Prospects for Coal Briquettes as a Substitute Fuel for Wood and ...

Prospects for Coal Briquettes as a Substitute Fuel for Wood and ...

Prospects for Coal Briquettes as a Substitute Fuel for Wood and ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

3 4456 000Ltb4’7 5<br />

77<br />

b

^I..__ ~-.-_______x . . . . . __ -. .<br />

Printed ii-s the UiliZed States of America. Available fr0ir-i<br />

N at i o na I I- ec 1-1 n ica I I n f o rm at i o i7 Se rv i cc<br />

U .S. Department of Commerce<br />

5285 Pori Soya? Road, Springfield. Virginia 72i8;<br />

NTIS price codes---Printed Copy: ,405; Microfiche A01<br />

Tills report w<strong>as</strong> prapared <strong>as</strong> an account of work sponsored by an agency of the<br />

Unit& States Gowcinnmt. Nsilhei the (1 niied States Gounrl?:ne<br />

thereof, nor any of their employees, makes any warraniy, expr<br />

<strong>as</strong>sui’iles any legal liability or responsibility <strong>for</strong> the accuracy. completeness, or<br />

i.sefuIness of any in<strong>for</strong>mation, npparatus, product. or process disclosed, or<br />

represznts thst its usewould not infringe privatsly awned rights. Re!c:ence herein<br />

to any specific commsrcial product, process, or service by tiade name, trademark,<br />

manufacturer, or otherwise, does not necessarily constilde or imoiv 12<br />

endoisemen!. recommendation, or favoring by ihe LJnited Staies Govz:<br />

any agsilcy thereof. The V ~~VJS <strong>and</strong> opinions of authors e<br />

necessarily state or refkct those of theunited StatssGo!,<br />

thereof.<br />

._______I_ . ._._I____. .........<br />

___.......-..

ORNL/T&977 0<br />

IN U. S.<br />

PROSPECTS FOR COAL BRIQUETTES AS A<br />

SUBSTITUTE FUEL FOR WOOD AND CHARCOK<br />

AGENCY FOR INTERNATIONAL DEVELOPMENT<br />

ASS IS TED COUNTRIES<br />

R. D. Per1 ack<br />

G. G. Stevenson<br />

R. B. She1 ton<br />

Energy Division<br />

Oak Ridge Nati mal Laboratory<br />

Date of issue - February 1986<br />

Prepared <strong>for</strong> the<br />

Office @If Energy<br />

Bureau of Science <strong>and</strong> Technology<br />

U. S. Agency <strong>for</strong> International Devel opment<br />

under Contract No. E6T-57 26-P- ER-4257 -01<br />

Interagency Agrement No. 40-1485-84<br />

<strong>as</strong> part of the Energy Pol icy Development <strong>and</strong><br />

Canservati on Project<br />

Prepared by the<br />

Oak Ridge Nati mal Laboratory<br />

Oak Ridge, Tennessee 37831<br />

operated by<br />

Marti n Mar? etta Energy Systems, Inc.<br />

<strong>for</strong> the<br />

U. S. DEPARTMINT OF ENERGY<br />

under Contract No. DE-AC05-84OR21400<br />

3 4456 0004b47 5

TPBLE OF CONTENTS<br />

LIST OF TPB LES ..................................................<br />

LIST OF FIGURES .................................................<br />

ABSTRACT ........................................................<br />

EXECUTIVE SUMMARY ...............................................<br />

I. INTRODUCTION ...............................................<br />

11. FUELWOOD DEFICIENCIES AND COAL AVAILABILITY IN A. I. D.<br />

ASSISTED COUNTRIES .........................................<br />

111. SMOKELESS COPL BRIQUETTES AS A POSSIBLE SUBSTITUTE FOR<br />

FUELWOOD................ ....................................<br />

IV. INTERNATIONAL EXPERIENCES W IW CDPC BRIQUETTING :<br />

INDIA AND KOREA.............................................<br />

V. THE POTENTIAL FOR COAL BRIQUETTE SUBSTITUTION<br />

IN A. I.D. ASSISTED COUNTRIES., ..............................<br />

V<br />

vii<br />

ix<br />

xi<br />

1<br />

6<br />

13<br />

16<br />

21<br />

VI. STRATEGIES FOR REALIZING M E POTENTI& FOR COPL<br />

BRIQUETTING IN A. I.D. ASSISTED COUNTRIES... .................<br />

APPENDIX A: COAL BRIQUETTING AND CARBONIZATION PROCESSES,. ......<br />

APPENDIX B: POTENTIAL HEKM EFFECTS OF BURNING RPW COAL. .......<br />

24<br />

A-1<br />

B-1<br />

APPENDIX C:<br />

REVIRJ OF COR. BRIQUEITTING POTENTIAL<br />

IN A. I.D. ASSISTED COLJNTRIES. .......................<br />

c-1<br />

REFERENCES.......................................................<br />

Rl<br />

iii

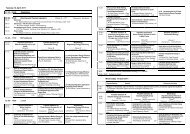

LIST OF TPBLES<br />

Tabl e 1. FA0 qualitative fuelwood deficiencies in A. 1.0.<br />

<strong>as</strong>sisted countries ............................... 8<br />

Tabl e 2. <strong>Coal</strong> avail abil ity in A. 1:. D. <strong>as</strong>sisted countrfes<br />

with fuelwood deficiencies e ....... ................ 11<br />

Table 3. Cooking fuel costs in Peru .............. ............. 17<br />

Table 4.<br />

Tabl e C. 1.<br />

Table C.2.<br />

Table 6.3.<br />

Table C.4,<br />

Tabl e 6.5.<br />

Table C.6.<br />

Table C.7.<br />

Table 6.8.<br />

Potentf a1 of A. I. 0. <strong>as</strong>si sted count r I es <strong>for</strong><br />

coal briquetting ...................................<br />

<strong>Fuel</strong> wood energy bal ance <strong>for</strong> Botswana (1961) . . . . . . . . .<br />

<strong>Fuel</strong> wood energy bl ance <strong>for</strong> Morocco (19Bl.l ...... .....<br />

<strong>Fuel</strong> wood energy bal ance <strong>for</strong> Niger (19811 ... ...*... .<br />

<strong>Fuel</strong> wood energy bal ance <strong>for</strong> Tanzania (1981) .. .....<br />

<strong>Fuel</strong> wood energy bal ancf <strong>for</strong> Zambia (1981) ... ..... .<br />

<strong>Fuel</strong> wood energy bal ance <strong>for</strong> Zimbabwe (1981) ... .....<br />

<strong>Fuel</strong>wood energy balance <strong>for</strong> Haiti (19791 ...........*<br />

<strong>Fuel</strong>wood energy balance <strong>for</strong> the Sierra of<br />

Peru (1981) .......................................<br />

23<br />

C-2<br />

c-3<br />

@-4<br />

C-6<br />

c-7<br />

C-9<br />

C-13<br />

C-15<br />

V

LIST OF 'IG<br />

URES<br />

Fig. 1. Percentage of traditional fuels in total energy<br />

consunption .............................................. 2<br />

Fig. 2.<br />

Total rural <strong>and</strong> urban populations affected by acute<br />

fuelwood scarcities <strong>and</strong> fuelwood deficits in<br />

1980 <strong>and</strong> 2000 ............................................ 7<br />

vi i

AB STR ACT<br />

<strong>Fuel</strong> wood shortages <strong>and</strong> potonti a1 shortages are widespread<br />

throughout the devel oping world, <strong>and</strong> are becoming incre<strong>as</strong>ingly more<br />

prwal ent because of the cl e<strong>as</strong>i ng of 1 <strong>and</strong> <strong>for</strong> subsi stence <strong>and</strong> pl antati on<br />

agriculture, excessive <strong>and</strong> ineffici snt commerci a1 timber harvesting <strong>for</strong><br />

domestic <strong>and</strong> export construction, <strong>and</strong> charcoal production to meet risi ng<br />

urban dem<strong>and</strong>s. It is estimated that three billion people w i l l live in<br />

acute wood scarcity <strong>and</strong> wood deficit regions by the year 20QQ. Further,<br />

the env iromental <strong>and</strong> socioeconomic consequences of the resulting<br />

de<strong>for</strong>estatdon are both perv<strong>as</strong>ive <strong>and</strong> complex. There are three energy<br />

policy options <strong>for</strong> mitigating the onslaught of de<strong>for</strong>estatjon <strong>and</strong> the<br />

1 nev itabl e <strong>and</strong> perni ci ous effects of fuel wood scarcities --<br />

conservation, re<strong>for</strong>estation, <strong>and</strong> substitution. This report focuses on<br />

the substitution of coal briquettes <strong>for</strong> fuelwood. <strong>Coal</strong> briquetting is a<br />

process by which raw coal is compacted into uni<strong>for</strong>m, usually hardr <strong>and</strong><br />

impact res4 stant aggl omerations. A1 though substantial adverse heal th<br />

effects could be expected from burning non-anthracite coal or coal<br />

briquettes, a we1 1-devel oped technique, carbonization, exists to convert<br />

coal to a safer <strong>for</strong>m <strong>for</strong> combustion. The costs <strong>as</strong>sociated with<br />

brfquetting <strong>and</strong> carbonizing coal indicate that 8fsmokel esstV coal<br />

briquettes can be produced at costs competitive with fuel wood <strong>and</strong><br />

charcoal. <strong>Coal</strong> briquetting <strong>and</strong> carbonization have bean practiced<br />

extensively in India, <strong>and</strong> this experience is instructjve because of the<br />

wlde range of technologies <strong>and</strong> coal types uti1 ized. The U. S. Agency <strong>for</strong><br />

International Development (USAID) is working on imp1 emanling this energy<br />

option in Haiti <strong>and</strong> Pakistan by (1) evaluating resources, (2) <strong>as</strong>sessing<br />

markets, (3) analyzing techno7 ogi esr (4) studying government pol icy <strong>and</strong><br />

plannings <strong>and</strong> (5) packaging the idea <strong>for</strong> the private sector to<br />

implement. A prel iminary exarninatjcn of other USAID <strong>as</strong>sisted countries<br />

Indicates that an additional fifteeii countries have the necessary coal<br />

reserves to become c<strong>and</strong>idates <strong>for</strong> sonikel ess coal briq uetti ng.<br />

ix

I.<br />

INTRODUCTION<br />

WE U.S. KiENCY FOR INTERNATION D ~ V ~ O ~ ~ ~ N ~<br />

WORKING ON A PRCBLEM TI-%A"- IS CRITICAL IN D<br />

DEV El OPING GO NTRIES. TF.IAT PROBLEM IS F11ELWOOD SHORTPGES.<br />

IMPLEMENTATION OF OWE PQTENTIAL SauTrm IS OCCURRING IN<br />

HAITI AND PAKISTAN--SMOKEL ESS COAL BHIQLIETTES.<br />

EA. I. D. 1<br />

TRADITIONAL ENERGY SOURCES ,@E A SIGNIFICANT FRACTION OF<br />

ND IN DEVELOPING COUNTRIES. THESE TRADITIONAL<br />

SOURCES, ESPECIALLY FIREWOCO AND CHARCOEV., WAVE BECOME<br />

INCREASINGLY SCARCE BECAUSE OF THE CLEARING OF LAND FOR<br />

ffi RI GULTU REI WAhiCQpL PRODUCT ION D EXCESSIVE TIlirE1ER<br />

WARV ESTING.<br />

IS<br />

WERE ARE MREE PQLICY OPTIONS FOR MITIGATING ME FUELWOOD<br />

CRISIS CONSERVATIQN> REFORESTATIONI AND SUBSTITUTING COAL<br />

BRIQUETTES. THIS PROSPECTUS ADDRESSES THE LAST OF THESE<br />

OPTIONS -- USE OF SWKELESS COPL BRIQUETTES.<br />

RESWRCE AND MARKET NDITIONS ARE EXCELLENT IN SOME<br />

DEVELOPING COUNTRIES FOR THE SUBSTITUTION OF COAL<br />

BRIQUETTES FOR F ~ ~ 7H€ ~ POTENTIAL ~ O ~ FOR * SUBSTITUTION IS<br />

GREATEST IN UWW AREAS, WHEkE FUR CHOICE IS LAFGELY BASED<br />

ON RELATIVE FUEL PRICE.<br />

COAL BRIQUETTING PROVIDES AN EXCELLENT OPPORTUNITY FOR THE<br />

PRIVATE SECTOR TQ CONTRIBUTE TO SOLVING A DEVELOPING WORLD<br />

PRCBLEM. ST ASPECTS OF RESGLlRCE SUPPLY<br />

PRQ5UCTION CAN BE HANDLED BY PRIVATE ENTREPRENEURS.<br />

11.<br />

F U DEFICIENCIES ~ ~ AND COPL ~ WAIL ~ ILITY ~ IN A. I. 13.<br />

AS S IS<br />

TED COU NTRIE S<br />

IF NO CORRECTIVE ACTIONS A9E TAKEN, AN ESTIMATED THREE<br />

BILLION PEOPLE WILL LIVE IN PCXlTE WOOD SCARCITY AND DEFICIT<br />

REGIONS BY THE YEAR 2000, PL ST ALL A. 1.5. SUPFQRTED<br />

COUNTRIES PRE EXPERIENCIMGI OR WILL EXPERIENCE, ACUTE OR<br />

DEFICiT FLSECWOQD SITUATIONS.<br />

LBUNTRIES REPORT<br />

TELY 50 Q E V ~ ~ ~ ~ G<br />

GE<br />

COAL RESQURCES. ENTY A.~,D. COUNTRIES REPORT COAL<br />

RESERVES. WERE ARE 1-8 A.I.D. COUNTRIES THAT ESPECIALLY<br />

APPEAR TO BE CAND ATES FOR I ~ T ~ ~ Q COPS, U C I BRIQUETTES ~ ~ --<br />

EIGHT IN AFRICA, S EN IN ASIA, AND TWO IN LATIN AMERICA.<br />

Xi

111"<br />

KELESS COAL BRIQUETTES AS A POSSIBLE SUBSTITUTE FOR<br />

FUELWOOD<br />

SQME CON BRIQUETTING TECHNIQUES MAKE COAL AN ATTRACTIVE<br />

FUELWOOD SUBSTITUTE BY CONVERTING IT INTO A SMOKELESS,<br />

COMPACT, STABLE, AND INEXPENSIVE FORM OF FUEL.<br />

COK BRIUUETTING HAS BEE3 SH N WORLD-WIDE TO BE A<br />

TECHNOLOGY CAPABLE OF USING COAL OF VARIOUS GRADES AND<br />

PRODUCING BRIQUETTES WITH DIFFERENT CHARACTERISTICS FOR<br />

DIFFERENT USES.<br />

OR UNTREATED BRIQUETTED COAL PRODUCES EMISSIONS<br />

THAT CAN HAVE SERIOUS HEPLTH EFFECTS.<br />

HWEVER, CON CARBONIZATION SIGNIFICANTLY REDUCES THE<br />

ADVERSE HEALTH EFFECTS FROM BURNING COAL OR COAL<br />

BRIQUETTES. THE RESULT OF CAFa88NIZATION IS A "SOFT<br />

SMOKELESS COKE. WHILE TESTING IS CURRENTLY IN PRGRESS,<br />

EMISSIONS FROM SMOKELESS COAL ARE PREDICTED TO BE NO WORSE<br />

MCVJ 'THOSE EMANATING FRON THE CURRENT FUELS OF CI-lARCOK AND<br />

F I REW OOD.<br />

IV .<br />

THE COSTS ASSQCIATED WITH BRIQUETTING AND CARBONIZING CON<br />

INDICATE A SELLING PRICE FOR SMOKELESS COAL BRIQUETTES IN<br />

SOME UWAN AREAS THAT MAKE THEN COMPETITIVE WITH FUELWOOD<br />

AND WARCONL.<br />

INTERNATIONAL EXPERIENCES WITH COAL BRIQUETTING:<br />

KOREA<br />

INDIA AND<br />

COAL CARBONIZATION HAS BEEN PRACTICED EXTENSIVELY IN INDIA.<br />

THE INDIAN EXPERIENCE IS INSTRUCTIVE BECAUSE A WIDE RANGE<br />

OF TECHNOLOGIES AND CO TYPES HAS BEEN UTILIZED. INDIA<br />

HAS DEWSITS OF BITUMINOUS# SUBBITUMINCUSt AND LIGNITE<br />

COALSa AND ALL HAVE BEEN USED FOR CARBONIZATION.<br />

TECHNOLOGIES RANGE FROM ONE-PERSON, "VILLAGE COPe PILES" TO<br />

ADV AFlCED TECHNOL CGY CARBONIZATION hz. ANTS.<br />

INDIA HAS DEVELOPED A SMOKELESS COOKING STOVE WHICH CAN USE<br />

COAL AS A FUEL SOURCE WITH NO SIGNIFICANT ADVERSE<br />

HEKM EFFECTS.<br />

KOREANS HAVE USED R ANPH RACITE COAL BRIQUETTES<br />

EXTENSIVELY FOR COOKING AND HEATING. THE KOREANS STARTED<br />

CQPL BKIQUETTING IN 1930s AND THERE ARE NW APPROXIMATUY<br />

20 LARGE BRIQUETTING RANTS IN ME CQUNTRY.<br />

xi i

V. TBE KITENTI& FOR COAL BRIQUETTE SUBSTITUTION IN A. I. D.<br />

ASSISTED COUNTRIES<br />

. SIGNIFICANT OPPORTUNITIES EXIST TO MITIGATE THE FUELWOOD<br />

CRISlS AROUND THE WORLD. A PRELIMINARY E ~ ~ I OF N THE A ~ ~ ~ ~<br />

SEVENTEEN A. I. D. COUNTRIES XIENTIFIED AS HAVING BOTH COPL<br />

RESERVES AND A FUELWOOD SHOR’f&E INDICATES THAT FOUR APPEAR<br />

TO HAVE AN IMMEDIATE POTENTIAL: BOTSWANA, HAITI8 INDIA,<br />

AND PAKISTAN. ANOTHER EIGHT COUNTRIES APPEAR TO HAVE A<br />

NEAR-TERM (3 TO 5 YEARS) POTENTIAL: INDONESIA, MOROCCO,<br />

NIGER$ PERU3 PHILIPPINES, TWANIA, THAILAND, SWAZILAND,<br />

ZAIRE8 ZAM3IAp AND ZIM3ABWE.<br />

VI.<br />

STRATEGIES FOR REALIZING M E POTENTIAL FOR COFL BRIQUETTING<br />

IN A. I. D. ASSISTED COUNTRIES<br />

. IblPLEMENTING SMOKELESS COAL BRIQUETVING IN A. I. D ASSISTED<br />

COUNTRIES WILL BE BASED ON EXPERIENCES GAINED BY A. I.D. IN<br />

HAITI AN5 PAKISTAN.<br />

. FIVE STEPS ARE NECESSARY TO SUCCESSFULLY IMPLEMENT<br />

SMOKELESS COAL BRIQUETTING AND MARKETING IN A. 1.0.<br />

OOUNTRIES. THESE INCLUDE A RESOURCE EVALUATION, A MARKET<br />

ASSESSMENT, A TECHNOLOGY ASSESSMENT, A STUDY OF GOVERNMENT<br />

POLICY AND PLANNING# AND PACKAGXNG THE IDEA FOR THE PRIVATE<br />

SECTOR TO IMFLEMENT.<br />

. USAID/WASHINGTON, OFFICE OF ENERGY8 WILL PROVIDE TECHNICAL<br />

ASSISTANCE TO MISSIONS IN IMPLEMENTING THE SMOKELESS COAL<br />

BRIQUETTE TECHNCLOGY.<br />

xiii

I.<br />

A. A.I.D. IS ~~R~~~~ ON A F5RCBLEF MAT IS ITICAL IN DOZENS OF<br />

5EVEbOPING COUNTRIES. THAT PRCX3.LEW I FU ELWOOD SHQRTPC; ES.<br />

~ ~ E ~ N OF ~ A ONE ~ POTE I O TIAL ~ samm IS OCCURRING EN<br />

HAITI AND ~A~ISTAN--S~~~~<br />

ESS IXAL BRIQUETTES,<br />

<strong>Fuel</strong>wood shortages <strong>and</strong> potenti al shortages are perv<strong>as</strong>qve ~ ~ r the ~ ~ g<br />

developing world, <strong>as</strong> the following sections document. One proposed<br />

solutfon is the substitution of a mokeless, coal-b<strong>as</strong>ed cookTng fuel<br />

where coal resources are available. The idea is even movlng towards<br />

realization ln two developing countriesa Hait! <strong>and</strong> Pakistan. Phls<br />

prospectus descri bes the probl m oi' fuel wood shortage, the mokel css<br />

coal a1 ternative, <strong>and</strong> A. I. D. s active ro't e in bringing the alternative<br />

solution to fruition.<br />

B. TRA51TIONAL ENERGY S FXES AliE A SIGNIFICA T FRACTION OF<br />

ENERGY DEMAND I DEVELOPING COUNTRIES. IHESE TRaDITIONPk<br />

SOURESr ESPECI LY FIRBJOOD AND CHARCOALI HAVE BECOME<br />

INCREASINGLY SCARE BECAUSE OF THE CLEARING OF L<br />

FGRIQXILTURE, CHARCB PRODUCTIONI AN5 EXCESSIVE<br />

H MV ESTING n<br />

The traditional energy sources, firewood, charcoal $ animal dungt <strong>and</strong><br />

agricultural residues account <strong>for</strong> nearly all of the rural household<br />

energy dem<strong>and</strong>, <strong>and</strong> a significant portion of the energy dem<strong>and</strong> among the<br />

urban poor, In Africa, it h<strong>as</strong> been estimated that traditional faiels<br />

account <strong>for</strong> about 65 percent of total per capita energy consumption; in<br />

Asia they account <strong>for</strong> nearly 30 percent; <strong>and</strong> in Latin America<br />

tradi tl anal energy cmpri ses appraxi matel y 25 percent of total per<br />

caplta energy cons~~~pti~n (see Figure l.l~~I.41 In many of these<br />

countri 8s the percentage of traditional energy cansumpti on is expe&ed<br />

to incre<strong>as</strong>e concomitantly with exp<strong>and</strong>ing popul atlonsr particularly in<br />

urban are<strong>as</strong>. As stated In the A. 1.B Pol icy Paper on Energyp Wssurlng<br />

uate domestic energy suppl ies far cooking presents a signiffcant<br />

chal i enge in the years aheado 99 E221<br />

1

2<br />

64<br />

29.7<br />

25.4<br />

8.1<br />

Africu<br />

Latin ,Am<br />

Asia<br />

1.3<br />

*-<br />

Developed World<br />

Fig. 1. Percentage of traditional fuels in<br />

total energy consumption

3<br />

The priincipal causes of de<strong>for</strong>estatdon in developing countrjes usual 7y<br />

can be attributed to three factors: (1) the clearing of l<strong>and</strong> <strong>for</strong><br />

subsistence <strong>and</strong> pl antatian agriculture; (2) the production of charcoal<br />

to meet rapidly rising dem<strong>and</strong>s by urban populations; <strong>and</strong> (3) excesslve<br />

<strong>and</strong> inefficient commerci a1 timber harvssti ng <strong>for</strong> domestic <strong>and</strong> export<br />

construction <strong>and</strong> manufacturing IndJstries. The dem<strong>and</strong> <strong>for</strong> fisewoood by<br />

rural populations is generally not the maJw cause of de<strong>for</strong>estation.<br />

Rural firewood dem<strong>and</strong> is often characterized by the cuttfng of branches<br />

from live trees, shrubsr <strong>and</strong> bushesI <strong>and</strong> gathering of seed wood <strong>and</strong> does<br />

not always require the destruction of whole trees. In HaitSr <strong>for</strong><br />

exampl er studies indicate that househol d caoki ng is done most often with<br />

scavenged deadwood, On the other h<strong>and</strong>, mal 1 industri a1 <strong>and</strong> cmmerci al<br />

fuelwood consumer^ in Haiti do cut 1 ive trees.<br />

C, THE ENVIRONMENTAL PND S0CIOEC:ONQMIC IMPACTS OF DEFORESTATION<br />

ARE BOTH PERVASIVE MD CQIU(PLEY.<br />

The rate of de<strong>for</strong>estation h<strong>as</strong> been esttmated at about 7.3 rnilll’an<br />

hectares per year <strong>for</strong> tropical <strong>for</strong><strong>as</strong>ts <strong>and</strong> about 4 mill ion hectares per<br />

year in semi-arid regions.C81 New wood suppl ies frm re<strong>for</strong>estation<br />

programs have had 1 ittle real impact to date. The Food <strong>and</strong> Agriculture<br />

Organization (FA01 estimates that <strong>for</strong> every ten hectares of cl eared<br />

<strong>for</strong>est there is only one hectar.9 reg1 anted, C 63 The environmental<br />

impacts of l<strong>and</strong> clearance are cumulative <strong>and</strong> usually begin with reduced<br />

i nf il trati on ratesl incre<strong>as</strong>ed w ater runof fl <strong>and</strong> i ncre<strong>as</strong>ed soi 1<br />

temperatures. Water <strong>and</strong> w ind erosion quickly sets In motion an al most<br />

Irreversible process of soil degradation. In West Africap soil loss<br />

from cultivated fields is <strong>as</strong> much <strong>as</strong> 6300 times greater than that <strong>for</strong><br />

<strong>for</strong>est l<strong>and</strong>; in Senegal8 soil loss from grounanut cultivation is nearly<br />

750 times greater than that <strong>for</strong> dry <strong>for</strong>est.LJ.51 De<strong>for</strong>estation also<br />

reduces up1 <strong>and</strong> water storage <strong>and</strong> Intensifies sll tati on of reservoi rs <strong>and</strong><br />

rivers resultfng in higher fncidences of se<strong>as</strong>onal flooding, whr”ch leads<br />

to additional soil erosion. Mareoverl the removal af bush vegetation in<br />

arid <strong>and</strong> semi-arid regions contributes to the onslaught of<br />

deserti f icati on. In some are<strong>as</strong>8 particul arl y the Indi an subcontl nent,<br />

the rural population h<strong>as</strong> turned to the burning of‘ dung <strong>and</strong> agricultural<br />

residues, The use of these fuels deprives the l<strong>and</strong> of crucially needed<br />

nutrients <strong>and</strong> soil condittoners. The end result is a dramatic decline<br />

in agricul tural product-ivity--the backbone of a1 1 devel oping countries.<br />

Reduced agrdcul tural productivity sets i n motion a cycl e of unempl oyment<br />

<strong>and</strong> underemployment that serves only to accelerate the mlgrall’an of<br />

rural populations to overly crwdad urban centers. The scarclty of<br />

fuel wood al so means that wood gatherersr primarily wmen <strong>and</strong> chS1 dt-en,<br />

must now spend consdderably more time in search of feaelwaod, For<br />

exampl el in up3 <strong>and</strong> are<strong>as</strong> of Nepal househol ds are spendfng fr<br />

workdays per year on firewood col‘~lec-tian, <strong>and</strong> up to 300 workdays pes<br />

year l”n some parts of Tanzania hay& been abserved.Cl 1 The scarcity of<br />

wood h<strong>as</strong>r in most urban are<strong>as</strong>s resulted in the creation of markets <strong>for</strong><br />

fuelwood. These markets have placed a heavy burden on the c<strong>as</strong>h<br />

resources of the rural <strong>and</strong> poor urban populations. In the capital of

4<br />

Burundi, househol ds are spending <strong>as</strong> much <strong>as</strong> 30 percent of thei r income<br />

<strong>for</strong> fuel. As prices rise <strong>for</strong> woad <strong>and</strong> charcoal8 populations begin to<br />

cut back on thei r consumption, <strong>and</strong> in some c<strong>as</strong>es are reduced to cooking<br />

only once per day. In acute scarclty regions.. fuelwood disappears<br />

altogether frm the urban markets.CZ1 The fuelwood crisis can become so<br />

severe that In sme African towns the cost of fuelwood exceeds the costs<br />

of commercial fuels such a5 kerosene <strong>and</strong> el ectricity.<br />

D. WERE ME THREE POLICY OPPIQNS FOR MITIGATING WE FUELWOOD<br />

CRISIS : CONSERVATION, REFORESTATION, AND SUBSTITUTING COAL<br />

BRIQUETTES. THIS FWSPECTUS ADDRESSES THE LAST OF THESE<br />

OPTIONS -- USE OF SMOKELESS COAL BRIQUETTES.<br />

There are three energy policy options that have been advanced <strong>for</strong><br />

mitigating the onslaught of de<strong>for</strong>estation <strong>and</strong> the inevitable <strong>and</strong><br />

perni ci ous effects of fuel wood scarci ti es, a1 1 of which are consi stent<br />

with A.I.D.1s Policy Paper on Energy. They include: (1) conservation<br />

through improvements in fuel wood end-use efficiencies, speci f ical ly the<br />

di ffusi on of fuel -ef f ici ent cooki ng stoves <strong>and</strong> reducti on i n conversi on<br />

1 <strong>as</strong>ses i n charcoal production w ith use of earthen, transpartabl e metal<br />

<strong>and</strong> m<strong>as</strong>onry kilns; (21 incre<strong>as</strong>ing the supply of fuelwood through<br />

refsrestati an, agro<strong>for</strong>estry, <strong>and</strong> improved <strong>for</strong>est management; <strong>and</strong> (3)<br />

sukstituti ng other sources of energy <strong>for</strong> fuel wood. This prospectus<br />

concentrates on opt1 on (3).<br />

E. RESWRCE AND MARKET CONDITIONS ARE EXCELLENT IN SOME<br />

DEVELOPING COUNTRIES FOR THE SUBSTITUTION OF COAL BRIQUETTES<br />

FOR FURWOOD. ME POTENTIAL FOR SUBSTITUTION IS GREATEST IN<br />

AN AREAS# WHERE FUEL CHOICE IS LARGELY BASED ON RELATIVE<br />

FUEL PRICE.<br />

As the real costs of using fuelwood incre<strong>as</strong>et the substitution of other<br />

fuels <strong>for</strong> firmcmd <strong>and</strong> charcoal w i l l become more favorable. Because of<br />

fuelwood scarcities, the costs af traditianal fuels are, in some<br />

1 acati oris, higher than cornmerci a1 substitutes. C13 In other 1 ocationsr<br />

such <strong>as</strong> Peru <strong>and</strong> Indonesia, cornmerci a1 substitutes 1 ike kerosene are<br />

heavily subsidized to help the poor or -to reduce de<strong>for</strong>estation.Cl8, 191<br />

Yet, despite higher fuelwood prices substitution often does not take<br />

p? ace untll fuelwood suppl ies have been virtually depleted <strong>for</strong> <strong>as</strong> much<br />

<strong>as</strong> 100 kilometers or more surrounding urban are<strong>as</strong>.Cl1 In rural are<strong>as</strong>,<br />

high di stri buti an costs do not favor cornmerci a1 fuel substitutes, <strong>and</strong><br />

besides the psopls in these are<strong>as</strong> often 1 ive outside the commercial<br />

ectan~my which makes the penetratlon of cmmerci a1 substitutes less<br />

1 ikely. Stil’s8 cmrnerci a1 substitutes do have potenti a1 where the costs<br />

ood <strong>and</strong> charcoal have risen suffjciently8 particularly in<br />

concentrated urban markets.

5<br />

F. COAL BRIQUETTING PROVIDES Ah1 EXCELLENT OPPORTUNITY FOR THE<br />

PRIVATE SECTOR TO ONTRIBUTE TO SOLVING A DEVELOPING WON0<br />

PRB L EM. M3ST ASPECTS OF RESOURCE SUPPLY AND PRODUCT<br />

PRODUCTION CAN BE HANDLED BY PRIVATE ENTREPRENEURS.<br />

On the supply side, virtually all <strong>as</strong>pects of coal briquetting<br />

manufacture <strong>and</strong> distribution can be controlled by the prfvate sector.<br />

Under agreement with the government, which most often h<strong>as</strong> ownership<br />

rights to coal in developing countries, private enterprises can mIne the<br />

needed coal. Whether this means exp<strong>and</strong>i ng exi sti ng mini ng operati ons or<br />

establ ishing new ones, significant new employment is possible. Private<br />

manufacturers can briquette <strong>and</strong> carbonize the coal--especi a1 ly if an<br />

intermediate level of technology wlth re<strong>as</strong>onable capital costs is used.<br />

In some countries, the needed machfnery can be manufactured locally, <strong>as</strong><br />

is the c<strong>as</strong>e in India. Finally, the distribution network can e<strong>as</strong>ily<br />

consist of private deal ers. Indeed, in many countries where fuel wood or<br />

charcoal is traded <strong>as</strong> a commercial item in urban are<strong>as</strong>., the potential<br />

private distributors already exist in the <strong>for</strong>m of wood <strong>and</strong> charcoal<br />

deal ers.<br />

The substitution of coal briquettes <strong>for</strong> fuelwood, including the re<strong>as</strong>ons<br />

<strong>for</strong> it, a nontechnical dfscusslon of the technologies involved, <strong>and</strong> some<br />

possible market strategiesr is the focus of the remainder of thls<br />

Prospectus.

A. IF NO CORRECTIVE ACTIONS ARE TAKEN, AN ESTIMATED THREE<br />

BILLION PEOPLE WILL LIVE IN ACUTE WOOD SCA CITY AND DEFICIT<br />

REGIONS BY ‘THE YEAR 2000. AL ST ALL A.I.D. SUPFSORTED<br />

COUNTRIES ARE EXPERIENCINGI OR WILL EXPERIENCE, ACUTE OR<br />

REFICIT FUELWOOD SITU ATIQNS.<br />

The traditional energy crisis in developing countries is in part a<br />

consequence of utilizs’ng wood resources over many years at a rate much<br />

f<strong>as</strong>ter than they can be renewed naturally or by af<strong>for</strong>estation. In<br />

accordance with a recommendation by a United Nations Technical Panel on<br />

<strong>Fuel</strong>woo& the FAO identified regions wdth fualw od shortagesP the<br />

severity of the shortages in these regions, <strong>and</strong> the affected population<br />

involved. The FAQ concluded that some 96 mil 1 ion rural people <strong>and</strong> 16<br />

million urban people now live in acute wood scarclty situations (see<br />

Figure 2) .C111 These acxk wood scarcity regions are defined <strong>as</strong><br />

negative woad energy bal ance are<strong>as</strong> where existing resources have been<br />

depl etecl through overeutti ng to the poi nt where popul ations cannot<br />

obtal n suf f Ici ent fuel wood.<br />

Acute fuelwsod scarcity are<strong>as</strong> include the arid <strong>and</strong> semi-arid regions<br />

south of the Saharal E<strong>as</strong>t <strong>and</strong> Southe<strong>as</strong>t Africa, the Himalay<strong>as</strong> <strong>and</strong><br />

mountainous regions of South Asia, the Andean Plateau, the arid are<strong>as</strong> in<br />

western South Americap <strong>and</strong> in many of the densely populated urban are<strong>as</strong><br />

in Latln America. Furtherp the FA0 estimates that over one billion<br />

rural people <strong>and</strong> 230 mlllian urban people 1 ive in wood deficit<br />

situations (see Figure 2). <strong>Wood</strong> deficit are<strong>as</strong> are defined <strong>as</strong> regions<br />

where populations are still able to meet minimu fuel wood needs, but<br />

only by harvesting in excess of the sustadn le fuelwood supply.<br />

Deficit are<strong>as</strong> include the Af rican savannah regions, the Indo-Gangetic<br />

Plains in southern Asiar the plains <strong>and</strong> isl<strong>and</strong>s in Southe<strong>as</strong>t Asia, <strong>and</strong><br />

the populated semi-arid are<strong>as</strong> <strong>and</strong> Andean zones of South herfca. The<br />

FA0 study goes on to project that -if no Immediate correctlve actlons are<br />

taken3 then sane three billion people w i l l live in acute wood scarcity<br />

<strong>and</strong> deficit regions by the year 2000. Mor err the prices of firewood<br />

<strong>and</strong> charcoal w i l l continue to incre<strong>as</strong>e h the scarcity <strong>and</strong> only<br />

exacerbate an a1 ready i ntol erabl e situation.<br />

Current fuel wood d@f ici enci OS in A. I. D. <strong>as</strong>si sted countries are<br />

summarized in Table h. This tabulation shows that nearly all of the<br />

A. I. D. supported countries are now experiencing acute or deficit<br />

fuelwood scarcities or w i l l have fuelwood problems by the year 2000.<br />

The perv<strong>as</strong>iveness <strong>and</strong> severity of the probl underscores the urgency<br />

w1t.h which it should be h<strong>and</strong>led.<br />

6

7<br />

R u ra I<br />

pop u I uti o n s<br />

Year<br />

t;<br />

d.<br />

c<br />

198E<br />

R 200c<br />

-<br />

Africa<br />

Ma/Pacific<br />

Near E<strong>as</strong>t/No. Africa Latin Ametica<br />

Source: FAC<br />

Urban populations<br />

"T Year<br />

El 1980<br />

I I<br />

237<br />

2000<br />

Africa<br />

ksia/Pacific<br />

Near E<strong>as</strong>t/No. Africa Latin Amerlca<br />

I<br />

Source: FA0<br />

fuelwood scarcities <strong>and</strong> fuelwoad deficits in<br />

1980 an3 2000

8<br />

Table 1.<br />

FAQ qualitative fuelwood deficiencies in A.1.D<br />

<strong>as</strong>sisted countrl es<br />

Go u n t ry<br />

AFRICA<br />

ana (Nestern)<br />

Burundi<br />

Cameroon (Northern 8 Western)<br />

Cape Yerde<br />

Chad (North)<br />

(Southern 8 Central 1<br />

Dj i bouti<br />

Gambia<br />

Ghana<br />

Gui nea (Northern)<br />

(Southern)<br />

Guinea-Bissau<br />

Kenya (Northern)<br />

(Co<strong>as</strong>tal 8 Central)<br />

Lesotho<br />

Libes-ia<br />

Ma daga scar<br />

Mal aw i<br />

Mal i ( Northern)<br />

(Southern)<br />

Mauri tan1 a<br />

Niger (Southwest)<br />

(Southern 8 E<strong>as</strong>tern)<br />

(Northern)<br />

Senegal (Central West a River Plain)<br />

Sierra Leone<br />

Smal ia<br />

Sudan (Northern)<br />

(Central 1<br />

Sw az il <strong>and</strong><br />

Tanzani a (Northern)<br />

(Southern)<br />

Togs North ern 1<br />

(Southern)<br />

Ug<strong>and</strong>a<br />

Upper Vol ta (Central 1<br />

Zai re (Northern)<br />

(Southern)<br />

Zarnbi a (E<strong>as</strong>tern)<br />

Z irnbabwe<br />

(E<strong>as</strong>tern & Western)<br />

NORTH AFRICA 8 NEAR EAST<br />

Pt<br />

Jordan<br />

L @Sa non<br />

Marocco<br />

Deficiency<br />

Acute<br />

Acute<br />

Def ici t<br />

Sat1 sf actory<br />

Acute<br />

Prospective<br />

Acute<br />

Deficit<br />

Prospective<br />

Deficit<br />

Prospect i v e<br />

Satisfactory<br />

Acute<br />

Deficit<br />

Ac ut e<br />

Sa ti sf act ory<br />

Deficit<br />

Def ici t<br />

Acute<br />

Prospective<br />

Acute<br />

Def i ci 2:<br />

Prospectdve<br />

Acute<br />

Ac ut e<br />

Deficit<br />

Prospective<br />

Acute<br />

Acute<br />

Prospect i ve<br />

Acute<br />

Def ici t<br />

P r os pect i v e<br />

Prospect i v e<br />

Deficit<br />

Befici t<br />

Def .ici t<br />

Prospective<br />

Prospective<br />

Def Ici t<br />

Deficit<br />

Prospective<br />

Deflci "t<br />

Def -I ci t<br />

Def Ici t<br />

Deficit

9<br />

Table 1. (Continued)<br />

Oman<br />

Tuni si a<br />

Yemen<br />

LATIN AMERICA<br />

Barbados<br />

Bel ize<br />

Bo1 ivia (Western)<br />

Costa Rica<br />

Dominican Republ i c<br />

Ecuador (Central 1<br />

El Salvador<br />

Guatemal a (Southern)<br />

Guy ana<br />

Haiti<br />

Hondur<strong>as</strong><br />

Jamaica<br />

N i ca ragua<br />

Pa nam a<br />

Paraguay (E<strong>as</strong>tern)<br />

Peru (Co<strong>as</strong>tal 1<br />

(Central 1<br />

ASIA & FAR EAST<br />

Bang1 adesh<br />

Burma (Southern)<br />

Fiji<br />

India (Western Himalay<strong>as</strong>)<br />

(Remainder)<br />

Indonesi a (Java)<br />

(Sumatra, Sul awesis Timar)<br />

Nepal (Hi11 s)<br />

(Foothills)<br />

Paki stan<br />

Phil ippines (Luzon)<br />

(Central 1<br />

Sri Lanka<br />

Thai1 <strong>and</strong> (Co<strong>as</strong>tal 1<br />

(Central 1<br />

Sati sf actory<br />

Deficit<br />

Deficit<br />

Satisfactory<br />

Sati sf actory<br />

Acute<br />

Sat1 sf actory<br />

Deficit<br />

Deficit<br />

Acute<br />

Deficit<br />

Sati sf actory<br />

Acute<br />

Sati sf actory<br />

Acute<br />

Sati sf actory<br />

Satisfactory<br />

Prospective<br />

Acute<br />

Dsf ici t<br />

Def id t<br />

Prospective<br />

Sati sf actory<br />

Acute<br />

Deficit<br />

Deficit<br />

Prospect i ve<br />

Acute<br />

Dof ici t<br />

Deficit<br />

Prospective<br />

Def ic4 t<br />

Def fci t<br />

P r os pect i v e<br />

Deficit<br />

Acute scarcity = <strong>Fuel</strong>wood resources have been so reduced that the<br />

popul ation is no 1 onger ab1 e to obtain a minimal supply.<br />

Deficit = Present fuel wood resources are bel ow requi rments, ob1 igi ng<br />

the popul ati on to overexpl oi t.<br />

Prospective deficit = Present fuelwoDd resources are higher than<br />

requirements, but situation evolving toward a crisis in 2000.<br />

Sat1 sfactory = Resources considerably exceed present <strong>and</strong> <strong>for</strong>eseeabl e<br />

needs.<br />

.Devel opi w, Food <strong>and</strong> AgricJl ture Organization of the United<br />

Nations, Rme, 1983.<br />

Source: M. R. de Montalembert <strong>and</strong> J. Clement, f m w w

€3. APPROXIMATELY 50 DEVELOPING COUNTRIES REPORT GEGLOGICAL COAL<br />

RESOURCES. TWENTY-QNE A. I. D. COUNTRIES REPQRT COAL RESERVES.<br />

WERE ARE 17 A.I.D. COUNTRIES THAT ESPECIALLY APPEAR TO BE<br />

CANDIDATES FOR INTRODUCING COAL BRIQUETTES -- EIGHT IN<br />

AFRICA9 SEVEN IN ASIA? AND WQ IN LATIN AMERICA.<br />

Exploration of coal in developing countries h<strong>as</strong> been very limited to<br />

date, <strong>and</strong> only began in earnest sfnce the second major 011 price<br />

incre<strong>as</strong>e in the late 1970s. Despite the lack of exploration, about 50<br />

developing countries now report geol ogical coal resources <strong>and</strong> 19 have<br />

technically <strong>and</strong> econ ically-recoverabl e reserves. C253 The di stribution<br />

<strong>and</strong> size of proven coal reserves arer hwever, skewed <strong>and</strong> are<br />

concentrated in a few developing countries. To be sure, coal resources<br />

are broadly distributed throughout the world, <strong>and</strong> the reported<br />

occurrences of coal in the developing countries are widely recognized to<br />

be v<strong>as</strong>t1 y understated.<br />

The availability <strong>and</strong> current production af coal in A. I.D. <strong>as</strong>sisted<br />

countries is reported in Table 2, The data indicate that 21 A.I.D.<br />

countries have coal reserves. These coal reserve data are very<br />

encouragi ng, but devel opment of coal reserves h<strong>as</strong> high f ront-end costs<br />

<strong>and</strong> long lead times. Consequently, the countries that have ongoing<br />

production or the potential <strong>for</strong> immediate development are 1 ikely to be<br />

the best c<strong>and</strong>idates <strong>for</strong> coal briquetti ng.<br />

The A. I. D. <strong>as</strong>sisted countries that appear to have the requisites <strong>for</strong><br />

coal briquetting techno1 ogy ( i. e. , fuel wood deficiencies <strong>and</strong><br />

availability of coal) are:<br />

Bots ana Bang1 adesh Haiti<br />

Morocco Burma Peru<br />

Niger<br />

Indi a<br />

Swaz 11 <strong>and</strong> Indonesi i9<br />

Tanzani a Pakistan<br />

Zad re<br />

Phil ippines<br />

bambi a<br />

Thai 1 <strong>and</strong><br />

Z i mba bw e

11<br />

Table 2. <strong>Coal</strong> availability ‘ln A.I.D. <strong>as</strong>sisted countries with<br />

fuel wood def ici enci es<br />

Resources<br />

Country ( MMtonnes) *<br />

Re se rv e s<br />

( MMtonnesIY<br />

Production<br />

MMton nes 1 *<br />

AFRICA<br />

Botswana (1)<br />

Burundi (3) (1)<br />

Cameroon (3)<br />

Chad<br />

Dj ibouti<br />

GambSa (1)<br />

Ghana<br />

Gui nea<br />

Kenya (1)<br />

Lesotho (1)<br />

Ma daga sca r ( 21<br />

Malawi (3)<br />

Mal i<br />

lclaur i tani a<br />

Niger (1)<br />

Rw<strong>and</strong>a (1)<br />

Senegal (1)<br />

Sierra Leone (3)<br />

Somalia (3)<br />

Sudan (1)<br />

Swazil<strong>and</strong> (3)<br />

Tanzania (1)<br />

Togo<br />

Ug<strong>and</strong>a (1)<br />

Upper Vol ta<br />

Zaire (3)<br />

Zambia (1)<br />

Zimbabwe (1)<br />

100,000<br />

n. a.<br />

500<br />

--<br />

--<br />

n. a.<br />

I-<br />

n. a.<br />

n. a.<br />

92<br />

14<br />

--<br />

n. a.<br />

n. a.<br />

n. a.<br />

n. a.<br />

n. a.<br />

n. a.<br />

5 9 000<br />

1,900<br />

I-<br />

--<br />

n. a.<br />

73<br />

228<br />

29,000<br />

17,000<br />

n. a.<br />

n. a.<br />

--<br />

--<br />

n. a.<br />

--<br />

--<br />

n. a.<br />

n. a.<br />

n. a.<br />

n. a.<br />

--<br />

--<br />

12<br />

n. a.<br />

n. a.<br />

n. a.<br />

n. a.<br />

n. a.<br />

1,620<br />

304<br />

--<br />

--<br />

n. a.<br />

n. a.<br />

58<br />

2,200<br />

0.415<br />

n. a.<br />

n. a.<br />

--<br />

--<br />

n. a.<br />

--<br />

2-<br />

n. a.<br />

n. a.<br />

L-<br />

n. a.<br />

n. a.<br />

n. a.<br />

n. a.<br />

n. a.<br />

n. a,<br />

n. a.<br />

0.100<br />

0.010<br />

--<br />

n. a.<br />

*...<br />

0.108<br />

0.610<br />

3.20<br />

NORM AFRICA 8 NEAR EAST<br />

Egypt (3)<br />

Jordan<br />

Lebanon<br />

Morocoo (1)<br />

Oman<br />

Tunisia (3)<br />

Yemen<br />

80<br />

--<br />

-I<br />

96<br />

e-<br />

-..<br />

n. a.<br />

n. a<br />

--<br />

--<br />

--<br />

--<br />

0.750<br />

n. a.<br />

LATIN AMERICA<br />

Bo1 iv .la (1)(2) Dominican Republ ic n. a.<br />

--<br />

Eucador (3) 22<br />

n. a.<br />

--<br />

n. a.<br />

--<br />

n. a.<br />

n. a.

12<br />

El Salvador (2)<br />

Guatemala (21<br />

Haiti (51<br />

Jamaica (2)<br />

Paraguay ( 1)<br />

Peru (1)<br />

n. a.<br />

n. a.<br />

-...<br />

n. a.<br />

n. ae<br />

9 97<br />

n. a.<br />

n. a.<br />

4.2.<br />

n. a.<br />

n. a.<br />

126<br />

n. a.<br />

n. a.<br />

A. SONE COAL BRIQUETTING TECHNIQUES MAKE COAL AN ATTRACTIVE<br />

FUEL-MOOD SUBSTITUTE BY CONVERTING IT INTO A SMOKELESS,<br />

COMPACT, STABLE, AND INEXPENSIVE FORM OF RIEL.<br />

<strong>Coal</strong> is often described <strong>as</strong> a 'tdirtyfl fuelr emitting smoke that is<br />

offensive <strong>and</strong> contai ni ng constituents that are harmful to human health.<br />

Moreover, sune raw coals are highly friable <strong>and</strong> are not e<strong>as</strong>ily h<strong>and</strong>led<br />

or distributed in their natural state. However, by briquetting <strong>and</strong><br />

carbonizing when necessary, coal can be put into a relatively clean,<br />

compact, <strong>and</strong> stable <strong>for</strong>m <strong>for</strong> use. The resulting fuel is also not<br />

expensive.<br />

B. COAL BRIQUElTING HAS BEEN SHCWN WORLD-WIDE TO BE A TECHNCLGY<br />

CAPABLE OF USING COPL OF VARIOUS GkADES AND PRODUCING<br />

BRIQUETTES W IM DIFFERENT CHARACTERISTICS FOR DIFFERENT USES.<br />

<strong>Coal</strong> brlquetting is a process z~y which raw coal is compacted into<br />

uni <strong>for</strong>m, usual 1 y hard, <strong>and</strong> 1mpac:t- res1 stant aggl omerati ons, maki ng it<br />

more suitable <strong>for</strong> use? transport, <strong>and</strong>/or further processing. It h<strong>as</strong><br />

been practiced <strong>for</strong> many years, at le<strong>as</strong>t since the beginning of this<br />

century.Cl21 It is also a technology that ha5 been researched<br />

worldwide, in such widely dlspersed places <strong>as</strong> Germany, USSR, Austral ia,<br />

Korea, India, <strong>and</strong> the United States. The wide extent of the research<br />

h<strong>as</strong> several re<strong>as</strong>ons. First, all coals are not a1 ike, <strong>and</strong> often research<br />

h<strong>as</strong> been aimed at developing aF" improved brfquetting process <strong>for</strong> a<br />

particular coal. Second, briquetting can be done with or without an<br />

additive (binder) to help in agglmerating <strong>and</strong> giving cohesive strength<br />

to the briquette. Much research h<strong>as</strong> gone into suitable binders, <strong>as</strong> well<br />

<strong>as</strong> into processes by which briquetting can be per<strong>for</strong>med without a<br />

binder. Third, same research h<strong>as</strong> been directed at improving the<br />

properties of the briquettes, such <strong>as</strong> maintaining ignitabil ity while<br />

keeping volatile matter low <strong>as</strong> well <strong>as</strong> reducing smoke <strong>and</strong> sulfur<br />

cmissians upon burning.<br />

It should be emph<strong>as</strong>ized that there is not just a single briquetting<br />

technologyr nor wen a set of two or three or a half dozen well-defined<br />

technologies <strong>for</strong> coal briquetting. Rather, a set of parameters <strong>for</strong> the<br />

briquetti ng of coal such <strong>as</strong> tc-mperature, pressure, pressing time,<br />

binderr type of coalp type of press, pretrealnent, etc., can be varied<br />

to produce unique briquetting processes.<br />

<strong>Coal</strong> briquetti ng can be per<strong>for</strong>med on 1 ump coal or on coal fjnesr the<br />

latter appl Ication often being an attempt to salvage an otherwise w<strong>as</strong>ted<br />

product of coal h<strong>and</strong>ling. The usual process of coal briquetting<br />

1 3

14<br />

consists of crushing, sizing, drying, poss-ibly mixing wfth a binder,<br />

often heating, pressing in molds, cool ing, <strong>and</strong> packagdng or loadlng.<br />

[See Appendix A <strong>for</strong> a more detailed description of coal briquetting<br />

process. 1<br />

In the United States in recent yearsp coal briquetting research h<strong>as</strong> been<br />

di rected mai nl y at manufacturing an aggl ornerate sui tab1 e <strong>for</strong> coal<br />

g<strong>as</strong>ification. Because this is an industrial application <strong>and</strong> not one<br />

aimed at domestic user properties such <strong>as</strong> mokiness or sulfur emissions<br />

have rece?ved secondary attention. A domestic 1 ndustry in %charcoal It<br />

briquettes supplying the “backyard barbeque market9! al so exists, <strong>and</strong> the<br />

producers of this product use some coal <strong>as</strong> a csnstltuent. However, it<br />

may be mixed with true charcoal in the production process. The amount<br />

of coal used varies, depending upon the location of the plant relative<br />

to a coal source <strong>and</strong> the type of coal available. Bituminous <strong>and</strong> 1 ignite<br />

coals must be carbonized, <strong>as</strong> described In a later section, be<strong>for</strong>e they<br />

can be used in the ?!backyard barbeque briquette.” Anthracite coal does<br />

not need to be carbonized in the manufacture of the Ifcharcoalst<br />

briquette.<br />

In other parts of the world, coal briquettes play other roles. In<br />

Europe <strong>and</strong> the Soviet Union, they continue to be used <strong>for</strong> domestic<br />

purposesI especially home heating$ <strong>and</strong> some attention h<strong>as</strong> been paid to<br />

the smokiness of the product. In India, where briquettes ders’vec! frm<br />

coal are used not only in space heating but a1 SO coaki ng, emissions are<br />

a primary concern.<br />

C. BURNING R N OR UNTREATED BRIQUETTED COAL PRODUCES EMISSIONS<br />

7HAT CAN HAVE SERIOUS HEALTH EFFECTS.<br />

Whether raw or briquetted, the burning of coal produces emissions that<br />

can be harmful to human health. This is especially relevant to the<br />

substitution of a coal-b<strong>as</strong>ed product <strong>for</strong> fuelwaoch since the latter is<br />

used extensively in developing countries <strong>for</strong> cooking, often in<br />

unventll ated situations. Depending on the composition of the coal <strong>and</strong><br />

the compl eteness of combusti on, burning coal re1 e<strong>as</strong>es vol atil e organ1 c<br />

matter, sul fur compoundsp nitrogen oxide5, particul ates, <strong>and</strong> trace<br />

elements. Each of these h<strong>as</strong> potential adverse effects on human health,<br />

<strong>and</strong> are discussed in more detail in Appendix B.<br />

EVER8 COAL CARBONIZATION SIGNIFICANTLY REDUCES ME ADVERSE<br />

HEALTI1 EFFECTS FROM BURNING COAL OR COAL BRIQUETTES. THE<br />

RESULT OF CARBONIZATION IS A 50FT SMOKELESS COKE. Is WHILE<br />

TESTING IS CURRENTLY IN PR(XRESS9 EMISSIONS FROM SMOKELESS<br />

COAL ARE REDICTED TO BE NO WORSE WAN THOSE EMANATING FROM<br />

THE CURRENT FUELS OF CHARCOAL AND FIRENO0D.<br />

A1 though substanti a1 adverse heal th effects coul d be expected f ran<br />

burning coal or coal briquettes <strong>for</strong> cooki ng purposes~ a we1 l-devel oped<br />

technique exists to convert coal to a safer <strong>for</strong>m <strong>for</strong> combustion. This

15<br />

is coal carbonization, converting it to a "'soft coke" by pyrolysls.<br />

This is simllar to the conversion of wood to charcoal. During the<br />

heating of the coal without its combustion, vol atile content is reduced,<br />

<strong>and</strong> g<strong>as</strong>es <strong>and</strong> tars containing some of the other harmful constituents are<br />

glven off. The result is a product high in fixed carbon, which can be<br />

burned with 1 ittle or no smoke <strong>and</strong> missions no worse than the present<br />

practice of burning coal <strong>and</strong> firewood. Carbonization can be per<strong>for</strong>med<br />

be<strong>for</strong>e or after briquetting -- or wen without briquetting, if irregular<br />

"soft coke" lumps <strong>and</strong> loss of the coal fines are acceptable. [See<br />

Appendix A,] Because the soft coke is vlrtually smokeless9 it w i l l be<br />

referred to often <strong>as</strong> ?"smokeless coal" in the remainder of this document.<br />

One of the important <strong>as</strong>pects of the coal carbonization process is that<br />

many of the potentially harmful constituents of coal are removed. As<br />

mentioned, most of the volatiles are driven off during pyrolysis fnto<br />

the off-g<strong>as</strong>es, tars, or liquors. A certain level of volatiles is left<br />

in the soft coke (approximately 1% to 20%) to promote its e<strong>as</strong>y ignition<br />

C61, but this level is deemed safe <strong>and</strong> does not allow the fuel to smoke<br />

significantly. Many of the potentially carcinogenic <strong>and</strong> other organic<br />

constituents, such <strong>as</strong> benzo(a1pyrene (BaP), to1 uener benzene, etc. , cane<br />

out in the tar.<br />

The sulfur content is also reduced <strong>as</strong> the sulfur is converted to<br />

hydrogen sulfide g<strong>as</strong>. Actually, several steps can be taken <strong>for</strong> sulfur<br />

removal to make the final smokeless coal lump or briquette rather clean<br />

with respect to sulfur oxide emissions. W<strong>as</strong>hing the coal with water<br />

prior to pyrolysis is a simple, inexpensive, <strong>and</strong> effective step. More<br />

sulfur is removed during the carbonization process. Finally, if the<br />

coal is a higher sulfur coal, lime or limestone can be added to the<br />

final briquette so that any remaining sulfur combines with it <strong>and</strong><br />

remains in the <strong>as</strong>h upon combustion. The cost of 1 ime, if needed, Is<br />

also very lowp representing only 1% of the price of a soft coke<br />

briquette in a model plant scenario constructed by Fabuss <strong>and</strong> Tatm.C63<br />

Particulates are considerably reduced by the process of carbonization.<br />

Only minor fly <strong>as</strong>h results from combustion of the carbonized fuel.<br />

Also, while the temperature of carbonization is not high enough to<br />

remove many of the trace elements by volati~ation~ neither is the<br />

temperature of combustion of the smoke1 ess coal. Thus, without<br />

particulates to which to adsorb, the trace elements remain in the <strong>as</strong>h<br />

when the smokeless coal briquettes are burned. This keeps the level of<br />

human exposure to trace elements at an insignificant level.<br />

One remaining health effect shoul d be mentioned. The production of soft<br />

coke can expose workers to dangerous conditions unless strict control s<br />

are imposed. <strong>Coal</strong> dust in coking plants is often very high <strong>and</strong><br />

difficult to suppress. The potential carcinogens in the coal tarsr such<br />

<strong>as</strong> BaP, suggest careful h<strong>and</strong>1 ing of these by-products. In developing<br />

countries, attention to worker safeTy in carbonization plants Is not<br />

a1 ways given due attention. [I61<br />

It should be noted that Carbonization is only needed <strong>for</strong> coals below the<br />

rank of anthracite, that is, <strong>for</strong> bituminous, subbituminous, <strong>and</strong> 1 ignite<br />

coals. Anthracite in its natural state is sufficiently low in volatile

16<br />

<strong>and</strong> <strong>as</strong>h contents <strong>and</strong> high in fixed carbon that carbonization is<br />

unnecessary <strong>for</strong> a ,smoke1 ess fuel. Hwever, anthracites are re1 atively<br />

rare.<br />

E. THE COSTS ASSOCIATED WITH 3RIQUETTING PND CARBONIZING COAL<br />

INDICATE A SELLING PRICE FOR SNOKELESS COAL BRIQUETTES IN<br />

SOME URBAN AREAS THAT MAKE THEM CX)MPETITIVE W I T H FUELWOOD AND<br />

CHrnCQK.<br />

Fabuss <strong>and</strong> Tatm C6l estimate the costs of constructing a 100 metric ton<br />

par day (coal input) briquetting <strong>and</strong> carbonization plant <strong>for</strong> Pakistan.<br />

Whdfo this is a moderately sized plant <strong>and</strong> to a certaln extent tied to<br />

conditions found in Pakistanr a review of their estimates can give an<br />

idea of the econmic viabil ity of the coal brlquetting/carbonization<br />

techno1 ogy.<br />

The plant viwed in thelr scenario takes the path of an "intermediate<br />

technology." It would be capable of recovering the coal tar <strong>and</strong> oil,<br />

but none of the U~QUS liquors. The process off-g<strong>as</strong> would be used to<br />

generate 100% of the power rquirements <strong>for</strong> the plant. Uti1 izing<br />

Pakistan's high sulfur lignite coal, the briquettes would be <strong>for</strong>med<br />

without a binder, but 1 ime would have to be added prior to briquetting<br />

to reduce sul fur missions. The plant would have 66 tons per day output<br />

of mokel ess coal briquettes. The ratio of 100 tons per day coal input<br />

to 66 tons per day output of smokeless coal briquettes w<strong>as</strong> figured <strong>for</strong> a<br />

ticular Pakistani coalr <strong>and</strong> other coals would give varying yields.<br />

ever, the PO0 to 66 ratio is In the middle of a range of about 55% to<br />

75% that might be expected from various coals.<br />

Total investment costs, including the cost of installed equipment, site<br />

preparation, bui 1 di rigs, engi neeri ng <strong>and</strong> conti ngenci esa are put at<br />

2,130,000 U.S. dollars (1982$). About half of this amount would be<br />

rqui red tn <strong>for</strong>eign exchange. Operating co~ts, including coalr 1 ime,<br />

1 abor, mai ntenancep 1 oan reti r ent, a 25% prof it on these manufacturing<br />

costs, <strong>and</strong> transportation brlng the price of smokeles 1 briquettes<br />

to 1528 Pakistani rupees (Rs.) per metric ton of oil ival ent (TOE)<br />

anywhere within a one hundred mile radius of the plan By varying<br />

the scale of the plant, Fabuss <strong>and</strong> Tatcxn further estimate that the cost<br />

of smokeless coal briquettes per TOE would be Rs. 1622, Rs. 1466, <strong>and</strong><br />

Rs. 1407 <strong>for</strong> plants with coal inputs of 25, 300, <strong>and</strong> 1,000 metric tons<br />

(tonnes) per dayr respectively. 3y c parison, fir ood costs a87<br />

average of Rs. 2117/TOE. Thusl the coal briquetti ng/carbonination<br />

operation appears to be econcmical ly competitive, Moreover, this is the<br />

c<strong>as</strong>e without even considering the potential value of the coal tar byproduct.<br />

If a market <strong>for</strong> this can be found, wen if used only <strong>as</strong> boiler<br />

fuel, either plant profits could be raised or the price of the mokeless<br />

1/ In 1982 when the cost estimates were mader 1 US$ equalled<br />

approximately 12 Rs. In 1985, the exchange rate is approximately 1<br />

US$ t o 16 Rs.

17<br />

coal briquettes could be subsi dized w 4th the by-product i ncme <strong>and</strong><br />

brought to a yet lower level.<br />

Favorable economics <strong>for</strong> coal briquettes a1 so appear 1 ikely <strong>for</strong> two urban<br />

are<strong>as</strong> in Peru, namely Lima <strong>and</strong> Puancayo. brewer, this country<br />

provides an example where heavily subsidized kerosene might be displaced<br />

by smokeless coal briquettes. As smmarized in Table 3, the UNDP/World<br />

Bank estimate that coal briquettes a:; a cooking fuel would cost US$ 9.30<br />

- 13.30 per capita per year.C1812/ By comparison, fuelwood used in an<br />

open fire costs US$ 10.80 - 15.00 per capita per year in Wuancayo <strong>and</strong><br />

US$ 27.58 - 31.70 in Lima. Although the cost of a stove is not included<br />

in these estimates, the coal briquettes appear economically competitlve<br />

with fuelwood on an operating cost b<strong>as</strong>is. With respect to kerosene,<br />

Table 3 indicates that it is cheaper than coal briquettesl but only<br />

because of a large subsidy. If the subsidy on kerosene were 7 ifted,<br />

coal briquettes could displace It <strong>as</strong> a cooking fuel, at le<strong>as</strong>t on a costof-fuel<br />

b<strong>as</strong>is. Since kerosene is subsidized in other countries <strong>as</strong> well,<br />

this conclusion might be general.<br />

Table 3. Cooking fuel costs in Peru<br />

(US$ per capita per year)<br />

FUR- H U ANCA YO<br />

L LMA<br />

<strong>Wood</strong><br />

used in open fire<br />

use in improved stove<br />

10.80 - 15.00 27.50 - 31.70<br />

5.40 - 11.20 13.80 - 23.70<br />

C h a rcoal 33.90 5 8.50<br />

<strong>Coal</strong> <strong>Briquettes</strong> 9.30 - 13.30 9.30 - 13.30<br />

Kerosene<br />

w ith current subsidy<br />

unsubsi dized<br />

7.70<br />

21 .oo<br />

7.70<br />

18.50<br />

Source:<br />

UNDP/Worl d Bank C181<br />

- 2/ This translates into US$ 139 - 1!39 per TOE. Costs of other cooking<br />

fuel s are not trans? ated into dol'lars per TOE because the method used<br />

by the UNDP/World Bank to estimate their costs per capita per year<br />

involved different uti1 ization eff Iciencies <strong>for</strong> the different fuels.<br />

Giving a cost per TOE <strong>for</strong> all fuels would be misleading.

IV.<br />

A. COAL CARBONIZATION HAS BEEN PRACTICED EXTENSIVUY IN INDIA.<br />

WE INDIAN EXPERIENCE IS INSTRUCTIVE BECAUSE A WIDE RANGE OF<br />

TECHNOLOGIES AND COAL TYPES HAS BEEN UTILIZED. INDIA HAS<br />

DEPQSITS OF BITUMINOUSI SUB-BITUMINWS, AND LIGNITE COALS,<br />

AND ALL HAVE BEEN USED FOR CARBONIZATION. TEWNQLGIES RANGE<br />

FROM ONE-PERSONS "V1LLPl;rE CO PILES!' TO ADVANCED TECHNOLOGY<br />

CARBON IZ ATION PL ANTS.<br />

The advanced technol ogy coal carbonization pl ants .B n India demonstrate<br />

several di fferent technol ogies. The m<strong>as</strong>t advanced, which are either<br />

government pi1 ot pl ants or comrnerci a1 pl ants model ed on government<br />

projects aractice full by-product recovery. The smokeless coal (soft<br />

coke) is &ten produced in a continuous process with crushed <strong>and</strong> sized<br />

coal or briquetted coal entering the top of carbonlzing retorts <strong>and</strong> soft<br />

coke issuing at the bottom. The g<strong>as</strong> may be used to cool the soft coker<br />

<strong>and</strong>, having been heated, reenter the carbonizing section <strong>as</strong> a fuel. If<br />

the cleaned g<strong>as</strong> is not immeddately recycled <strong>as</strong> fuel, it can be used <strong>for</strong><br />

electricity generation or <strong>for</strong> town g<strong>as</strong>? the latter use being planned <strong>for</strong><br />

the city of Calcutta. Similarly, the tars <strong>and</strong> 1 iquors are retainedr <strong>and</strong><br />

may be (1) used <strong>as</strong> fuel in the carbonizing operation or sold <strong>for</strong> boiler<br />

fuel or (2) be refined into fine chemicals. The scales of the pilot<br />

plants run from 20 to 25 tons per day (TPD) of coal input, where<strong>as</strong> the<br />

full scale plants can have design input of 1500 to 2700 TPD. The plants<br />

at the upper end of this range do not generally run at full capacity.<br />

Intorrnedi ate technol ogy pl ants a1 so exi sL in Indi a, Agai n, crushed or<br />

briquetted coal travels through retorts or possibly on chain grates<br />

through a kiln <strong>for</strong> carbonization. The intermediate technology pl ants,<br />

however, practice limited or no by-product recovery. If no by-product<br />

recovery is pursued, these plants can be heavy polluters. Often, the<br />

off-g<strong>as</strong>es aro p<strong>as</strong>sed through a scrubber, but then vented to the<br />

atmosphere. Tars <strong>and</strong> liquors also are not recovered. Still, it is<br />

possi bl e to construct i nterrnedi ate technol oyy pl ants which, while not<br />

recxwering every chemical fraction separately, retain useful by-products<br />

such <strong>as</strong> soad-surfaci ng material, bail er fuel , <strong>and</strong> off-g<strong>as</strong> fuel. Fabuss<br />

<strong>and</strong> Tatom indicate that such an operation "can be accornpl ished<br />

re1 atlvely e<strong>as</strong>ily <strong>and</strong> yet w ithcrut great cost . . . . srC61 Additional<br />

capital costs can be expected to run on the order of 5% to lmr <strong>and</strong> it<br />

wok11 d reduce the pollution problem. In Indda, the scale of the<br />

intemedi ate technol ogy pl ants runs f ran 25 to 100 TPD coal input. c161<br />

The stvillage coal pile'! is the simplest technology of all9 <strong>and</strong> the<br />

heaviest polluter. A pile of coal <strong>and</strong> coal fines is ignited <strong>and</strong> when<br />

the smoking stopss it is nates quenched. By rmoving outer <strong>as</strong>hr an<br />

18

19<br />

inner char is found that can be used <strong>as</strong> a smokeless fuel.<br />

such a process can be seen <strong>for</strong> miles.<br />

Smoke frm<br />

The major difference introduced by -:he different types of feed coal used<br />

in the industrial carbonization plants h<strong>as</strong> to do with briquetting. The<br />

bituminous <strong>and</strong> subbltuminous coals may only be crushed <strong>and</strong> sized, but<br />

not briquetted prior to carbonlzation. Hwever, briquetting of the coal<br />

or smokeless coal .fines may occur. <strong>Coal</strong> fines are briquetted with<br />

mol<strong>as</strong>ses, bentonite (clay), or an inorganic binder by the Indians. Soft<br />

coke fines may be briquetted with a starch binder. With the lignitic<br />

coal sp briquetting prior to carbonization is per<strong>for</strong>med. The producers<br />

take advantage of the property of 1 ignite that allows it to be<br />

briquetted without a binder. The briquetted <strong>for</strong>m of the smokeless coal<br />

output gives it a distinctive appearance. This allows it to be e<strong>as</strong>ily<br />

distinguished from lump coalr so that it cannot be adulterated by<br />

di shonest deal ers.<br />

Profitability of the village coal pile <strong>and</strong> intermediate technology<br />

producers is positive, if only marginal at times. Costs are reduced by<br />

avoiding capital investment to recover by-products. The high technol ogy<br />

producers must often operate unprofitably <strong>for</strong> seven, eight, or ten years<br />

be<strong>for</strong>e reaching the break-even poi nt. The di ff icul ties that pl ague the<br />

larger operations, in addition to higher costs, are irregular coal<br />

suppl ies, transportation difficulties, power outages, labor probl cans$<br />

<strong>and</strong> the inabil ity to sell by-products. A1 though high technol ogy<br />

appl ications may be more prof itable in the long-run, Schwartz <strong>and</strong> Tatom<br />

C161 recommend appl ication of intermed-l ate 1 eve1 s of technol ogy with<br />

some by-product recovery <strong>for</strong> other developing countries. In this<br />

f<strong>as</strong>hion, sane of the risk of high technology plants <strong>as</strong> well <strong>as</strong> the<br />

pol 1 ution probl ems of vent? ng by-products can be avoided.<br />

B. INDIA HAS DEVELOPED A SMOKELESS COOKING STOVE WHICH CAN USE<br />

RAW COAL AS A FUEL SOURCE WITH NO DETRIMENTAL HEALTH EFFECTS.<br />

Finally, a technology unique unto itself h<strong>as</strong> arisen fran the Indian<br />

experience. Thls is the %smokeless cooking stove,'! which u5es raw coal<br />

rather than smokeless coal <strong>as</strong> its initial fuel. It there<strong>for</strong>e cmpletely<br />

avoids the cost of coal carbonization plants. Developed by the Indian<br />

Central <strong>Fuel</strong> Research Institute (CFRI), the stove can be manufactured<br />

<strong>for</strong> about 50 rupees (soft coke stoves cost approximately 30 rupee+--1982<br />

rupees). B<strong>as</strong>ed on the savings of buying coal rather than smokeless<br />

coal, the cost of the stove can be rfxovered in only a few months. This<br />

Is b<strong>as</strong>ed on a 1982 retail coal price in India of about 180 rupees per<br />

tonne <strong>and</strong> the soft coke cost of about 720 rupees per tonne. Assuming a<br />

family of five, which would use about a tonne of soft coke per year., a

20<br />

net savings of 490 rupees could be realized by the family in the flrst<br />

ye<strong>as</strong> of operation on coal-C1613/<br />

The stove consists of two cylindrical, concentrlc compartments, the<br />

inner one being a smokeless coal combustion zonep <strong>and</strong> the outer one<br />

being an air-tight coal carbonization mane. Sized or briquetted coal is<br />

loaded in the outer zone to be carbonized fran the heat of burning<br />

smokeless coal in the inner zonep which al SO suppl ies cooking <strong>and</strong> space<br />

heating needs. The off-g<strong>as</strong>es are mixed with air below the mokeless<br />

coal bed <strong>and</strong> thus consumed. The next day, the carbonized coal from the<br />

outer zone is consumed in the inner zone, while ne# coal is added to the<br />

outer compartment. The only disadvantages appear to be that the coal<br />

must be sized carefully, the optlmal stove design depends on the type of<br />

coal burned--a1 though a1 1 types are c<strong>and</strong>i dates--<strong>and</strong> no by-product<br />

recovery is possi bl e. Thus, the CFRI smoke1 ess stove potenti a1 ly<br />

represents an extradordi nary innovation, being "a cl ean-burning, sel f-<br />

sustaining system in which tmorrewts [soft] coke is produced today,<br />

whilo the Csoft3 coke made yesterday is bafng consumed~~.C161<br />

C. KOREANS HAVE USED RM ANTHRACITE CBfik BRIQUETTES EXTENSIVELY<br />

FOR COOKING AND HEATING. THE KOREANS STARTED CON<br />

BRIQUETTING IN 1930, AND THERE AF?E NCW APPROXIMATELY 20 LARGE<br />

BRIQUETTING PLANTS IN ME COUNTRY.<br />

Korean briquettes are comprised of 90% Korean anthracite <strong>and</strong> 10% Chinese<br />

coking coal, They are very large? by comparison to other coal<br />

briquettes, weighing approximately 8 to 16.5 pounds each. They are<br />

pressed at only 170 to 240 psi, <strong>and</strong> do not meet normal briquette<br />

compression strength criteria: they can be broken with the fingers,<br />

they crush when dropped, <strong>and</strong> probably would not st<strong>and</strong> up to weathering.<br />

They really art3 only Ita well compacted coal that is in a convenient <strong>for</strong>m<br />

<strong>for</strong> h<strong>and</strong>1 iny. rlC61<br />

It is important to note that the Korean experience could not be<br />

transferred to many other countries. First, anthracite (along with a<br />

mall amount of coking coal) is used to manufacture the Korean<br />

briquettes. As mentionedr anthracite can be used <strong>as</strong> a smokeless fuel<br />

<strong>for</strong> cooking without carbonization. However, anthracites are rare, <strong>and</strong><br />

thus the Korean method of briquettl ng without carbonization cannot be<br />

transferred to many other countries. Second, the size of the Korean<br />

briquettes is abnormally large. Thls is because they use than <strong>for</strong> both<br />

cooking <strong>and</strong> heatingr involving a 24-hour operation. This would not be<br />

rqui red in most A. I. D. countries.<br />

In this examples Schwartz <strong>and</strong> Patm E161 have obviously <strong>as</strong>sumed that<br />

a family using one tonne of soft coke per year would also use about<br />

one tonne of coal pet- year in the smokeless stove. Since there may<br />

be heat losses in converting from coal to soft coker thts nay not be<br />

compl etely accurate. Still, the econ ic advantage of the makeless<br />

cooking stove is large enough that thls should not change the<br />

concl usi on of quick cost recovery.

V. THE POTEl!UILLFOR CCEAL.B.RIQUETTETITU.TION<br />

JN A. I.D. ASSLSIED C m<br />

A. SIGNIFICANT OPPORTUNITIES EIST TO MITIGATE THE FUELWOOD<br />

CRISIS AROUND THE WORD. A PRELIMINARY EXAMINATION OF THE<br />

SEVENTEEN RE3 IOUSLY IDENTIFIED COUNTRIES INDICATES THAT FOUR<br />

APPEAR TO HAVE AN IMMEDIATE POTENTIN: BOTSANA, HAITII<br />

INDIA, AND PAKISTAN. ANOTHER ELEVEN COUNTRIES APPEAR TO HAVE<br />

A NEAR-TERM (3 TO 5 YEARS) POTENTIAL: INDONESIA, MIROCCO,<br />

NIGER, PERU, PHILIPPINES, ‘TANZANIA, THAILAND, SWAZILAND,<br />

ZAIRE, ZAIUBIA, AND ZIMBABWE.<br />

The perv<strong>as</strong>iveness of the fuel wood crisis among A. 1.5. <strong>as</strong>sisted countries<br />

is exemplified by the fact that wily two African, one Near E<strong>as</strong>tern,<br />

seven Latin American, <strong>and</strong> one Asian country have satisfactory wood<br />

energy suppl ies. The reserves <strong>and</strong> production of coal in A. I. D. <strong>as</strong>sisted<br />

countries were a1 so determined. Of the twenty-one previously identified<br />

countries sixteen have sane me<strong>as</strong>ure of current coal production <strong>and</strong> one<br />

country, Haiti h<strong>as</strong> the potenti a1 <strong>for</strong> immedi ate coal devel opnent.<br />

Although the availability of coal is, of course, a necessary<br />

prerq ui site <strong>for</strong> substi tuti ng a smoke1 ess coal-derived fuel far f i rwood<br />

<strong>and</strong> charcoalp other factors are equally important. Among these are:<br />

(1) the nature of fuelwood use ard supply, (2) the location of coal<br />

deposits re1 ative to dem<strong>and</strong> centers, (3) demographics, (4) the extent<br />

<strong>and</strong> adequacy of distribution systms, (5) markets, (6) the extent of<br />

government involvement in energy pl anni ngO <strong>and</strong> (7) the compati bil ity of<br />

fuel use with social custcxns.<br />

The examlnation of these seventeen countries is b<strong>as</strong>ed solely on<br />

secondary data sources. The uni<strong>for</strong>mity <strong>and</strong> consistency of in<strong>for</strong>mation<br />

varies considerably among countries, <strong>and</strong> <strong>for</strong> saner in<strong>for</strong>mation is not<br />

available. To be sure, sane countr;ies have a higher immediate potential<br />

<strong>for</strong> coal brlquetting techno1 ogy. Countries that have especially<br />

favorable ci rcwnstances are briefly discussed bel ow. Appendix C<br />

provides a more detailed examinatlon of the seventeen identified<br />

count r i es.<br />

In Africa, Botswana appears to have an immediate potential <strong>for</strong> coal<br />

briquetting. Botswana h<strong>as</strong> large coal reserves <strong>and</strong> relatfvely lw coal<br />

extraction <strong>and</strong> transportation costs. Further, the population is<br />

concentrated in the e<strong>as</strong>tern thirc of the country <strong>and</strong> is favorably<br />

located to railroads <strong>and</strong> roads. Bec:ause there is no charcoal productlon<br />

in the country, smokeless coal briquettes would have to substitute<br />

directly <strong>for</strong> firewood. Hwever, the diffusion of coal briquettes could<br />

be coordinated with the USAID program to develop <strong>and</strong> demonstrate fuelef<br />

f ici erst stoves. Morocco, Niger, Tanzani a, Zambial <strong>and</strong> Zimbabwe a1 1<br />

have a nearterm potential that depends largely on the additional<br />

development of coal reserves. In<strong>for</strong>mation is not available on two<br />

21

22<br />

countriesr Swazil<strong>and</strong> <strong>and</strong> Zalrep with which to make an evaluation.<br />

However, the UNDP/World Bank w i l l have completed an energy <strong>as</strong>sessment in<br />

both of these countries within the next six months.<br />