often are basing their opinions on older<br />

software versions.<br />

Scan Tool Comparison Overview<br />

Discussing the intricacies of how an automotive<br />

scan tool works is beyond the<br />

scope of this book. Therefore, this section<br />

will focus on examining the experience<br />

of using a PC-based scan tool in<br />

lieu of a scan tool based on proprietary<br />

hardware.<br />

All OBD-II compliant scan tools perform<br />

the Global OBD-II functions similarly;<br />

therefore, the information provided will<br />

focus on features unique to the PCbased<br />

platform.<br />

The areas of comparison include:<br />

• Company Overview - Basic information<br />

will be included about each<br />

© 2009 - All Rights Reserved | DLP Publishing | Grant Swaim

<strong>Chapter</strong> 26: PC-Based Diagnostic Equipment 371<br />

company’s background.<br />

• Noted Strengths - This information<br />

is based on user comments aggregated<br />

from multiple online sources.<br />

• Min. Hardware Requirements -<br />

Minimum hardware requirements<br />

for all of the supported platforms.<br />

• Unique Features - This section identifies<br />

any significant feature that is<br />

not offered by other vendors.<br />

• Enhanced Coverage - This section<br />

identifies the Year/Make/Model<br />

coverage of features that exceed the<br />

Global OBD-II level.<br />

This feature set is the one most<br />

exploited by the tool vendor’s marketing<br />

departments and is the root<br />

cause for many disgruntled users.<br />

What does “enhanced” really mean?<br />

How can two products be compared<br />

that offer enhanced coverage on the<br />

same cars?<br />

To make an accurate comparison,<br />

it is necessary to dig deep into the<br />

specifications:<br />

• Parameter Set - OBD-II regulations<br />

mandate the availability<br />

of about 25 parameters, while<br />

some OEMs can deliver well<br />

over 500 parameters to the OEM<br />

scan tool. How close to the OEM<br />

parameter set is the aftermarket<br />

tool delivering?<br />

• Bidirectional Controls - The<br />

ability to control events on the<br />

car directly from a scan tool is<br />

known as bidirectional control.<br />

Enhanced coverage should support<br />

the bidirectional controls<br />

that are supported on the car.<br />

Again, how close to the actual<br />

number of OEM supported bidirectional<br />

controls are supported<br />

on the aftermarket tool?<br />

• OEM Like Features - The level of<br />

“enhanced” functionality is really<br />

a comparison of the aftermarket<br />

scan tool’s capabilities against<br />

the OEM scan tool. So the closer<br />

an aftermarket scan tool feature<br />

set mimics the feature set of the<br />

OEM scan tool, the better.<br />

• Connectivity - This section will list<br />

all the ways the scan tool’s hardware<br />

platform can connect to the car.<br />

• Upgrade Program - This section<br />

looks at how the software is upgraded,<br />

including the actual process and<br />

cost (when available).<br />

• Screen Captures - Several screen<br />

captures of each tool are included at<br />

the end of this chapter.<br />

Equipment Overview Statement<br />

Information about the AutoEnginuity,<br />

EASE Diagnostics. and ATS EScan diagnostic<br />

equipment is listed in this section<br />

simply as examples of full-featured<br />

pc-based scan tools. This information<br />

should not be considered a “buyers<br />

guide” and the author of this book is not<br />

endorsing any equipment.<br />

Most of the product information was<br />

taken from their websites in May 2010.<br />

For the most current information on<br />

these scan tools, or any other pc-based<br />

Resource links, and other web enhanced features, are available at digitalliteracyproject.com/book.

372<br />

Part III: <strong>Automotive</strong> Applications of Technology<br />

scan tools, contact the tool manufacturer.<br />

AutoEnginuity<br />

Company Overview<br />

AutoEnginuity was founded in 2002 by<br />

a computer hardware engineer who<br />

also tuned and raced his own cars.<br />

AutoEnginuity has grown to become a<br />

leading provider of PC-based scan tools<br />

in the world.<br />

Figure 26-15: AutoEnginuity<br />

Noted Strengths<br />

AutoEnginuity, considering its level<br />

of enhanced coverage, has one of the<br />

most affordable upgrade plans in the<br />

industry.<br />

Minimum Hardware Requirements<br />

Windows PC<br />

• Windows 2000/XP/Vista/7<br />

• 50 MB of free drive space<br />

• CD-ROM or DVD-ROM<br />

• 1 GB of memory<br />

• USB 2.0<br />

Handheld Platforms<br />

AutoEnginuity does offer software for<br />

Windows Mobile (2003SE / Mobile 5)<br />

hand-held devices; however, due to<br />

hardware and operating system limitations<br />

of these devices, not all features<br />

are supported. For a complete list of<br />

compatible hand-held units and the<br />

limitations of specific units, contact<br />

AutoEnginuity’s tech support.<br />

Unique Features<br />

Every AutoEnginuity purchase includes<br />

SpeedTracer which can measure vehicle<br />

performance including:<br />

• 0-60 ft time<br />

• 0-60 MPH<br />

• 1/8 mile time<br />

• 1/8 mile speed<br />

• 1/4 mile time<br />

• 1/4 mile speed<br />

• G Forces<br />

• SAE Horsepower<br />

• Torque<br />

• Boost Pressure<br />

• SAE Horsepower and Torque vs RPM<br />

graphing<br />

• Speed vs Time graphing<br />

Enhanced Coverage<br />

• Audi / VW (1996-2009)<br />

• BMW and MINI (1996-2009)<br />

• Chrysler/Dodge/Plymouth/Eagle<br />

(1996-2009)<br />

• Ford (1995-2009)<br />

• GM (1995-2009)<br />

• Honda and Acura (1996-2009)<br />

• Hyundai and Kia (1998-2009)<br />

• Isuzi (1996-2009)<br />

• Jaguar (1995-2009)<br />

© 2009 - All Rights Reserved | DLP Publishing | Grant Swaim

<strong>Chapter</strong> 26: PC-Based Diagnostic Equipment 373<br />

• Land Rover (2002-2009)<br />

• Mazda (1996-2009)<br />

• Mercedes (1998-2009)<br />

• Mitsubishi (1996-2009)<br />

• Nissan and Infiniti (2000-2009)<br />

• Porsche (1997-2009)<br />

• Subaru (1999-2009)<br />

• Toyota/Scion/Lexus (1995-2009)<br />

Connectivity<br />

• USB 2.0 (True Plug & Play)<br />

• Bluetooth Wireless<br />

• Proprietary Wireless Radio<br />

Update Program<br />

AutoEnginuity is noted for having one<br />

of the more affordable update programs<br />

in the industry. After a full year of<br />

free updates, annual update plans are<br />

available for $50-$150, depending on<br />

the number of enhanced modules that<br />

are being covered.<br />

Screen Captures (At End of <strong>Chapter</strong>)<br />

Figure 26-25 Monitor Status View<br />

Figure 26-26 DTC & Freeze Frame View<br />

Figure 26-27 Digital Data View<br />

Figure 26-28 Graphing view<br />

AutoEnginuity<br />

autoenginuity.com<br />

EASE Diagnostics<br />

Company Overview<br />

EASE Diagnostics began in 1993 with a<br />

dream by its founder, Stephen Golenski,<br />

to provide training equipment for<br />

educators training students how to diagnose<br />

electronic problems in automobiles.<br />

Soon EASE evolved into a diagnostic<br />

tool manufacturer and unveiled the<br />

Figure 26-16: EASE Diagnostics Generic Kit<br />

industry’s first Windows PC-Based Scan<br />

Tool in 1998.<br />

EASE continues to bring innovative<br />

products to the market and is a leading<br />

provider of PC-based scan tools in the<br />

world.<br />

Noted Strengths<br />

EASE has a strong feature set; however,<br />

the company is best noted for its graphing<br />

capabilities which are extremely<br />

configurable and consistently the best<br />

in the industry.<br />

Minimum Hardware Requirements<br />

Windows PC<br />

• Windows 2000 / XP / Vista / 7<br />

• Pentium II 400 MHz<br />

• 1 GB RAM<br />

• 500 MB HDD space<br />

• CD-ROM Drive<br />

• Monitor<br />

• Mouse<br />

• Keyboard<br />

• USB<br />

Windows PocketPC / PalmOS<br />

Note that the Windows PocketPC and<br />

PalmOS products do not support all the<br />

Resource links, and other web enhanced features, are available at digitalliteracyproject.com/book.

374<br />

Part III: <strong>Automotive</strong> Applications of Technology<br />

EASE features. You will need to contact<br />

EASE for additional information.<br />

Unique Features<br />

EASE offers an innovative<br />

accessory for the<br />

EASE scan tool called<br />

the Data Logger. This<br />

compact hardware<br />

device (Figure 26-17)<br />

can record up to 12<br />

hours of data from the<br />

OBD-II data link connector<br />

(DLC) without a<br />

computer. This allows<br />

for easy collection of<br />

data while road testing<br />

a vehicle for intermittent<br />

problems.<br />

Figure 26-17: D. Logger The data logger is<br />

equipped with four<br />

buttons which allow the technician to<br />

“mark” the recordings to easily find a<br />

point when analyzing the information<br />

with the EASE scan tool software.<br />

The indisputable record of parameters<br />

mined from a long recording period is<br />

great for verifying performance, verifying<br />

customer complaints, and resolving<br />

customer-perceived drivability issues.<br />

Enhanced Coverage<br />

• Chrysler (1992 to 2008)<br />

• Ford (1984 to 2008)<br />

• General Motors (1982 to 2008)<br />

• Hyundai (2005-2007)<br />

• Isuzu (1996 to 2008)<br />

• Kia (2005-2007)<br />

• Mazda (1996 to 2008)<br />

• Nissan (2000-2008)<br />

• Toyota (1996 to 2008)<br />

Connectivity<br />

• USB<br />

• Wireless - Radio Frequency (RF)<br />

Update Program<br />

Yearly software updates are available<br />

that include vehicle data for the current<br />

year as well as new functions and<br />

software enhancements. Updates are<br />

purchased through an EASE sales representative.<br />

If an update plan is not maintained, the<br />

software continues to work; however,<br />

upon the reestablishment of an update<br />

plan you will be charged for all time that<br />

was not previously covered.<br />

EASE now supports built-in automatic<br />

web updates for their scan tool software.<br />

Screen Captures (At End of <strong>Chapter</strong>)<br />

Figure 26-29 Graphing View<br />

Figure 26-30 Parameter List View<br />

Figure 26-31 Freeze Frame View<br />

Figure 26-32 Bidirectional Control View<br />

<br />

ATS EScan<br />

EASE Diagnostics<br />

www.obd2.com<br />

Company Overview<br />

<strong>Automotive</strong> Test Solutions (ATS) was<br />

formed by Bernie Thompson and Neal<br />

Pederson in 2001. Bernie is a graduate<br />

of Lincoln Tech and owns a 10-bay<br />

repair facility in Albuquerque, NM. Neal<br />

is an electrical engineer/computer<br />

programmer who has experience in<br />

© 2009 - All Rights Reserved | DLP Publishing | Grant Swaim

<strong>Chapter</strong> 26: PC-Based Diagnostic Equipment 375<br />

Figure 26-18: ATS EScan With Bluetooth<br />

designing control systems for equipment<br />

ranging from particle accelerators<br />

to nuclear reactors.<br />

Together, Bernie and Neal have released<br />

patented and proven technologies that<br />

have been recognized by Motor Magazine’s<br />

prestigious Top 20 Awards.<br />

Noted Strengths<br />

The EScan is an interesting tool that<br />

works at the Global OBD-II level. The<br />

software processes the generic data and<br />

displays it in a way that no other Global<br />

OBD-II scan tool has ever done.<br />

Many seasoned professional drivability<br />

technicians rave about this tool. John<br />

Anello of Scan Tool on Wheels stated,<br />

“I own 19 factory scan tools and<br />

several aftermarket scan tools. For<br />

drivability problems, my first choice<br />

is EScan by ATS. This tool is simply<br />

incredible!”<br />

Minimum Hardware Requirements<br />

Windows PC<br />

• XGA (1024x768)<br />

• 1 GHz Processor Speed (faster is better)<br />

• Windows 2000 / XP / Vista / 7<br />

• 1 GB RAM<br />

• 500 MB Available Hard Disk Space<br />

• RS-232 Serial Port or USB/RS-232<br />

Adaptor<br />

Unique Features<br />

This tool is unique in the ways it processes<br />

and displays global OBD-II data.<br />

Enhanced Coverage<br />

ESCan only works at the Globel OBD-<br />

II level; therefore, it does not support<br />

enhanced coverage.<br />

Connectivity<br />

• USB<br />

• RS232 (9-pin Serial Port)<br />

• Bluetooth Wireless<br />

Update Program<br />

This software is relatively static; therefore<br />

there is no official update program.<br />

Screen Captures (At End of <strong>Chapter</strong>)<br />

Figure 26-33 Adv Fuel Trim Analysis<br />

Figure 26-34 Volumetric Efficiency View<br />

<br />

ATS’s EScan<br />

atsnm.com/escan.htm<br />

Other PC-Based Scan Tools<br />

AutoTap<br />

www.autotap.com<br />

OBDLink CI<br />

www.scantool.net<br />

OBD Pros<br />

www.obdpros.com<br />

Resource links, and other web enhanced features, are available at digitalliteracyproject.com/book.

376<br />

Part III: <strong>Automotive</strong> Applications of Technology<br />

PC-Based Oscilloscopes<br />

Overview<br />

Digital storage oscilloscopes (DSOs) are<br />

migrating toward the PC platform for all<br />

of the same reasons that scan tools are,<br />

including:<br />

• Bigger display screens<br />

• More processing power<br />

• Lower overall equipment cost<br />

With PC-based DSOs, all of the test leads<br />

plug into an interface box. The interface<br />

box, in turn, communicates with a computer<br />

over a USB connection.<br />

In most cases one PC could be used to<br />

support both a scan tool and a DSO.<br />

PicoScope<br />

Overview<br />

One of the best examples of a PC-based<br />

DSO is the PicoScope by Pico Technology.<br />

The company was established in<br />

1991, offering PC-based DSOs and data<br />

loggers for general electronics testing.<br />

Tom Roberts of Autonerdz posted the<br />

first screen capture of a PicoScope on<br />

the International <strong>Automotive</strong> Technicians’<br />

Network (iATN) in August 2001.<br />

The use of PicoScopes has since grown<br />

to the point that Pico Technology now<br />

offers automotive kits. Everything needed<br />

to turn a laptop or desktop PC into a<br />

powerful automotive diagnostic tool is<br />

Figure 26-19: Typical PicoScope Diagnostic <strong>Automotive</strong> Kit<br />

© 2009 - All Rights Reserved | DLP Publishing | Grant Swaim

<strong>Chapter</strong> 26: PC-Based Diagnostic Equipment 377<br />

Current <strong>Automotive</strong> PicoScope Kits<br />

Feature 4223 Kit 4423 Kit 4423 Adv Kit<br />

Channels 2 4 4<br />

Accuracy ± 1% ± 1% ± 1%<br />

Memory 32 M1 32 M1 32 M1<br />

Max Sample Rate 1-2 Channels 80 MS/s 80 MS/s 80 MS/s<br />

Max Sample Rate 3-4 Channels — 20 MS/s 20 MS/s<br />

60A DC Current Clamp 1 1 2<br />

600A AC/DC Current Clamp 1 1 1<br />

20:1 Attenuator 2 4 4<br />

TA000 BNC to 4mm Test Lead 2 4 4<br />

Secondary Ignition Pickup 2 4 4<br />

Spark Plug Leads — — 4<br />

COP Probe — — 1<br />

2-Pin Break Out Lead 1 1 1<br />

Breakout Cable Small — — 1<br />

Breakout Cable Medium — — 1<br />

Breakout Cable Large — — 1<br />

Fuse Buddies - ATC — — 1<br />

Fuse Buddies - Mini ATC — — 1<br />

60 MHz Oscilloscope Probe — — 2<br />

Multi-Meter Probes 42 42 42<br />

Small Alligator Clips 42 42 42<br />

Dolphin Clips 23 23 23<br />

Insulation Piercing Probes 1 1 1<br />

Acupuncture Probes 1 1 1<br />

S-Hook 1 1 1<br />

Cable Identifier Kit 1 1 1<br />

<strong>Electronics</strong> Diagnostic CD-ROM 1 1 1<br />

<strong>Automotive</strong> Software CD-ROM 1 1 1<br />

Powered by USB 2.0 X X X<br />

Carrying Case 1 1 1<br />

1 32 Million Sample Buffer<br />

2 2 Red and 2 Black<br />

3 1 Red and 1 Black<br />

Table 26-1: Current <strong>Automotive</strong> PicoScope Kits<br />

Resource links, and other web enhanced features, are available at digitalliteracyproject.com/book.

378<br />

Part III: <strong>Automotive</strong> Applications of Technology<br />

included in these kits (Figure 26-19).<br />

The first automotive kit, offered in 2002,<br />

was an adaptation of existing testing<br />

and measurement units. In 2005, Pico<br />

Technology offered the first dedicated<br />

automotive DSO kit which was based on<br />

their 3000 series. <strong>Automotive</strong> kits based<br />

on the more powerful 4000 series are<br />

now available.<br />

Models<br />

The PicoScope is available as a twochannel<br />

input or a 4-channel input built<br />

on two different platforms, the 3000 series<br />

and the 4000 series. The 4000 series<br />

is significantly more powerful than the<br />

3000 series and for the small difference<br />

in price (less than $200), the 4000 series<br />

should be the professional’s choice.<br />

A matrix showing the contents of the<br />

three current 4000 series diagnostic<br />

kits is shown in Table 26-1. Additional<br />

specifications for the PicoScope 4223<br />

and 4423 units are available at the links<br />

provided in the section resource box.<br />

Minimum Hardware Requirements<br />

Windows PC<br />

• 1 GHz processor, or equivalent<br />

• 1GB Memory (XP) - more is better<br />

• 2GB Memory (Vista/7) - more is better<br />

• 500 MB of free drive space<br />

• Windows XP SP2 / Vista / 7<br />

• USB 2.0 compliant port<br />

Training & Support<br />

Even though the PicoScope DSO is<br />

manufactured in England, the training<br />

and support of this product in the United<br />

States is excellent. The PicoScope<br />

website offers a full list of U.S. distributors,<br />

but the two most supportive of the<br />

automotive service industry are Autonerdz<br />

of East Olympia, WA and AES Wave<br />

of Fresno, CA.<br />

Tom Roberts, of Autonerdz, is a nationally<br />

recognized PicoScope expert and<br />

his website offers many PicoScope training<br />

and information resources, most of<br />

which are free.<br />

The PicoScope website also offers a<br />

large amount of training and support<br />

material. Their <strong>Automotive</strong> Library is<br />

excellent and contains:<br />

• 10 Tutorials on engine management<br />

• 15 Real world case studies<br />

• Waveform Library (130+ Examples)<br />

• 7 Articles about DSO usage<br />

• 6 Videos - PicoScope DSO Guide<br />

Screen Captures (At End of <strong>Chapter</strong>)<br />

Figure 26-35 Graphing View<br />

• 100 second capture at 690x zoom<br />

• More than 16.5 million samples per<br />

channel<br />

Figure 26-36 Graphing View<br />

• 50 second capture at 264x zoom<br />

• More than 16.6 million samples per<br />

channel<br />

© 2009 - All Rights Reserved | DLP Publishing | Grant Swaim

<strong>Chapter</strong> 26: PC-Based Diagnostic Equipment 379<br />

<br />

PicoScope <strong>Automotive</strong> Home Page<br />

www.picoauto.com<br />

Diagnostic Kit Home Page<br />

www.picoauto.com/diagnostic-kits.<br />

html<br />

3000 Series Specifications<br />

www.picoauto.com/labscopes.html<br />

4000 Series Specifications<br />

www.picoauto.com/diagnosticscopes.html<br />

<strong>Automotive</strong> Library<br />

www.picoauto.com/automotivelibrary.html<br />

Autonerdz - U.S. Distributor<br />

autonerdz.com<br />

AES Wave - U.S. Distributor<br />

www.aeswave.com<br />

Figure 26-20: EScope Limited Kit<br />

ATS EScope<br />

CRAG Technologies - U.S. Distributor<br />

www.pc-oscilloscopes.com<br />

Company Overview<br />

<strong>Automotive</strong> Test Solutions (ATS) was<br />

formed by Bernie Thompson and Neal<br />

Pederson in 2001. Bernie is a graduate<br />

of Lincoln Tech and owns a 10-bay<br />

repair facility in Albuquerque, NM. Neal<br />

is an electrical engineer/computer programmer<br />

with experience in designing<br />

control systems for equipment ranging<br />

from particle accelerators to nuclear<br />

reactors.<br />

Together, Bernie and Neal have released<br />

patented and proven technologies that<br />

have been recognized by Motor Magazine’s<br />

prestigious Top 20 Awards.<br />

Models<br />

ATS offers EScope Limited, a 4-channel<br />

DSO (Figure 26-21) and EScope Pro, an<br />

Figure 26-21: 4-Channel EScope Limited<br />

Figure 26-22: 8-Channel EScope Pro<br />

8-channel DSO (Figure 26-22). Detailed<br />

specifications on the scope’s capabilities<br />

are on the ATS website, but the contents<br />

of each kit and minimum hardware<br />

requirements are:<br />

Resource links, and other web enhanced features, are available at digitalliteracyproject.com/book.

380<br />

Part III: <strong>Automotive</strong> Applications of Technology<br />

4-Channel EScope Limited<br />

Kit Includes:<br />

• 4 - 9 ft BNC - Banana Plug Leads<br />

• 4 - 12 ft Extensions<br />

• 1 - Ground Lead<br />

• 8 - Back Probes<br />

• 1 - Banana Plug Adapter<br />

• 4 - Alligator Clips<br />

• 4 - “T” Wire Piercers<br />

• 1 - 3 ft USB Cable<br />

• 2 - Extra EScope Fuses<br />

• EScope & Software<br />

Minimum hardware requirements:<br />

• XGA Screen Resolution<br />

(1024x768)<br />

• 1 GHz Processor Speed<br />

• Windows 2000 / XP / Vista / 7<br />

• 1GB RAM (more is better)<br />

• 500 MB Available Hard Disk<br />

Space<br />

• USB 2.0 Hi-Speed Port<br />

8-Channel EScope Pro<br />

Kit Includes:<br />

• High Current Amp Clamp (600A<br />

Max)<br />

• Low Current Amp Clamp (60A<br />

Max)<br />

• 9 - 12 ft Color Coded Cable<br />

Extensions<br />

• 9 ft Battery Ground Cable<br />

• 8 - Color Coded Back Probes<br />

with Banana Jacks<br />

• 2 - Banana Plug Adapters<br />

• 12 - Color Coded Alligator Clips<br />

with Banana Jacks<br />

• 2 - Test Probes with Banana<br />

Jacks (One Black, One Red)<br />

• 10 - Color Coded 6 ft BNC Ba-<br />

nana to Plug Leads<br />

• 8 - Color Coded T Wire Piercers<br />

• AC Coupler<br />

• 12V DC Power Supply (Battery Clips)<br />

• Power Supply to Cigarette lighter<br />

• Power Cord<br />

• USB Cable<br />

• Bracket Set for Laptop<br />

• 2 - Extra EScope Fuses<br />

• EScope Pro and Software<br />

• Hard Plastic Case with Foam Padding<br />

for Accessory Kit<br />

Minimum Hardware Requirements:<br />

• XGA Screen Resolution (1024x768)<br />

• 2 GHz or Duo Core Processor)<br />

• Windows 2000 / XP / Vista / 7<br />

• 1GB RAM (more is better)<br />

• 500 MB Available Hard Disk Space<br />

• USB 2.0 Hi-Speed Port<br />

Screen Captures (At End of <strong>Chapter</strong>)<br />

Figure 26-37 8 Graph View<br />

Figure 26-38 2 Graph View<br />

Figure 26-39 8 Graph View<br />

<br />

Screen Capture Software<br />

Overview<br />

ATS’s EScope Home Page<br />

automotivetestsolutions.com/scopes.<br />

htm<br />

With screen capture software a technician<br />

can easily add a known good pattern,<br />

or a known bad pattern, from diagnostic<br />

equipment into a database for<br />

future reference. These programs make<br />

it possible for a technician to build up a<br />

large library of information that is easy<br />

to manage.<br />

© 2009 - All Rights Reserved | DLP Publishing | Grant Swaim

<strong>Chapter</strong> 26: PC-Based Diagnostic Equipment 381<br />

Capturing Image vs. Data Points<br />

Screen capture software stores information<br />

either as an image or as a set of<br />

data points.<br />

• Image Capture - With this technique,<br />

the result of a print command<br />

is sent to a PC instead of a printer.<br />

The screen capture software converts<br />

the printer output to a graphic<br />

image.<br />

While this technique will produce<br />

an accurate representation of the<br />

screen it is difficult, to manipulate<br />

any of the information in the screen<br />

capture.<br />

• Data Point Capture - With this technique<br />

the data points originally used<br />

to draw the waveform on the tester’s<br />

screen are sent to a PC. Screen<br />

capture software can then recreate<br />

a waveform dynamically using these<br />

data points.<br />

Since this technique stores data<br />

points, and not a static image,<br />

manipulation of the output is supported.<br />

Changing the scale of a<br />

waveform or combining multiple<br />

waveforms into one chart are just<br />

a couple of ways to manipulate an<br />

image saved using use data point<br />

capture. However, not all diagnostic<br />

equipment will output data point<br />

sets.<br />

AES Wave<br />

The <strong>Automotive</strong> Electronic <strong>Services</strong><br />

(AES) Wave program is among the<br />

more popular choices used to store<br />

waveforms. This software was written<br />

by Jorge Menchu a former automotive<br />

technician and owner of AES, which is<br />

one of the best sources for automotive<br />

testing equipment and accessories.<br />

Jorge is also a popular presenter at automotive<br />

conferences and has contributed<br />

much to the industry.<br />

Using the AES Wave program is straightforward<br />

as indicated in these steps:<br />

• Install- Install the AES software on a<br />

Windows PC<br />

• Configure - Follow the detailed<br />

instructions to configure both the<br />

software and the test equipment<br />

• Connect - Connect the test equipment<br />

from the tester’s printer<br />

output port to a serial port on the<br />

computer<br />

• Print - Use the tester’s print feature<br />

to send the screen to the PC where<br />

AES will add the image to a database.<br />

When the screen capture is saved in the<br />

AES Wave program, a prompt asks for<br />

information such as: Year, Make, Model,<br />

Symptom, Test Point, and Testing Conditions.<br />

This information can then be used<br />

later to filter a search.<br />

The AES Wave proggram not only captures<br />

images, but can optionally capture<br />

data points from Fluke 97 and Fluke 98<br />

testers. AES Wave can also be used to<br />

Resource links, and other web enhanced features, are available at digitalliteracyproject.com/book.

382<br />

Part III: <strong>Automotive</strong> Applications of Technology<br />

Figure 26-23: The Single Record View of the AES Wave Software<br />

store and manage any image on the<br />

computer.<br />

A built-in report generator makes it easy<br />

to print copies of any information stored<br />

in the program.<br />

AES Wave is compatible with the following<br />

automotive testers:<br />

• ADL 7100 Sensor Scope<br />

• Counselor 2<br />

• Edge PAC unit<br />

• ET-2020<br />

• Fluke 190-series<br />

• Fluke 97/97a<br />

• Fluke 98 and 98 series 2<br />

• Interro PDA<br />

• KAL 575/565a/565<br />

• LS-2000<br />

• Mac Quick Scope<br />

• MasterTech<br />

• Matco Insight<br />

• NGS (Power User Module required)<br />

• OTC Genisys (screen capture from<br />

REMOTE DISPLAY software)<br />

• OTC Perception (screen capture from<br />

GTI software)<br />

• OTC Vision and Vision II<br />

• Snap-On/Edge PAC unit<br />

• Snap-On Scanner (frame captures<br />

only)<br />

• Snap-On Vantage PGM<br />

• Snap-On MODIS, SOLUS and VantagePro<br />

(via CF card)<br />

• Tek 565/575<br />

• Tek THS 710/720<br />

<br />

AES Wave Software<br />

www.aeswave.com/Products/Product.<br />

asp?i=97<br />

© 2009 - All Rights Reserved | DLP Publishing | Grant Swaim

<strong>Chapter</strong> 26: PC-Based Diagnostic Equipment 383<br />

Waveform Manager Pro<br />

Waveform Manager Pro is a screen capturing<br />

program offered by Metratek. The<br />

program is based on the data capture<br />

model; however, the program is also<br />

able to capture screen images.<br />

Progressive Diagnostics Co. initially<br />

marketed the program as WaveFile AutoPro<br />

and a large library of automotive<br />

waveforms saved with this program,<br />

is available on the Metratek site as a<br />

free download. This waveform library is<br />

compatible with the current version of<br />

Waveform Manager Pro.<br />

Waveform Manager Pro’s strength is its<br />

ability to manipulate waveforms at any<br />

point in the future. Some of the ways<br />

to control the display of a stored set of<br />

data points include:<br />

• Change the scale of waveforms<br />

• Combine multiple waveforms on<br />

one screen<br />

• Change the color of a waveform<br />

• Add annotations<br />

• Control of colors fonts, styles<br />

• Drag & Drop waveform placement<br />

The program supports the printing of<br />

waveforms and can also output waveforms<br />

as graphics files.<br />

System Requirements<br />

Windows PC<br />

• Windows: 2000 / XP / Vista / 7<br />

• One serial port<br />

Figure 26-24: Waveform Manager Pro - Record View<br />

Resource links, and other web enhanced features, are available at digitalliteracyproject.com/book.

384<br />

Part III: <strong>Automotive</strong> Applications of Technology<br />

Supported Test Equipment<br />

• Bosch - PMS100<br />

• Cornwell - TechTrace<br />

• Ferret - Model 91<br />

• Fluke - Series 97A, 98<br />

• Hickock - NGS<br />

• ITTI - L110<br />

• Kenwood - DLS505<br />

• Mac Tools - ET2010, ET2020, ET2025<br />

• Matco - InSight, Reality<br />

• OTC - Vision, Perception<br />

• Snap-On/Sun - LS2000, LS2000a,<br />

• Snap-On EEOS306A<br />

• Snap-On Vantage<br />

• Snap-On Counselor II<br />

• Snap-On MT2500 Scanner<br />

• Summit - SAS 6000<br />

• Sun - LS2000<br />

• Tektronix - THM571U (Mac ET2020),<br />

• TektronixTHM575 (Kal-Equip)<br />

• UEI - ADL7100<br />

• Vetronix - Mastertech<br />

<br />

Waveform Manager Pro<br />

www.metratek.com/ds_pro.html<br />

WaveFile AutoPro Library<br />

www.metratek.com/WfmLib.htm<br />

© 2009 - All Rights Reserved | DLP Publishing | Grant Swaim

<strong>Chapter</strong> 26: PC-Based Diagnostic Equipment 385<br />

PC- Based Equipment Screen Captures<br />

Figure 26-25: AutoEnginuity’s Monitor Status View<br />

Figure 26-26: AutoEnginuity’s DTC & Freeze Frame View<br />

Resource links, and other web enhanced features, are available at digitalliteracyproject.com/book.

386<br />

Part III: <strong>Automotive</strong> Applications of Technology<br />

Figure 26-27: AutoEnginuity’s Digital Data View<br />

Figure 26-28: AutoEnginuity’s Graphing View<br />

© 2009 - All Rights Reserved | DLP Publishing | Grant Swaim

<strong>Chapter</strong> 26: PC-Based Diagnostic Equipment 387<br />

Figure 26-29: EASE Diagnostic’s Graphing Mode<br />

Figure 26-30: EASE Diagnostic’s Parameter List View<br />

Resource links, and other web enhanced features, are available at digitalliteracyproject.com/book.

388<br />

Part III: <strong>Automotive</strong> Applications of Technology<br />

Figure 26-31: EASE Diagnostic’s Freeze Frame View<br />

Figure 26-32: EASE Diagnostic’s Bidirectional Control Screen<br />

© 2009 - All Rights Reserved | DLP Publishing | Grant Swaim

<strong>Chapter</strong> 26: PC-Based Diagnostic Equipment 389<br />

Figure 26-33: EScan’s Advanced Fuel Trim Analysis<br />

Figure 26-34: EScan’s Volumetric Efficiency View - 2000 GM 3.1 Liter With Bad MAF Sensor<br />

Resource links, and other web enhanced features, are available at digitalliteracyproject.com/book.

390<br />

Part III: <strong>Automotive</strong> Applications of Technology<br />

Figure 26-35: PicoScope Graphing View - 100 Second Capture at 690x Zoom - More Than 16.5 Million Samples per Channel<br />

Figure 26-36: PicoScope Graphing View - 50 Second Capture at 264x Zoom - More Than 16.5 Million Samples per Channel<br />

© 2009 - All Rights Reserved | DLP Publishing | Grant Swaim

<strong>Chapter</strong> 26: PC-Based Diagnostic Equipment 391<br />

Figure 26-37: EScope 8-Graph View - Toyota With Failing Injectors<br />

Figure 26-38: EScope 2-Graph View - Chevy Injector and O2 Sensor Signal<br />

Resource links, and other web enhanced features, are available at digitalliteracyproject.com/book.

392<br />

Part III: <strong>Automotive</strong> Applications of Technology<br />

Figure 26-39: EScope 8-Graph View - Jeep Injectors Out of Sync<br />

© 2009 - All Rights Reserved | DLP Publishing | Grant Swaim