Combining slash bundling with in-woods grinding operations

Combining slash bundling with in-woods grinding operations

Combining slash bundling with in-woods grinding operations

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Grappl<strong>in</strong>g the bundles and compact<strong>in</strong>g them <strong>in</strong>to the b<strong>in</strong> proves to significantly affect the load<strong>in</strong>g<br />

cycle time. Loaded sw<strong>in</strong>g degrees <strong>in</strong> which the mach<strong>in</strong>e had to rotate to place a bundle <strong>in</strong> the b<strong>in</strong><br />

was also found to be significant, along <strong>with</strong> the travel distance necessary to reach a bundle. The<br />

regression analysis suggests that decreas<strong>in</strong>g the travel distance and m<strong>in</strong>imiz<strong>in</strong>g sw<strong>in</strong>g degrees<br />

would greatly reduce the predicted cycle time.<br />

The transportation distance along various road types positively affected the haul<strong>in</strong>g cycle time.<br />

Only loaded haul<strong>in</strong>g distances were used to develop the truck<strong>in</strong>g regression equation because the<br />

same routes were used to and from harvest units. The position<strong>in</strong>g distance for a hook-lift truck to<br />

position himself to be loaded was also found to have a significant effect on cycle time because<br />

this was done while driv<strong>in</strong>g <strong>in</strong> reverse, and had to be done carefully to properly align himself for<br />

load<strong>in</strong>g by the Hitachi loader.<br />

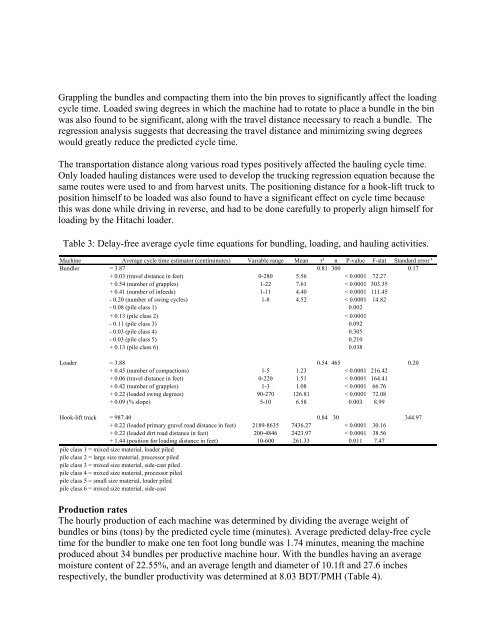

Table 3: Delay-free average cycle time equations for <strong>bundl<strong>in</strong>g</strong>, load<strong>in</strong>g, and haul<strong>in</strong>g activities.<br />

Mach<strong>in</strong>e Average cycle time estimator (centim<strong>in</strong>utes) Variable range Mean r² n P-value F-stat Standard error ¹<br />

Bundler = 3.87 0.81 300 0.17<br />

+ 0.03 (travel distance <strong>in</strong> feet) 0-280 5.56 < 0.0001 72.27<br />

+ 0.54 (number of grapples) 1-22 7.61 < 0.0001 303.35<br />

+ 0.41 (number of <strong>in</strong>feeds) 1-11 4.40 < 0.0001 111.45<br />

- 0.20 (number of sw<strong>in</strong>g cycles) 1-8 4.52 < 0.0001 14.82<br />

- 0.08 (pile class 1) 0.002<br />

+ 0.13 (pile class 2) < 0.0001<br />

- 0.11 (pile class 3) 0.092<br />

- 0.03 (pile class 4) 0.305<br />

- 0.03 (pile class 5) 0.210<br />

+ 0.13 (pile class 6) 0.038<br />

Loader = 3.88 0.54 465 0.20<br />

+ 0.45 (number of compactions) 1-5 1.23 < 0.0001 216.42<br />

+ 0.06 (travel distance <strong>in</strong> feet) 0-220 1.51 < 0.0001 164.41<br />

+ 0.42 (number of grapples) 1-3 1.08 < 0.0001 66.76<br />

+ 0.22 (loaded sw<strong>in</strong>g degrees) 90-270 126.81 < 0.0001 72.08<br />

+ 0.09 (% slope) 5-10 6.58 0.003 8.99<br />

Hook-lift truck = 987.40 0.84 30 344.97<br />

+ 0.22 (loaded primary gravel road distance <strong>in</strong> feet) 2189-8635 7436.27 < 0.0001 30.16<br />

+ 0.22 (loaded dirt road distance <strong>in</strong> feet) 200-4846 2423.97 < 0.0001 38.56<br />

+ 1.44 (position for load<strong>in</strong>g distance <strong>in</strong> feet) 10-600 261.33 0.011 7.47<br />

pile class 1 = mixed size material, loader piled<br />

pile class 2 = large size material, processor piled<br />

pile class 3 = mixed size material, side-cast piled<br />

pile class 4 = mixed size material, processor piled<br />

pile class 5 = small size material, loader piled<br />

pile class 6 = mixed size material, side-cast<br />

Production rates<br />

The hourly production of each mach<strong>in</strong>e was determ<strong>in</strong>ed by divid<strong>in</strong>g the average weight of<br />

bundles or b<strong>in</strong>s (tons) by the predicted cycle time (m<strong>in</strong>utes). Average predicted delay-free cycle<br />

time for the bundler to make one ten foot long bundle was 1.74 m<strong>in</strong>utes, mean<strong>in</strong>g the mach<strong>in</strong>e<br />

produced about 34 bundles per productive mach<strong>in</strong>e hour. With the bundles hav<strong>in</strong>g an average<br />

moisture content of 22.55%, and an average length and diameter of 10.1ft and 27.6 <strong>in</strong>ches<br />

respectively, the bundler productivity was determ<strong>in</strong>ed at 8.03 BDT/PMH (Table 4).