DMLS Materials - Technical Specifications

DMLS Materials - Technical Specifications

DMLS Materials - Technical Specifications

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Stewart Golf design,<br />

develop and manufacture<br />

luxury powered golf caddies and<br />

recently launched the F1 Lithium to the<br />

market; a fully remote-controlled top of<br />

the range golf trolley, retailing at £2,500.<br />

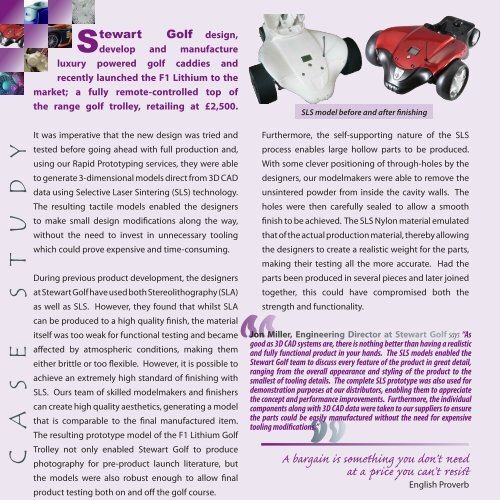

SLS model before and after finishing<br />

C A S E S T U D Y<br />

It was imperative that the new design was tried and<br />

tested before going ahead with full production and,<br />

using our Rapid Prototyping services, they were able<br />

to generate 3-dimensional models direct from 3D CAD<br />

data using Selective Laser Sintering (SLS) technology.<br />

The resulting tactile models enabled the designers<br />

to make small design modifications along the way,<br />

without the need to invest in unnecessary tooling<br />

which could prove expensive and time-consuming.<br />

During previous product development, the designers<br />

at Stewart Golf have used both Stereolithography (SLA)<br />

as well as SLS. However, they found that whilst SLA<br />

can be produced to a high quality finish, the material<br />

Furthermore, the self-supporting nature of the SLS<br />

process enables large hollow parts to be produced.<br />

With some clever positioning of through-holes by the<br />

designers, our modelmakers were able to remove the<br />

unsintered powder from inside the cavity walls. The<br />

holes were then carefully sealed to allow a smooth<br />

finish to be achieved. The SLS Nylon material emulated<br />

that of the actual production material, thereby allowing<br />

the designers to create a realistic weight for the parts,<br />

making their testing all the more accurate. Had the<br />

parts been produced in several pieces and later joined<br />

together, this could have compromised both the<br />

strength and functionality.<br />

itself was too weak for functional testing and became “Jon Miller, Engineering Director at Stewart Golf says “As<br />

good as 3D CAD systems are, there is nothing better than having a realistic<br />

affected by atmospheric conditions, making them and fully functional product in your hands. The SLS models enabled the<br />

either brittle or too flexible. However, it is possible to Stewart Golf team to discuss every feature of the product in great detail,<br />

ranging from the overall appearance and styling of the product to the<br />

achieve an extremely high standard of finishing with smallest of tooling details. The complete SLS prototype was also used for<br />

SLS. Ours team of skilled modelmakers and finishers demonstration purposes at our distributors, enabling them to appreciate<br />

the concept and performance improvements. Furthermore, the individual<br />

can create high quality aesthetics, generating a model components along with 3D CAD data were taken to our suppliers to ensure<br />

that is comparable to the final manufactured item. the parts could be easily manufactured without the need for expensive<br />

tooling modifications.”<br />

”<br />

The resulting prototype model of the F1 Lithium Golf<br />

Trolley not only enabled Stewart Golf to produce<br />

photography for pre-product launch literature, but<br />

A bargain is something you don’t need<br />

at a price you can’t resist<br />

the models were also robust enough to allow final<br />

English Proverb<br />

product testing both on and off the golf course.