TONG YUNG IND. CO. LTD. - Lockwood International

TONG YUNG IND. CO. LTD. - Lockwood International

TONG YUNG IND. CO. LTD. - Lockwood International

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>IND</strong>EX<br />

BRIEF HISTORY<br />

APPROVAL CERTIFICATES<br />

I<br />

12<br />

.. 13<br />

14<br />

15<br />

.. 16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

Y II . .... :"' .•. 32<br />

33<br />

34<br />

.... 35<br />

36<br />

. ... ... .... .... ~ . · 37<br />

38<br />

· 39<br />

40<br />

········· 41

BRIEF HISTORY<br />

BRIEF HISTORY<br />

DESCRIPTION<br />

MAIN <strong>CO</strong>NTENTS<br />

SEPTEMBER 10. 1973. A JOINT-VENTURED <strong>CO</strong>MPANY APPROVAL FROM GOVERNMENT<br />

NOVEMBER 13. 1973. ES TABLISHED WITH MEISE <strong>IND</strong>. MACH INERY <strong>CO</strong> . <strong>LTD</strong>., IN JAPAN<br />

SEPTEMBER 21. 1974. OBTAINED A PATENT OF SPECIAL CASTING METHOD<br />

DECEMBER 7. 1974. STARTED EXPORT OF VALVES & CASTI NGS<br />

JUNE 30. 1978. EXPANSION OF FACTORY FACILI TIES<br />

NOVEMBER 30. 1982. RECEIVED THE PR IME M INISTER PRIZE IN TH E NINETEENTH<br />

EXPORT DAY<br />

NOVEMBER 30. 1983. RECEIVED "TOWER OF EXPORT( $ 1,000,000)" BY THE TWEN TIETH<br />

EXPORT DAY<br />

NOVEMBER 30. 1984. RECEIVED "TOWER OF EXPORT( $ 2,000,000)" BY THE TWENTIETH<br />

EXPORT DAY<br />

NOVEMBER 30. 1987. RECE IVED "<strong>IND</strong>USTRIAL DE<strong>CO</strong>RATION" & "TOWER OF EXPORT( $<br />

5,000,000)" BY THE TWENTY-FOUR TRADE CELEBRATION DAY<br />

NOVEMBER 30. 1988. RECEIVED "TOWER OF EXPORT( $ 10,000,000)" BY THE TWENTY FIVE<br />

)<br />

TRADE CE LEBRATION DAY<br />

DECEMBER 199 1. OPENED NEW FACTOR(ASSEMBL Y SHOP)<br />

CERTIFICATES AND APPROVALS<br />

SEPTEMBER 18. 1981. APPROVED BY THE KOREAN REGISTER OF SH IPPING<br />

JANUARY 4. 1983. APPROVED BY A.P.I 60<br />

OCTOBER 4. 1983. APPROVED BY D.N.V<br />

OCTOBER 4. 1984. APPROVED BY LLOYD'S REGS TER OF SHIPPING<br />

MARCH 1. 1989. CERTI FIED BY B.S.I ON FIRE SAFE BALL VALVE TEST<br />

MARCH 15. 1993. APPROVED BY "EXXON"<br />

SEPTEMBER 1. 1993. APPROVED BY LLOYS'S ON "I.S.0 9001"<br />

DECEMBER 1. 1993. APPROVED BY "MOBIL"<br />

MAY 1996. APPROVED BY "DOW"<br />

JULY 1996. APPROVED BY "DUPONT"<br />

SEPTEMBER 16. 1996. APPROVED BY "SHELL"<br />

SEPTEMBER 14. 1996. CERTIFIED BY A.P.I 607. ON FIRE SAFE BALL VALVE TEST(SRI)<br />

JUNE 11. 1997. AP PROVED BY ''TUV''<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.<br />

4

ORIGINAL LICENSE NO. _ .:::.:6D:::...--,,- Ol ::..:9c::. 9 _ _ _<br />

American Petroleum Institute<br />

Certificate of Authority To Use Official Monogram<br />

THE AMERICAN PETROLEUM INSTITUTE hereby grants to<br />

<strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>USTRIAL <strong>CO</strong>., <strong>LTD</strong>.<br />

Busan, Korea<br />

the right to use the Official Monogram<br />

~ on manufactured products under the<br />

conditions specified in the official publications of the American petroleum institute<br />

entitled AP[ Spec Q[ and _ _ ____ S_p_ec_ifl _c_a_ti_on_ 6_D _ _ _ _ _ _ _ _ _ _<br />

and in accordance with the provisions of the License Agreement.<br />

[n all cases where the Official Monogram ~ is appl ied, the Monogram<br />

should be used in conjunction with th is certificate number _ _ _ 6_D_-O_l_9_9 ____<br />

_ _<br />

The American Petroleum Institute reserves the right to revoke this<br />

authorization to use the Official Monogram, for any reason satisfactory to the<br />

Board of Directors of the American Petroleum Institute.<br />

Effective Date FEBRUARY 20,<br />

Expiration Date FEBRUARY 20,<br />

[9 99<br />

20 02<br />

AMER[CAN PETROLEUM [NST[TUTE,<br />

Secretary

®<br />

CERTIFICATE OF APPROVAL<br />

This is certify that Quality Management System of:<br />

Tong Yung Industria1. Co., Ltd<br />

Busan, Korea<br />

has been approved by Lloyd's Register Quality Assurance<br />

to the following Quality Management System Standards:<br />

ISO 9001:1994<br />

BS EN ISO 9001:1994<br />

KS A 9001:1998<br />

The Quality Management System is applicable to:<br />

Design, manufacture and in-house servicing of valves<br />

including casting, machining and assembly.<br />

Approval<br />

Certificate No:92831 0<br />

Original Approval: 1st September 1993<br />

Current Certiilcate: 1st September 1999<br />

Certiilcate Expiry: 31stjuly 2002<br />

- 0?~QQ<br />

on behalfofLRQA -Korea<br />

~ ~<br />

UKAS<br />

QUALITY<br />

MANAG[.\IENT<br />

001 RvA<br />

TGA-ZM-02-91-00<br />

~<br />

11li5 npproVll/ is ~d (Jut in flccordana with lIre LRQA ~5l11tnf and rerliftmlion prorollires find monitored by LRQA<br />

TI,e U~ of tile UKAS Accrcddalwn M/Uk il/dimle:; Acrnditatjon in rtsptc/ of these a.clivilics ~d by tire Accrcditathm Orfijimte Nllmber 001<br />

,",""

APPROVAL CERTIFICATES<br />

LLOYD<br />

•--E"'........<br />

=: ..""::"'" ~ .. oo:::.IV"l~<br />

SINCE 1973<br />

T .... y:::,.":..

PRODUCTS & MATERIAL<br />

CAST STEEL<br />

CARBON AND LOW ALLOY STEEL<br />

TYPE RATING SIZE MATERIAL REMARKS<br />

GATE VALVE 150# 1 In" -.48" WCB, WCl<br />

300# 1 1 /2" - 36" WC 6, WC9<br />

600# 2"-24" C5, C12, LCC<br />

900# 2" - 20" LCB, LC1, LC3, etc,<br />

1500# 2"-20"<br />

2500 # 2" -I Z"<br />

GLOBE VALVE<br />

150 # Z"-12"<br />

300# 2" -1 2"<br />

600# 2"-12"<br />

900# 2"'-12""<br />

1500# 2"-IZ"<br />

2500# 2"- 12"<br />

SWING CHEC K VALVE<br />

150# 1 112 " -30"<br />

300# 1',2" - 24"<br />

600# 2"-Z4"<br />

900# 2" - 20'"<br />

1500# 2"-ZO"<br />

Z500# 2" - 12"<br />

BALL VALVE 150# I/Z"-Z4"<br />

300# 1 / Z" -Z4"<br />

600# Z"-24"<br />

3- WAY BALL VALVE 150 # 1 1/ 2" -S"<br />

300# 1 I/Z"-S"<br />

BUTTERFLY VALVE 150# 2"-24"<br />

300J; Z"-Z4"<br />

STAINLESS AND HIGH ALLOY STEEL<br />

TYPE RATING SIZE MATERIAL REMARKS<br />

GATE VALVE 150# I /Z" - 4S" CFS, CFSM<br />

300# I /Z"-36" CF3, CF3M<br />

600# Z"-Z4" CFSC, CN7M ,<br />

900# 2"-20" HASTELLOY B,C,<br />

1500# Z"-ZO" CGSM , CG3M,<br />

Z500# Z" - IZ" M35-1, Z<br />

150# I/Z"-IZ"<br />

GLOBE VALVE<br />

300# I/Z"-IZ"<br />

DU PLEX etc.<br />

600# 2"-IZ"<br />

900# Z"-I Z"<br />

1500# Z" -I Z"<br />

Z500# Z" -I Z"<br />

SWING CHECK VA LVE<br />

150# I / Z"-30"<br />

300# I /Z"-Z4"<br />

600# Z"-Z4"<br />

900# Z"-ZO"<br />

1500# Z"-ZO"<br />

Z500# Z"-IZ"<br />

BALL VALVE 150# I /Z" -Z4"<br />

300# 1 /Z"- Z4"<br />

600# Z"-Z4"<br />

3- WAY BALL VALVE 150# I I / Z"-S"<br />

300# 1 I /Z"-S"<br />

KNI FE GATE VALVE 150 # 2'" - 24"<br />

BU TTERFLY VALVE 150# Z"-Z4"<br />

300 j;, Z" -Z4"<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.<br />

S

GENERAL INFORMATION<br />

<strong>TONG</strong> <strong>YUNG</strong> STAINLESS STEEL VALVES<br />

1. CASTINGS<br />

All castings for valve production are manufactured in our own casting shop. Raw materials purchased are carefully<br />

inspected before being entered into production to ensure conformity with our standards & required specifications<br />

to meet ASTM. JIS. KS. DIN. & etc.<br />

2. BODIES<br />

Bodies are designed to provide a minimum pressure drop and have a sufficient wall thickness to withstand the<br />

torsion forces and stresses normally encountered in piping systems and to compensate for erosion and corrosion<br />

effects. All wa ll thicknesses are inspected by ultrasonic wall thickness digital indicator.<br />

3. BONNETS<br />

Bonnets are designed in various forms to meet the valve body & operational requirements with connection such as<br />

flat faced, male & female, tongue & groove and ring jOints with gaskets.<br />

4. STEMS<br />

Stems are made in one piece by forging with "r head or "Y" head are provided with bevelled shoulders forming<br />

back seat bushing so that va lves can be easily repacked under pressure when fully opened.<br />

5. GASKETS<br />

Gaskets are made with quality graphite, teflon, soft metal and spiral wound. Asbestos free gaskets are also avaliable.<br />

Gaskets are selected generally accord ing to application flowing media pressure & temperature.<br />

6, PACKINGS<br />

Same as above gaskets.<br />

7. GLANDS<br />

All valves have two piece type gland with a ball joint between the<br />

valve stem.<br />

two in order to prevent marring or binding of t he<br />

8. RATINGS AND FLANGE DIMENSIONS<br />

Ratings, flange dimensions, facings and drilli ngs comply with ANSI B16.5<br />

9. FACE TO FACE DIMENSIONS & END TO END DIMENSIONS<br />

These are conforming to ANSI B16.10 and MSS SP .:12. Valves are furnished with screwed ends, flanged ends and<br />

butt welding ends. When ordering other than standard butt welding ends Please specify schedule of tubing or pipe.<br />

10. HEAVY WALL STAINLESS STEEL VALVES<br />

Heavy wall stainless steel va lves meet API 600 and are manufactured by buyer's request in stead of light wa ll stainless<br />

steel va lves meeting API 603 and ANSI B16.34<br />

11. SPECIFICATIONS<br />

1) Our standards cover valves in classes 150 through 2500. Our valves are the outside screw and yoke type(GATE<br />

& GLOBE VALVE) with a rising stem, bolted bonnet (B.8). pressure Seal Bonnet(P.S) and flexible wedges (from 2" to 48")<br />

2) The body & bonnet's wall thickness shall be kept to control within over minimum shell by ultrasonic wall<br />

thickness digital indicator.<br />

3) The stem connection to a wedge gate shall be a ''1'' head which is integral( without welding) with the one piece<br />

forged stem.<br />

4) The threads of the stem and stem nut shall be the acme type and shall be controlled by gages(go gage & no<br />

go gage).<br />

5) The stem's threads don't run over by lim ited switch controlled automatically as only threading attachment fo r<br />

preventing packing damages.<br />

6) The main trims(yoke sleeve, stem and disc)are pull tested in connected situation.<br />

7) Our chemical compositions are checked by spectrometer(Top Performance Vacuum Em ission Spectrometer).<br />

8) Heat number controls are made by preparing Y-block for chemical compositions and physical properties of each<br />

charge.<br />

9<br />

®<br />

<strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.

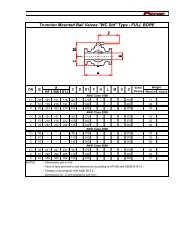

FIGURE NUMBER<br />

)<br />

RATINGS<br />

HEAVY WALL LIGHT WALL<br />

(API 600) (API 603,ANSI BI 6,34)<br />

15 = 150PSI = 10<br />

25= 300PSI =20<br />

35= 600PSI =30<br />

45= 900PSI =40<br />

55= 1500PSI =50<br />

65= 2500PSI = 60<br />

16= lOkg/cm' = II<br />

26= 2Okgfcm' = 21<br />

36= 40kg/cm' = 31<br />

46= 60kglcm ' = 41<br />

56 = 100kg/cm' = 51<br />

VALVE TYPE<br />

1 = Gate<br />

2 = Globe<br />

3 = Swing Check<br />

4:::; Kn ife Gate<br />

5 = Full Port Ball<br />

6 = Reduced Port Ba ll<br />

7 = Butterfly<br />

8::::: Strainer<br />

9=3-Way Ba ll<br />

H = High Temp<br />

END <strong>CO</strong>NNECTIONS<br />

RF = RAISED<br />

FF=FLAT FACE<br />

RJ = RING JOI NT<br />

BW= BUTT WELD<br />

SW = SOCKET WELD<br />

SE = THREADED END<br />

101<br />

RF 001<br />

BODY {BONNET MATERIALS<br />

00 = WCB( Carbon Steel)<br />

01 = WCI(",Mo)(0.5 Mo)<br />

02 = WC6( 1 ",Cr- ",Mo)( 1.25Cr-0.5Mo)<br />

03 = WC 9( 2",Cr-1 Mo)<br />

04 = C5( 5Cr-",Mo)<br />

05=C12(9Cr-1Mo)<br />

06= LC B(Carbon 51. Low Temp.)<br />

07 = LC3(3,,, Ni. Low Temp)<br />

08=CF8(Type 304)<br />

09 = CF8M(Type 316 )<br />

10=CF3( Type 304L )<br />

11 = CF3M(Type 316L)<br />

12 = CF8C( Type 347)<br />

13 = CN7M(Alloy 20)<br />

14 = N- 12MV(HASTELLOY B)<br />

15 = CW-12MW(HASTELLOY C)<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.·<br />

16 = LCC<br />

17 = CFIO<br />

18=M-35(MONEL)<br />

19 = CG8M(Type 317)<br />

20 = CG3M ( Type 317L)<br />

21 = OTHERS<br />

10<br />

TRIM MATERIALS<br />

Page 62

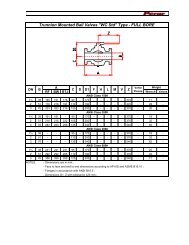

GATE VALVE<br />

BOLTED BONNET, OUT SIDE SCREW & YOKE<br />

CLASS 150<br />

Description Material Specs.<br />

Body Stainless Steel A351 Gr.CF8M<br />

Bonnet Stainless Steel A351 Gr.CF8M<br />

Disc Stainless Steel A351 Gr.CF8M<br />

Stem Stainless Steel AI82 Gr.F316,<br />

Hand Wheel<br />

Ductile Iron or Carbon Steel<br />

Yoke Sleeve Ductile Iron A439 Gr.D2C<br />

Gland Flange Stainless Steel A35 1 Gr.CF8.<br />

Gland Ring Sta inless Steel A276 TYPE316<br />

Bonnet Bolt Stainless Steel AI93 Gr.B8<br />

Bonnet Nut Stainless Steel A194 Gr.8<br />

Gland Bolt Stainless Steel A193 Gr.B8<br />

Gland Nut Stainless Steel A194 Gr.8<br />

Gla nd Bolt Pin Stainless Steel A276 Type304<br />

Sleeve Gland<br />

Wheel Nut<br />

Bearing<br />

Grease Nipple<br />

Set Screw<br />

Name Plate<br />

Packing<br />

Gasket<br />

Stain less Steel<br />

Stainless Steel<br />

Thrust Ba ll<br />

Carbon Steel / Cr Plating<br />

Stainless Steel<br />

Sta inless Steel<br />

PTFE or Graphite<br />

PTFE or Graphite<br />

(/)<br />

0<br />

Face to Face/ End to End ANSI BI 6.IO/ B I 6.25<br />

Flange Dimensions ANS I BI6.5/ B I 6.47<br />

~<br />

~<br />

Basic Design API 603/ ANSI B16.34<br />

Testing API 598<br />

26 " and Larger Flange DimenSions are<br />

AP I 605 or MSS SP 44<br />

~c~<br />

~~ ! I<br />

~ ~ I ~<br />

8<br />

I<br />

I<br />

+<br />

I<br />

r ~ I r- 1t<br />

~ I<br />

I<br />

~<br />

~rCb'<br />

h<br />

'----r-<br />

+--<br />

\TI<br />

I<br />

.- - i '-----<br />

)<br />

f---I<br />

L-J<br />

t=<br />

1:::::1<br />

~-------A --------~<br />

Size(ln Inches} 1/2 3/4 1 1,n 2<br />

A. Face to Face R.F<br />

4 1 1 ~<br />

4" 5 6 1 !1<br />

7<br />

A. End to End 8.W. '1' /4 iI!>' 5 6'" 8,n<br />

B. Valve Open . 7'" 8 8" 11 14 143.'4<br />

C. Hand Wheel Dia 6 6 6 7 7<br />

We ight( Lbs) 11 12 15 25 36<br />

2,n<br />

7'"<br />

9'"<br />

16 114<br />

7<br />

46<br />

3<br />

8<br />

lllill<br />

18 1n<br />

9<br />

57<br />

4 6<br />

9<br />

JOIIZ<br />

12 15 M1<br />

22 718 29~<br />

10 12<br />

92 155<br />

8 10 12<br />

11 ln 13 14<br />

16 1 /2 18 19'"<br />

37S18 45 531 !B<br />

14 16 18<br />

230 345 495<br />

14 16<br />

15 16<br />

22,n 24<br />

SO" 67 112<br />

22 22<br />

740 IIXlI<br />

18 20 22 24 26 28 30 32 36<br />

17 18 20 20 22 24 24 26 26<br />

26 28 30 32 34 36 36 38 40<br />

76 84)/1) 92" 99 1Ot'1 114 123 14 128'1Z 141 1 .':<br />

22 24 26 26 32 32 32 32 32<br />

42 48<br />

31 36<br />

43 -<br />

181'/1 lW''3 )<br />

- -<br />

I~ 1!ill 2210 1740 3320 4510 4.'lXI 5IISJ 6850 11400 15450<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.<br />

12

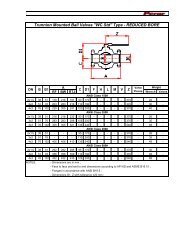

GATE VALVE<br />

BOLTED BONNET, OUT SIDE SCREW & YOKE<br />

CLASS 300<br />

Description Material Specs.<br />

Body Stainless Steel A351 Gr .CFSM<br />

Bonnet Stainless Steel A35 1 Gr .CFSM<br />

Disc Stainless Steel A35 1 Gr.CFSM<br />

Stem Stainless Steel AIS2 Gr.F 316.<br />

Hand Wheel<br />

Ductile Iron or Carbon Steel<br />

Yoke Sleeve Ductile Iron A439 Gr.D2C<br />

Gland Flange Stainless Steel A351 Gr. CFS.<br />

Gland Ring Stainless Steel A276 Type316<br />

Bonnet Bolt Stainless Steel AI 93 Gr.BS<br />

Bonnet Nut Stainless Steel AI 94 Gr .S<br />

Gland Bol t Stainless Steel AI93 Gr .BS<br />

Gla nd Nut Stainless Steel AI 94 Gr .S<br />

Gland Bolt Pin Stainless Steel A276 Type304<br />

Sleeve Gland<br />

Wheel Nut<br />

Bearing<br />

Grease Nipple<br />

Set Screw<br />

Name Plate<br />

Packing<br />

Gasket<br />

Stainless Steel<br />

Stai nless Steel<br />

Thr ust Ball<br />

Carbon Steel / Cr Plating<br />

Stainless Steel<br />

Stainless Steel<br />

PTFE or Graphite<br />

PTFE or Graphite<br />

C/)<br />

£:)<br />

Face to Face/ End to End ANSI BI 6.1 0/ B I 6. 25<br />

Flange Dimensions ANSI 8 16.5/ 8 16.47<br />

~<br />

~<br />

Basic Design API 600/ ANSI 816.34<br />

Test ing<br />

API 59S<br />

26" and La rger Flange Dimen si ons are<br />

API 605 or MSS SP 44<br />

c<br />

A<br />

} II?<br />

Size(ln Inches) 1/ 2 3/ 4 I<br />

A. Fa ce to Fa ce R.F. 5 1 • 1 6 6'·7 7'.1<br />

A. End to End B.W. 5"1 6 6)·7 7'"<br />

B. Valve Open 7"<br />

8' ,' ~<br />

9 14<br />

C. Hand Wheel Dia 4 4 7 9<br />

2<br />

8'·1<br />

8' ·1<br />

1~ '<br />

9<br />

2 1 r. 3 4<br />

9'i2 1 1 1 , ~<br />

12<br />

9 'il 11 ,,1 12<br />

17 1 9 ' 1~<br />

23'"<br />

9 10 12<br />

"<br />

6 S 10 12 14 16 I S 20 24 26 2S 30 32 36<br />

IS)'! 16 1 .'1<br />

18 1~ 30 33 36 39 45 49 53 55 60 68<br />

IS'" 16'" 18 19"1 30 33 36 39 45 49 53 55 60 68<br />

3 1 ~$<br />

35" 46'/1 54 M WI'l 70 'i~<br />

TI" 86" 101 '12 110),1 121 "<br />

1 1 3 1 ~! 140"7 153"<br />

16 18 20 22 22 22 24 25 32 32 40 40 40 59<br />

Welght( Lbs) 12 IS 22 36 47 67 90 136 270 420 620 865 1345 2140 2580 31 50 5120 6620 8325 10035 11 970 15835<br />

13<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.

GATE VALVE<br />

BOLTED BONNET, OUT SIDE SCREW & YOKE<br />

CLASS 600<br />

Description Material Specs.<br />

Body Stainless Steel A351 Gr.CFBM<br />

Bonnet Stainless Steel A351 Gr.CFBM<br />

Disc Stainless Steel A351 Gr.CFBM<br />

Stem Stainless Steel AIB2 Gr.F316,<br />

Hand Wheel<br />

Ductue Iron or Carbon Steel<br />

Yoke Sleeve Ductile Iron A439 Gr.D2C<br />

Gland Flange Stainless Steel A351 Gr.CFB.<br />

Gland Ring Stainless Steel A276 Type316<br />

Bonnet Bol t Stainless Steel AI93 Gr.BB<br />

Bonnet Nut Stainless Steel AI 94 Gr.B<br />

Gland Bolt Stainless Steel AI93 Gr,8B III<br />

Gland Nut Stainless Steel AI94 Gr,B<br />

Gland 80lt Pin Stainless Steel A276 Type304<br />

Sleeve Gland Stainless Steel<br />

Wheel Nut<br />

Stainless Steel<br />

Bearing<br />

Thrust Ball<br />

Grease Nipple Carbon Steel 1 Cr Pla ting<br />

Set Screw Stainless Steel<br />

Name Pla te Stainless Steel<br />

'---<br />

Packing<br />

PTFE or Gra ph ite<br />

Gasket<br />

PTFE or Graph ite<br />

en<br />

0<br />

Face to FacelEnd to End ANSI 8 16.10/816.25<br />

Flange Dimensions ANSI 816.5/BI6.47<br />

~<br />

~<br />

Basic Design API 600 / ANSI 8 16.34<br />

en Testing API 59B<br />

,<br />

,.,<br />

c<br />

-:::::: ;::::::-<br />

l )<br />

~<br />

~<br />

~<br />

r-- ---..,<br />

i<br />

/I<br />

.-- r--l<br />

f---<br />

~ 6 /<br />

~<br />

- -"....<br />

f..---+<br />

+= ==l<br />

::::j<br />

t:::<br />

A<br />

Size(ln Inches) 2 t /2 3 4 6 8<br />

A. Face to Face R.F. I llfl 13 14 17 22 26<br />

A. Face to Face R.T.J. 11 ~ Ia<br />

13 1111 14 118 17 118 22 118 26 118<br />

A. End to End B.W. 111 ft 13 14 17 22 26<br />

B. Va lve Height ISm 18 20' 14 25 118 33 40 112<br />

C. Lever Length 9 10 12 16 20 22<br />

Weight( Lbs) 70 90 120 220 490 800<br />

10 12 14 16 18 20 24 -<br />

31 33 35 39 43 47 55<br />

31 111 33 1 / 8 35 118 39 118 43118 47 1/ 8 551/8<br />

31 33 35 39 43 47 55<br />

50 58 112 65 518 72'18 79' ,4 92 102 314<br />

22 24 26 26 32 32 32<br />

1480 2040 2810 3600 4920 6350 9480<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.<br />

14

GATE VALVE<br />

BOLTED BONNET, OUT SIDE SCREW & YOKE<br />

CLASS 900<br />

Description Material Specs.<br />

Body Stainless Steel A351 Gr.CF8M<br />

Bonnet Stainless Steel A351 Gr.CF8M<br />

Disc Stainless Steel A351 Gr.CF8M<br />

Stem Stainless Steel AI82 Gr.F316<br />

Hand Wheel<br />

Ductile Iron or Carbon Steel<br />

Yoke Sleeve Ductile Iron A439 Gr.D2C<br />

Gland Flange Stainless Steel A351 Gr.CF8.<br />

Gland Ring Stainless Steel A276 Gr.316<br />

Bonnet Bolt Stainless Steel AI93 Gr.B8<br />

Bonnet Nut Sta inless Steel AI94 Gr.8<br />

Gland Bolt Stainless Steel AI93 Gr.B8<br />

Gland Nut Stainless Steel AI 94 GL8<br />

Gland Bolt Pin Stainless Steel A276 Type304<br />

Sleeve Gland<br />

Wheel Nut<br />

Grease Nipple<br />

Set Screw<br />

Name Plate<br />

Packing<br />

Gasket<br />

Stainless Steel<br />

Stainless Steel<br />

Carbon Steel 1 Cr Plating<br />

Stainless Steel<br />

Stainless Steel<br />

Graphite(V.D.C)<br />

Stainless Steel<br />

Face to Face/ End to End ANSI BI 6.IO/B I 6.25<br />

~<br />

Flange Dimensions ANS I B16.5<br />

~<br />

Cl B.W End Dimensions AN SI 816.25<br />

~<br />

Basic Design API 600, ANSI B16.34<br />

Testing API 598<br />

IilC<br />

A<br />

Size(ln Inches) 2<br />

2 112<br />

3 4 6 8 10 12 14 16 18 20<br />

A. R.F-BW<br />

14 1 1 ~<br />

\6 111 15 18 24 29 33 38<br />

.tlQlll Ll4 12 48 52<br />

A. R.T.!. 14 5/5 i6'!S 15"a 18 1/t 24 11S 29" B 33,·a 38 1 / 8 40 71 6 Ll4 718 48 '1Z 52" 2<br />

B. Va lve Open. 25 28 28 32 1/8 43 52 112 61 73 '/2 85" 2 95 103 1 ; l 110 112<br />

C. Hand Wheel Dia 14 14 18 22 24 32 32 32 40 40 51 51<br />

Weight( Lbs) 220 310 320 530 1070 1870 2200 3750 5250 7400 9510 12390<br />

15<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.

GATE VALVE<br />

BOLTED BONNET, OUT SIDE SCREW & YOKE<br />

CLASS 1500<br />

Descri ption Material Specs.<br />

80dy Stainless Steel A351 Gr.CF8M<br />

Bonnet Stainless Steel A351 Gr.CF8M<br />

Disc Stainless Steel A351 Gr .CF8M<br />

Stem Stainless Steel AI82 Gr. F316<br />

Hand Wheel<br />

Ductile Iron or Carbon Steel<br />

Yoke Sleeve Ductile Iron A439 Gr.D2C<br />

Gland Fl ange Stainless Steel A35 1 Gr.CF8.<br />

Gland Ring Stainless Steel A276 Type316<br />

Bonnet Bolt Stainless Steel AI93 Gr .88<br />

Bonnet Nut Stainless Steel AI94 Gr.8<br />

r land 80lt Stainless Steel AI93 Gr.88<br />

Gland Nut Stainless Steel AI94 Gr.8<br />

Gland 80lt Pin Stainless Steel A276 Type304<br />

Sleeve Gland<br />

Wheel Nut<br />

Grease Nipple<br />

Set Screw<br />

Name Plate<br />

Packing<br />

Gasket<br />

Stainless Steel<br />

Stainless Steel<br />

Carbon Steel 1 Cr Plating<br />

Stainless Steel<br />

Stainless Steel<br />

Graphite(V.D.C)<br />

Stainless Steel<br />

Face to Face/End to End ANSI 816.1 0/816.25<br />

gs<br />

Flange Dimensions ANSI 816.5<br />

~ B.W End Dimensions ANSI 816.25<br />

g Basic Design API 600, ANSI 816.34<br />

Testing API 598<br />

~c<br />

HI-"'~ ft- - --<br />

A<br />

Size(ln Inches) 2<br />

21 / 2<br />

3 4 6 8<br />

A. R.F-8W 14'1< 16'12 18 21 27 31 4 32 31 4<br />

A. R.T .J. 14 S,S 16 s/ 8 lS s,a 21 5/8 28 33' IS<br />

8. Va lve Open. 25 28 30 3 / 4 36 47 114 57<br />

C. Hand Wheel Dia 14 14 18 22 24 32<br />

Weight( Lbs) 220 310 360 562 1300 2400<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.<br />

16<br />

10 12 14 16 18 20<br />

39 44 49'/2 54'1< 60'/2 65" 2<br />

39 J / 8 45'18 50" 4 55 318 613/3 66 318<br />

64 1 / ' 73 80 " 4 88 1 / " 96 105<br />

32 40 40 51 51 51<br />

4200 7620 10620 14550 17320 20800

GATE VALVE<br />

BOLTED BONNET, OUT SIDE SCREW & YOKE<br />

CLASS 2500<br />

Description Material Specs.<br />

c<br />

Body Stainless Steel A351 Gr.CFSM<br />

Bonnet Stainless Steel A35 1 Gr.CFSM<br />

Disc Stainl ess Steel A351 Gr .CFSM<br />

Stem Stainless Steel A1S2 Or .F3 16<br />

Hand Wheel<br />

Ductile Iron or Carbon Steel<br />

Yoke Sleeve Ductile Iron A439 Gr.D2C<br />

Gland Flange Stainless Steel A351 Or .CF8.<br />

Gland Ring St ainless Steel A276 Type316<br />

Bonnet 60lt Stainless Steel A193 Gr.BS<br />

Bonnet Nut Stainless Steel A194 Or.8<br />

Oland Bolt Stainless Steel A1 93 Or .6S<br />

Oland Nut Stainless Steel A1940r.S<br />

Gland Bolt Pin Stainless Steel A276 Type304<br />

Sleeve Gland<br />

Wheel Nut<br />

Grease Nipple<br />

Set Screw<br />

Name Plate<br />

Packing<br />

Gasket<br />

Stainless Steel<br />

Stainless Steel<br />

Carbon Steel 1 Cr Plating<br />

Stainless Steel<br />

Stainless Steel<br />

Graphite(V.O.C)<br />

Stain less Steel<br />

Face to Face/End to End ANSI 616.10/616.25<br />

en<br />

Cl<br />

Flange Dimensions ANSI B16.5<br />

~ B.W End Dimensions ANSI 6 16.25<br />

g Basic Design API 600, ANSI B16.34<br />

Testing API 59S A<br />

CD<br />

$- - --Ht- : -1-

GATE VALVE<br />

PRESSURE SEAL TYPE<br />

CLASS 600<br />

Description<br />

Body<br />

Bon net<br />

Disc<br />

Stem<br />

Hand Wheel<br />

Material<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Specs.<br />

A351 Gr.CF8M<br />

A351 Gr .CF8M<br />

A351 Gr.CF8M<br />

AI 82 Gr.F316.<br />

Ductile Iron or Carbon Steel<br />

Yoke Sleeve Duct ile Iron A439 Gr.D2C<br />

Gland Flange Stainless Steel A351 Gr.CF8.<br />

Gland Ring Stainless Steel A276 Type316<br />

Bonnet Bolt Stainless Steel AI93 Gr.B8<br />

Bonnet Nut Stainless Steel AI94 Gr.8<br />

Gland Bolt Stainless Steel AI 93 Gr .B8<br />

Gland Nut Stainless Steel AI 94 Gr.8<br />

Gland Bolt Pin Stainless Steel A276 Type304<br />

Sleeve Gland<br />

Wheel Nut<br />

Bearing<br />

Grease Nipple<br />

Set Screw<br />

Name Plate<br />

Packing<br />

Gasket<br />

Stainless Steel<br />

Stain less Steel<br />

Thrust Ball<br />

Carbon Steel 1 Cr Plating<br />

Stainless Steel<br />

Stainless Steel<br />

Graphite(V.O.C)<br />

Stainless Steel<br />

Face to Face/End to End<br />

ANSI BI6.10/BI6.25<br />

~ Flange Dimensions ANSI B16.5<br />

~ B. W End Dimensions ANSI B16.25<br />

~<br />

Basic Design API 600, ANSI B16.34<br />

en<br />

Testing API 598<br />

ID<br />

c<br />

A<br />

Size(ln Inches) 2<br />

2 112<br />

3 4 6<br />

A. R. F. 11112 13 14 17 22<br />

A. Shot Pattern aw. 7 8 1f1 10 12 18<br />

B. Va lve Open. 16'/2 20 1/~ 22 25 36<br />

C. Hand Wheel Dia 9 10 12 16 20<br />

Weight( Lbs) 100 140 180 290 615<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.<br />

8 10 12 14 16 18 20 24<br />

26 31 33 35 39 43 47 55<br />

23 28 32 35 39 43 47 55<br />

45 ' 11 54 62 66 112 74 '12 81 92 l iD<br />

22 22 24 26 26 32 32 32<br />

940 1360 2030 2600 3860 5150 6400 8400<br />

18

GATE VALVE<br />

PRESSURE SEAL TYPE<br />

CLASS 900<br />

Description Material Specs.<br />

Body Stainless Steel A351 Gr.CF8M<br />

Bonnet Stainless Steel A35 1 Or.C F8M<br />

Disc Stainless Steel A35 1 Or.CF8M<br />

Stem Stainless Steel AI82 Or.F316,<br />

Hand Wheel<br />

Ductile Iron or Carbon Steel<br />

Yoke Sleeve Ductile Iron A439 Or.D2C<br />

Oland Flange Stainless Steel A351 Or.CF8.<br />

Oland Ring Stainless Steel A276 Type316<br />

Bonnet Bolt Stainless Steel A1930r.B8<br />

Bonnet Nut Stainless Steel AI 94 Or.8<br />

Oland Bol t Stainless Steel AI93 Or.B8<br />

Oland Nut Stainless Steel AI94 Or.8<br />

Oland Bolt Pin Stainless Steel A276 Type304<br />

Sleeve Oland<br />

Wh eel Nut<br />

Bearing<br />

Grease Nipple<br />

Set Screw<br />

Name Plate<br />

Packing<br />

Oasket<br />

Stainless Steel<br />

Stainless Steel<br />

Thrust Ball<br />

Carbon Steel / Cr.plating<br />

Stainless Steel<br />

Stainless Steel<br />

Graphite(V.O.C)<br />

Stainless Steel<br />

en Face to Face/ End to End ANSI BI6.10/ BI 6.25<br />

Cl<br />

Flange Dimensions ANSI B16.5<br />

~ B.W End Dimensions ANSI B16.25<br />

~ Basic Design API 600, ANSI B 16.34<br />

en<br />

Testing API 598<br />

ID<br />

c<br />

A<br />

Size(ln Inches) 2<br />

2 1/2<br />

3 4 6<br />

A. R.F. 14"2 16 '12 15 18 24<br />

8<br />

29<br />

10 12<br />

33 38<br />

14<br />

40'12<br />

16 18 20<br />

44 "2 48 52<br />

A. Shot Pattern B.W. 8 H 2 10 12 14 20<br />

B. Valve Open. 23 114 2r l s 29 118 34'14 44 ' / 8<br />

C. Hand Wh eel Dia 14 16 18 22 24<br />

26<br />

5271 ~<br />

32<br />

31 36<br />

59 11 2 67 J/ B<br />

32 32<br />

39<br />

74<br />

40<br />

43 48 52<br />

S1 118 89 114 96,,.5<br />

40 51 51<br />

Weight(Lbs) 160 220 250 470 870<br />

1650<br />

2200 2900<br />

3700<br />

4900 6100 8000<br />

Note 900" 8 2" & 2, n- are the same as 1500 ' 9 2" & 2 112"<br />

19<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.

GATE VALVE<br />

PRESSURE SEAL TYPE<br />

CLASS 1500<br />

Description<br />

Body<br />

Bonnet<br />

Disc<br />

Stem<br />

Hand Wheel<br />

Material<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Specs.<br />

A351 Gr.CF8M<br />

A351 Gr.CF8M<br />

A351 Gr.CF8M<br />

A182 Gr .F3 16,<br />

Ductile Iron or Carbon Steel<br />

Yoke Sleeve Ductile Iron A439 Gr .D 2C<br />

Gland Flange Stainless Steel A35 1 Gr. CF8.<br />

Gland Ring Stainless Steel A276 Type316<br />

Bonnet Bolt Stainless Steel AI93 Gr .B8<br />

Bonnet Nut Stainless Steel AI94 Gr.8<br />

Gland Bolt Stainless Steel A193 Gr.B8<br />

Gland Nut Stainless Steel AI94 Gr.8<br />

Gland Bolt Pin Stainless Steel A276 Type304<br />

Sleeve Gland<br />

Wheel Nut<br />

Bearing<br />

Grease Nipple<br />

Set Screw<br />

Name Plate<br />

Stainless Steel<br />

Stainless Steel<br />

Thrust Bal l<br />

Ca rbon Steel / Cr. plating<br />

Stainless Steel<br />

Stainless Steel<br />

Packing Graphite(V.O.C )<br />

Gasket<br />

Stainless Steel<br />

Face to Face/ End to End AN SI BI 6.IO/ BI 6.25<br />

en<br />

0<br />

a: Flange Dimensions ANSI B16.5<br />

C§ B.W End Dimensions ANSI B16.25<br />

~<br />

Basic Design API 600, ANSI B16.34<br />

en<br />

Testing API 598<br />

c<br />

A<br />

SizeOn Inches) 2 t /2 3 4 6<br />

A. R. F 111 " z 16 11l 18 11Z 211 /2 27 316<br />

A. End to End BW 8" 2 10 12 16 22<br />

B. Valve Open. 23'/4 27 5 i ~<br />

30 m 34 51 8 L16,n<br />

C. Hand Wheel Oia 14 16 18 22 24<br />

Weight (Lbs) 160 220 300 600 1460<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.<br />

8 10 12 14 16 18 20<br />

32 3/~<br />

39 44 1 1< 49 112 54 112 60 tl2 65 112<br />

28 34 39 42 47 53 58<br />

52 m 59 112 67 3/8 74 81 1 8<br />

89 114 96 111 6<br />

32 32 40 40 51 51 51<br />

2790 3700 4870 6560 9470 12280 15130<br />

20

GATE VALVE<br />

PRESSURE SEAL TYPE<br />

CLASS 2500<br />

Description Material Specs.<br />

Body Stainless Steel A351 Gr .C FSM<br />

Bonnet Stainless Steel A351 Gr.CFSM<br />

Disc Sta inless Steel A351 Gr.CFSM<br />

Stem Stainless Steel A1S2 Gr.F316.<br />

Hand Wheel<br />

Ductile Iron or Carbon Steel<br />

Yoke Sleeve Ductile Iron A439 Gr.D2C<br />

Gland Flange Stainless Steel A351 Gr .CFS.<br />

Gland Ring Stainless Steel A276 Type3 16<br />

Bonnet Bolt Stainless Steel A193 Gr .B8<br />

Bonnet Nut Stainless Steel A194 Gr.8<br />

Gland Bolt Stainless Steel A193 Gr.B8<br />

Gland Nut Sta inless Steel A194 Gr.8<br />

Gland Bolt Pin Sta inless Steel A276 Type304<br />

Sleeve Gland<br />

Wheel Nut<br />

Bearing<br />

Grease Nipple<br />

Set Screw<br />

Name Plate<br />

Packing<br />

Gasket<br />

Sta inless Steel<br />

Stainless Steel<br />

Thrust Bali<br />

Carbon Steel 1 Cr Plating<br />

Stainless Steel<br />

Stainless Steel<br />

Graphite<br />

Stainless Steel<br />

Face to Facel End to End ANSI BI6.10/ 8 16.25<br />

(J)<br />

Cl Flange Dimensions AN SI B16.5<br />

~ B.W End Dimensions ANSI 816.25<br />

z<br />

~<br />

Bas ic Design API 600. ANSI 816.34<br />

Testing API 598<br />

OJ<br />

c<br />

A<br />

Size(ln Inches) 2<br />

2 1/2<br />

3 4 6<br />

8<br />

10<br />

12<br />

A. Face to Face R.F. 171/4 20 22 11 &<br />

26 'lZ 36<br />

L1D It '<br />

50<br />

56<br />

A. End to End B.W 11 13 14'11 I S 24<br />

8. Valve Open. 20 ' f 4 25 25 718 26'12 40<br />

C. Hand Wheel Dia 16 18 20 22 24<br />

Weight( Lbs) 176 352 375 620 1460<br />

30<br />

4S<br />

32<br />

3300<br />

36<br />

60 1i 2<br />

40<br />

4400<br />

41<br />

66 1;1<br />

40<br />

63S0<br />

21<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.

GLOBE VALVE<br />

BOLTED BONNET, OUT SIDE SCREW & YOKE<br />

CLASS 150<br />

Description Material Specs.<br />

Body Stainless Steel A351 Gr .CFSM<br />

Bonnet Stainless Steel A351 Gr .CFSM<br />

Disc Stainless Steel A351 Gr.CFSM<br />

St em Stainless Steel AI S2 Gr.F316,<br />

Hand Wheel<br />

Ductil e [ron or Carbon Steel<br />

Gland Flange Stainless Steel A351 Gr.CFS<br />

Gland Ring Stainless Steel A276 Type316<br />

Disc Gland Stainl ess Steel A35 1 Gr.CFSM<br />

Yoke Bush Ductile Iron A439 Gr.D2C<br />

Bonnet Bolt Stainless Steel AI93 Gr.BS<br />

Bonnet Nut Stainless Steel AI94 Gr.S<br />

Gland Bolt Stainl ess Steel AI 93 Gr.BS<br />

Gland Nut Stainless Steel AI 94 Gr. S<br />

Gland Bolt Pin Stainless Steel A276 Ty pe304<br />

Wheel Nut Stainless Steel<br />

Name Plate Stainless Steel<br />

Packing<br />

PTFE or Graphite, Asbestos free<br />

Gasket<br />

PTFE or Graphite<br />

B<br />

CIJ<br />

0<br />

Face to Face/End to End ANSI BI6.10/ BI 6.25<br />

~<br />

Flange Dimensions ANSI B16.5<br />

Basic Design ANSI B16.34<br />

~<br />

CIJ Testing API 59S<br />

10" & Larger : 1. Yoke sleave with bearing<br />

2. Stem Guide<br />

I-----.A -<br />

-----J.I<br />

SizeOn Inches) 1/2 3/4 1<br />

A. Face to Face R,F.<br />

4 1/ 4<br />

4 518 5<br />

A. End to End B, W<br />

4 1/ 4<br />

4 5/ 6 5<br />

B. Va lve Open. 7 314 S 9'/8<br />

1 1/ 2<br />

6 112<br />

6 112<br />

11 118<br />

2<br />

S<br />

S<br />

1 1"~<br />

2 112<br />

8 1/ 2<br />

8 1/ 2<br />

12 3/ 4<br />

3 4 6 8 10 12 -<br />

91/2 11 11 ,<br />

16 19'/2 241/2 27 12 -<br />

9 112 11112 16 19' 12 241/2 271/2 -<br />

147IB 17 J ! 4 20'14 22 31 4 2931 ~<br />

32 m -<br />

C. Hand Wheel Dia 4 4 5<br />

S<br />

S<br />

9<br />

10 12 14 16 22 22 -<br />

Weight( Lbs) S I I 14<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.<br />

27<br />

3S<br />

52<br />

74 109 205 345 655 1045 -<br />

22

GLOBE VALVE<br />

BOLTED BONNET, OUT SIDE SCREW & YOKE<br />

CLASS 300<br />

Description Material Specs.<br />

Body St ainless Steel A35 1 Gr.CF8M<br />

Bonnet Stainless Steel A351 Gr .CF8M<br />

Disc Stainless Steel A351 Gr.C F8M<br />

Stem Stainless Steel AI 82 Gr.F316.<br />

Hand Wheel<br />

Ductile Iron or Carbon Steel<br />

Gland Fla nge Stainless Steel A35 1 Gr.CF8<br />

Gland Ring Stainless Steel AI 82 Gr .F316<br />

Disc Gland Stainl ess Steel A35 1 Gr.CF8M<br />

Yoke Bush Ductile Iron A439 Gr.D2C<br />

Bon net Bolt Stainless Steel AI 93 Gr.B8<br />

Bonnet Nut Stai nless Steel AI 94 Gr.8<br />

Gland Bol t Stain less Steel A 193 Gr. B8<br />

Gland Nut Stainless Steel AI94 Gr.8<br />

Gland Bolt Pin Stainless Steel AI 82 Gr .F304<br />

Wheel Nut<br />

Name Plate<br />

Packing<br />

Gasket<br />

Stainless Steel<br />

Stainless Steel<br />

Asbestos Free<br />

PTFE or Graphite<br />

PTFE or Graphite<br />

(f)<br />

Face to Face/ End to End ANSI B 16.1 OI B 16.25<br />

0<br />

;§ Flange Dimensions ANSI B16. 5<br />

Basic Design ANSI 600.<br />

~<br />

(f) Test ing API 598<br />

8 ~ & Larger : 1. Yoke sleave wit h bearing<br />

2. St em Guide<br />

B16.34<br />

B<br />

~-------- c --------~<br />

f------------A ----------I<br />

Size(ln Inches) 1/2 3/4 1<br />

A. Face to Face R. F. 6 7 8<br />

A. End to End B.W 6 7 8<br />

B. Va lve Open. 8'18 9 10 118<br />

C. Hand Wheel Oia 4 5 6<br />

Weight( Lbs) I I 14 19<br />

1 1/2<br />

9<br />

9<br />

11 5/ 8<br />

8<br />

40<br />

2<br />

101/2<br />

1 GI /Z<br />

l t l2<br />

8<br />

51<br />

2 1/2<br />

3 4 6 8 10 12 -<br />

111 12 12 112 14 17112 22 24 12 28 -<br />

11112 12'/2 14 17 Tn 22 241/2 28 -<br />

13'12 15,18 l S: lIS 2t / S 27 s/S 32 s/8 367/S -<br />

9 10 12 16 22 22 22 -<br />

78 100 135 300 510 830 1460 -<br />

23<br />

®<br />

<strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.

GLOBE VALVE<br />

BOLTED BONNET, OUT SIDE SCREW & YOKE<br />

CLASS 600<br />

Description Material Specs.<br />

Body Stainless Steel A351 Gr.CF8M<br />

Bonnet Stainless Steel A351 Gr.CF8M<br />

Disc Stainless Steel A351 Gr.CF8M<br />

Stem Stainless Steel AI82 Gr. F316,<br />

Hand Wheel<br />

Ductile Iron or Carbon Steel<br />

Gland Flange Stainless Steel A35 1 Gr.CF8<br />

Gland Ring Stainless Steel AI 82 Gr.F316<br />

Disc Gland Stainless Steel A351 Gr.CF8M<br />

Yoke Bush Ductile Iron M39 Gr.D2C<br />

Bonnet Bolt Stainless Steel A193 Gr.B8<br />

Bonnet Nut Stainless Steel A194 Gr.8<br />

Gland Bolt Stainless Steel A193 Gr.B8<br />

Gland Nut Stainless Steel A194 Gr.8<br />

Gla nd Bolt Pin Stainless Steel AI82 Gr.F304<br />

Wheel Nut Stainless Steel<br />

Name Plate Stainless Steel<br />

Packing<br />

Asbestos Free<br />

PTFE or Graphite<br />

Gasket<br />

PTFE or Graphite<br />

'"<br />

(f)<br />

Face to Face/ End to End ANSI BI 6.10/ BI6.25<br />

~<br />

~<br />

Flange Dimensions ANSI B16.5<br />

Ba sic Design ANSI B16.34<br />

(f) Testing API 598<br />

6" & Larger: 1. Yoke sleave with bearing<br />

2. Stem Guide<br />

c<br />

~~------<br />

A<br />

Size(ln Inches) 2 t '2 3<br />

A. Face to Face RF. 11112 13 14<br />

A. Face 10 Face R.T.J 11 5ft 13" 8 14'/8<br />

4<br />

17<br />

17"8<br />

6<br />

22<br />

22'/8<br />

8<br />

26<br />

26 '/8<br />

10 12<br />

31 33<br />

31 1ft 33"'<br />

A. End to End B.W 11 1l 13 14<br />

B. Valve Open. 16 314 17 1/~ 21 12<br />

17<br />

16 518<br />

22<br />

35<br />

26<br />

39 1 /~<br />

31 33<br />

38 43 318<br />

C. Hand Wheel Dia 10 12 14<br />

18<br />

22<br />

26<br />

24 26<br />

Weight( Lbs) 95 127 205<br />

335<br />

734<br />

1120<br />

1515 1970<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.<br />

24

GLOBE VALVE<br />

BOLTED BONNET, OUT SIDE SCREW & YOKE<br />

CLASS 900<br />

Description Material Specs. ~c<br />

Body Sta inless Steel A351 Gr.C F8M<br />

Bonnet Stainless Steel A351 Gr.CF8M<br />

Disc Stamless Steel A351 Gr.CF8M<br />

Stem Stainless Steel AI82 Gr.F316<br />

Hand Wheel<br />

Duct ile Iron or Carbon Steel<br />

Seat Ring Stainless Steel AI82 Gr.F316<br />

Yoke Sleeve Duc tile Iron A439 Gr.D2C<br />

Sleeve Gland Stainless Steel A35 1 Gr.CF8<br />

Gland Flange Sta inless Steel A35 1 Gr.CF8<br />

Gland Ring Stainless Steel A276 Type3 16<br />

Disc Gland Stainless Steel A351 Gr.CF8M<br />

Wheel Nut Stainless Steel A351 Gr.CF8<br />

CD<br />

Bon net Bolt Stainless Steel AI93 Gr .B8<br />

Bonnet Nut Stainless Steel AI94 Gr.8<br />

Gland Bolt Stainless Steel AI93 Gr.B8<br />

Gland Nut Stainless Steel AI 94 Gr.8<br />

Gland Bolt Pin Stainless Steel A276 Type304<br />

Bearing<br />

thrust Ball<br />

Name Plate Stainless Steel<br />

Packing<br />

Graphite(V.O.C). Asbestos free<br />

Gasket<br />

Stainless Steel<br />

Face to Face/ End to End ANSI B16. 10<br />

en<br />

0 Flange Dimensions ANSI B16.5<br />

g B.W End Dimensions ANSI B16.25<br />

~ Basic Design BS 1873<br />

en<br />

Testing API 598<br />

A<br />

Size(ln Inches) 2<br />

2 112<br />

3 4 6 8 10 12<br />

A. Face to Face R.F-BW Ill! l? 16 112 15 18 24 29 33 38<br />

A. Face to Face R.T.! 1.:1 513 165/ ~<br />

15 118 18 118 24 118 29 11 8 33 ' /8 38 ' 18<br />

B. Valve Open. 23 26 1/ 2 2r l8 33 41 112 47 54 112 65<br />

C. Hand Wheel Dia 16 16 22 24 32 32 32 40<br />

Weight( Lbs) 260 400 380 590 1050 1780 2710 3950<br />

25<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.

GLOBE VALVE<br />

BOLTED BONNET, OUT SIDE SCREW & YOKE<br />

CLASS 1500<br />

Description Material Specs.<br />

Body Stainless Steel A351 Gr .C F8M<br />

Bonnet Stainless Steel A351 Gr.CF8M<br />

Disc Stainless Steel A351 Gr.CF8M<br />

Stem Stainless Steel AI82 Gr.F316<br />

Hand Wheel<br />

Ductile Iron or Carbon Steel<br />

Yoke Sleeve Ductile Iron A439 Gr .D2C<br />

Sleeve Gland Stainless Steel A35 1 GL CF8<br />

Gland Flange Stainless Steel A35 1 Gr.CFB<br />

Gland Ring Stainless Steel A276 Type316<br />

Disc Gland St ainless Steel A35 1 Gr.C FSM<br />

Wheel Nut Stainless Steel A35 1 Gr.CFS<br />

Bonnet 80lt Stainless Steel AI 93 Gr .BS<br />

Bonnet Nut Stainless Steel AI 94 Gr .S<br />

Gland Bolt Stainl ess Steel AI 93 Gr.BS<br />

Gland Nut Stainless Steel AI 94 Gr.8<br />

Glan d Bolt Pin Stai nl ess Steel A276 Type304<br />

Bearing<br />

Name Plate<br />

Packing<br />

Gasket<br />

thrust Ball<br />

Stainless St eel<br />

Graphite(V.O.C ) . Asbestos free<br />

Stainless Steel<br />

Face to Face/End to End ANSI B1 6.10<br />

en<br />

0 Flange Dimensions ANSI B16.5<br />

~ B. W End Dimensions ANSI B16.25<br />

~ Basi c Design BS I S73<br />

en<br />

Test ing API 598<br />

CD<br />

!6C<br />

A<br />

Size(Jn Inches) 2<br />

2 112<br />

3 4 6 8<br />

A. Face to Face R.F. 14'12 16 '12 18,n 21 '12 27 Ji4 32 314<br />

A. Face to Face R.T.J 1 4 S ' ~ 16 5/ & 18 518 2]5/8 28 33' ,8<br />

B. Valve Open. 23 26'12 31 33 '12 443/4 54' .14<br />

C. Hand Wheel Dia 16 16 22 24 32 32<br />

Weight ( Lbs) 260 400 450 700 1480 2240<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>. 26<br />

10 12<br />

39 44'IZ<br />

39 ~,e<br />

45 ' 18<br />

60 74'12<br />

40 40<br />

35 10 5060

GLOBE VALVE<br />

BOLTED BONNET, OUT SIDE SCREW & YOKE<br />

CLASS 2500<br />

Description Material Specs.<br />

c<br />

Body Stain less Steel A35 1 Gr.CFSM<br />

Bonnet St ain less Steel A351 Gr.CFSM<br />

Disc Stainless Steel A351 Gr.CFSM<br />

Stem Stainless Steel AIS2 Gr. F316<br />

Hand Wheel<br />

Ductile Iron or Carbon Steel<br />

Yoke Sleeve Duct ile Iron A4 39 Gr. D2C<br />

Sleeve Gland Stainless Steel A35 1 Gr.CFS<br />

Gland Flange Stainless Steel A351 Gr.CFS<br />

Gland Ring Stainless Steel A276 Type316<br />

Oisc Gland Stainless Steel A351 Gr.CFSM<br />

Wheel Nut Stainless Steel A35 1 Gr.CFS<br />

Bonnet Bolt Stainless Steel AI 93 Gr.BS<br />

Bonnet Nut Stainless Steel AI94 Gr.S<br />

Gland Bolt Stainless Steel AI93 Gr. BS<br />

Gland Nut Stainless Steel AI 94 Gr.S<br />

Gland Bolt Pin Stainless Steel A276 Type304<br />

Bearing<br />

Name Plate<br />

Packing<br />

Gasket<br />

en<br />

thrust Ball<br />

Stainless Steel<br />

Graphite(V.O.C). Asbestos free<br />

Stainless Steel<br />

Face to Face/End to End AN SI B1 6.10<br />

Cl Flange Dimensions ANS I B16.5<br />

~ B. W End Dimensions AN SI B1 6. 25<br />

~ Basic Design BS IS73<br />

en<br />

Testing API 59S A<br />

CD<br />

Size(ln Inches) 2<br />

2 112<br />

3 4 6 8 10 12<br />

A. Face to Face R.F 17 m 20 22 31 • 26 112 36 40 1/4 50 56<br />

A. R.T.J. 171/8 20 1/ 4 23 267/a 36 11l 40 7/8 50 7/ 6 56718<br />

B. Va lve Open. 2S 31 112 34 112 50 75 97 110 13S<br />

C. Hand Wheel Dia 16 20 22 24 32 40 40 40<br />

Weight( Lbs) 410 652 780 1855 5050 10620 15200 I S524<br />

27<br />

®<br />

<strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.

GLOBE VALVE<br />

PRESSURE SEAL TYPE<br />

CLASS 600<br />

Description Material Specs.<br />

Body Stainless Steel A351 Gr.CF8M<br />

Bonnet Stainless Steel A35 1 Gr.CF8M<br />

Disc Sta inless Steel A351 Gr. CF8M<br />

Stem Sta inless Steel AI 82 Gr.F316<br />

Hand Wheel<br />

Ductile Iron or Carbon Steel<br />

Oland Flange Stainless Steel A35 1 Or.CFS.<br />

Oland Ring Stainless Steel AIS2 Or.F316<br />

Disc Oland Stainless Steel A35 1 Or.CFSM<br />

Yoke Sleeve Ductile Iron A439 Or.D2C<br />

Bonnet Bolt Stainless Steel AI93 Or .B8<br />

Bonnet Nut Stainless Steel AI 94 Or.8<br />

Oland Bolt Stainless Steel AI93 Or. B8<br />

Oland Nut Stainless Steel AI 94 Or.S<br />

Oland Bolt Pin Sta inless Steel AIS2 Or.F304<br />

Wheel Nut Stainless Steel<br />

Name Plate Stainless Steel<br />

Asbestos Free<br />

Packing<br />

Oraphite(V.D.C)<br />

Oasket<br />

Sta inless Steel<br />

gs Face to Face/End to End ANS I BI6.10/ BI6.25<br />

~<br />

Flange Dimensions ANSI B16.5<br />

Basic Design B.S 1873<br />

~<br />

Testing API 598<br />

c<br />

A<br />

Size(ln Inches) 2<br />

2 112<br />

3 4 6<br />

A. Face to Face R.F. 11 112 13 14 17 22<br />

A. Stat Patton End 10 End BW 7 Bill 10 12 18<br />

B. Va lve Open. 16 19 19 21 29<br />

C. Hand Wheel Dia 10 12 14 IS 22<br />

Weight(Lbs) 60 SO 125 200 440<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.<br />

8 10 12<br />

26 31 33<br />

23 28 32<br />

34 39 43<br />

24 24 26<br />

700 950 1200<br />

28

GLOBE VALVE<br />

PRESSURE SEAL TYPE<br />

CLASS 900<br />

Description Material Specs.<br />

Body Stainless Steel A351 Gr.CF8M<br />

Bonnet Stainless Steel A35 1 Gr .CF8M<br />

Disc Stainless Steel A351 Gr.CFBM+STL<br />

Stem Stainless Steel A182 Gr. F3 16<br />

Hand Wheel<br />

Ductile Iron or Carbon Steel<br />

Gland Flange Stain less Steel A35 1 Gr.CFB.<br />

Gland Ring Stainless Steel A182 Gr .F3 16<br />

Disc Gla nd Stainless Steel A351 Gr.CF8M<br />

Yoke Sleeve Ductile Iron A439 Gr .D2C<br />

Bonnet Bolt Stai nless Steel A193 Gr .B8<br />

Bonnet Nut Stainless Steel A194 Gr.8<br />

Gland Bolt Stainless Steel A193 Gr.B8<br />

Gland Nut Stainless Steel A194 Gr.B<br />

Gland Bolt Pin Stai nless Steel A182 Gr.F304<br />

Wheel Nut Stainl ess Steel<br />

Name Pla te Stainless Steel<br />

Packing<br />

Asbestos Free<br />

Graphite(V.O.C)<br />

Gasket<br />

Sta inless Steel<br />

(JJ<br />

0 Face to Face/End to End ANSI BI 6. IO/ BI 6.25<br />

~<br />

Flange Dimensions ANSI B16.5<br />

Basic Design B.S 1873<br />

~<br />

Testing API 598<br />

CD<br />

c<br />

A<br />

Size(ln Inches) 2<br />

21/2<br />

3 4 6<br />

A. Face to Face R.F. 14 12 16 112 15 18 24<br />

A. SIKIt Pan", End In End BW 8" 2 10 12 14 20<br />

B. Va lve Open. 23 1n 25 112 28 112 32 314 40' 18<br />

C. Hand Wheel Dia 16 18 22 24 32<br />

Weight( Lbs ) 230 390 310 510 850<br />

Note = gOOlS 2" & 2 11z l> are the same as 1S00 l S 2" & 2 112 "<br />

29<br />

8 10<br />

29 33<br />

26 31<br />

46' 12 48<br />

32 40<br />

1990 2400<br />

12<br />

38<br />

36<br />

51<br />

40<br />

2890<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.

GLOBE VALVE<br />

PRESSURE SEAL TYPE<br />

CLASS 1500<br />

Description Material Specs.<br />

Body Stainless Steel A351 Gr.CFBM<br />

Bonnet Stainless Steel A35 1 Gr.CFBM<br />

Disc Stainless Steel A351 Gr.CF8M+STL<br />

Stem Stainless Steel AIB2 Gr.F316<br />

Ha nd Wheel<br />

Ductile Iron or Carbon Steel<br />

Gland Flange Stainless Steel A35 1 Gr.CFB.<br />

Gland Ring Stainless Steel AIB2 Gr.F316<br />

Disc Gland Stainless Steel A35 1 Gr.CF8M<br />

Yoke Sleeve Ouct ile Iron M39 Gr.D2C<br />

Bonnet Bolt Stainless Steel AI93 Gr.BB<br />

Bonnet Nut Stainless Steel AI 94 Gr.B<br />

Gland Bolt Stainless Steel AI93 Gr.BB<br />

Gland Nut Stainless Steel AI 94 Gr.B<br />

Gland Bolt Pin Stainless Steel A I B2 Gr.F304<br />

Wheel Nut<br />

Name Plate<br />

Packing<br />

Gasket<br />

Stainless Steel<br />

Stainless Steel<br />

Graphite(V.O.C ). Asbestos free<br />

Stainless Steel<br />

en Face to Face/End to End ANSI BI6.10/ BI 6.25<br />

0<br />

g<br />

~<br />

Flange Dimensions ANSI B16.5<br />

Basic Design<br />

B.S I B73<br />

en Testing API 59B<br />

c<br />

A<br />

Size(ln Inches) 2<br />

2 112<br />

3 4 6<br />

A. Face to Face R.F. 14 \12 16 1/2 18 11l 2111l 27 3/4<br />

A. Sli

GLOBE VALVE<br />

PRESSURE SEAL TYPE<br />

CLASS 2500<br />

Description Material Specs.<br />

Body Stainless Steel A351 Gr.CF8M<br />

Bonnet Stainless Steel A35 1 Gr.CF8M<br />

Disc Stainless Steel A351 Gr.CF8M + STl<br />

Stem Stainless Steel AI 82 Gr.F316<br />

Hand Wheel<br />

Ductile Iron or Carbon Steel<br />

Gland Flange Stainless Steel A35 1 GLCF8.<br />

Gland Ring Stainless Steel AI82 Gr.F316<br />

Disc Gland Stainless Steel A351 Gr.CF8M<br />

Yoke Sleeve Ductile Iron A439 Gr .D2C<br />

Bonnet Bolt Stainless Steel AI93 Gr.B8<br />

Bonnet Nut Stainless Steel AI 94 Gr.8<br />

Gland Bolt Stainless Steel AI 93 Gr.B8<br />

Gla nd Nut Stainless Steel AI 94 Gr.8<br />

Gland Bol t Pin Stainless Steel AI 82 Gr.F304<br />

Wh eel Nut<br />

Stainless Steel<br />

Name Plate Stainless Steel<br />

Packing<br />

Graph ite(V.O.C ), Asbestos free<br />

Gasket<br />

Stainless Steel<br />

~ Face to Face/ End to End ANSI BI 6.IO/ BI6.25<br />

~<br />

Fl ange Dimensions ANSI B16.5<br />

Basic Design BS I 873<br />

~<br />

Test ing API 598<br />

CD<br />

c<br />

A<br />

Size(ln Inches) 2<br />

21 /2<br />

3 4 6<br />

A. Face to Face RJ 17 314 20 22 1J4 26 1/t 36<br />

A. SliJI Pallon End 10 End S.w I I 13 14 11l 18 24<br />

8. Va lve Open. 19 112 23 314 25 28 112 39<br />

C. Hand Wheel Dia 16 20 22 24 32<br />

Weight( Lbs) 220 430 460 720 1520<br />

31<br />

8 10<br />

40 1f4 50<br />

30 36<br />

44 49<br />

40 40<br />

3380 4650<br />

12<br />

56<br />

41<br />

54<br />

40<br />

6600<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.

SWING CHECK VALVE<br />

CLASS 150<br />

Description Material Specs<br />

Body Stainless Steel A351 Gr.CF8M<br />

Cover Stainless Steel A351 Gr.CF8M<br />

Disc Stainless Steel A35 1 Gr.CF8M<br />

Hinge Stainless Steel A351 Gr.CF8M<br />

Hinge Pin Stainless Steel A182 Gr.F316<br />

Plug Stainless Steel AI93 Gr .B8M<br />

Cover Bolt Stainless Steel AI93 Gr.88<br />

Cover Nut Stainless Steel AI94 Gr.8<br />

Disc Nut Stainless Steel AI94 Gr.8M<br />

Washer Stainless Steel A276 Type316<br />

Eye 8alt Stainless Steel AI93 Gr.S8<br />

Name Plate Stainless Steel<br />

Gasket<br />

PTFE or Graphite<br />

en Face to Face/End to End ANSI 816.IO/BI6.25<br />

Cl<br />

Flange Dimensions ANSI 8 16.5<br />

~<br />

~<br />

Basic Design ANSI 8 16.34<br />

en Testing API 598<br />

B<br />

i----~- A -- ---J<br />

Size(ln Inches) 1/2 3/4 1 1'/2 2 2'12 3 4 6 8 10 12 14 16 18 20 24 30<br />

A. R.F-BW 4 1/ •<br />

4 5/ e 5 6 1/2 8 8 1 1< g ll2 11 1/2 14 19 11l 24 12 27112 31 34 38 1 /2 38' /2 51 60<br />

A. R.T.J.<br />

41 12 5'/8 5'12 7<br />

S112<br />

9 10 12 141 12 20 25 28 31 1 /2 34 112 39 39 51 I!?<br />

60 ln<br />

B. Valve Height 3718 3 118 3 718 4 4' ,2 5 5 518 6 l / ~ 10 314 12 31 $ 1 3 1 1 ~<br />

15 5/8 ltl2 20',l 22 23' /4 27 518 34 1, •<br />

Weight( Lbs) 8 9 10 16 27 35 50 80 145 245 380 505 655 1250 1550 1950 3440 4965<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.<br />

32

SWING CHECK VALVE<br />

CLASS 300<br />

Description Material Specs<br />

Body Stainless Steel A35 1 Gr. CF 8M<br />

Cover Stainless Steel A351 Gr. CF8M<br />

Disc Stainless Steel A351 Gr . CF8M<br />

Hinge Stainless Steel A351 Gr. CF8M<br />

Hinge Pin Stainless Steel AI82 Gr. F31 6 8<br />

Plug Stainless Steel AI 93 Gr. B8M<br />

Cover Bolt Stainless Steel AI93 Gr. B8<br />

Cover Nut Stainless Steel AI94 Gr . 8<br />

Disc Nut Stainless Steel AI94 Gr. 8M<br />

Wa sher St ain less Steel A276 Type316<br />

Eye Bolt Stainless Steel AI 93 Gr. 88<br />

Name Plate<br />

Stainless Steel<br />

Gasket<br />

PTFE or Graphite<br />

en Face to Face/End to End ANSI BI 6. 1O/816.25<br />

Cl<br />

Fla nge Dimensions ANS I B16.5<br />

~<br />

~<br />

Basic Design ANSI 816.34<br />

Testing API 598<br />

. ··· A-· -. ~<br />

Size(Jn Inches) 1/2 3/4 1 1'/2 2 2'/2 3 4 6 8 10 12 14 16 18 20 24<br />

A. R.F- 8W 5 112 6 8 1 /2<br />

9 1f1 IOIIZ 1 11fZ 1 t il 14 17 1fZ 21 24 111 28 33 34 38 1n 40 53<br />

A. R.T.J. 6 6 112 9 10 11 118 12 116 13 118 14 5/ 8 JS I / ! 21 SI B<br />

25 118 28 St S 33 51 8 34 518 39 1 / 8 40 314 537/8<br />

B. Va lve Height 31/S 3 1/8 3118 5 112 5 314 6 112 7'/8 8 11 m 13 11 • 16 17 118 20 518 3/8 3} 114<br />

22 31 ]18 34" 4<br />

Weight( Lbs) 10<br />

"<br />

14 30 35 55 80 125 225 360 555 840 1575 1970 22 10 2605 4300<br />

33<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.

SWING CHECK VALVE<br />

CLASS 600<br />

Description Material Specs<br />

Body Stain less Steel A351 Gr.CFSM<br />

Cover Stainless Steel A35 1 Gr.CFSM<br />

Disc Stainless Steel A351 Gr.CFSM<br />

Hinge Stainless Steel A351 Gr.CFSM<br />

Hinge Pin Stainless Steel AIS2 Gr.F316<br />

Plug Stainless Steel AI93 Gr .BSM<br />

Cover Bolt Stainless Steel AI 93 Gr.BS<br />

Cover Nut Stainless Steel AI 94 Gr.S<br />

Disc Nut Stainless Steel AI 94 Gr.SM<br />

Washer Stainless Steel A276 Type316 --l-~~' - ----- -<br />

Eye Bolt Stainless Steel AI 93 Gr.BS<br />

Name Plate Stainless Steel A240 Type304<br />

Gasket<br />

Graphite<br />

(f)<br />

Cl<br />

Face to Face/End to End ANSI 816.IO/BI6.25<br />

Flange Dimensions ANSI B16.5<br />

~<br />

~<br />

Basic Design ANSI B16.34<br />

(f) Testing API 59S<br />

CD<br />

A<br />

Size(ln Inches) 1 112<br />

2<br />

2 112<br />

3 4 6 8 10 12 14 16 18 20 24<br />

A. Face to Face R.F. 9 112 11'12 13 14 17 22 26 31 33 35 39 43 47 55<br />

A. Face 10 Faoe R.T.J. 9 5/ 8 t 15/8<br />

13 1/ 8 14'/8 17 118 22 118 26' /8 31 1/8 33'18 35"8 391/8 43 118 471/4 55 JI8<br />

A. End to End B. W gll2 11 1l 13 14 17 22 26 31 33 35 39 43 47 55<br />

B. Valve Height 5 11 • 61/ ~ TIS<br />

7 314 11112 13 7/8 15 518 19 JiS 19 3/8 23 5/ 8 29 30 1/ 8 34 36<br />

We i g~t( Lbs) 45 7S lOS 147 245 464 70S 1192 1575 2185 3006 3900 5000 6930<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.<br />

34

SWING CHECK VALVE<br />

BOLTED BONNET<br />

CLASS 900<br />

Description Material Specs<br />

Body Stainless Steel A351 Gr.CF8M<br />

Cover Stainl ess Steel A351 Gr.CF8M<br />

Disc Stainless Steel A351 Gr.CF8M<br />

Hinge Stainless Steel A351 Gr.C F8M<br />

Hinge Pin Stainless Steel A276 Type3 16<br />

Seat Ring Stainless Steel AI82 Gr.F316<br />

Plug Stainless Steel AI82 Gr.F316<br />

Cover Bol t Stainless Steel AI93 Gr.B8<br />

Cover Nut Stainless Steel AI94 Gr.8<br />

Disc Nut Stainless Steel AI94 Or.8M<br />

Washer Stainless Steel A276 Type316<br />

Eye Bol t Stainless Steel AI93 Gr.B8<br />

Name Pla te<br />

Gasket<br />

Sta inless Steel<br />

Stainless Steel<br />

Face to Face/End to End ANSI BI6.IO<br />

(f)<br />

0 Flange Dimensions ANSI B16.5<br />

~ B.W End Dimensions ANSI B16.25<br />

~ Basic Design BS 1868. ANSI B16.34<br />

(f)<br />

Testing API 598<br />

IX!<br />

-- - -I-+--+l~-- ----- -<br />

A<br />

SizeOn Inches) 2<br />

2 t/2<br />

3 4 6<br />

A. R.F-B.W 1,4 112 16 1 / 2 15 18 24<br />

A. R.T.!. 1,4518 16 5/8 15 118 18 118 24 1/ 8<br />

B. Va lve Height 10 I I 10 1/ 2 12 5/8 15<br />

Weight( Lbs) 160 210 190 320 690<br />

35<br />

8 10<br />

29 33<br />

29 1/3 33 1 / 8<br />

18 19 112<br />

1100 1700<br />

12 14 16 18 20<br />

38 40 112 44 112 48 52<br />

38 1 / 8 llO716 411 118 48 112 52 112<br />

23 118 25 28 112 30 112 34<br />

2380 3050 4000 5280 7800<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.

SWING CHECK VALVE<br />

BOLTED BONNET<br />

CLASS 1500<br />

Description<br />

Body<br />

Cover<br />

Disc<br />

Hinge<br />

Hinge Pin<br />

Seat Ring<br />

Plug<br />

Cover Bolt<br />

Cover Nut<br />

Disc Nut<br />

Washer<br />

Eye Bolt<br />

Name Plate<br />

Gasket<br />

Material<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Specs<br />

A35 1 Gr.CFBM<br />

A35 1 Gr.CFBM<br />

A35 1 Gr.CFBM<br />

A351 Gr.C F8M<br />

A276 Type316<br />

AI 82 Gr.F316<br />

AI 82 Qr. F316<br />

AI 93 Gr.BB<br />

AI94 Gr.B<br />

Face to Face/End to End ANSI B16.10<br />

~ Flange Dimensions ANSI B16.5<br />

~ 8. W End Dimensions ANSI B16.25<br />

AI94 Gr.BM<br />

A240 Type3 16<br />

AI93 Gr.BB<br />

~ Basic Design BS IB6B. ANSI B16.34<br />

en<br />

Testing<br />

API 59B<br />

CD<br />

----1-+-"=<br />

A<br />

Size(ln Inches) 2<br />

2112<br />

3 4 6<br />

A. R.F-B.W 1L1 ln 16 112 18 112 21 1'2 27 314<br />

A. R.T.!. lLl S / 8 16 518 18 51 8 21 St ! 2B<br />

B. Valve Height 10 II Iti2 13 5ft 18 112<br />

Weight(Lbs) 170 210 310 4BO 970<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.<br />

8<br />

32 314<br />

33 11 &<br />

20<br />

20BO<br />

36<br />

10 12 14 16 18 20 24<br />

39 3B 44 1 /2 511 t/2 60 1lZ 65 112<br />

39J1e 38 116 45 TI 8 55 318 61 JI !<br />

66 313<br />

22 23 1/a 26 30 36 1 / 2 40<br />

2950 2380 4320 5630 8900 13000

SWING CHECK VALVE<br />

BOLTED BONNET<br />

CLASS 2500<br />

Description Material Specs<br />

Body Stainless Steel A351 Gr.CFBM<br />

Cover Stainless Steel A351 Gr.CFBM<br />

Disc Sta inless Steel A35 1 Gr.CFBM<br />

Hinge Stainless Steel A35 1 Gr.CFBM<br />

Hinge Pin Stainless Steel A276 Type316<br />

Seat Ring Stainless Steel AI82 Gr. F316<br />

Plug St ainless Steel AI82 Gr .F316<br />

Cover Bolt Stainless Steel AI93 Gr.BB<br />

Cover Nut Stainless Steel AI94 Gr.B<br />

Disc Nut Stainless Steel AI94 Gr.8M<br />

Washer Stainless Steel A240 Type316<br />

Eye Bol t Stainless Steel AI93 Gr.BB<br />

Name Plate<br />

Gasket<br />

Stainless Steel<br />

Stainless Steel<br />

Face to Face/End to End ANS I B16.10<br />

~ Flange Dimensions ANSI B16 .5<br />

g B.W End Dimensions ANSI B16.25<br />

~ Basic Design BS I B68. ANSI B16.34<br />

en<br />

Testing<br />

API 59B<br />

f----A"'~II i<br />

'-----+------ ~~ -I-I--B!t -- --- --- E;:~-. - .- -<br />

!<br />

A<br />

Size(ln Inches) 2<br />

2 1/2<br />

3 4 6<br />

A. R.F-B.W 17l/4 20 22 m 26 112 36<br />

A. R.T.J. 177/8 20 1/ 4 23 26 JI8 36 112<br />

B. Va lve Height 16 318 16 3 / 4 17 112 19 118 20<br />

Weight(Lbs) 310 525 765 1450 3B20<br />

37<br />

8 10 12<br />

40 "t 50 56<br />

40 718 50718 567/8<br />

327/8 37 5/8 42 118<br />

5570 61BO 11033<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.

SWING CHECK VALVE<br />

PRESSURE SEAL TYPE<br />

CLASS 600<br />

Description<br />

Body<br />

Cover<br />

Disc<br />

Hinge<br />

Hinge Pin<br />

Plug<br />

Cover Bol t<br />

Cover Nut<br />

Disc Nut<br />

Washer<br />

Eye Bolt<br />

Name Plate<br />

Material<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Stainless Steel<br />

Specs<br />

A35 1 Gr.CFSM<br />

A35 1 Gr.CFSM<br />

A351 Gr. CF8M +STL<br />

A351 Gr.CFSM<br />

A276 Type3 16<br />

AIS2 F3 16<br />

AI93 Gr.BS<br />

AI94 Gr.S<br />

AI 94 Gr. SM<br />

A240 Type316<br />

AI93 Gr.BS<br />

Gasket<br />

Stainless Steel<br />

en Face to Face/End to End ANSI BI 6.10/BI6.25<br />

Cl<br />

Flange Dimensions ANSI B16.5<br />

g<br />

~<br />

BaSic Design B81868 AN81 B16.34<br />

en Testing API 598<br />

A<br />

Size(ln Inches) 2<br />

2112<br />

3 4 6<br />

A. Face to Face R. F 11'12 13 14 17 22<br />

A. Soot Patt~n End 10 SW 7 8.5 10 12 I S<br />

B. Va lve Height 6 112 6'12 7 8'/4 9 3 1 ~<br />

Weight( Lbs) 40 50 70 145 305<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.<br />

8<br />

26<br />

23<br />

13 ' 12<br />

570<br />

38<br />

10 12 14 16 18 20 24<br />

31 33 35 39 43 47 55<br />

28 32 35 39 43 47 55<br />

14 51 8 17 19 ' / 2 24 25 112 26 '1l 30<br />

930 1300 1600 2300 3300 4500 6500

SWING CHECK VALVE<br />

PRESSURE SEAL TYPE<br />

CLASS 900<br />

Description Material Specs<br />

80dy Stainless Steel A351 Gr .CF8M<br />

Cover Stainless Steel A351 Gr.CF8M<br />

Disc Stainless Steel A351 Gr.CF8M +STL<br />

Hinge Stainless Steel A351 Gr.CF8M<br />

Hinge Pin Sta inless Steel AI82 Gr.F316<br />

Plug Stainless Steel AI93 Gr.B8M<br />

Cover Bol t Stainless Steel AI93 Gr.B8<br />

Cover Nut Stainless Steel AI94 Gr.8<br />

Disc Nut Stainless Steel AI94 Gr.8M<br />

Washer Stainless Steel A240 Type316<br />

Eye Bolt<br />

Stainless Steel<br />

Name Plate Stainless Steel<br />

Gasket<br />

Stainless Steel<br />

~<br />

Face to Face/End to End AN SI 81 6.10/816.25<br />

Flange Dimensions ANSI 8 16.5<br />

~<br />

~<br />

Basic Design BS1868. ANSI 816.34<br />

Testing API 598<br />

I--_____ A ___ _ __ ~<br />

Size{ln Inches) 2 t '2 3 4 6<br />

A. Face to Face R. F. 14112 16 112 15 18 24<br />

A. Shorl Pallern End to End SW. 8 112 10 12 14 20<br />

B. Va lve Height 13 118 14 sIa 111/s 13 318 16 314<br />

Weight ( Lbs) 110 150 195 250 550<br />

"<br />

39<br />

8<br />

29<br />

26<br />

19' /2<br />

1030<br />

10 12 14 16 18 20<br />

33 38 40 112 4£1 111 48 52<br />

31 36 39 43 48 52<br />

22 112 25 27 29 114 32'14 34<br />

1410 2040 2650 3550 4770 6220<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.

SWING CHECK VALVE<br />

PRESSURE SEAL TYPE<br />

CLASS 1500<br />

Description Material Specs<br />

Body<br />

Stainless Steel A351 Gr.CFSM<br />

Cover<br />

Stainless Steel A351 Gr.CFSM<br />

Disc<br />

Stainless Steel A351 Gr.CFSM + STL<br />

Hinge<br />

Stainless Steel A35 1 Gr.CFSM<br />

Hinge Pin<br />

Stainless Steel AI B2 Gr.F316<br />

Plug<br />

Stainless Steel Al 93 Gr.BBM<br />

Cover Bolt<br />

Stainless Steel AI93 Gr.BS<br />

Cover Nut<br />

Stainless Steel AI94 Gr.S<br />

Disc Nut<br />

Stainless Steel AI94 Gr.SM<br />

Wash er<br />

Stainless Steel A240 Type3 16<br />

Eye Bolt<br />

Stainless Steel<br />

Name Plate Stainless Steel<br />

Gasket<br />

Stainl ess Steel<br />

en Face to FacelEnd to End ANS I BI 6.I O/BI6.25<br />

'"<br />

~<br />

~<br />

Flange Dimensions ANS I B16.5<br />

BaSic Design BS I B6B. ANSI B16.34<br />

en Testing API 59B<br />

A<br />

SizeOn Inches) 2<br />

2 1/2<br />

3 4 6<br />

A. Face to Face R.F.<br />

, £1 112 16, n 18 1/ ~ 21"2 27 J/4<br />

A. Short Pattern End to End B.W. 8 1/2 10 12 16 22<br />

B. Valve Height 13 318 14 5/5 11 7/8 13 S/8 16 314<br />

Weight(Lbs) 110 ISO 250 350 750<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.<br />

8<br />

32 1 / 4<br />

2S<br />

19\1z<br />

1490<br />

40<br />

10 12 14 16 18 20<br />

39 44 112 49 112 54',2 60 112 65 1n<br />

34 39 42 47 60 ltz 65" 2<br />

221/2 25 27 29 314 32 1/4 34<br />

2340 3440 4S70 7170 9BOO 105BO

SWING CHECK VALVE<br />

PRESSURE SEAL TYPE<br />

CLASS 2500<br />

Description Material Specs<br />

80dy Stainless Steel A351 Gr .CF8M<br />

Cover Stainless Steel A351 Gr.CF8M<br />

Disc Stainless Steel A351 Gr.CFBM + STL<br />

Hinge Stainless Steel A351 Gr.CF8M<br />

Hinge Pin Stainless Steel A276 Type316<br />

Plug Stainless Steel AI82 F3 16<br />

Cover 80lt Stainless Steel AI93 Gr.88<br />

Cover Nut Stain less Steel AI94 Gr.8<br />

Disc Nut Sta inless Steel AI 94 Gr.8M<br />

Washer Stainless Steel A240 Type316<br />

Eye Bolt<br />

Stainless Steel<br />

Name Plate Stainless Steel<br />

Gasket<br />

Stainless Steel<br />

en<br />

0<br />

Face to Face/End to End ANS I 816.10/816.25<br />

Flange Dimensions ANSI 816.5<br />

~<br />

~<br />

Basic Design BS 1868. ANSI B16.34<br />

Testing AP I 598<br />

A<br />

f---.-------.-- ---<br />

Size(1n Inches) 2<br />

2 1/2<br />

3 4 6<br />

8<br />

10<br />

12<br />

A. Face to Face R.F. 17 314 20 22 314 26'11 36<br />

40 1/4<br />

50<br />

56<br />

A. Slat Pattro1 EM 10 EM BW II 13 14'12 18 24<br />

30<br />

36<br />

41<br />

B. Valve Height 7 Tn 9 I I 13<br />

17<br />

20" 2<br />

22 314<br />

Weight( Lbs) 165 260 350 620 1430<br />

2900<br />

4200<br />

5800<br />

41<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.

BALL VALVE<br />

CLASS 150(FULL BORE)<br />

Description Material Specs.<br />

Body Stainless Steel A351 Gr.CF8M<br />

Bonnet Stainl ess Steel A35 1 Gr.CF8M<br />

Ball St ainless Steel A35 1 Gr.C F8M<br />

Yoke Stainless Steel A35 1 Gr.CF8<br />

Stem Stainless Steel A182 Gr.F316,<br />

Lever Ductile Iron A536 Gr.65-45-12<br />

Gla nd Flange Stainless Steel A351 Gr.CF8<br />

Gland Ring Stainless Steel A182 Gr.F316<br />

Stopper Stainless Steel A35 1 Gr .CF8<br />

Ball Seat<br />

ME-PTF E<br />

Thrust Washer PTFE Re inforced PTFE<br />

Bonnet Bolt Stainless Steel A193 Gr.B8<br />

Bonnet Nut Stainless Steel A194 Gr.8<br />

Snap Ri ng<br />

Packing<br />

Ca rbon Tool Steel<br />

Asbestos Free<br />

PTFE or Graphite<br />

Gasket<br />

PTFE or Gra phite<br />

en Face to Face/End to End ANSI BI 6.1O/BI6.25<br />

Cl<br />

a:<br />

Flange Dimensions ANSI B16.5<br />

c5<br />

~<br />

en<br />

Basic Design<br />

BS5351,<br />

Testing AP I 598<br />

Floating Type = 1/2" ~8'<br />

Trunnion Mounted Type = 6" ........... 24"<br />

Fire Safe Design<br />

Anti Blow- Qut stem<br />

Anti statiC Electricity<br />

ISO 5211 Mounting pad<br />

Locking Device<br />

ANS I B16.34<br />

Sea lant Fitting(Required for trunnion mounted type)<br />

Bi-directional<br />

B<br />

I<br />

I<br />

'---<br />

I<br />

I<br />

._j_.<br />

I<br />

---A ------I<br />

Size(Jn Inches) 1/2 3/4 1<br />

1 112<br />

2<br />

2 112<br />

3<br />

A. R.F<br />

4 114<br />

4 5/ 8 5 6 112 7 7 112 8<br />

A. B.W - - - 7 112 Bill g ll2 11 TI8<br />

B. Va lve Height<br />

2,18 ZTl2<br />

2 3/ 4 4318 5'/3 5 3/8 671e<br />

C. Lever Length 5 5 6 318 9 14 14 16<br />

Floating 5 6 8 15 28 40 55<br />

Welght(lbs)<br />

Trunnion - - - - - - -<br />

® <strong>TONG</strong> <strong>YUNG</strong> <strong>IND</strong>. <strong>CO</strong>. <strong>LTD</strong>.<br />

4 6 8 10 12 14 16 18 20 24<br />

9 15 112 18 21 24 27 30 34 36 42<br />

12 18 20 112 22 25 30 33 36 39 45<br />

8 1/8 117/8 14 17 s / S 19 3/ 8 23 1/ 4 24 5/8 26 314 28 1/ 4 317/8<br />

26 40 48 60 60 - - - - -<br />

90 210 260 - - - - - - -<br />

- 250 425 780 1020 1750 2230 2765 3790 5470<br />

42

BALL VALVE<br />

CLASS 300{FULL BORE)<br />

Description Material Specs.<br />

Body Stainless Steel A35 1 Gr.CF8M<br />

Bonnet Stainless Steel A35 1 Gr.CF8M<br />

Ball Stainless Steel A351 Gr.CF8M<br />

Yoke Stainless Steel A35 1 Gr.CF8<br />

Stem Stainless Steel A1 82 Gr.F316<br />

Lever Ductile Iron A536 Gr .65- 45-1 2<br />

Gland Flange Stainless Steel A35 1 Gr.CF8,<br />