PDF/14.4MB - Kyocera

PDF/14.4MB - Kyocera

PDF/14.4MB - Kyocera

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

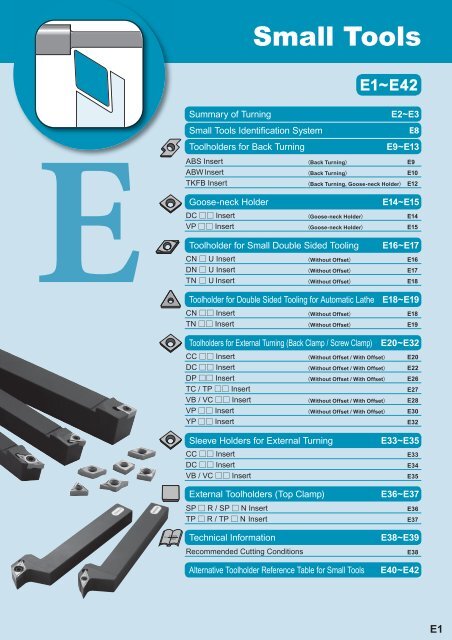

Small Tools<br />

E1~E42<br />

Summary of Turning<br />

Small Tools Identifi cation System<br />

Toolholders for Back Turning<br />

E2~E3<br />

E8<br />

E9~E13<br />

ABS Insert Back Turning E9<br />

ABW Insert Back Turning E10<br />

TKFB Insert<br />

Back Turning, Goose-neck Holder E12<br />

Goose-neck Holder<br />

E14~E15<br />

DC Insert Goose-neck Holder E14<br />

VP Insert Goose-neck Holder E15<br />

Toolholder for Small Double Sided Tooling<br />

E16~E17<br />

CN U Insert Without Offset E16<br />

DN U Insert Without Offset E17<br />

TN U Insert Without Offset E18<br />

Toolholder for Double Sided Tooling for Automatic Lathe E18~E19<br />

CN Insert Without Offset E18<br />

TN Insert Without Offset E19<br />

Toolholders for External Turning (Back Clamp / Screw Clamp) E20~E32<br />

CC Insert Without Offset / With Offset E20<br />

DC Insert Without Offset / With Offset E22<br />

DP Insert Without Offset / With Offset E26<br />

TC / TP Insert<br />

E27<br />

VB / VC Insert Without Offset / With Offset E28<br />

VP Insert Without Offset / With Offset E30<br />

YP Insert<br />

E32<br />

Sleeve Holders for External Turning<br />

CC Insert<br />

DC Insert<br />

VB / VC Insert<br />

External Toolholders (Top Clamp)<br />

SP R / SP N Insert<br />

TP R / TP NInsert<br />

Technical Information<br />

Recommended Cutting Conditions<br />

Alternative Toolholder Reference Table for Small Tools<br />

E33~E35<br />

E33<br />

E34<br />

E35<br />

E36~E37<br />

E36<br />

E37<br />

E38~E39<br />

E38<br />

E40~E42<br />

E1

Summary of Turning<br />

External / Copying<br />

93<br />

93<br />

93<br />

95<br />

95<br />

62.5 62.5<br />

ADJC-FF<br />

Back Clamp<br />

Without Offset<br />

E22<br />

SDJC-FF<br />

Screw Clamp<br />

Without Offset<br />

E23<br />

SDJC<br />

Screw Clamp<br />

With Offset<br />

E23<br />

SDLC-FF<br />

SDLP-FF<br />

Screw Clamp<br />

Without Offset<br />

E24,E26<br />

SDLN-FF<br />

Screw Clamp<br />

Without Offset<br />

E16<br />

SDNC-F<br />

Screw Clamp<br />

With Offset<br />

E25<br />

SDNC<br />

Screw Clamp<br />

With Offset<br />

E25<br />

E<br />

Small Tools<br />

External / Facing<br />

External<br />

95 95 95<br />

95<br />

91<br />

95<br />

ACLC-FF<br />

Back Clamp<br />

Without Offset<br />

E20<br />

SCLC-FF<br />

Screw Clamp<br />

Without Offset<br />

E21<br />

SCLC<br />

Screw Clamp<br />

With Offset<br />

E21<br />

SCLN-FF<br />

Screw Clamp<br />

Without Offset<br />

E16<br />

STGC(P)<br />

Screw Clamp<br />

With Offset<br />

E27<br />

STLN-FF<br />

Screw Clamp<br />

Without Offset<br />

E17<br />

Tooling exampleCNC Automatic lathe (Gang Type)<br />

Cut-Off<br />

(Chapter H)<br />

Back<br />

Turning<br />

Grooving External<br />

(Chapter G)<br />

Threading<br />

(Chapter J)<br />

Boring<br />

(Chapter F)<br />

E2

Back Turning<br />

2.8<br />

2.8<br />

4.7<br />

4.7<br />

4.7<br />

4.7<br />

4.2<br />

4.2<br />

4.2<br />

4.2<br />

8.2<br />

8.2<br />

AABS-40F<br />

Back Clamp<br />

Edge Width:2.8<br />

ap:~4.0<br />

SABS-40F<br />

Screw Clamp<br />

Edge Width:2.8<br />

ap:~4.0<br />

AABW-40F<br />

Back Clamp<br />

Edge Width:4.7<br />

ap:~4.0<br />

SABW-40F<br />

Screw Clamp<br />

Edge Width:4.7<br />

ap:~4.0<br />

AABW-50F<br />

Back Clamp<br />

Edge Width:4.7<br />

ap:~5.0<br />

SABW-50F<br />

Screw Clamp<br />

Edge Width:4.7<br />

ap:~5.0<br />

KTKF<br />

Screw Clamp<br />

Edge Width:1.5~3.8<br />

ap:1.8~5.5<br />

E<br />

E9<br />

E9<br />

E10<br />

E10<br />

E11<br />

E11<br />

E12<br />

External / Facing /<br />

Copying / Undercutting<br />

117.5 117.5 <br />

Small Tools<br />

SVPB<br />

Screw Clamp<br />

With Offset<br />

E29<br />

SVPP<br />

Screw Clamp<br />

With Offset<br />

E31<br />

SVPP-FF<br />

Screw Clamp<br />

Without Offset<br />

E31<br />

Tooling exampleCNC Automatic lathe (Gang Type)<br />

Boring<br />

(Chapter F)<br />

Cut-Off<br />

(Chapter H)<br />

Back<br />

Turning<br />

External Grooving<br />

(Chapter G)<br />

Threading<br />

(Chapter J)<br />

E3

Summary of Turning<br />

Swiss Tool Automatic Lathe (Guide Bush System)<br />

Goose-neck holder is applicable to automatic lathes whose toolholder does not move to<br />

longitudinal direction (Z-axis direction).<br />

In case of machining with the conventional toolholder<br />

Before Machining<br />

E<br />

Guide bush<br />

Bar material<br />

(Workpiece Material)<br />

Constant distance<br />

(1~2mm)<br />

Small Tools<br />

During Machining<br />

(Z-axis direction)<br />

(X-axis direction)<br />

Toolholder motion<br />

The tool position is fixed and the workpiece<br />

moves longitudinally.<br />

Problems<br />

1Problems in attachment<br />

When using a conventional toolholder,<br />

1) Additional space is required for an adopter.<br />

2) Toolholder's handling is diffi cult due to limited space.<br />

3) Necessary to buy an adopter.<br />

4) An adopter may interfere with the next toolpost.<br />

For step turning with multiple passes, the<br />

machined part returns into the guide bush and<br />

causes various problems.<br />

Adopter<br />

Toolpost<br />

2Problems during machining<br />

when machining with a conventional toolholder<br />

Case1<br />

During multiple passes,<br />

when the bar material<br />

returns into the guide<br />

bush, the burr contacts<br />

and breaks the guide<br />

bush.<br />

Case 2<br />

The workpiece burr contacts<br />

the guide bush and causes<br />

dimensional variation.<br />

Case 3<br />

When roughing, chips<br />

come into the guide bush.<br />

E4

Advantages of Goose-neck Holder<br />

In Case of Goose-neck Holder<br />

When using a Goose-neck holder<br />

1) Maximum number of toolholders can be attached.<br />

2) No interference with next toolpost.<br />

Goose-neck holder<br />

Toolpost<br />

E<br />

1Advantages of Using Goose-neck Holder<br />

With a Goose-neck Holder<br />

Small Tools<br />

1) Machining precision improves by additional finishing process.<br />

2) Chips do not get into the guide bush.<br />

3) Better chip control due to large chip evacuation space.<br />

Goose-neck Holder Lineup<br />

External / Copying<br />

For threading<br />

SDJC<br />

Screw Clamp<br />

E14<br />

SVLP<br />

Screw Clamp<br />

E15<br />

KTKF Threading<br />

Screw Clamp<br />

J18<br />

E5

Summary of Turning<br />

External / Copying<br />

External / Facing / Copying<br />

72.5 93 93 93 95<br />

105<br />

100<br />

E<br />

SVVB<br />

Screw Clamp<br />

E29<br />

AVJB-FF<br />

Back Clamp<br />

Without Offset<br />

E28<br />

SVJB-FF<br />

SVJP-FF<br />

Screw Clamp<br />

Without Offset<br />

E28,E30<br />

SVJB<br />

Screw Clamp<br />

E28<br />

SVLP-FF<br />

Screw Clamp<br />

Without Offset<br />

E30<br />

SDXC<br />

Screw Clamp<br />

E24<br />

SYXP-F<br />

Screw Clamp<br />

E32<br />

Small Tools<br />

Small Double Sided Tooling (Screw Clamp)<br />

Machining type External / Facing External / Up Facing External / Copying<br />

Cutting Edge Angle 95° 95° 95°<br />

Screw Clamp<br />

(Without Offset)<br />

5°<br />

5°<br />

<br />

5°<br />

Ref. Page E16 E17 E16<br />

The double-sided design offers less cost per insert and more stability with newly-designed negative inserts.<br />

Sharp cutting performance equivalent to conventional positive inserts.<br />

Toolholder for Double Sided Tooling for<br />

Automatic Lathe (Without Offset : Lever Lock)<br />

Application External / Facing External / Up Facing<br />

Cutting Edge Angle 95° 95°<br />

Lever Lock<br />

(Without Offset)<br />

5°<br />

5°<br />

5°<br />

Ref. Page E18 E19<br />

The Lever lock type is available for small tools for external machining.<br />

Top Clamp (For Insert without Hole)<br />

Machining type External / Chamfering External / Facing / Chamfering External Facing<br />

Cutting Edge Angle 45° 60° 45° 75° 91° 15° -1°<br />

Top Clamp<br />

E6<br />

CSDP CTTP CSSP CSBP CTGP CSKP CTFP<br />

Ref. Page E36 E37 E36 E36 E37 E36 E37

External Sleeve Holder Tools<br />

More tools attachable to CNC Automatic lathe<br />

Limit to attachable tools for intricate part machining<br />

▲<br />

▲<br />

▲<br />

Use External Sleeve Holder Tools<br />

5 3 5 3<br />

S...SCLC<br />

Screw Clamp<br />

Shank Dia.<br />

ø12~ø25.4<br />

E33<br />

See Page<br />

S...SDUC<br />

Screw Clamp<br />

Shank Dia.<br />

ø14~ø25.4<br />

E34<br />

S...SDLC<br />

Screw Clamp<br />

Shank Dia.<br />

ø12~ø25.4<br />

E34<br />

S...SVUB(C)<br />

Screw Clamp<br />

Shank Dia.<br />

ø12~ø25.4<br />

E35<br />

R34~R40 for Tooling Layout and Automatic Lathe List by Manufacturer.<br />

Tooling exampleCNC Automatic LatheOpposed Gang Type<br />

E<br />

Small Tools<br />

External / Facing<br />

External / Copying<br />

Grooving<br />

Threading<br />

(Chapter G)<br />

Boring<br />

(Chapter J)<br />

(Chapter F)<br />

E7

Small Tools Identification System<br />

Square Shank Identification System<br />

A : Back Clamp<br />

C : Top Clamp<br />

S : Screw Clamp<br />

C : 80°Rhombic<br />

D : 55°Rhombic<br />

S : Square<br />

T : Triangle<br />

V : 35°Rhombic<br />

R : Right-hand<br />

L : Left-hand<br />

N : Neutral<br />

Shank Height<br />

(mm)<br />

Shank Width<br />

(mm)<br />

Optional Code<br />

Optional Mark<br />

or Number<br />

e.g.)<br />

FF : Without Offset<br />

Clamping System Insert Shape Hand of Tool Shank Height Shank Width Others<br />

E<br />

S C L C R 12 12 JX 09<br />

FF<br />

Small Tools<br />

90°<br />

45°<br />

A<br />

J<br />

93°<br />

S<br />

75°<br />

B<br />

K<br />

75°<br />

T<br />

60°<br />

Cutting Edge Angle Insert Relief Angle Toolholder Length Insert Size<br />

95°<br />

D<br />

45°<br />

L<br />

V<br />

72.5°<br />

95°<br />

F<br />

N<br />

63°<br />

90°<br />

90°<br />

G<br />

P<br />

117.5°<br />

α<br />

B : 5°Positive F : 80<br />

C : 7°Positive<br />

(85)<br />

H : 100<br />

N : 0°Negative<br />

P : 11°Positive<br />

L1<br />

JX : 120<br />

K : 125<br />

M : 150<br />

(mm)<br />

L<br />

T<br />

L<br />

D<br />

S<br />

L<br />

V<br />

C<br />

L<br />

L<br />

Sleeve Holder<br />

S<br />

Steel<br />

F : 80<br />

(85)<br />

G : 90<br />

H : 100<br />

K : 125<br />

(120) S : Screw Clamp<br />

C 80°Rhombic<br />

D 55°Rhombic<br />

V 35°Rhombic<br />

L Left-hand<br />

Shank<br />

Toolholder Length<br />

Clamping System Insert Shape Hand of Tool<br />

S<br />

20<br />

K<br />

<br />

S C L<br />

C L 09<br />

Bar Diameter Cutting Edge Angle Insert Relief Angle Insert Size<br />

L<br />

U<br />

95<br />

93<br />

C<br />

D<br />

95<br />

<br />

L<br />

L<br />

B5° <br />

V<br />

C7° <br />

L<br />

E8<br />

● The dimensions and specifi cations are subject to change for improvement without notice.<br />

● Depending on the machine specifi cations such as attachment dimension, the symbol may<br />

not match the actual toolholder length.

Toolholders for Back Turning [ABS15Insert]<br />

Back Clamp / Screw Clamp<br />

AABS-40F (Edge Width: 2.8mm, MAX Depth: 4mm)<br />

4.2<br />

*Lock Screw is operated from this direction.<br />

h F1<br />

30°<br />

L1<br />

H1 B<br />

Right-hand shown<br />

L2<br />

H2<br />

SABS-40F(Edge Width: 2.8mm, MAX Depth: 4mm)<br />

E<br />

4.2<br />

h F1<br />

30°<br />

L2<br />

H1 B<br />

Small Tools<br />

Toolholder Dimensions<br />

Description<br />

Right-hand shown<br />

Std.<br />

Dimension (mm)<br />

H1=h H2 B L1 L2 F1<br />

Standard Corner-R(rε)<br />

Spare Parts<br />

Anchor Pin Lock Screw Clamp Screw Wrench<br />

AABSR 1010JX-40F 10 10<br />

10.2<br />

LPA-11<br />

1212JX-40F 12 - 12 120 - 12.2 0.15 LPA-13 HSB4X8R - FH-2<br />

1616JX-40F 16 16 16.2 LPA-17<br />

SABSR 1010JX-40F 10 10<br />

10.2<br />

1212JX-40F 12 - 12 120 - 12.2 0.15 - - SB-3080TR FT-10 <br />

1616JX-40F 16 16 16.2<br />

SABSR 1212F -40F 12 12 85 12.2<br />

-<br />

-<br />

2020K -40F 20 20 125 20.2<br />

0.15 - - SB-3080TR FT-10<br />

Applicable Inserts<br />

Insert<br />

Description<br />

Corner-R<br />

(rε: mm)<br />

Reference<br />

Page<br />

(mm)<br />

6<br />

Application Range<br />

(Steel)<br />

7.0<br />

2.8<br />

0.4<br />

15<br />

15.4<br />

4.2<br />

4.2<br />

30<br />

r<br />

3.97<br />

ABS15R4005<br />

15R4015<br />

ABS15R4005M<br />

15R4015M<br />

0.05<br />

0.15<br />

0.05<br />

0.15<br />

B82<br />

ap<br />

5<br />

4<br />

3<br />

2<br />

1<br />

ABS15<br />

0.1<br />

f (mm/rev)<br />

0.2<br />

Recommended Cutting Conditions<br />

E39<br />

: Std. Item : Check Availability<br />

E9

Toolholders for Back Turning [ABW15 Insert]<br />

Back Clamp / Screw Clamp<br />

AABW-40F (Edge Width: 4.7mm, MAX Depth: 4mm)<br />

4.2<br />

*Lock Screw is operated from this direction.<br />

h F1<br />

45°<br />

L1<br />

H1 B<br />

Right-hand shown<br />

L2<br />

H2<br />

E<br />

SABW-40F (Edge Width: 4.7mm, MAX Depth: 4mm)<br />

4.2<br />

Small Tools<br />

h F1<br />

45°<br />

L1<br />

H1 B<br />

Right-hand shown<br />

Toolholder Dimensions<br />

Description<br />

Std.<br />

Dimension (mm)<br />

H1=h H2 B L1 L2 F1<br />

Standard Corner-R(rε)<br />

Spare Parts<br />

Anchor Pin Lock Screw Clamp Screw Wrench<br />

AABWR 1010JX-40F 10 10<br />

10.2<br />

LPA-11<br />

1212JX-40F 12 - 12 120 - 12.2 0.15 LPA-13 HSB4X8R - FH-2<br />

1616JX-40F 16 16 16.2 LPA-17<br />

SABWR 1010JX-40F 10 10<br />

10.2<br />

1212JX-40F 12 - 12 120 - 12.2 0.15 - - SB-3080TR FT-10<br />

1616JX-40F 16 16 16.2<br />

SABWR 2020K -40F 20 - 20 125 - 20.2 0.15 - - SB-3080TR FT-10<br />

Applicable Inserts<br />

Insert<br />

Description<br />

Corner-R<br />

(rε: mm)<br />

Reference<br />

Page<br />

(mm)<br />

6<br />

Application Range<br />

(Steel)<br />

15.4<br />

7.0<br />

4.7<br />

15° 0.6<br />

4.2<br />

4.2<br />

45°<br />

<br />

3.97<br />

ABW15R4005<br />

15R4015<br />

ABW15R4005M<br />

15R4015M<br />

0.05<br />

0.15<br />

0.05<br />

0.15<br />

B82<br />

ap<br />

5<br />

4<br />

3<br />

2<br />

1<br />

ABW15<br />

0.1<br />

f (mm/rev)<br />

0.2<br />

Recommended Cutting Conditions<br />

E39<br />

E10<br />

Std. Item

Toolholders for Back Turning [ABW23 Insert]<br />

Back Clamp / Screw Clamp<br />

AABW-50F (Edge Width: 4.7mm, MAX Depth: 5mm)<br />

8.2<br />

*Lock Screw is operated from this direction.<br />

h<br />

F1<br />

40°<br />

H1<br />

B<br />

L1<br />

Right-hand shown<br />

L2<br />

H2<br />

SABW-50F (Edge Width: 4.7mm, MAX Depth: 5mm)<br />

E<br />

8.2<br />

h F1<br />

40°<br />

L1<br />

B<br />

H1<br />

Small Tools<br />

Toolholder Dimensions<br />

Description<br />

Right-hand shown<br />

Std.<br />

Dimension (mm)<br />

H1=h H2 B L1 L2 F1<br />

Standard Corner-R(rε)<br />

Spare Parts<br />

Anchor Pin Lock Screw Clamp Screw Wrench<br />

AABWR 1010JX-50F 10 10<br />

10.2<br />

LPA-11<br />

1212JX-50F 12 - 12 120 - 12.2 0.15 LPA-13 HSB4X8R - FH-2<br />

1616JX-50F 16 16 16.2 LPA-17<br />

SABWR 1010JX-50F 10 10<br />

10.2<br />

1212JX-50F 12 - 12 120 - 12.2 0.15 - - SB-3080TR FT-10<br />

1616JX-50F 16 16 16.2<br />

SABWR 2020K -50F 20 - 20 125 - 20.2 0.15 - - SB-3080TR FT-10<br />

Applicable Inserts<br />

Insert<br />

23.4<br />

5.1<br />

15°<br />

40°<br />

7.0<br />

4.7<br />

Description<br />

0.5 ABW23R5005<br />

ABW23R5015<br />

<br />

8.2<br />

3.97<br />

ABW23R5005M<br />

ABW23R5015M<br />

Corner-R<br />

(rε: mm)<br />

0.05<br />

0.15<br />

0.05<br />

0.15<br />

Recommended Cutting Conditions<br />

Reference<br />

Page<br />

B82<br />

E39<br />

ap<br />

(mm)<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

ABW23<br />

0.1<br />

fmmrev<br />

Application Range<br />

(Steel)<br />

0.2<br />

Std. Item<br />

E11

Toolholders for Back Turning (TKFB Insert)<br />

Screw Clamp<br />

KTKF/KTKF (Goose-neck Holder)<br />

T<br />

h<br />

F1<br />

10<br />

F1<br />

B<br />

KTKFR/L1616·· -12<br />

KTKFR/L1616·· -16<br />

shows above figure.<br />

2°<br />

60°<br />

Fig.1<br />

KTKFR/L1010·· -12<br />

KTKFR/L1010·· -16<br />

shows above figure.<br />

L2<br />

h<br />

H1<br />

2<br />

L1<br />

Right-hand shown<br />

R-hand Insert for R-hand Toolholder<br />

E<br />

<br />

T<br />

8<br />

Small Tools<br />

Left-hand Shown<br />

B<br />

H1<br />

L1<br />

h F1<br />

1°<br />

KTKFL1620JX-12<br />

shows above fi gure.<br />

T<br />

F1<br />

1°<br />

Fig.2<br />

L-hand Insert for L-hand Toolholder<br />

Toolholder Dimensions<br />

Description<br />

Std.<br />

R<br />

L<br />

Dimension (mm)<br />

H1=h B L1 L2 F1 T<br />

Drawing<br />

Spare Parts<br />

Clamp Screw Wrench<br />

Applicable<br />

Inserts<br />

KTKF 1010JX-12 10 10<br />

15 10<br />

1212JX-12 12 12 120<br />

12 6<br />

SB-4590TRWN LTW-10S TKFB12 …<br />

-<br />

1616JX-12 16 16 16<br />

KTKF 1010JX-16 10 10<br />

20 10<br />

Fig.1<br />

1212JX-16 12 12 120<br />

12 8 SB-4590TRWN LTW-10S TKFB16 …<br />

-<br />

1616JX-16 16 16 16<br />

KTKF 1212F-12 <br />

6<br />

12 12 85 - 12<br />

SB-4590TRWN LTW-10S TKFB12 …<br />

1212F-16 8 TKFB16 …<br />

KTKFL 1216JX-12 12 16<br />

16<br />

120 -<br />

6 Fig.2 SB-4590TRWN LTW-10S TKFB12L …<br />

1620JX-12 16 20 20<br />

Dimension T shows the distance from the Toolholder to the cutting edge.<br />

Applicable Inserts<br />

Insert<br />

Photo shows Right-hand<br />

W a r<br />

4°<br />

B<br />

60°<br />

d<br />

Right-hand shown<br />

W<br />

r<br />

a<br />

4°<br />

B<br />

60°<br />

d<br />

Left-hand shown<br />

T<br />

H<br />

T<br />

H<br />

Description<br />

Corner-R<br />

rε:mm<br />

TKFB 12R15005M 0.05<br />

12R28005M 0.05<br />

12R28010M 0.1<br />

TKFB 16R38005M 0.05<br />

16R38010M 0.1<br />

TKFB 12L28005MR 0.05<br />

12L28010MR 0.1<br />

TKFB 16L38005MR 0.05<br />

16L38010MR 0.1<br />

Ref. Page<br />

B81<br />

Recommended Cutting Conditions<br />

E39<br />

Applicable Chipbreaker Range<br />

(ap indicates radius)<br />

TKFB12R15..<br />

TKFB12R28..<br />

ap (mm)<br />

ap (mm)<br />

3<br />

2<br />

1<br />

(Steel)<br />

0.1 0.2<br />

f (mm/rev)<br />

TKFB16R38..<br />

6<br />

5<br />

4<br />

3<br />

2<br />

(Steel)<br />

ap (mm)<br />

5<br />

4<br />

3<br />

2<br />

1<br />

(Steel)<br />

0.1 0.2<br />

f (mm/rev)<br />

1<br />

0.1 0.2<br />

(mm/rev)<br />

E12<br />

: Std. Item

Combination of Toolholders and Inserts (See Table.1)<br />

Toolholder<br />

Insert<br />

R-hand(R)<br />

R-hand(R)<br />

Table1<br />

Toolholder<br />

Insert<br />

L-hand(L)<br />

L-hand(L)<br />

Advantages of TKFB type for Back Turning<br />

1. Minimal defl ection due to lower cutting<br />

force<br />

2. Smooth chip control<br />

3. Better surface fi nish owing to optimal<br />

wiper edge angle<br />

Variation of Cutting Dia (Transfer of Cutting Edge)<br />

TKFB edge shape<br />

Shallow wiper edge angle<br />

External face of workpiece<br />

Side face of workpiece<br />

Comparison of surface fi nish<br />

E<br />

Small Tools<br />

50<br />

TKFB type<br />

Competitor B<br />

(μm)<br />

Variation of Cutting Dia<br />

40<br />

30<br />

20<br />

10<br />

0<br />

Cutting Dia.<br />

Competitor A<br />

TKFB type<br />

0.05 0.1 0.15<br />

f (mm/rev)<br />

Feed Rate<br />

(mm/rev)<br />

f=0.05<br />

Rz=3.3μm<br />

Rz=11.2μm<br />

ø10<br />

Cutting Conditions: Vc=80m/min<br />

ap=1mm f=0.03~0.12mm/rev WET C45<br />

Feed Rate<br />

(mm/rev)<br />

f=0.07<br />

Rz=4.6μm<br />

Cutting Conditions: Vc=80m/min<br />

Rz=14.2μm<br />

ap=1mm WET(oil-base)C45<br />

When using TKF-AS type<br />

The KTKF holder can be used as a multi-functional<br />

tooling for nonferrous and nonmetal materials when<br />

combined with a TKF-AS insert (See Fig.1).<br />

Fig.1Example of the pass of KTKF toolholder + TKF-AS insert<br />

Insert Description W Reference<br />

Page<br />

Handed Insert shows R-hand.<br />

±0.03<br />

rW<br />

r<br />

<br />

d<br />

<br />

T<br />

TKF12$ 200-AS 2.0<br />

250-AS 2.5<br />

C25<br />

<br />

The cutting edge of the TKF..-AS will be<br />

1 mm lower than the center line when<br />

attached to the KTKF toolholder (See<br />

Fig.2). Adjust the height by making NC lathe<br />

parameter settings or inserting a plate.<br />

Longitudinal turning /<br />

Grooving<br />

B<br />

H<br />

TKF16$ 250-AS 2.5<br />

Recommended Cutting Conditions<br />

E39<br />

øDmax<br />

h<br />

H1<br />

1<br />

KTKF Toolholder<br />

Fig.2When a TKF-AS insert is attached<br />

(The cutting edge is 1 mm lower than the center line.)<br />

E13

Goose-neck Holder [DC Insert]<br />

Screw Clamp<br />

SDJC (External / Copying)<br />

32°<br />

32°<br />

27<br />

S<br />

93°<br />

S<br />

B<br />

F1<br />

F1<br />

F2<br />

93°<br />

E<br />

SDJCR1620JX-11-F05<br />

shows above fi gure.<br />

h<br />

0°<br />

L2<br />

70°<br />

L1<br />

H1<br />

Right-hand shown<br />

Toolholder Dimensions<br />

Small Tools<br />

Description<br />

Std.<br />

Dimension (mm)<br />

H1=h B L1 L2 F1 F2 S<br />

Standard Corner-R(rε)<br />

Spare Parts<br />

Clamp Screw Wrench<br />

SDJCR 1216JX-11-F05 <br />

15.4 18 2 5<br />

12 16<br />

1216JX-11-F15 19 28 12 15<br />

120<br />

1620JX-11-F05 <br />

15.4 20 - 5<br />

16 20<br />

1620JX-11-F15 19 28 8 15<br />

0.2 SB-4085TR FT-15<br />

Applicable Inserts<br />

Application Minute ap Finishing Finishing-Medium Finishing-Medium Finishing Finishing / Precision Low Feed Low Feed / Precision Low Feed Low Feed / Precision<br />

Ref. Page B52 B52 B53 B53 B55 B55 B56 B56 B57 B57<br />

CF GF GK GQ -F -FSF (E/F) -U F-USF (E/F)-J F-JSF<br />

Insert<br />

Toolholder<br />

SDJCR..-11-F..<br />

DCGT11T3.. DCGT11T3.. DCMT11T3.. DCGT11T3.. DCGT11T3.. DCET11T3.. DCGT11T3.. DCET11T3.. DCGT11T3.. DCET11T3..<br />

Low Carbon Steel / Low Carbon Steel /<br />

Application Finishing Finishing-Medium Stainless Steel Cast Iron Non-ferrous Metals Non-ferrous Metals Non-ferrous Metals Hard materials<br />

Ref. Page B54 B54 B54 B57 B57 B57 C19 C11<br />

Toolholde<br />

SDJCR..-11-F..<br />

Insert<br />

XP XQ MQ Without Chipbreaker AH -A3 PCD CBN<br />

DCMT11T3.. DCMT11T3.. DCMT11T3.. DCGW11T3.. DCGT11T3.. DCGT11T3.. DCMT11T3.. DCMW11T3..<br />

Recommended Cutting Conditions<br />

Goose-neck holder is available for multiple passes at roughing and finishing<br />

E38<br />

<br />

The workpiece burr does<br />

not contact the guide<br />

bush and no breakage<br />

will be caused.<br />

<br />

Longitudinal dimension<br />

will be stable.<br />

External diameter will be<br />

stable owing to multiple<br />

pass machining (roughing<br />

and fi nishing).<br />

<br />

Large space for chip<br />

evacuation.<br />

Better and smooth chip<br />

control.<br />

E14<br />

: Std. Item

95°<br />

Goose-neck Holder[VP Insert<br />

Screw Clamp<br />

SVLP (External / Copying)<br />

27<br />

50°<br />

S<br />

B<br />

F1<br />

F2<br />

L2<br />

<br />

70°<br />

L1<br />

0°<br />

h1<br />

H<br />

E<br />

Right-hand shown<br />

Toolholder Dimensions<br />

Description<br />

Std.<br />

Dimension (mm)<br />

H1=h B L1 L2 F1 F2 S<br />

Standard Corner-R(rε)<br />

Spare Parts<br />

Clamp Screw Wrench<br />

Small Tools<br />

SVLPR 1216JX-11-F15 12 16<br />

10<br />

120 18 26<br />

1620JX-11-F15 16 20 6<br />

15 0.2 SB-2570TR FT-8<br />

Applicable Inserts<br />

Application Minute ap Finishing Finishing Finishing / Precision Low Feed Low Feed / Precision<br />

Ref. Page B75 B75 B75 B76 B76 B76<br />

CF CK GF -FSF F-U F-USF<br />

Insert<br />

Toolholder<br />

SVLPR...-11-F..<br />

VPGT1103.. VPGT1103.. VPGT1103.. VPET1103.. VPGT1103.. VPET1103..<br />

Recommended Cutting Conditions<br />

E38<br />

One toolholder for complex shape workpiece<br />

Toolholder for VP type insert is available.<br />

Complex shape workpiece can be processed with one<br />

toolholder.<br />

It can be used for undercutting and external/face fi nishing.<br />

: Std. Item<br />

E15

Toolholders for Small Double Sided Tooling<br />

Screw Clamp<br />

SCLN (Without Offset) (External / Facing)<br />

<br />

Side Rake Angle: -6°<br />

Angle of Inclination: -6°<br />

<br />

<br />

<br />

5°<br />

5°<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Right-hand shown<br />

E<br />

Toolholder Dimensions<br />

Description<br />

Std.<br />

Dimension (mm)<br />

H1=h B L1 L2 F1 S<br />

Standard Corner-R(rε)<br />

Clamp Screw<br />

Spare Parts<br />

Wrench<br />

Applicable<br />

Inserts<br />

Small Tools<br />

SCLNR 1010K-07FF 10 10 120 10<br />

1212F-07FF <br />

85<br />

12 12 15 12<br />

1212K-07FF <br />

120<br />

1616K-07FF 16 16 16<br />

Applicable Inserts<br />

0 0.2 SB-3080TR LTW-10SS<br />

CNGU0703..<br />

CNMU0703..<br />

Toolholder<br />

Applications Finishing-Medium Medium-Roughing Finishing Low Feed<br />

Ref. Page B42 B42 B42 B42<br />

SK GK FR-F (F / E) R-U<br />

Insert<br />

SCLNR...-07FF CNGU0703.. CNMU0703.. CNGU0703.. CNGU0703..<br />

SDLN (Without Offset) (External / Copying)<br />

<br />

Side Rake Angle: -6°<br />

Angle of Inclination: -7°<br />

<br />

5°<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Right-hand shown<br />

Toolholder Dimensions<br />

Description<br />

Std.<br />

Dimension (mm)<br />

H1=h B L1 L2 F1 S<br />

Standard Corner-R(rε)<br />

Clamp Screw<br />

Spare Parts<br />

Wrench<br />

Applicable<br />

Inserts<br />

SDLNR 1010K-08FF 10 10 120 10<br />

1212F-08FF <br />

85<br />

12 12 18 12 0 0.2 SB-3080TR LTW-10SS<br />

1212K-08FF <br />

120<br />

1616K-08FF 16 16 16<br />

Applicable Inserts<br />

Applications Finishing-Medium Medium-Roughing Finishing Low Feed<br />

Ref. Page B43 B43 B43 B43<br />

SK GK FR-F F<br />

(F / E) R-U<br />

Insert<br />

Toolholder<br />

DNGU0803..<br />

DNMU0803..<br />

SDLNR...-08FF DNGU0803.. DNMU0803.. DNGU0803.. DNGU0803..<br />

E16<br />

: Std. Item: Check Availability

Screw Clamp<br />

STLN (External / Up Facing)<br />

<br />

Side Rake Angle: -6°<br />

Angle of Inclination: -7°<br />

<br />

<br />

5°<br />

<br />

<br />

<br />

<br />

<br />

Right-hand shown<br />

<br />

<br />

Toolholder Dimensions<br />

Description<br />

Std.<br />

Dimension (mm)<br />

H1=h B L1 L2 F1 S<br />

Standard Corner-R(rε)<br />

Clamp Screw<br />

Spare Parts<br />

Wrench<br />

Applicable<br />

Inserts<br />

E<br />

STLNR 1010K-09FF 10 10 120 10<br />

1212F-09FF <br />

85<br />

12 12 15 12<br />

1212K-09FF <br />

120<br />

1616K-09FF 16 16 16<br />

Applicable Inserts<br />

Applications Finishing Low Feed<br />

Ref. Page B44 B44<br />

FR-F<br />

(E / F) R-U<br />

Insert<br />

Toolholder<br />

0 0.2 SB-2570TR LTW-8SS TNGU0903..<br />

Small Tools<br />

STLNR...-09FF TNGU0903.. TNGU0903..<br />

Smaller double sided tooling for precision machining<br />

Double-sided design allows all edges to be used. Compared to the positive type,<br />

the double-sided design offers less cost per insert and more stability.<br />

Surface roughness comparison (Sharp edge)<br />

TNGU09 Type<br />

Small Negative Insert<br />

TNGG16 Type<br />

Negative Insert<br />

Surface roughness Ra(μm)<br />

2.0<br />

1.5<br />

1.0<br />

0.5<br />

Negative Type<br />

DNGU080302MFR-U (PR1025)<br />

Positive Type<br />

DCGT11T302MFR-U (PR1025)<br />

0.0<br />

0 10 20 30 40 50<br />

Cutting Time (min)<br />

<br />

Workpiece Material : C45 Vc=100m/min, ap=1.5mm, f=0.03mm/rev, Wet<br />

Internal evaluation<br />

<br />

Recommended Cutting Conditions<br />

Workpiece<br />

Material<br />

Free-cutting<br />

steel<br />

Carbon Steel<br />

Alloy Steel<br />

Stainless<br />

Steel<br />

Insert Grade<br />

PR1005 PR1025 PR1225<br />

Vc=100m/min<br />

(60~150)<br />

Vc=100m/min<br />

(60~150)<br />

Vc=100m/min<br />

(60~150)<br />

Vc=100m/min<br />

(60~150)<br />

Continuous to Light Interruption / 1st Choice<br />

Continuous to Light Interruption / 2nd Choice<br />

Vc=100m/min<br />

(60~150)<br />

Vc=100m/min<br />

(60~150)<br />

Case Studies<br />

X10CrNiS18-9 (SUS303)<br />

Spool<br />

<br />

Vc=66m/min<br />

ap=1.25mm<br />

f=0.025mm/rev<br />

Wet<br />

<br />

Vc=130m/min<br />

ap=0.25mm<br />

f=0.025mm/rev<br />

Wet<br />

DNGU080302MF-SK (PR1025)<br />

Competitor D (DCGT type)<br />

ø8<br />

48<br />

ø6<br />

Required Surface Roughness: 0.8μmRa<br />

60,000 pcs/insert (4 corners)<br />

20,000 pcs/insert (2 corners)<br />

Competitor D (DCGT type) machined 10,000 pcs/edge. PR1025 machined 15,000 pcs/edge resulting<br />

in 3 times longer tool life per insert.<br />

<br />

Evaluation by the user<br />

: Std. Item: Check Availability<br />

E17

Toolholder for Double Sided Tooling for Automatic Lathe<br />

Lever Lock<br />

PCLN (Without Offset) (External / Facing)<br />

5°<br />

Side Rake Angle-6°<br />

Angle of Inclination-6°<br />

Right-hand shown<br />

E<br />

Small Tools<br />

Toolholder Dimensions<br />

Dimension (mm)<br />

Description Std.<br />

H1=h B L1 L2 F1 S<br />

Standard Corner-R(rε)<br />

Spare Parts<br />

Lever Lock Screw Shim Shim Pin Punch Wrench<br />

PCLNR 1620JX-12FF 16 20 120 26 20 0 0.8 LL-2N LS-2N LC-42N LSP-2 PC-2 LW-3<br />

Applicable Inserts(1st Choice)<br />

Application Medium-Roughing<br />

Ref. Page<br />

B44<br />

TK<br />

Insert<br />

Toolholder<br />

PCLNR 1620JX-12FF CNGG1204..FP-TK<br />

Recommended Cutting Conditions E17<br />

Applicable Inserts (Optional)<br />

Application Finishing Finishing-Medium Finishing Finishing-Medium Finishing-Medium Finishing-Medium Medium-Roughing Medium-Roughing<br />

WP (Wiper) WQ(Wiper) GP HQ CQ CJ GS PS<br />

Size 12 12 12 12 12 12 12 12<br />

Page B14 B14 B14 B14 B14 B14 B15 B15<br />

Application Medium-Roughing Medium-Roughing Medium-Roughing /<br />

High Feed Roughing Roughing Single Sided / Roughing /<br />

High Feed Medium<br />

HS CS PT<br />

Standard PH PX $<br />

Insert<br />

Insert<br />

Size 12 12 12 12 12 12 12<br />

Page B15 B15 B15 B16 B16 B16 B18<br />

Application Medium-Roughing /<br />

Low Cutting Force<br />

$-25R<br />

Low Carbon Steel /<br />

Finishing<br />

XP-T<br />

Low Carbon Steel /<br />

Medium<br />

XQ<br />

Low Carbon Steel<br />

Roughing<br />

XS<br />

Stainless Steel Finishing<br />

MQ<br />

Stainless Steel<br />

Medium-Roughing<br />

MS<br />

Stainless Steel<br />

Medium-Roughing<br />

MU<br />

Cast Iron<br />

C<br />

Insert<br />

Size 12 12 12 12 12 12 12 12<br />

Page B18 B16 B16 B16 B17 B17 B17 B17<br />

Application Cast Iron Cast Iron Cast Iron Cast Iron Non-ferrous Metals Non-ferrous Metals Non-ferrous Metals Hard materials<br />

ZS GC Without Chipbreaker Ceramic AH A3<br />

PCD CBN<br />

Insert<br />

F1<br />

B<br />

5°<br />

5°<br />

S<br />

95°<br />

L2<br />

L1<br />

h<br />

H1<br />

Size 12 12 12 12 12 12 12 12<br />

Page B17 B18 B18 B85 B18 B18 C17 C5<br />

E18<br />

: Std. Item

Toolholder for Double Sided Tooling for Automatic Lathe<br />

Lever Lock<br />

PTLN(Without Offset) (External / Up Facing)<br />

Side Rake Angle-6°<br />

Angle of Inclination-6°<br />

Right-hand shown<br />

Toolholder Dimensions<br />

Description<br />

Std.<br />

Dimension (mm)<br />

H1=h B L1 L2 F1 S<br />

PTLNR 1620JX-16FF 16 20 120 25 20 0 0.8 LL-1N LS-1N<br />

Standard Corner-R(rε)<br />

Spare Parts<br />

Lever Lock Screw Shim Shim Pin Punch Wrench<br />

LT-32N<br />

LT-32N-20<br />

LSP-1 PC-1 FH-2.5<br />

E<br />

Small Tools<br />

Applicable Inserts (1st Choice)<br />

Application Medium-Roughing<br />

Ref. Page<br />

B44<br />

TK<br />

Insert<br />

Toolholder<br />

PTLNR 1620JX-16FF TNGG1604..FP-TK<br />

Recommended Cutting Conditions E17<br />

Application Finishing Finishing-Medium Finishing-Medium Medium-Roughing Medium-Roughing Medium-Roughing<br />

Medium-Roughing / Medium-Roughing /<br />

High Feed<br />

High Feed<br />

GP HQ CQ GS PS HS PT GT<br />

Roughing<br />

PH<br />

Insert<br />

Size 16 16 16 16 16 16 16 16 16<br />

Page B30 B30 B30 B30 B30 B30 B31 B31 B31<br />

Single Sided /<br />

Application Roughing / High Feed<br />

Roughing Finishing-Roughing Finishing-Roughing Medium-Roughing / Low Carbon Steel Low Carbon Steel Low Carbon Steel Stainless Steel<br />

Low Cutting Force Finishing Medium Roughing Finishing<br />

PX Standard -S - -25R XP-T XQ XS MQ<br />

Insert<br />

Size 16 16 16 16 16 16 16 16 16<br />

Page B31 B31 B34 B34 B34 B31 B31 B31 B32<br />

Application<br />

Stainless Steel Stainless Steel<br />

Medium-Roughing Medium-Roughing<br />

Cast Iron Cast Iron Cast Iron Cast Iron Cast Iron Non-ferrous Metals Non-ferrous Metals<br />

C ZS GC<br />

Without Chipbreaker Ceramic AH -A3<br />

Insert<br />

Size 16 16 16 16 16 16 16 16 16<br />

Page B32 B32 B33 B33 B33 B33 B90 B33 B33<br />

Application Non-ferrous Metals Hard materials<br />

PCD CBN<br />

Insert<br />

B<br />

5°<br />

S<br />

95°<br />

L2<br />

L1<br />

h<br />

H1<br />

F1<br />

When using inserts whose corner R(rε) is larger than 1.6 mm, please purchase a shim with * mark and use it in order to prevent workpiece and shim from interfering each other.<br />

Applicable Inserts (Optional)<br />

MS<br />

MU<br />

Size 16 16<br />

Page C17 C7<br />

: Std. Item<br />

E19

External Toolholders [CC Insert<br />

Back Clamp<br />

ACLC-FF (Without Offset) (External / Facing)<br />

95<br />

5<br />

F1 2<br />

S<br />

5°<br />

16<br />

95° 0<br />

ACLC$1010JX-09FF<br />

shows above figure.<br />

F1<br />

S<br />

h<br />

5<br />

*Lock Screw is operated from this direction.<br />

95°<br />

L1<br />

H1 B<br />

Right-hand shown<br />

L2<br />

H2<br />

E<br />

Small Tools<br />

Toolholder Dimensions<br />

Description<br />

Std.<br />

Dimension (mm)<br />

R L H1=h H2 B L1 L2 F1 S<br />

ACLC 1010JX-06FF 10 - 10 120 - 10<br />

LPF-11<br />

1010JX-09FF 10 2 10 16 10<br />

0 0.2 LPF-13<br />

1212JX-09FF 12 12 120 12<br />

-<br />

-<br />

1616JX-09FF 16 16 16 LPF-17<br />

Lock Screw : HSB4×8R for R-hand Toolholder, HSB4×8L for L-hand Toolholder.<br />

Standard Corner-R(rε)<br />

Spare Parts<br />

Anchor Pin Lock Screw Wrench<br />

HSB4X8<br />

FH-2<br />

Applicable Inserts<br />

Applications Finishing Finishing-Medium Finishing-Medium Low Feed Stainless Steel Cast Iron Non-ferrous Metals Non-ferrous Metals Non-ferrous Metals Hard Materials<br />

Ref. Page B45 B45 B45 B48 B46 B47 B46 B46 C18 C10<br />

Toolholder<br />

Insert<br />

Back Clamp Holders<br />

GF GK GQ (E / F) -U MQ Without Chipbreaker AH -A3 PCD CBN<br />

ACLC...-06FF CCGT0602.. CCMT0602.. CCGT0602.. CCGT0602.. - CCGW0602.. - -<br />

CCMT0602..<br />

CCGW0602..<br />

CCMW0602..<br />

ACLC...-09FF CCGT09T3.. CCMT09T3.. CCGT09T3.. CCGT09T3.. CCMT09T3.. CCGW09T3.. CCGT09T3.. CCGT09T3..<br />

CCMT09T3..<br />

CCGW09T3..<br />

CCMW09T3..<br />

For recommended cutting conditions, see page<br />

E38<br />

Simple insert replacement,<br />

including with gang-tooling<br />

1. The lock screw can be operated from the back side and<br />

allows simple insert replacement on Swiss type automatic<br />

lathes (Fig.1)<br />

2. Simple insert replacement by slightly turning the wrench.<br />

3. Rigid clamping with anchor pin and lock screw. (Fig.2)<br />

The lock screw<br />

can be operated from<br />

the back side.<br />

insert<br />

Conventional tool is not<br />

available for gang-tooling.<br />

Anchor Pin<br />

(Fig.1)<br />

Lock<br />

Screw<br />

(Fig.2)<br />

E20<br />

: Std. Item : Check Availability

External Toolholders [CC Insert<br />

Screw Clamp<br />

SCLC-FF (Without Offset) (External / Facing)<br />

L2<br />

5°<br />

2.5<br />

5°<br />

95°<br />

5°<br />

F1<br />

F1<br />

B<br />

S<br />

95°<br />

SCLC$1010JX-09FF<br />

shows above figure.<br />

S<br />

0<br />

95°<br />

L1<br />

Right-hand shown<br />

h<br />

H1<br />

Toolholder Dimensions<br />

Description<br />

Std.<br />

Dimension (mm)<br />

R L H1=h B L1 L2 F1 S<br />

Standard Corner-R(rε)<br />

Spare Parts<br />

Clamp Screw Wrench Wrench<br />

SCLC 0808F-06FF 8 8<br />

8<br />

SB-2570TR FT-8 -<br />

85 - 0 0.2<br />

1212F-09FF 12 12 12 SB-4085TR FT-15 -<br />

SCLC 1010JX -06FF 10 10 - 10<br />

0.2 SB-2570TR FT-8 -<br />

1010JX-09FF 10 10 15 10<br />

120<br />

0<br />

1212JX-09FF 12 12<br />

12<br />

0.2 SB-4085TR FT-15 -<br />

-<br />

1616JX-09FF 16 16 16<br />

E<br />

Small Tools<br />

SCLC (External / Facing)<br />

95<br />

5<br />

Right-hand shown<br />

F1 2<br />

5<br />

16<br />

95<br />

SCLC$1010F-09<br />

shows above figure.<br />

F1<br />

h<br />

0<br />

5<br />

L2 95<br />

L1<br />

H1 B<br />

Toolholder Dimensions<br />

Description<br />

Std.<br />

Dimension (mm)<br />

R L H1=h B L1 L2 F1<br />

Standard Corner-R(rε)<br />

Spare Parts<br />

Clamp Screw Wrench Wrench<br />

SCLC 1010F -06 10 10 80 9 12 0.2 SB-2570TR FT-8 -<br />

1010F -09 10 10 80 14<br />

14<br />

1212H -09 12 12 16<br />

100<br />

1616H -09 16 16 15 20<br />

0.2 SB-4085TR FT-15 -<br />

2020K -09 20 20 125 20 25<br />

2525M -09 25 25 150 22 32<br />

1616H -12 16 16 100 20 20<br />

2020K -12 20 20 125 25<br />

0.4 SB-5090TR - LTW-20<br />

22<br />

2525M -12 25 25 150 32<br />

Applicable Inserts (SCLC-FF / SCLC)<br />

Toolholder<br />

Applications Finishing Finishing-Medium Finishing-Medium Low Feed Stainless Steel Cast Iron<br />

Non-ferrous<br />

Metals<br />

Non-ferrous<br />

Metals<br />

Non-ferrous<br />

Metals Hard Materials<br />

Ref. Page B45 B45 B45 B48 B46 B46 B46 B46 C18 C10<br />

GF GK GQ (E/F) -U MQ Without Chipbreaker AH -A3 PCD CBN<br />

Insert<br />

CCMT0602..<br />

SCLC...-06FF/-06 CCGT0602.. CCMT0602.. CCGT0602.. CCGT0602.. - CCGW0602.. - -<br />

CCMW0602..<br />

CCGW0602..<br />

CCMT09T3..<br />

SCLC...-09FF/-09 CCGT09T3.. CCMT09T3.. CCGT09T3.. CCGT09T3.. CCMT09T3.. CCGW09T3.. CCGT09T3.. CCGT09T3..<br />

CCMW09T3..<br />

CCGW09T3..<br />

SCLC...-12 - CCMT1204.. - - - - - CCGT1204.. - -<br />

For recommended cutting conditions, see page<br />

E38<br />

: Std. Item<br />

E21

External Toolholders [DC Insert]<br />

Back Clamp<br />

ADJC-FF(Without Offset) (External / Copying)<br />

F2<br />

32°<br />

L2<br />

F1<br />

32°<br />

*Lock Screw is operated from this direction.<br />

B<br />

93°<br />

32°<br />

F1<br />

S<br />

ADJC$1010JX-11FF<br />

ADJC$1212JX-11FF<br />

shows above figure.<br />

S<br />

h<br />

0°<br />

L1<br />

H1<br />

Right-hand shown<br />

For recommended cutting conditions, see page E38<br />

L2<br />

H2<br />

E<br />

Small Tools<br />

Toolholder Dimensions<br />

Spare Parts<br />

Std.<br />

Dimension (mm)<br />

Anchor Pin Lock Screw Wrench<br />

Description<br />

R L H1=h H2 B L1 L2 F1 F2 S<br />

ADJC 1010JX -07FF 10 - 10 - 10 - 0.2 LPF-11<br />

1010JX-11FF 10 2 10<br />

10 3<br />

120 20<br />

0 LPF-13 HSB4X8 FH-2<br />

1212JX -11FF 12 12 12 1 0.2<br />

-<br />

1616JX-11FF 16 16 - 16 - LPF-17<br />

Lock Screw : HSB4×8R for Right-hand Toolholder, and HSB4×8L for Left-hand Toolholder.<br />

Standard Corner-R(rε)<br />

Applicable Inserts<br />

Toolholder<br />

ADJC...-07FF<br />

Applications Minute ap Finishing Finishing-Medium Finishing-Medium Medium Medium Finishing Finishing / Precision Low Feed Finishing / Precision<br />

Ref. Page B52 B52 B53 B53 B54 B53 B55 B55 B56 B56<br />

CF GF GK GQ FN-Z Standard -F -FSF (E / F) -U F-USF<br />

Insert<br />

DCGT0702.. DCGT0702.. DCMT0702.. DCGT0702.. DCGT0702.. DCGT0702.. DCGT0702.. DCET0702.. DCGT0702.. DCET0702..<br />

ADJC...-11FF<br />

DCGT11T3.. DCGT11T3.. DCMT11T3.. DCGT11T3.. DCGT11T3.. DCGT11T3.. DCGT11T3.. DCET11T3.. DCGT11T3.. DCET11T3..<br />

DCMT11T3..<br />

Low Carbon Steel<br />

Applications Low Feed Low Feed / Precision Low Carbon Steel Finishing Finishing-Medium Stainless Steel Cast Iron Non-ferrous Metals Non-ferrous Metals Non-ferrous Metals Hard Materials<br />

Ref. Page B57 B57 B54 B54 B54 B57 B57 B57 C19 C11<br />

(E / F) -J F-JSF XP XQ MQ Without Chipbreaker AH -A3 PCD CBN<br />

Insert<br />

Toolholder<br />

ADJC...-07FF - - DCMT0702.. - DCMT0702.. DCGW0702.. - - DCMT0702.. DCMW0702..<br />

ADJC...-11FF<br />

DCGT11T3.. DCET11T3.. DCMT11T3.. DCMT11T3.. DCMT11T3.. DCGW11T3.. DCGT11T3.. DCGT11T3.. DCMT11T3.. DCMW11T3..<br />

E22<br />

: Std. Item : Check Availability

External Toolholders [DC Insert]<br />

Screw Clamp<br />

SDJC-FF(Without Offset) (External / Copying)<br />

93°<br />

32°<br />

F2<br />

F1<br />

L2<br />

32°<br />

S F1<br />

32°<br />

L1<br />

B<br />

S<br />

SDJC$0808F-07FF<br />

SDJC$1010JX-11FF<br />

SDJC$1212..-11FF<br />

shows above figure.<br />

h<br />

0°<br />

H1<br />

Right-hand shown<br />

Toolholder Dimensions<br />

Description<br />

Std.<br />

Dimension (mm)<br />

R L H1=h B L1 L2 F1 F2 S<br />

Standard Corner-R(rε)<br />

Clamp Screw<br />

SDJC 0808F -07FF 8 8 14 8 0.5<br />

SB-2570TR FT-8<br />

85<br />

0 0.2<br />

1212F -11FF 12 12 20 12 1 SB-4085TR FT-15<br />

SDJC 1010JX-07FF 10 10 - 10 - 0.2 SB-2570TR FT-8<br />

1010JX-11FF 10 10<br />

10 3<br />

120 20<br />

0<br />

1212JX-11FF 12 12 12 1 0.2 SB-4085TR FT-15<br />

1616JX-11FF 16 16 - 16 -<br />

Spare Parts<br />

Wrench<br />

E<br />

Small Tools<br />

SDJC (External / Copying)<br />

32<br />

F1<br />

B<br />

32<br />

93<br />

0<br />

93<br />

L2<br />

L1<br />

Right-hand shown<br />

h<br />

H1<br />

Applicable Inserts<br />

Description<br />

Std.<br />

Dimension (mm)<br />

R L H1=h B L1 L2 F1<br />

Standard Corner-R(rε)<br />

Clamp Screw<br />

SDJC 1010F -07 10 10 80 12 12 0.2 SB-2570TR FT-8<br />

SDJC 1010F -11 10 10 80 12<br />

1212H -11 12 12 16<br />

100<br />

1616H -11 16 16 18 20<br />

0.2 SB-4085TR FT-15<br />

2020K -11 20 20 125 25<br />

2525M -11 25 25 150 32<br />

Applicable Inserts<br />

Toolholder<br />

SDJC...-07FF/-07<br />

Spare Parts<br />

Wrench<br />

Applications Minute ap Finishing Finishing-Medium Finishing-Medium Medium Medium Finishing Finishing / Precision Low Feed Finishing / Precision<br />

Ref. Page B52 B52 B53 B53 B54 B53 B55 B55 B56 B56<br />

CF GF GK GQ FN-Z Standard -F -FSF (E / F) -U F-USF<br />

Insert<br />

DCGT0702.. DCGT0702.. DCMT0702.. DCGT0702.. DCGT0702.. DCGT0702.. DCGT0702.. DCET0702.. DCGT0702.. DCET0702..<br />

SDJC...-11FF/-11 DCGT11T3.. DCGT11T3.. DCMT11T3.. DCGT11T3.. DCGT11T3.. DCGT11T3.. DCGT11T3.. DCET11T3.. DCGT11T3.. DCET11T3..<br />

DCMT11T3..<br />

Low Carbon Steel<br />

Applications Low Feed Low Feed / Precision Low Carbon Steel Finishing Finishing-Medium Stainless Steel Cast Iron Non-ferrous Metals Non-ferrous Metals Non-ferrous Metals Hard Materials<br />

Ref. Page B57 B57 B54 B54 B54 B57 B57 B57 C19 C11<br />

(E / F) -J F-JSF XP XQ MQ Without Chipbreaker AH -A3 PCD CBN<br />

Insert<br />

Toolholder<br />

SDJC...-07FF/-07 - - DCMT0702.. - DCMT0702.. DCGW0702.. - - DCMT0702.. DCMW0702..<br />

SDJC...-111FF/-11<br />

DCGT11T3.. DCET11T3.. DCMT11T3.. DCMT11T3.. DCMT11T3.. DCGW11T3.. DCGT11T3.. DCGT11T3.. DCMT11T3.. DCMW11T3..<br />

For recommended cutting conditions, see page<br />

E38<br />

: Std. Item<br />

E23

External Toolholders [DC Insert]<br />

Screw Clamp<br />

SDLC-FF(Without Offset) (External / Copying)<br />

F2<br />

30˚<br />

20<br />

30˚<br />

95˚<br />

30˚<br />

F1<br />

S<br />

Right-hand shown<br />

95˚<br />

SDLC$1010..-11FF<br />

SDLC$1212..-11FF<br />

shows above figure.<br />

h S F1<br />

0˚<br />

95˚<br />

L1<br />

B<br />

H1<br />

E<br />

Small Tools<br />

Toolholder Dimensions<br />

Description<br />

Std.<br />

Dimension (mm)<br />

R L H1=h B L1 F1 F2 S<br />

Standard Corner-R(rε)<br />

Clamp Screw<br />

SDLC 1010JX-07FF 10 10 10<br />

1212JX-07FF 12 12 120 12 - 0 0.2 SB-2570TR FT-8<br />

1616JX-07FF 16 16 16<br />

SDLC 1010JX-11FF 10 10 10 4<br />

1212JX-11FF 12 12 120 12 2 0 0.2 SB-4085TR FT-15<br />

1616JX-11FF 16 16 16 -<br />

SDLC 1212F -07FF 12 12 85 12 - 0 0.2 SB-2570TR FT-8<br />

SDLC 1010F -11FF 10 10 80 10 4<br />

1212F -11FF 12 12 85 12 2 0 0.2 SB-4085TR FT-15<br />

1616H -11FF 16 16 100 16 -<br />

Spare Parts<br />

Wrench<br />

SDXC (External / Facing / Copying)<br />

20<br />

20°<br />

105<br />

20<br />

F1 4<br />

SDXC$1010JX-11<br />

shows above figure.<br />

F1<br />

h<br />

0°<br />

105°<br />

L1<br />

H1 B<br />

Right-hand shown<br />

E24<br />

Applicable Inserts<br />

Description<br />

Std.<br />

Applicable Inserts (SDLC-FF / SDXC)<br />

Dimension (mm)<br />

R L H1=h B L1 F1<br />

Standard Corner-R(rε)<br />

Clamp Screw<br />

SDXC 1010JX-07 10 10 12 0.2 SB-2570TR FT-8<br />

1010JX-11 10 10 12<br />

120<br />

1212JX-11 12 12 16<br />

0.2 SB-4085TR FT-15<br />

1616JX-11 16 16 20<br />

Toolholder<br />

Spare Parts<br />

Wrench<br />

Applications Minute ap Finishing Finishing-Medium Finishing-Medium Medium Medium Finishing Finishing / Precision Low Feed Finishing / Precision<br />

Ref. Page B52 B52 B53 B53 B54 B53 B55 B55 B56 B56<br />

Insert<br />

CF GF GK GQ FN-Z Standard -F -FSF (E / F) -U F-USF<br />

SDLC...-07FF<br />

SDXC...-07<br />

DCGT0702.. DCGT0702.. DCMT0702.. DCGT0702.. DCGT0702.. DCGT0702.. DCGT0702.. DCET0702.. DCGT0702.. DCET0702..<br />

SDLC...-11FF<br />

SDXC...-11<br />

DCGT11T3.. DCGT11T3.. DCMT11T3.. DCGT11T3.. DCGT11T3.. DCGT11T3.. DCGT11T3.. DCET11T3.. DCGT11T3.. DCET11T3..<br />

DCMT11T3..<br />

Applications Low Feed Low Feed / Precision Low Carbon Steel Finishing<br />

Low Carbon Steel<br />

Finishing-Medium Stainless Steel Cast Iron Non-ferrous Metals Non-ferrous Metals Non-ferrous Metals Hard Materials<br />

Ref. Page B57 B57 B54 B54 B54 B57 B57 B57 C19 C11<br />

Toolholder<br />

SDLC...-07FF<br />

SDXC...-07<br />

SDLC...-11FF<br />

SDXC...-11<br />

Insert<br />

(E / F) -J F-JSF XP XQ MQ Without Chipbreaker AH -A3 PCD CBN<br />

- - DCMT0702.. - DCMT0702.. DCGW0702.. - - DCMT0702.. DCMW0702..<br />

DCGT11T3.. DCET11T3.. DCMT11T3.. DCMT11T3.. DCMT11T3.. DCGW11T3.. DCGT11T3.. DCGT11T3.. DCMT11T3.. DCMW11T3..<br />

For recommended cutting conditions, see page E38<br />

: Std. Item : Check Availability

External Toolholders [DC Insert]<br />

Screw Clamp<br />

SDNC-F (External / Copying)<br />

F1<br />

62.5<br />

h F2<br />

0<br />

62.5<br />

L1<br />

H1 B<br />

Right-hand shown<br />

SDNC (External / Copying)<br />

62.5<br />

E<br />

F1<br />

62.5<br />

h<br />

0<br />

62.5<br />

L1<br />

H1 B<br />

Small Tools<br />

Toolholder Dimensions<br />

Description<br />

SDNC 1010JX-07F 10 10 120 7 10.5 0.2 SB-2570TR FT-8<br />

SDNCN 1010JX-07 10 10 5<br />

1212JX-07 12 12 6<br />

- 0.2 SB-2570TR FT-8<br />

1010JX-11 10 10 120 5<br />

1212JX-11 12 12 6 - 0.2 SB-4085TR FT-15<br />

1616JX-11 16 16 8<br />

SDNCN 0808F -07 8 8 85 4 - 0.2 SB-2570TR FT-8<br />

SDNCN 1010F -11 10 10 80 5<br />

1212F -11 12 12 85 6 - 0.2 SB-4085TR FT-15<br />

1616H -11 16 16 100 8<br />

Applicable Inserts<br />

Toolholder<br />

SDNC...-07F<br />

SDNCN...-07<br />

SDNCN...-11<br />

Toolholder<br />

Std.<br />

Dimension (mm)<br />

R N L H1=h B L1 F1 F2<br />

Standard Corner-R(rε)<br />

Clamp Screw<br />

Spare Parts<br />

Wrench<br />

Applications Minute ap Finishing Finishing-Medium Finishing-Medium Medium Medium Finishing Finishing / Precision Low Feed Finishing / Precision<br />

Ref. Page B52 B52 B53 B53 B54 B53 B55 B55 B56 B56<br />

CF GF GK GQ FN-Z Standard -F -FSF (E / F) -U F-USF<br />

Insert<br />

DCGT0702.. DCGT0702.. DCMT0702.. DCGT0702.. DCGT0702.. DCGT0702.. DCGT0702.. DCET0702.. DCGT0702.. DCET0702..<br />

DCGT11T3.. DCGT11T3.. DCMT11T3.. DCGT11T3.. DCGT11T3.. DCGT11T3.. DCGT11T3.. DCET11T3.. DCGT11T3.. DCET11T3..<br />

DCMT11T3..<br />

Low Carbon Steel<br />

Applications Low Feed Low Feed / Precision Low Carbon Steel Finishing Finishing-Medium Stainless Steel Cast Iron Non-ferrous Metals Non-ferrous Metals Non-ferrous Metals Hard Materials<br />

Ref. Page B57 B57 B54 B54 B54 B57 B57 B57 C19 C11<br />

(E / F) -J F-JSF XP XQ MQ Without Chipbreaker AH -A3 PCD CBN<br />

Insert<br />

SDNC...-07F<br />

SDNCN...-07<br />

SDNCN...-11<br />

- - DCMT0702.. - DCMT0702.. DCGW0702.. - - DCMT0702.. DCMW0702..<br />

DCGT11T3.. DCET11T3.. DCMT11T3.. DCMT11T3.. DCMT11T3.. DCGW11T3.. DCGT11T3.. DCGT11T3.. DCMT11T3.. DCMW11T3..<br />

For recommended cutting conditions, see page E38<br />

: Std. Item : Check Availability<br />

E25

External Toolholders [DP Insert<br />

Screw Clamp<br />

SDLP-FF (Without Offset) (External / Copying)<br />

F2<br />

30°<br />

L2<br />

30°<br />

95˚<br />

30˚<br />

F1<br />

S<br />

95°<br />

SDLP$0808F-07FF<br />

SDLP$1212F-11FF<br />

SDLP$1010JX-11FF<br />

SDLP$1212JX-11FF<br />

shows above figure.<br />

h S F1<br />

0°<br />

95°<br />

L1<br />

B<br />

H1<br />

Right-hand shown<br />

E<br />

Small Tools<br />

Toolholder Dimensions<br />

Description<br />

Applicable Inserts<br />

Std.<br />

Dimension (mm)<br />

R L H1=h B L1 L2 F1 F2 S<br />

Standard Corner-R(rε)<br />

Clamp Screw<br />

SDLP 0808F -07FF 8 8 14 8 0.5<br />

SB-2570TR FT-8<br />

85<br />

0 0.2<br />

1212F -11FF 12 12 20 12 2 SB-4085TR FT-15<br />

SDLP 1010JX-07FF 10 10 - 10 - 0.2 SB-2570TR FT-8<br />

1010JX-11FF 10 10<br />

10 4<br />

120 20<br />

0<br />

1212JX-11FF 12 12 12 2 0.2 SB-4085TR FT-15<br />

1616JX-11FF 16 16 - 16 -<br />

Toolholder<br />

SDLP...-07FF<br />

SDLP...-11FF<br />

Applications Finishing / Precision Low Feed / Precision<br />

Ref. Page B59 B59<br />

-FSF F-USF<br />

Insert<br />

DPET0702.. DPET0702..<br />

DPET11T3.. DPET11T3..<br />

Spare Parts<br />

Wrench<br />

For recommended cutting conditions, see page<br />

E38<br />

E26<br />

: Std. Item

External Toolholders [TC / TP Insert<br />

Screw Clamp<br />

STGC(P) (External)<br />

F1 2.5<br />

15<br />

F1<br />

B<br />

91<br />

91°<br />

STGC(P)1010F-11<br />

shows above figure.<br />

0°<br />

91°<br />

L2<br />

L1<br />

Right-hand shown<br />

h<br />

H1<br />

Toolholder Dimensions<br />

Description<br />

Std.<br />

Dimension (mm)<br />

R L H1=h B L1 L2 F1<br />

STGC 0808E -08 8 8 70 10<br />

12<br />

1010F -08 10 10 80 12<br />

STGC 1010F -11 10 10 80 14<br />

1212H -11 12 12 16<br />

100 15<br />

1616H -11 16 16 20<br />

2020K -11 20 20 125 25<br />

2525M -11 25 25 150 20 32<br />

STGP 0808E -08 8 8 70 10<br />

12<br />

1010F -08 10 10 80 12<br />

STGP 1010F -11 10 10 80 14<br />

1212H -11 12 12 15 16<br />

100<br />

1616H -11 16 16 20<br />

Standard Corner-R(rε)<br />

Spare Parts<br />

Clamp Screw Wrench<br />

0.2 SB-2050TR FT-6<br />

0.4 SB-2570TR FT-8<br />

0.2 SB-2050TR FT-6<br />

0.2 SB-3080TR FT-10<br />

E<br />

Small Tools<br />

Applicable Inserts (STGC)<br />

Toolholder<br />

Applicable Inserts (STGP)<br />

Applications Low Feed Low Feed / Precision Cast Iron Non-ferrous Metals Non-ferrous Metals<br />

Ref. Page B63, B64 B64 B64 B64 C19, C20<br />

(E/F) -U F-USF Without Chipbreaker -A3 PCD<br />

Insert<br />

STGC...-08 TCGT0802.. TCET0802.. TCGW0802.. - TCMT0802..<br />

STGC...-11<br />

Toolholder<br />

TCGT1103.. TCET1103.. TCGW1103.. TCGT1103.. TCMT1103..<br />

TCGW1103..<br />

Low Carbon Steel Low Carbon Steel<br />

Applications Minute ap Finishing-Medium Finishing Finishing / Precision Low Feed / Precision Medium cutting Finishing Finishing-Medium Cast Iron Non-ferrous Metals<br />

Ref. Page B66 B66 B67 B68 B68 B67 B66 B66 B68 C20, C21<br />

CF HQ -FSF F-USF -H XP XQ Without Chipbreaker PCD<br />

Insert<br />

STGP...-08 TPGT0802.. - TPGH0802.. TPET0802.. TPET0802.. - - - TPGB0802.. TPMH0802..<br />

TPGB0802..<br />

STGP...-11 - TPMT1103.. TPGH1103.. TPET1103.. TPET1103.. TPGH1103.. TPMT1103.. TPMT1103.. TPGB1103.. TPMH1103..<br />

TPGB1103..<br />

Applications Hard Materials<br />

Ref. Page C12<br />

Toolholder<br />

Insert<br />

CBN<br />

STGP...-08<br />

TPGB0802..<br />

STGP...-11<br />

TPGB1103..<br />

For recommended cutting conditions, see page<br />

E38<br />

: Std. Item : Check Availability<br />

E27

External Toolholders [VB / VC Insert<br />

Back Clamp / Screw Clamp<br />

AVJB-FF (Without Offset) (External / Copying)<br />

52°<br />

*Lock Screw is operated from this direction.<br />

E<br />

SVJB-FF (Without Offset) (External / Copying)<br />

52°<br />

F1<br />

B<br />

F1<br />

B<br />

3°<br />

52°<br />

S<br />

0°<br />

93°<br />

L1<br />

Right-hand shown<br />

h<br />

H1<br />

3°<br />

52°<br />

S<br />

0°<br />

93°<br />

L1<br />

Small Tools<br />

Toolholder Dimensions<br />

Description<br />

Right-hand Shown<br />

Std.<br />

h<br />

Dimension (mm)<br />

R L H1=h B L1 L2 F1 S<br />

Standard Corner-R(rε)<br />

Spare Parts<br />

Anchor Pin Lock Screw Clamp Screw Wrench<br />

AVJB 1010JX-11FF 10 10<br />

10<br />

LPF-11<br />

1212JX-11FF 12 12 120 - 12 0 0.4 LPF-1113 HSB4X8 - FH-2<br />

1616JX-11FF 16 16 16 LPF-1117<br />

SVJB 1010JX-11FF 10 10<br />

10<br />

1212JX-11FF 12 12 120 - 12 0 0.4 - - SB-2570TR FT-8<br />

1616JX-11FF 16 16 16<br />

Lock Screw: HSB4×8R for R-hand Toolholder, HSB4×8L for L-hand Toolholder.<br />

SVJB (External / Copying)<br />

H1<br />

3<br />

52<br />

F1<br />

h<br />

0<br />

52<br />

L2<br />

93<br />

L1<br />

H1 B<br />

Right-hand shown<br />

Toolholder Dimensions<br />

Description<br />

Std.<br />

Dimension (mm)<br />

R L H1=h B L1 L2 F1<br />

SVJB 2020K-11 20 20 125 30 25<br />

2525M-11 25 25 150 35 32<br />

SVJB 2020K-16N 20 20 125 25 30<br />

2525M-16N 25 25 150 32<br />

Lock Screw: HSB4×8R for R-hand Toolholder, HSB4×8L for L-hand Toolholder.<br />

Applicable Inserts (AVJB-F / SVJB-F / SVJB)<br />

Toolholder<br />

Standard Corner-R(rε)<br />

Spare Parts<br />

Clamp Screw Wrench Shim Shim Screw Wrench<br />

0.4 SB-2570TR FT-8 - - -<br />

0.8 SB-40125TRN FT-15 SVN-32N SS-4N LW-4<br />

Application Finishing Finishing Finishing-Medium Finishing Finishing / Precision Finishing-Medium Medium Non-ferrous Metals Non-ferrous Metals Non-ferrous Metals Hard Materials<br />

Ref. Page B72 B72 B72, B73 B72 B72 B73 B72, B73 B73 B73 C22 C14<br />

GP VF HQ $-F $-FSF $-Y FN-Z AH $-A3 PCD CBN<br />

Insert<br />

VJB ...-11FF/-11 VBMT1103.. VBMT1103.. VBMT1103..<br />

VCMT1103.. VBGT1103.. VBET1103.. VBGT1103.. VBGT1103..<br />

- - VBMT1103.. VBGW1103..<br />

VCGT1103.. VCGT1103..<br />

SVJB ...-16 N VBMT1604.. VBMT1604.. VBMT1604..<br />

VBGT1604.. VBGT1604..<br />

VBGW1604..<br />

- -<br />

VCGT1604.. VCGT1604.. VBMT1604..<br />

VCMT1604..<br />

VCGT1604.. VCGT1604.. VCGW1604..<br />

For recommended cutting conditions, see page E38<br />

E28<br />

: Std. Item : Check Availability

External Toolholders [VB / VC Insert<br />

Screw Clamp<br />

SVPB (External / Facing / Copying / Undercutting)<br />

Undercutting diameter of SVPB<br />

27.5<br />

h F1<br />

27.5<br />

117.5<br />

0<br />

Right-hand shown<br />

L1<br />

H1 B<br />

Corner-R (rε)<br />

ap<br />

ap<br />

øD<br />

(MIN)<br />

Corner-R<br />

rε<br />

0.4<br />

0.8<br />

ap<br />

0.5<br />

1<br />

0.5<br />

1<br />

øD<br />

(MIN)<br />

ø25<br />

ø30<br />

ø45<br />

ø55<br />

Toolholder Dimensions<br />

Description<br />

Std.<br />

Dimension (mm)<br />

R L H1=h B L1 L2 F1<br />

Standard Corner-R(rε)<br />

Spare Parts<br />

Clamp Screw Wrench Shim Shim Screw Wrench<br />

SVPB 1010JX-11 10 10 14.5<br />

1212JX-11 12 12 120 - 16.5 0.4 SB-2570TR FT-8 - - -<br />

1616JX-11 16 16 20.5<br />

SVPB 2020K-11 20 20 125 25<br />

-<br />

2525M-11 25 25 150 32<br />

0.4 SB-2570TR FT-8 - - -<br />

SVPB 2020K-16N 20 20 125 25<br />

-<br />

2525M-16N 25 25 150 32<br />

0.8 SB-40125TRN FT-15 SVN-32N SS-4N LW-4<br />

E<br />

Small Tools<br />

SVVB (External / Copying)<br />

72.5<br />

F1<br />

72.5<br />

h<br />

0<br />

72.5<br />

L1<br />

H1 B<br />

Toolholder Dimensions<br />

Description<br />

Applicable Inserts<br />

: Std. Item : Check Availability<br />

Std.<br />

Dimension (mm)<br />

H1=h B L1 F1<br />

SVVBN 1212F-11 12 12 85 6<br />

SVVBN 1010JX-11 10 10 5<br />

1212JX-11 12 12 120 6<br />

1616JX-11 16 16 8<br />

SVVBN 1010F-11 10 10 80 5<br />

1616H-11 16 16 100 8<br />

2020K-11 20 20 125 10<br />

2525M-11 25 25 150 12.5<br />

SVVBN 2020K-16N 20 20 125 10<br />

2525M-16N 25 25 150 12.5<br />

Toolholder<br />

Standard Corner-R(rε)<br />

Spare Parts<br />

Clamp Screw Wrench Shim Shim Screw Wrench<br />

0.4 SB-2570TR FT-8 - - -<br />

0.4 SB-2570TR FT-8 - - -<br />

0.8 SB-40125TRN FT-15 SVN-32N SS-4N LW-4<br />

Application Finishing Finishing-Medium Finishing-Medium Finishing Finishing / Precision Finishing-Medium Medium Non-ferrous Metals Non-ferrous Metals Non-ferrous Metals Hard Materials<br />

Ref. Page B72 B72 B72, B73 B72 B72 B73 B72, B73 B73 B73 C22 C14<br />

GP VF HQ $-F $-FSF $-Y FN-Z AH $-A3 PCD CBN<br />

Insert<br />

SVPB...-11<br />

SVVBN...-11<br />

SVPB...-16N<br />

SVVBN...-16N<br />

VBMT1103.. VBMT1103.. VBMT1103..<br />

VCMT1103.. VBGT1103.. VBET1103.. VBGT1103.. VBGT1103..<br />

VCGT1103.. VCGT1103..<br />

VBMT1604.. VBMT1604.. VBMT1604..<br />

VCMT1604..<br />

- -<br />

- - VBMT1103.. VBGW1103..<br />

VBGT1604.. VBGT1604..<br />

VBGW1604..<br />

VCGT1604.. VCGT1604.. VBMT1604..<br />

VCGT1604.. VCGT1604.. VCGW1604..<br />

For recommended cutting conditions, see page<br />

E38<br />

E29

External Toolholders [ <br />

Screw Clamp<br />

SVJP-FF (Without Offset) (External / Copying)<br />

52˚<br />

3˚<br />

52˚<br />

h S F1<br />

0˚<br />

93˚<br />

L1<br />

B<br />

H1<br />

Right-hand shown<br />

E<br />

SVLP-FF (Without Offset) (External / Copying)<br />

50˚<br />

Small Tools<br />

5˚<br />

50˚<br />

Right-hand shown<br />

h S F1<br />

0˚<br />

95˚<br />

L1<br />

B<br />

H1<br />

Toolholder Dimensions<br />

Description<br />

Std.<br />

Dimension (mm)<br />

R L H1=h B L1 L2 L3 F1 S<br />

Standard Corner-R(rε)<br />

Clamp Screw<br />

SVJP 1212F -11FF 12 12 85<br />

12<br />

1212JX -11FF 12 12 - - 12 0 0.2 SB-2570TR FT-8<br />

120<br />

1616JX -11FF 16 16 16<br />

SVLP 1010JX -08FF 10 10<br />

10<br />

1212JX -08FF 12 12 120 - - 12 0 0.1 SB-2050TR FT-6<br />

1616JX -08FF 16 16 16<br />

SVLP 1212JX -11FF 12 12 12<br />

120 - -<br />

1616JX -11FF 16 16 16<br />

0 0.2 SB-2570TR FT-8<br />

SVLP 1212F -08FF 12 12 85 - - 12 0 0.1 SB-2050TR FT-6<br />

1212F -11FF 12 12 85 - - 12 0 0.2 SB-2570TR FT-8<br />

Applicable Inserts<br />

Toolholder<br />

Applications Minute ap Finishing Finishing Finishing / Precision Low Feed Low Feed / Precision<br />

Ref. Page B75 B75 B75 B76 B76 B76<br />

CF CK GF -FSF F-U F-USF<br />

Insert<br />

Spare Parts<br />

Wrench<br />

SVLP...-08FF - VPGT0802.. - VPET0802.. - VPET0802..<br />

SVP...-11FF<br />

VPGT1103.. VPGT1103.. VPGT1103.. VPET1103.. VPGT1103.. VPET1103..<br />

For recommended cutting conditions, see page<br />

E38<br />

E30<br />

: Std. Item : Check Availability

Screw Clamp<br />

SVPP-FF (Without Offset) (External / Facing / Copying / Undercutting)<br />

27.5˚<br />

L3<br />

27.5˚<br />

F1 F2<br />

B<br />

SVPPR1616H-08FF<br />

shows above figure.<br />

S<br />

0˚<br />

117.5˚<br />

L2<br />

45˚<br />

L1<br />

h<br />

H1<br />

Right-hand shown<br />

E<br />

SVPP (External / Facing / Copying / Undercutting)<br />

18<br />

27.5˚ 27.5˚<br />

27.5˚<br />

F1 2<br />

SVPPR1010F-11<br />

shows above figure.<br />

F1<br />

0˚<br />

117.5˚<br />

L1<br />

B<br />

h<br />

Small Tools<br />

H1<br />

Right-hand shown<br />

Toolholder Dimensions<br />

Description<br />

Std.<br />

Dimension (mm)<br />

R L H1=h B L1 L2 L3 F1 F2 S<br />

Standard Corner-R(rε)<br />

Clamp Screw<br />

SVPPR 1010JX-08FF 10 10<br />

10 4<br />

16<br />

1212JX-08FF 12 12 120 12 12 2 0 0.1 SB-2050TR FT-6<br />

1616JX-08FF 16 16 - 16 -<br />

SVPPR 1010JX-11FF 10 10<br />

10 8<br />

1212JX-11FF 12 12 120 16 20 12 6 0 0.2 SB-2570TR FT-8<br />

1616JX-11FF 16 16 16 2<br />

SVPPR 1212F -08FF 12 12 85 12 16 12 2 0 0.1 SB-2050TR FT-6<br />

1212F -11FF 12 12 85 16 20 12 6 0 0.2 SB-2570TR FT-8<br />

SVPP 1010F -11 10 10 80<br />

14.5<br />

- -<br />

1212H -11 12 12 100 16.5<br />

- - 0.2 SB-2570TR FT-8<br />

Spare Parts<br />

Wrench<br />

Applicable Inserts<br />

Applications Minute ap Finishing Finishing Finishing / Precision Low Feed Low Feed / Precision<br />

Ref. Page B75 B75 B75 B76 B76 B76<br />

CF CK GF -FSF F-U F-USF<br />

Insert<br />

Toolholder<br />

SVPPR...-08FF - VPGT0802.. - VPET0802.. - VPET0802..<br />

SVPPR...-11FF<br />

VPGT1103.. VPGT1103.. VPGT1103.. VPET1103.. VPGT1103.. VPET1103..<br />

SVPP...-11<br />

VPGT1103.. VPGT1103.. VPGT1103.. VPET1103.. VPGT1103.. VPET1103..<br />

For recommended cutting conditions, see page E38<br />

Undercutting diameter of<br />

SVPP-FF / SVPP<br />

Corner-R(rε)<br />

Corner-R<br />

(rε)<br />

0.2<br />

ap<br />

ap<br />

ap<br />

øD<br />

øD<br />

(MIN)<br />

0.5 ø20<br />

1 ø25<br />

(MIN)<br />

: Std. Item<br />

E31

External Toolholders [YP Insert<br />

Screw Clamp<br />

SYXP-F (External / Facing / Copying)<br />

35<br />

100<br />

35<br />

h F1<br />

0<br />

100<br />

L1<br />

B<br />

H1<br />

Right-hand shown<br />

E<br />

Toolholder Dimensions<br />

Description<br />

Std. Dimension (mm)<br />

R L H1=h B L1 F1<br />

Standard Corner-R(rε)<br />

Spare Parts<br />

Clamp Screw Wrench<br />

Small Tools<br />

SYXP 0808F -06F 8 8 80 8.5 0.2 SB-2050TR FT-6<br />

1010H-06F 10 10 100 10.5<br />

Applicable Inserts<br />

Applications Finishing Low Feed<br />

Ref. Page B80 B80<br />

-F F-U<br />

Insert<br />

Toolholder<br />

SYXP...-06F YPGT0602.. YPGT0602..<br />

For recommended cutting conditions, see page<br />

E38<br />

E32<br />

: Std. Item

External Sleeve Holders Insert<br />

Screw Clamp<br />

S...SCLC (External / Facing)<br />

16 H2<br />

95<br />

0<br />

80<br />

20<br />

L1<br />

H1<br />

F1<br />

Left-hand shown<br />

5<br />

d1<br />

D<br />

R-hand Insert for L-hand Toolholder.<br />

E<br />

Toolholder Dimensions<br />

Description<br />

Std.<br />

Dimension (mm)<br />

øD L1 F1 ød1 H1=H2<br />

S12F -SCLCL06 12 80<br />

11<br />

13.4<br />

S14H -SCLCL06 14 100 13<br />

S15F -SCLCL06 15.875<br />

85 15.4 15<br />

S16F -SCLCL06 16<br />

6<br />

S19G -SCLCL06<br />

<br />

90<br />

19.05<br />

18.4 17<br />

S19K -SCLCL06 120<br />

S20G -SCLCL06<br />

<br />

90<br />

20<br />

S20K -SCLCL06 120<br />

19.4 18<br />

S19G -SCLCL09<br />

<br />

90<br />

19.05<br />

S19K -SCLCL09 120<br />

18.4 17<br />

S20G -SCLCL09<br />

<br />

90<br />

20<br />

S20K -SCLCL09 120<br />

10 19.4 18<br />

S25.0H-SCLCL09 25 100 24.4<br />

S25K -SCLCL09 25.4 120 24.8<br />

23<br />

Standard Corner-R(rε)<br />

0.4<br />

Spare Parts<br />

Clamp Screw Wrench<br />

SB-2560TR<br />

FT-8<br />

SB-2570TR<br />

0.4 SB-4065TR FT-15<br />

Small Tools<br />

Applicable Inserts<br />

Toolholder<br />

Applications Finishing Finishing-Medium Finishing-Medium Low Feed Stainless Steel Cast Iron Non-ferrous Metals Non-ferrous Metals Non-ferrous Metals Hard Materials<br />

Ref. Page B45 B45 B45 B48 B46 B46 B46 B46 C18 C10<br />

GF GK GQ (E/F)R-U MQ Without Chipbreaker AH R-A3 PCD CBN<br />

Insert<br />

CCMT0602..<br />

S...SCLCL06 CCGT0602.. CCMT0602.. CCGT0602.. CCGT0602.. - CCGW0602.. - -<br />

CCMW0602..<br />

CCGW0602..<br />

CCMT09T3..<br />

S...SCLCL09<br />

CCGT09T3.. CCMT09T3.. CCGT09T3.. CCGT09T3.. CCMT09T3.. CCGW09T3.. CCGT09T3.. CCGT09T3..<br />

CCGW09T3.. CCMW09T3..<br />

For recommended cutting conditions, see page<br />

E38<br />

: Std. Item<br />

E33

External Sleeve Holder [DC Insert<br />

Screw Clamp<br />

S...SDUC (External / Copying) / S...SDLC (External / Copying)<br />

16 H2<br />

<br />

0<br />

55<br />

20<br />

L1<br />

H1<br />

F1<br />

S<br />

E<br />

93° (S...SDUC)<br />

95° (S...SDLC)<br />

Left-hand Shown<br />

(S...SDUC)<br />

(S...SDLC)<br />

3<br />