ENG, GER, FRA, ITA - Kyocera

ENG, GER, FRA, ITA - Kyocera

ENG, GER, FRA, ITA - Kyocera

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

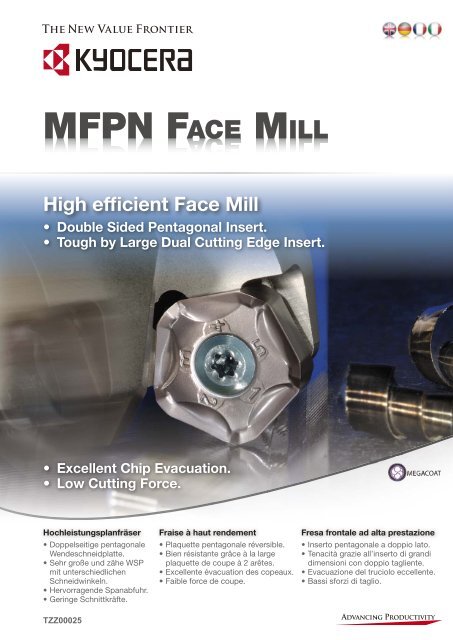

MFPN FACE MILL<br />

High efficient Face Mill<br />

• Double Sided Pentagonal Insert.<br />

• Tough by Large Dual Cutting Edge Insert.<br />

• Excellent Chip Evacuation.<br />

• Low Cutting Force.<br />

MEGACOAT<br />

Hochleistungsplanfräser Fraise à haut rendement Fresa frontale ad alta prestazione<br />

• Doppelseitige pentagonale<br />

Wendeschneidplatte.<br />

• Sehr große und zähe WSP<br />

mit unterschiedlichen<br />

Schneidwinkeln.<br />

• Hervorragende Spanabfuhr.<br />

• Geringe Schnittkräfte.<br />

• Plaquette pentagonale réversible.<br />

• Bien résistante grâce à la large<br />

plaquette de coupe à 2 arêtes.<br />

• Excellente évacuation des copeaux.<br />

• Faible force de coupe.<br />

• Inserto pentagonale a doppio lato.<br />

• Tenacità grazie all’inserto di grandi<br />

dimensioni con doppio tagliente.<br />

• Evacuazione del truciolo eccellente.<br />

• Bassi sforzi di taglio.<br />

TZZ00025<br />

1

■ Double Sided Pentagonal Insert<br />

Doppelseitige pentagonale Wendeschneidplatte<br />

Plaquette pentagonale réversible<br />

Inserto pentagonale a doppio lato<br />

10 cutting edges per insert and optimized insert holding system by 2 faces.<br />

10 Schneiden pro Wendeschneidplatte und optimaler Plattensitz mit zwei Anlagefl ächen.<br />

10 arêtes de coupe par plaquette et optimisation du serrage par 2 points d’appui.<br />

10 taglienti per inserto e sistema ottimizzato per il supporto bifacciale dell’inserto.<br />

12<br />

10<br />

8<br />

MSRS<br />

6<br />

5<br />

4<br />

3<br />

2<br />

Conventional<br />

MFPN<br />

0.5<br />

0.06 0.1 0.2 0.3 0.4 0.5 0.6<br />

ap (mm) Depth of cut<br />

fz (mm/t) Feed per tooth<br />

0.7<br />

Two-face holding<br />

Zwei Anlagefl ächen<br />

Tenue deux faces<br />

Supporto bifacciale<br />

Primary cutting edge<br />

Hauptschneide<br />

Principale aretes de coupe<br />

Primo tagliente<br />

Highly stabilized accuracy due to optimized holding angle of insert against the cutting force.<br />

Höhere Genauigkeit durch verbesserten Anstellwinkel gegen die Schnittkraft.<br />

Stabilité accrue grâce à l’optimisation du systeme de serrage de la plaquette.<br />

Precisione altamente stabile grazie all’ottimizzazione dell’angolo di supporto dell’inserto contro la forza di taglio.<br />

<br />

Cutting edge angle<br />

Schnittwinkel<br />

Angle d’arête de coupe<br />

Angolo del tagliente<br />

<br />

■ Low Cutting Force<br />

Geringe Schnittkraft<br />

Faible force de coupe<br />

Bassi sforzi di taglio<br />

Good shearing effect provides better bite into workpiece.<br />

Gute Schnittigkeit für besseren Eingriff ins Werkstück.<br />

Très bonne formation de copeaux dès le<br />

début de l’attaque de la pièce.<br />

Buon effetto di troncatura permette una<br />

migliore presa del pezzo.<br />

+10°<br />

<br />

High Axial Rake Angle (Max.+10°).<br />

Großer axialer Spanwinkel (Max. +10°).<br />

Angle axial très positif (Max. +10°)<br />

Alto angolo assiale di inclinazione (massimo +10°)<br />

Cutting force comparison<br />

2000<br />

1600<br />

1200<br />

800<br />

400<br />

0<br />

Comparison of cutting force<br />

Vergleich Schnittkraft<br />

Comparaison des force de coupe<br />

Comparazione degli sforzi di taglio<br />

16% reduction in comparison with competitor A<br />

14% reduction in comparison with GM<br />

GM<br />

SM<br />

Competitor A<br />

Competitor B<br />

Principal force<br />

Feed force<br />

Back force<br />

<br />

<br />

<br />

■ Dual Cutting Edge Design (High Toughness)<br />

Schneide mit unterschiedlichen Schneidwinkeln (Hohe Zähigkeit)<br />

Double arête de coupe réversible (grande ténacité)<br />

Design a doppio tagliente (alta tenacità)<br />

Comparison of fracture resistance<br />

Vergleich Bruchfestigkeit<br />

Comparaison de résistance à la rupture<br />

Confronto della resistenza alla frattura<br />

Wiper edge<br />

Secondary cutting edge<br />

Primary cutting edge<br />

PNMU1205ANER-GM<br />

(PR1225)<br />

Competitor C<br />

(PVD negative insert)<br />

Competitor D<br />

(PVD negative insert)<br />

No. of impacts<br />

0 5 10 15 20<br />

×<br />

×<br />

×<br />

×<br />

×<br />

×<br />

fz=0.5mm/t fz=0.6mm/t fz=0.7mm/t<br />

×<br />

○<br />

×<br />

No cracks<br />

Insert cracks<br />

0.5mm/t<br />

0.6mm/t<br />

0.7mm/t<br />

Primary Edge makes chips thinner and reduces impact force.<br />

Die Hauptschneide produziert dünnere Späne und reduziert Schnittkräfte.<br />

Grâce à l’arête de coupe primaire reduction des efforts d’attaque et naissance de copeaux fi ns.<br />

Il primo tagliente produce un truciolo fi ne riducendo le forze di impatto.<br />

<br />

<br />

<br />

~<br />

<br />

1

■ Long tool life with MEGACOAT<br />

Lange Werkzeugstandzeit mit MEGACOAT<br />

Longue durée de vie d’outil grâce au revêtment MEGACOAT<br />

Lunga vita utensile grazie al rivestimento MEGACOAT<br />

Wear comparison<br />

Vergleich des Verschleißverhaltens<br />

Comparaison des usures<br />

Confronto usura<br />

0.30<br />

40<br />

0.25<br />

30<br />

TiC<br />

MEGACOAT<br />

Flank wear [mm]<br />

0.20<br />

0.15<br />

0.10<br />

Competitor E<br />

Competitor F<br />

Hardness(GPa)<br />

20<br />

10<br />

TiCN<br />

TiN<br />

TiAlN<br />

0.05<br />

0.00<br />

0 20 40 60 80<br />

Cutting time [min]<br />

<br />

<br />

<br />

.<br />

<br />

Competitor G<br />

PR1225<br />

0 200 400 600 800 1000 1200<br />

Insert Grades<br />

MEGACOAT<br />

(PVD coated carbide)<br />

PR1225<br />

PR1210<br />

Oxidation temperature<br />

Workpiece Material<br />

Steel/Stainless steel<br />

Cast iron/Titanium alloy<br />

MEGACOAT<br />

Long tool life and high-speed milling due to<br />

high hardness and high oxidation resistance.<br />

Lange Standzeit und hohe Geschwindigkeiten durch<br />

hohen Härtegrad und Oxidationsbeständigkeit.<br />

Longue durée de vie et haute vitesse de coupe augmentée<br />

grâce à une plus grande duretée et résistance à l’oxydation.<br />

Lunga vita utensile e fresatura ad alta velocità per merito<br />

della durezza e dell’alta resistenza all’ossidazione.<br />

■ Excellent Chip Evacuation<br />

Hervorragende Spanabfuhr<br />

Excellente evacuation de copeaux<br />

Evacuazione del truciolo eccellente<br />

Smooth chip evacuation reduces chip-biting.<br />

Reduzierterter Spanschlag durch leichte Spanabfuhr.<br />

Design de la plaquette réduit les copeaux sur l’arête de coupe.<br />

L’evacuazione dei trucioli senza attrito, riduce l’impatto dei trucioli.<br />

Chipbreaker Applications Shape<br />

6<br />

SM<br />

GM<br />

General<br />

SM<br />

Low cutting force<br />

ap (mm) Depth of cut<br />

3<br />

GM<br />

GH<br />

1<br />

GH<br />

Heavy milling<br />

0.06 0.1 0.2 0.3 0.4 0.5 0.6 0.7<br />

fz (mm/t) Feed per tooth<br />

2

E<br />

<br />

A.R.<br />

R.R.<br />

Rake Angle(°)<br />

max +10°<br />

øD=63 -10°<br />

øD=80 -8°<br />

øD=100-250 -6°<br />

ød<br />

b<br />

6<br />

H<br />

E<br />

a<br />

a<br />

ød<br />

b<br />

ød<br />

b<br />

ø18<br />

6<br />

6<br />

H<br />

H<br />

E<br />

ød2<br />

ød1<br />

øD<br />

øD1<br />

45˚<br />

ød1<br />

øD<br />

øD1<br />

45˚<br />

ød2<br />

ød1<br />

øD<br />

øD1<br />

ø26<br />

45˚<br />

Fig.1 Fig.2 Fig.3<br />

Holder Dimension<br />

Description<br />

Standard<br />

No. of<br />

Insert<br />

Dimension (mm)<br />

øD øD1 ød ød1 ød2 H E a b<br />

Shape<br />

Weight<br />

(kg)<br />

Shim<br />

Bore Dia. mm spec<br />

Bore Dia. Inch spec<br />

Extra fi ne pitch<br />

Fine pitch<br />

Coarse pitch<br />

Extra fi ne pitch<br />

Fine pitch<br />

Coarse pitch<br />

MFPN 45063R-4T-M ● 4 63 76 22 19 11 40 21 6.3 10.4 0.5<br />

Fig.1<br />

45080R-5T-M ● 5 80 93 27 22 13<br />

24 7 12.4 1.1<br />

50<br />

45100R-6T-M ● 6 100 113 32 48<br />

30 8 14.4 1.4<br />

-<br />

Fig.2<br />

45125R-7T-M ● 7 125 138<br />

58<br />

2.6<br />

40<br />

32 9 16.4<br />

45160R-8T-M ● 8 160 173 68 66.7<br />

3.8<br />

63<br />

45200R-10T-M ● 10 200 213<br />

Fig.3 6.4<br />

60 110 101.6 40 14 25.7<br />

45250R-12T-M ● 12 250 263 9.1<br />

MFPN 45063R-5T-M ● 5 63 76 22 19 11 40 21 6.3 10.4 0.5<br />

Fig.1<br />

45080R-6T-M ● 6 80 93 27 22 13<br />

24 7 12.4 1.0<br />

50<br />

45100R-8T-M ● 8 100 113 32 48<br />

30 8 14.4 1.4<br />

-<br />

Fig.2<br />

45125R-10T-M ● 10 125 138<br />

58<br />

2.5<br />

40<br />

32 9 16.4<br />

45160R-12T-M ● 12 160 173 68 66.7<br />

3.8<br />

63<br />

45200R-14T-M ● 14 200 213<br />

Fig.3 6.5<br />

60 110 101.6 40 14 25.7<br />

45250R-16T-M ● 16 250 263 9.1<br />

MFPN 45063R-6T-M ● 6 63 76 22 19 11 40 21 6.3 10.4 0.5<br />

Fig.1<br />

45080R-8T-M ● 8 80 93 27 22 13<br />

24 7 12.4 1.1<br />

50<br />

45100R-10T-M ● 10 100 113 32 48 - 30 8 14.4 1.3<br />

Fig.2<br />

45125R-13T-M ● 13 125 138<br />

58 -<br />

2.6<br />

40<br />

32 9 16.4<br />

45160R-16T-M ● 16 160 173 68 66.7<br />

3.9<br />

63<br />

45200R-18T-M ● 18 200 213<br />

Fig.3 6.6<br />

60 110 101.6 40 14 25.7<br />

45250R-20T-M ● 20 250 263 9.3<br />

MFPN 45080R-5T 5 80 93 25.4 22 13<br />

27 6 9.5 Fig.1 1.1<br />

50<br />

45100R-6T 6 100 113 31.75 48<br />

32 8 12.7 1.4<br />

45125R-7T 7 125 138 38.1 58 -<br />

36 10 15.9 Fig.2 2.6<br />

45160R-8T 8 160 173 50.8 72 38 11 19.1 4.0<br />

63<br />

45200R-10T 10 200 213<br />

6.7<br />

47.625 110 101.6 40 14 25.4 Fig.3<br />

45250R-12T 12 250 263 9.4<br />

MFPN 45080R-6T 6 80 93 25.4 22 13<br />

27 6 9.5 Fig.1 1.1<br />

50<br />

45100R-8T 8 100 113 31.75 48<br />

32 8 12.7 1.4<br />

45125R-10T 10 125 138 38.1 58 -<br />

36 10 15.9 Fig.2 2.7<br />

45160R-12T 12 160 173 50.8 72 38 11 19.1 4.0<br />

63<br />

45200R-14T 14 200 213<br />

6.9<br />

47.625 110 101.6 40 14 25.4 Fig.3<br />

45250R-16T 16 250 263 9.6<br />

MFPN 45080R-8T 8 80 93 25.4 22 13<br />

27 6 9.5 Fig.1 1.1<br />

50<br />

45100R-10T 10 100 113 31.75 48<br />

32 8 12.7 1.3<br />

45125R-13T 13 125 138 38.1 58 -<br />

36 10 15.9 Fig.2 2.7<br />

45160R-16T 16 160 173 50.8 72 38 11 19.1 4.0<br />

63<br />

45200R-18T 18 200 213<br />

6.9<br />

47.625 110 101.6 40 14 25.4 Fig.3<br />

45250R-20T 20 250 263 9.6<br />

Yes<br />

<br />

<br />

Yes<br />

<br />

<br />

Standard Item Check Availability<br />

3

Spare parts from (mm/inch common spec)<br />

Spare Parts<br />

Description<br />

Clamp Screw<br />

TT<br />

Wrench<br />

DTM<br />

Shim Shim Screw Wrench<br />

Arbar<br />

Clamp Screw<br />

Coarse pitch<br />

Fine pitch<br />

Extra fi ne pitch<br />

MFPN 45063R-4T-M<br />

HH10x30<br />

MFPN 45080R-5T-M SB-50140TR TT-15 MFPN-45 SPW-7050 LW-5 HH12x40<br />

MFPN 45100R-6T-M<br />

-<br />

for Insert Clamp<br />

Recommended torque is 4.2 Nm.<br />

for Insert Clamp<br />

Recommended torque is 6.0 Nm.<br />

-<br />

45250R-12T-M<br />

MFPN 45063R-5T-M<br />

HH10x30<br />

MFPN 45080R-6T-M SB-50140TR TT-15 HH12x40<br />

MFPN 45100R-8T-M<br />

- - - -<br />

for Insert Clamp<br />

Recommended torque is 4.2 Nm.<br />

-<br />

45250R-16T-M<br />

MFPN 45063R-6T-M<br />

HH10x30<br />

MFPN 45080R-8T-M SB-40140TRN - DTM-15 HH12x40<br />

MFPN 45100R-10T-M<br />

- - -<br />

for Insert Clamp<br />

Recommended torque is 3.5 Nm.<br />

-<br />

45250R-20T-M<br />

~<br />

~<br />

~<br />

Classifi cation of usage P Steel ★<br />

Die Steel<br />

Milling Inserts (with hole)<br />

Shape<br />

Handled insert indicates Right-Hand<br />

★Roughing / 1st Choice<br />

★Roughing / 2nd Choice<br />

■Finishing / 1st Choice<br />

■Finishing / 2nd Choice<br />

(Hardened material is applicable only under 45HRC)<br />

Description<br />

★<br />

M Stainless Steel ★<br />

K<br />

Gray Cast Iron ★<br />

Nodular Cast Iron<br />

★<br />

N Non-ferrous Material ★<br />

S<br />

Heat-resistant Alloy ★<br />

Titanium alloy<br />

★<br />

H Hardened material<br />

Dimension (mm)<br />

MEGACOAT<br />

carbide<br />

A T ød X Z PR1225 PR1210<br />

Z<br />

A<br />

Ød<br />

PNMU<br />

1205ANER-GM<br />

●<br />

●<br />

General<br />

X<br />

T<br />

17.88 5.56<br />

Z<br />

A<br />

Ød<br />

PNMU 1205ANER-SM 6.2 2.0 2.0 ● ●<br />

Low cutting force<br />

X<br />

T<br />

Z<br />

A<br />

Ød<br />

PNMU 1205ANER-GH 17.98 6.17 ● ●<br />

Tough Edge (for heavy milling)<br />

X<br />

T<br />

Standard Item Check Availability<br />

Reference for selecting a facemill and insert suitable for each milling purpose<br />

Milling Purpose<br />

Coarse<br />

pitch<br />

Facemill-type<br />

Fine pitch<br />

Extra<br />

fi ne pitch<br />

Chipbreaker<br />

<br />

General milling of steel and alloy steel <br />

Steel and alloy steel (at chattering due to low rigidity machine or poor clamping power) <br />

Productivity oriented (Running cost decrease) <br />

General milling of stainless steel <br />

Stainless steel (at chattering due to low rigidity machine or poor clamping power) <br />

Cast iron (for processing effi ciency improvement) <br />

Cast iron (Over ap=4 mm, over fz=0.35 mm/t) <br />

4

Face milling (with meltdown surface)<br />

1500<br />

100<br />

200<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

ø3000<br />

80<br />

2000<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

•MFPN facemill enables stable milling due to reduced chip-biting and edge cracks.<br />

•MFPN facemill, no chattering, showed 3 times longer tool life than competitor.<br />

•MFPN facemill showed 1.5 times longer tool life than the competitor.<br />

•High feed rate of MFPN allowed 1.3 times higher milling efficiency compared to the<br />

competitor.<br />

Evaluation by the user<br />

Evaluation by the user<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Total D.O.C.<br />

100<br />

ø400<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Face milling<br />

3000<br />

300<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

•MFPN facemill showed 2 times longer tool life than competitor.<br />

•Competitor caused cracks by chip-biting. MFPN facemill had no cracks and allowed<br />

stable milling.<br />

•MFPN facemill enabled twice the table feed rate compared with the competitor. Milling<br />

efficiency improved two-fold.<br />

•Highly stable milling into the entrance of workpiece and less vibration than the<br />

competitor.<br />

•Cleanly curled chips which barely cause chip-biting.<br />

•Cutting speed has been changed Vc=110 m/min of conventional competitor's to Vc=130<br />

m/min, thereby the milling efficiency of MFPN increased 1.2 times.<br />

Evaluation by the user<br />

Evaluation by the user<br />

5

End face milling<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

80<br />

<br />

<br />

<br />

<br />

<br />

2000<br />

<br />

<br />

<br />

<br />

ø90<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

•Although the conventional tool causes chattering, MFPN facemill suppresses chattering,<br />

enabling stable milling.<br />

•Even if the feed rate is raised to 1.9 times, the insert wears less and there is no cracks<br />

on the insert.<br />

•Both the milling efficiency and the tool life have been improved.<br />

•MFPN facemill causes no vibration, enabling stable milling, even though the number<br />

of cutting edges of facemill has been increased by 4 and the feed per tooth has been<br />

increased by 1.3 times.<br />

•Does not generate much heat after milling and obtains the lustrous surface finish without<br />

burrs.<br />

•Milling efficiency increased 2.6 times with the high cutting conditions.<br />

Evaluation by the user<br />

Evaluation by the user<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

600<br />

<br />

<br />

<br />

<br />

<br />

<br />

800<br />

<br />

<br />

<br />

<br />

300<br />

400<br />

<br />

<br />

<br />

<br />

500<br />

(Conventional)<br />

Vc=140m/min<br />

apxae=3x80mm<br />

fz=0.11mm/t<br />

(Vf=230mm/min)<br />

•Even if the cutting speed and feed rate are raised up to the level of the conventional tool,<br />

the tool life of MFPN remains unchanged and milling efficiency increases by 2.6 times.<br />

•MFPN vibrates less right at entrance and exit on workpiece with reduced cutting sound.<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

•Even when the cutting depth, cutting speed and feed rate cannot be raised due to the<br />

low rigidity of a workpiece, MFPN facemill enables stable milling without chattering and<br />

also has an improved tool life of 1.5 times.<br />

Evaluation by the user<br />

Evaluation by the user<br />

6

1. Be sure to remove dust and chips from the insert mounting pocket.<br />

2. After applying anti-seize compound, while pressing the insert against the constraint surfaces, put the screw into the hole of the insert and tighten the screw with<br />

appropriate torque. See Fig. 1 and Fig. 2.<br />

Recommended tightening torqueThe torque for coarse pitch and cross pitch (using M5 screw) is 4.2 Nm.<br />

The torque for extra cross pitch (using M4 screw) is 3.5 Nm.<br />

3. After tightening the screw, make sure that there is no clearance between the insert seat surface and the bearing surface of the holder and between<br />

the insert side surfaces and the constraint surface of the holder.<br />

4. To change the cutting edge of the insert, turn the insert counterclockwise (see Fig. 3). Insert corner identifi cation number is stamped on the<br />

top surface of insert (Fig. 4). To protect the wiper edge, use the corners of insert in the sequence of corner numbers.<br />

Side surface of insert<br />

Top surface of insert<br />

Constraint surface<br />

Insert corner<br />

identification number<br />

<br />

(mm/t)<br />

Workpiece Material Insert Grade Cutting Speed (m/min) Chipbreaker<br />

0.06 0.1 0.2 0.3 0.4 0.5 0.6 0.7<br />

GM 0.1 0.2 0.4<br />

Carbon Steel<br />

PR1225 120~180~250 SM 0.06 0.12 0.25<br />

GH 0.2 0.4 0.7<br />

GM 0.1 0.2<br />

0.4<br />

Alloy Steel<br />

PR1225 100~160~220 SM 0.06 0.12<br />

0.25<br />

GH 0.2 0.4<br />

0.6<br />

GM 0.1 0.2<br />

0.35<br />

Die Steel<br />

PR1225 80~140~180 SM 0.06 0.1 0.2<br />

GH 0.2 0.35 0.5<br />

Stainless Steel PR1225 100~150~200<br />

GM 0.1 0.2<br />

0.4<br />

SM 0.06 0.12 0.25<br />

GM 0.1 0.2<br />

0.4<br />

Gray Cast Iron PR1210 120~180~250 SM 0.06 0.12 0.25<br />

GH 0.2 0.4 0.7<br />

GM 0.1 0.2<br />

0.35<br />

Nodular Cast Iron PR1210 100~150~200 SM 0.06 0.1 0.2<br />

GH 0.2 0.35 0.5<br />

Titanium Alloy PR1210 30~50~70 SM 0.06 0.08 0.15<br />

Coarse pitch (with shim)<br />

Type<br />

Fine pitch (without shim)<br />

(For GH chipbreaker, recommend under fz=0.4 mm/t.)<br />

Extra fi ne pitch (without shim)<br />

The use of the GH breaker is not recommended.<br />

The bold-faced number indicates a center value of recommended condition.<br />

★: 1st Recommendation ✩: 2nd Recommendation<br />

KYOCERA Fineceramics GmbH<br />

Cutting Tool Division<br />

Hammfelddamm 6, 41460 Neuss, Germany<br />

Phone: +49 (0) 2131 1637-115<br />

Fax: +49 (0) 2131 1637-152<br />

www.kyocera.de / www.kyocera.eu<br />

ceratip@kyocera.de<br />

KYOCERA Fineceramics SAS.<br />

Cutting Tool Division<br />

4, allee du Commandant Mouchotte<br />

Paray-vieille-poste 91781,Wissous Cedex, France<br />

Phone: +33 (0) 1 45 12 06 93 Fax: +33 (0) 1 56 72 18 94<br />

www.kyocera.fr<br />

KYOCERA Fineceramics GmbH sp. z o.o. Poland Branch Office<br />

Cutting Tool Division<br />

Leg. ul.Europejska 4, 55-220, Jelcz-Laskowice, Poland<br />

Phone: +48-(0)71-381-12-15 Fax: +48-(0)71-381-12-16<br />

www.kyocera.eu<br />

KYOCERA Fineceramics GmbH Italy Branch Office<br />

Cutting Tool Division<br />

Via Torino 51, 20123 Milan, Italy<br />

Phone: +39-02 00620 845 Fax: +39-02 00620 848<br />

www.kyocera.it<br />

KYOCERA Fineceramics GmbH Spain Branch Office<br />

Cutting Tool Division<br />

Avenida Manacor 4, 28290 Las Matas, Madrid, Spain<br />

Phone: +91-631-83-92-802 Fax: +91-631-82-19<br />

www.kyocera.es

![2012 - DRC Magic Drill - [ENG FRA ITA ESP] - 02.indd - Kyocera](https://img.yumpu.com/49215477/1/184x260/2012-drc-magic-drill-eng-fra-ita-esp-02indd-kyocera.jpg?quality=85)

![2012 - MEC series [GER ENG PL RUS].indd - Kyocera](https://img.yumpu.com/44428724/1/184x260/2012-mec-series-ger-eng-pl-rusindd-kyocera.jpg?quality=85)

![2012 - MEW - [ENG FRA ITA ESP].indd - Kyocera](https://img.yumpu.com/39423422/1/184x260/2012-mew-eng-fra-ita-espindd-kyocera.jpg?quality=85)