Service & Installation - Gas Equipment Company, Inc.

Service & Installation - Gas Equipment Company, Inc.

Service & Installation - Gas Equipment Company, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Gas</strong>tite<br />

<strong>Installation</strong> Instructions<br />

Step 4<br />

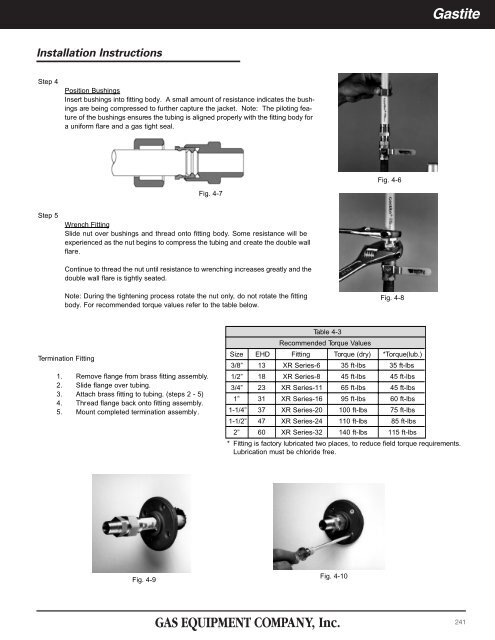

Position Bushings<br />

Insert bushings into fitting body. A small amount of resistance indicates the bushings<br />

are being compressed to further capture the jacket. Note: The piloting feature<br />

of the bushings ensures the tubing is aligned properly with the fitting body for<br />

a uniform flare and a gas tight seal.<br />

Fig. 4-6<br />

Fig. 4-7<br />

Step 5<br />

Wrench Fitting<br />

Slide nut over bushings and thread onto fitting body. Some resistance will be<br />

experienced as the nut begins to compress the tubing and create the double wall<br />

flare.<br />

Continue to thread the nut until resistance to wrenching increases greatly and the<br />

double wall flare is tightly seated.<br />

Note: During the tightening process rotate the nut only, do not rotate the fitting<br />

body. For recommended torque values refer to the table below.<br />

Fig. 4-8<br />

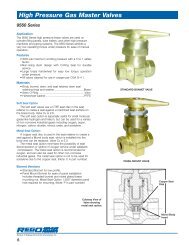

Termination Fitting<br />

1. Remove flange from brass fitting assembly.<br />

2. Slide flange over tubing.<br />

3. Attach brass fitting to tubing. (steps 2 - 5)<br />

4. Thread flange back onto fitting assembly.<br />

5. Mount completed termination assembly.<br />

Table 4-3<br />

Recommended Torque Values<br />

Size EHD Fitting Torque (dry) *Torque(lub.)<br />

3/8” 13 XR Series-6 35 ft-lbs 35 ft-lbs<br />

1/2” 18 XR Series-8 45 ft-lbs 45 ft-lbs<br />

3/4” 23 XR Series-11 65 ft-lbs 45 ft-lbs<br />

1” 31 XR Series-16 95 ft-lbs 60 ft-lbs<br />

1-1/4” 37 XR Series-20 100 ft-lbs 75 ft-lbs<br />

1-1/2” 47 XR Series-24 110 ft-lbs 85 ft-lbs<br />

2” 60 XR Series-32 140 ft-lbs 115 ft-lbs<br />

* Fitting is factory lubricated two places, to reduce field torque requirements.<br />

Lubrication must be chloride free.<br />

Fig. 4-9<br />

Fig. 4-10<br />

241