PROPERTIES OF CO2 AS A REFRIGERANT - Centro Studi Galileo

PROPERTIES OF CO2 AS A REFRIGERANT - Centro Studi Galileo

PROPERTIES OF CO2 AS A REFRIGERANT - Centro Studi Galileo

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

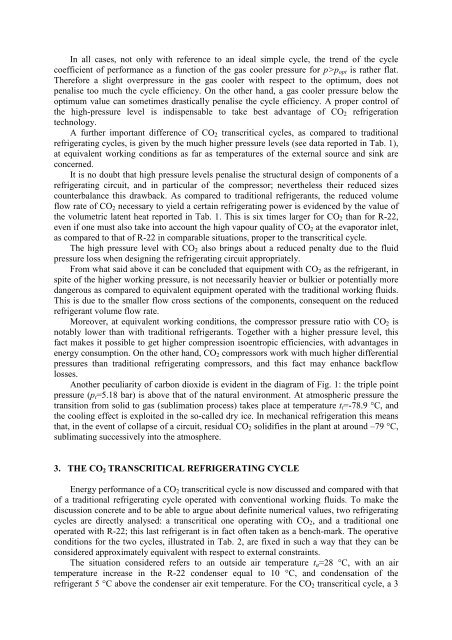

In all cases, not only with reference to an ideal simple cycle, the trend of the cycle<br />

coefficient of performance as a function of the gas cooler pressure for p>p opt is rather flat.<br />

Therefore a slight overpressure in the gas cooler with respect to the optimum, does not<br />

penalise too much the cycle efficiency. On the other hand, a gas cooler pressure below the<br />

optimum value can sometimes drastically penalise the cycle efficiency. A proper control of<br />

the high-pressure level is indispensable to take best advantage of CO 2 refrigeration<br />

technology.<br />

A further important difference of CO 2 transcritical cycles, as compared to traditional<br />

refrigerating cycles, is given by the much higher pressure levels (see data reported in Tab. 1),<br />

at equivalent working conditions as far as temperatures of the external source and sink are<br />

concerned.<br />

It is no doubt that high pressure levels penalise the structural design of components of a<br />

refrigerating circuit, and in particular of the compressor; nevertheless their reduced sizes<br />

counterbalance this drawback. As compared to traditional refrigerants, the reduced volume<br />

flow rate of CO 2 necessary to yield a certain refrigerating power is evidenced by the value of<br />

the volumetric latent heat reported in Tab. 1. This is six times larger for CO 2 than for R-22,<br />

even if one must also take into account the high vapour quality of CO 2 at the evaporator inlet,<br />

as compared to that of R-22 in comparable situations, proper to the transcritical cycle.<br />

The high pressure level with CO 2 also brings about a reduced penalty due to the fluid<br />

pressure loss when designing the refrigerating circuit appropriately.<br />

From what said above it can be concluded that equipment with CO 2 as the refrigerant, in<br />

spite of the higher working pressure, is not necessarily heavier or bulkier or potentially more<br />

dangerous as compared to equivalent equipment operated with the traditional working fluids.<br />

This is due to the smaller flow cross sections of the components, consequent on the reduced<br />

refrigerant volume flow rate.<br />

Moreover, at equivalent working conditions, the compressor pressure ratio with CO 2 is<br />

notably lower than with traditional refrigerants. Together with a higher pressure level, this<br />

fact makes it possible to get higher compression isoentropic efficiencies, with advantages in<br />

energy consumption. On the other hand, CO 2 compressors work with much higher differential<br />

pressures than traditional refrigerating compressors, and this fact may enhance backflow<br />

losses.<br />

Another peculiarity of carbon dioxide is evident in the diagram of Fig. 1: the triple point<br />

pressure (p t =5.18 bar) is above that of the natural environment. At atmospheric pressure the<br />

transition from solid to gas (sublimation process) takes place at temperature t t =-78.9 °C, and<br />

the cooling effect is exploited in the so-called dry ice. In mechanical refrigeration this means<br />

that, in the event of collapse of a circuit, residual CO 2 solidifies in the plant at around –79 °C,<br />

sublimating successively into the atmosphere.<br />

3. THE CO 2 TRANSCRITICAL REFRIGERATING CYCLE<br />

Energy performance of a CO 2 transcritical cycle is now discussed and compared with that<br />

of a traditional refrigerating cycle operated with conventional working fluids. To make the<br />

discussion concrete and to be able to argue about definite numerical values, two refrigerating<br />

cycles are directly analysed: a transcritical one operating with CO 2 , and a traditional one<br />

operated with R-22; this last refrigerant is in fact often taken as a bench-mark. The operative<br />

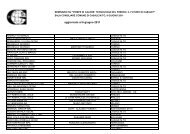

conditions for the two cycles, illustrated in Tab. 2, are fixed in such a way that they can be<br />

considered approximately equivalent with respect to external constraints.<br />

The situation considered refers to an outside air temperature t a =28 °C, with an air<br />

temperature increase in the R-22 condenser equal to 10 °C, and condensation of the<br />

refrigerant 5 °C above the condenser air exit temperature. For the CO 2 transcritical cycle, a 3