Combining slash bundling with in-woods grinding operations

Combining slash bundling with in-woods grinding operations

Combining slash bundling with in-woods grinding operations

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

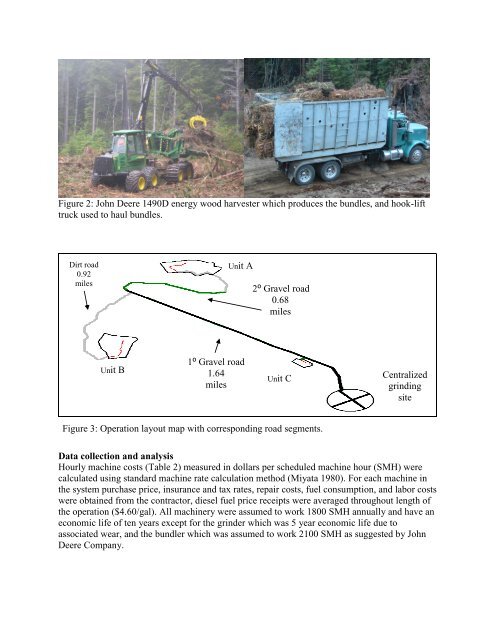

Figure 2: John Deere 1490D energy wood harvester which produces the bundles, and hook-lift<br />

truck used to haul bundles.<br />

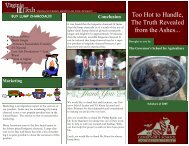

Dirt road<br />

0.92<br />

miles<br />

Unit A<br />

2⁰ Gravel road<br />

0.68<br />

miles<br />

Unit B<br />

1⁰ Gravel road<br />

1.64<br />

miles<br />

Unit C<br />

Centralized<br />

gr<strong>in</strong>d<strong>in</strong>g<br />

site<br />

Figure 3: Operation layout map <strong>with</strong> correspond<strong>in</strong>g road segments.<br />

Data collection and analysis<br />

Hourly mach<strong>in</strong>e costs (Table 2) measured <strong>in</strong> dollars per scheduled mach<strong>in</strong>e hour (SMH) were<br />

calculated us<strong>in</strong>g standard mach<strong>in</strong>e rate calculation method (Miyata 1980). For each mach<strong>in</strong>e <strong>in</strong><br />

the system purchase price, <strong>in</strong>surance and tax rates, repair costs, fuel consumption, and labor costs<br />

were obta<strong>in</strong>ed from the contractor, diesel fuel price receipts were averaged throughout length of<br />

the operation ($4.60/gal). All mach<strong>in</strong>ery were assumed to work 1800 SMH annually and have an<br />

economic life of ten years except for the gr<strong>in</strong>der which was 5 year economic life due to<br />

associated wear, and the bundler which was assumed to work 2100 SMH as suggested by John<br />

Deere Company.