Service & Installation - Gas Equipment Company, Inc.

Service & Installation - Gas Equipment Company, Inc.

Service & Installation - Gas Equipment Company, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

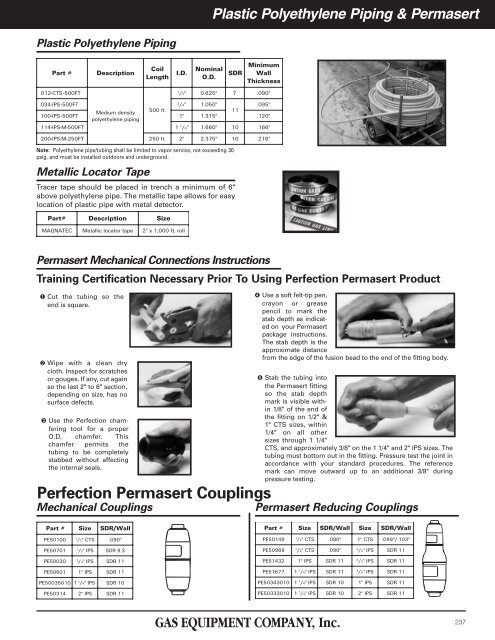

Plastic Polyethylene Piping & Permasert<br />

Plastic Polyethylene Piping<br />

Part<br />

#<br />

Description<br />

Coil<br />

Length<br />

I.D.<br />

Nominal<br />

O.D.<br />

SDR<br />

Minimum<br />

Wall<br />

Thickness<br />

012-CTS -500FT<br />

1<br />

/2" 0 .625"<br />

7 .090"<br />

034-IPS -500FT<br />

3<br />

/4" 1.050"<br />

.095"<br />

100-IPS -500FT<br />

Medium density<br />

500 ft.<br />

11<br />

1" 1.315"<br />

polyethylene piping<br />

.120"<br />

114-IPS-M-500FT 1 1<br />

/4" 1.660"<br />

10 .166"<br />

200-IPS-M-250FT 250 ft.<br />

2" 2.375"<br />

10 .216"<br />

Note: Polyethylene pipe/tubing shall be limited to vapor service, not exceeding 30<br />

psig, and must be installed outdoors and underground.<br />

Metallic Locator Tape<br />

Tracer tape should be placed in trench a minimum of 6"<br />

above polyethylene pipe. The metallic tape allows for easy<br />

location of plastic pipe with metal detector.<br />

Part#<br />

Description<br />

Size<br />

MAGNATEC<br />

Metallic<br />

locator tape<br />

2" x 1,000 ft. roll<br />

Permasert Mechanical Connections Instructions<br />

Training Certification Necessary Prior To Using Perfection Permasert Product<br />

➊ Cut the tubing so the<br />

end is square.<br />

➋ Wipe with a clean dry<br />

cloth. Inspect for scratches<br />

or gouges. If any, cut again<br />

so the last 2" to 6" section,<br />

depending on size, has no<br />

surface defects.<br />

➌ Use the Perfection chamfering<br />

tool for a proper<br />

O.D. chamfer. This<br />

chamfer permits the<br />

tubing to be completely<br />

stabbed without affecting<br />

the internal seals.<br />

➍ Use a soft felt-tip pen,<br />

crayon or grease<br />

pencil to mark the<br />

stab depth as indicated<br />

on your Permasert<br />

package instructions.<br />

The stab depth is the<br />

approximate distance<br />

from the edge of the fusion bead to the end of the fitting body.<br />

➎ Stab the tubing into<br />

the Permasert fitting<br />

so the stab depth<br />

mark is visible within<br />

1/8" of the end of<br />

the fitting on 1/2" &<br />

1" CTS sizes, within<br />

1/4" on all other<br />

sizes through 1 1/4"<br />

CTS, and approximately 3/8" on the 1 1/4" and 2" IPS sizes. The<br />

tubing must bottom out in the fitting. Pressure test the joint in<br />

accordance with your standard procedures. The reference<br />

mark can move outward up to an additional 3/8" during<br />

pressure testing.<br />

Perfection Permasert Couplings<br />

Mechanical Couplings<br />

Permasert Reducing Couplings<br />

Part<br />

#<br />

Size<br />

SDR/Wall<br />

PE50100 1<br />

/2" CTS<br />

.090"<br />

PE50701 1<br />

/2" IPS<br />

SDR 9. 3<br />

PE50030 3<br />

/4" IPS<br />

SDR 11<br />

PE50601 1"<br />

IPS<br />

SDR 11<br />

PE50035010 1 1<br />

/4" IPS<br />

SDR 10<br />

PE50314 2"<br />

IPS<br />

SDR 11<br />

Part<br />

#<br />

Size<br />

SDR/Wall<br />

Size<br />

SDR/Wall<br />

PE50149 1<br />

/2" CTS<br />

. 090"<br />

1 " CTS<br />

.099"/.103"<br />

PE50969 1<br />

/2" CTS<br />

. 090"<br />

3<br />

/4" IPS<br />

SDR 11<br />

PE51432 1"<br />

IPS<br />

SDR<br />

11 3<br />

/4" IPS<br />

SDR 11<br />

PE51677 1 1<br />

/4" IPS<br />

SDR 11<br />

3<br />

/4" IPS<br />

SDR 11<br />

PE50343010 1 1<br />

/4" IPS<br />

SDR 10<br />

1"<br />

IPS<br />

SDR 11<br />

PE50333010 1 1<br />

/4" IPS<br />

SDR 10<br />

2"<br />

IPS<br />

SDR 11<br />

237