RUSSULA NEWSLETTER No. 11

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

RECENT PROJECTS<br />

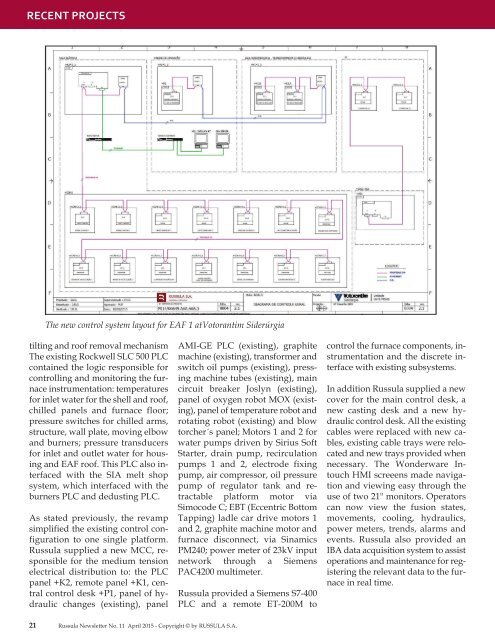

The new control system layout for EAF 1 atVotorantim Siderúrgia<br />

tilting and roof removal mechanism<br />

The existing Rockwell SLC 500 PLC<br />

contained the logic responsible for<br />

controlling and monitoring the furnace<br />

instrumentation: temperatures<br />

for inlet water for the shell and roof,<br />

chilled panels and furnace floor;<br />

pressure switches for chilled arms,<br />

structure, wall plate, moving elbow<br />

and burners; pressure transducers<br />

for inlet and outlet water for housing<br />

and EAF roof. This PLC also interfaced<br />

with the SIA melt shop<br />

system, which interfaced with the<br />

burners PLC and dedusting PLC.<br />

As stated previously, the revamp<br />

simplified the existing control configuration<br />

to one single platform.<br />

Russula supplied a new MCC, responsible<br />

for the medium tension<br />

electrical distribution to: the PLC<br />

panel +K2, remote panel +K1, central<br />

control desk +P1, panel of hydraulic<br />

changes (existing), panel<br />

AMI-GE PLC (existing), graphite<br />

machine (existing), transformer and<br />

switch oil pumps (existing), pressing<br />

machine tubes (existing), main<br />

circuit breaker Joslyn (existing),<br />

panel of oxygen robot MOX (existing),<br />

panel of temperature robot and<br />

rotating robot (existing) and blow<br />

torcher´s panel; Motors 1 and 2 for<br />

water pumps driven by Sirius Soft<br />

Starter, drain pump, recirculation<br />

pumps 1 and 2, electrode fixing<br />

pump, air compressor, oil pressure<br />

pump of regulator tank and retractable<br />

platform motor via<br />

Simocode C; EBT (Eccentric Bottom<br />

Tapping) ladle car drive motors 1<br />

and 2, graphite machine motor and<br />

furnace disconnect, via Sinamics<br />

PM240; power meter of 23kV input<br />

network through a Siemens<br />

PAC4200 multimeter.<br />

Russula provided a Siemens S7-400<br />

PLC and a remote ET-200M to<br />

control the furnace components, instrumentation<br />

and the discrete interface<br />

with existing subsystems.<br />

In addition Russula supplied a new<br />

cover for the main control desk, a<br />

new casting desk and a new hydraulic<br />

control desk. All the existing<br />

cables were replaced with new cables,<br />

existing cable trays were relocated<br />

and new trays provided when<br />

necessary. The Wonderware Intouch<br />

HMI screeens made navigation<br />

and viewing easy through the<br />

use of two 21" monitors. Operators<br />

can now view the fusion states,<br />

movements, cooling, hydraulics,<br />

power meters, trends, alarms and<br />

events. Russula also provided an<br />

IBA data acquisition system to assist<br />

operations and maintenance for registering<br />

the relevant data to the furnace<br />

in real time.<br />

21 Russula Newsletter <strong>No</strong>. <strong>11</strong> April 2015 - Copyright © by <strong>RUSSULA</strong> S.A. S.A.