ENG, FRA, ITA, ESP - Kyocera

ENG, FRA, ITA, ESP - Kyocera

ENG, FRA, ITA, ESP - Kyocera

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

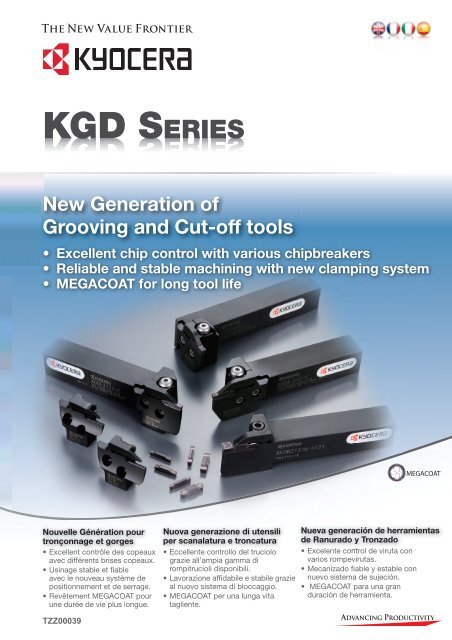

KGD SERIES<br />

New Generation of<br />

Grooving and Cut-off tools<br />

• Excellent chip control with various chipbreakers<br />

• Reliable and stable machining with new clamping system<br />

• MEGACOAT for long tool life<br />

MEGACOAT<br />

Nouvelle Génération pour<br />

tronçonnage et gorges<br />

• Excellent contrôle<br />

des<br />

copeaux<br />

avec différents brises copeaux.<br />

• Usinage stable et fiable<br />

avec le nouveau système de<br />

positionnement et de serrage.<br />

• Revêtement MEGACOAT pour<br />

une durée de vie plus longue.<br />

Nuova generazione di utensili Nueva generación de herramientas<br />

per scanalatura e troncatura de Ranurado y Tronzado<br />

• Eccellente controllo del truciolo<br />

• Excelente control lde viruta con<br />

grazie all’ampia gamma di<br />

varios rompevirutas.<br />

rompitrucioli disponibili.<br />

• Mecanizado fiable y estable con<br />

• Lavorazione affidabile e stabile grazie nuevo sistema de sujeción.<br />

al nuovo sistema di bloccaggio. • MEGACOAT para una gran<br />

• MEGACOAT per una lunga vita duración de herramienta.<br />

tagliente.<br />

TZZ00039

Good chip control<br />

Bon controle des copeaux<br />

Buon controllo del truciolo<br />

Buen control de viruta<br />

High precision molding technology, width tolerance ±0.03mm (Edge width 2,3,4mm type)<br />

Technologie de frittage de haute précision avec une tolérance de ±0,03 mm (largeur d’arête 2,3,4 mm)<br />

Alta tecnologia di stampaggio di precisione, tolleranza larghezza ±0.03mm (larghezze disponibili 2,3,4mm)<br />

Tecnología de moldeado de alta precisión, tolerancia de anchura de ±0,03mm (anchura de aristas de tipo 2,3,4mm)<br />

Monoblock type toolholder and seperate type toolholder are available<br />

Porte outils type monobloc et à cassette sont disponible<br />

Disponibili portautensili sia a monoblocco sia a lame intercambiabili<br />

Se dispone de portaherramientas de tipo monobloque y de tipo modular<br />

Application Maps│Tableau d’application│Mappa applicazioni│Esquemas de aplicaciones<br />

External Grooving & Traversing<br />

Cut-off<br />

Cutting Force High<br />

Low<br />

Low Feed<br />

GL<br />

Low cutting force<br />

GS<br />

General<br />

GM<br />

High Feed<br />

PH<br />

Cutting Force High<br />

Low<br />

General<br />

PM<br />

High Feed<br />

PH<br />

Low<br />

feed<br />

High<br />

Low<br />

feed<br />

High<br />

Inserts lineup for external grooving, traversing and cut-off<br />

Gamme de plaquettes pour tronçonnage Tournage et tronçonnage<br />

Linea inserti per scanalatura esterna, tornitura bidirezionale e troncatura<br />

Gama de plaquitas para ranurado externo, transversal y tronzado<br />

Application<br />

External Grooving<br />

Cut-off<br />

Copying<br />

Non-ferrous<br />

Low rigid<br />

material<br />

Low feed<br />

Carbon Steel<br />

Alloy Steel<br />

Stainless Steel<br />

High feed<br />

Interrupted<br />

Continuous<br />

Low cutting<br />

force<br />

GS<br />

Low feed<br />

GL<br />

General<br />

grooving<br />

GM<br />

High feed<br />

PH<br />

General<br />

cut-off<br />

PM<br />

Copying<br />

CM<br />

1

Monoblock Type<br />

Type Monoblock<br />

Tipo Monoblocco<br />

Tipo monobloque<br />

MEGACOAT<br />

PR1225<br />

1st Recommendation for cut-off, grooving and<br />

traversing of steel and stainles steel.<br />

1 ère Recommandation pour Tronçonnage,<br />

gorges et tournage de l'acier et l'acier inoxydable.<br />

Prima scelta. Raccomandato per taglio,<br />

scanalatura e tornitura bidirezionale di acciaio e<br />

acciaio inossidabile.<br />

1ª Recomendación para tronzado, ranurado y<br />

transversal de acero y acero inoxidable.<br />

PR1215<br />

1st Recommendation for machining of cast iron.<br />

With superior wear resistance, recommended for<br />

grooving and cut-off of steel and stainless steel<br />

under stable conditions.<br />

Prima scelta per lavorazioni di ghisa.<br />

Ottima restenza all’usura, raccomandato per<br />

scanalatura e troncatura in condizioni stabili di<br />

acciaio e acciaio inossidabile.<br />

Hardness(GPa)<br />

40<br />

30<br />

20<br />

10<br />

TiC<br />

TiCN<br />

TiN<br />

MEGACOAT<br />

TiAlN<br />

0 200 400 600 800 1000 1200<br />

Oxidation temperature <br />

1 ère Recommandation pour usinage des fontes.<br />

Pour resistance à l’usure supérieure , recommandé<br />

pour gorges et tronçonnage sous conditions stable<br />

de l'acier et l'acier inoxydable.<br />

1ª Recomendación para el mecanizado de hierro<br />

fundido.<br />

Con mayor resistencia al desgaste, recomendado<br />

para ranurado y tronzado en condiciones estables<br />

de acero y acero inoxidable.<br />

Seperate Type<br />

Type à cassette<br />

Tipo lama<br />

Tipo modular<br />

Toolholder and Inserts for Face Grooving<br />

Outils et plaquettes pour gorges frontales<br />

Utensile e inserti per scanalatura frontale<br />

Portaherramientas y plaquitas para ranurado frontal<br />

The new "W grip" is applied for more rigid<br />

clamping and stable machining.<br />

High rigidity, reliability and clamping strength.<br />

L’application de la nouvelle localisation en W<br />

Permet plus de rigidité pour le serrage et un<br />

usinage plus stable.<br />

Haute rigidité, fi abilité, et force de serrage.<br />

Il nuovo fi ssaggio tipo “W grip” conferisce<br />

maggior rigidità e stabilità nella lavorazione.<br />

Elevata rigidità, affi dabilità e forza di serraggio.<br />

Se aplica la nueva "sujeción W" para una<br />

sujeción más rígida y un mecanizado estable.<br />

Gran rigidez, fi abilidad y fuerza de sujeción.<br />

holder<br />

Insert<br />

holder<br />

W grip<br />

2

KGD/KGDF grooving tool series<br />

Série d’outils à gorges KGD/KGDF<br />

KGD/KGDF serie portautensili per scanalatura<br />

Serie de herramientas de ranurado de tipo KGD y KGDF<br />

Grooving<br />

Copying<br />

Cut-off<br />

90°separate<br />

type holder<br />

Grooving<br />

Face grooving<br />

monoblock type holder<br />

Expanding<br />

KGD series lineup<br />

Straight type holder<br />

Face grooving<br />

Grooving<br />

Copying<br />

Straight type holder<br />

Monoblock type toolholder with wide lineup (for various groove width and depth).<br />

Seperate type toolholder: Applicable for various types of grooving and cut-off, such as<br />

external and face cutting by replacing blade parts.<br />

Porte outils type monoblock avec une large gamme (pour differentes largeur et profondeur).<br />

Porte outils à cassette: Applicable pour differentes type de gorges et tronçonnage tel que<br />

l’usinage exterieur et gorges frontales en remplaçant la cassette.<br />

Utensile tipo monoblocco disponibile in ampia gamma, per differenti profondità e larghezze<br />

di taglio.<br />

Utensile tipo lama. Utilizzato per differenti tipi di scanalatura e troncatura frontale, offrendo<br />

versatilità attraverso la sostituzione delle lame stesse.<br />

Amplia gama de portaherramientas tipo monobloque (para distintas anchuras y<br />

profundidades de ranura).<br />

Portaherramientas de tipo modular: Aplicable a varios tipos de ranurado y tronzado, como<br />

corte externo y frontal, reemplazando el cartucho.<br />

3

Combination of Shank & Blade (for external grooving, traversing, cut-off)<br />

Combinaison des portes outils et cassettes (Pour Gorges , tronçonnage et tournage Exterieur)<br />

Combinazione di attacco e Lama (per scanalatura esterna, tornitura bidirezionale e troncatura)<br />

Combinación de mango y cartucho (para ranurado externo, transversal y corte)<br />

0° seperate type<br />

Cassette type 0°<br />

0° a lama<br />

Tipo modular a 0°<br />

0° seperate type<br />

Cassette type 90°<br />

90° a lama<br />

Tipo modular a 90°<br />

Blade<br />

Cassette<br />

Lama<br />

Cartucho<br />

Insert clamp bolt<br />

vis de serrage<br />

vite di serraggio<br />

el tornillo de apriete<br />

Shank<br />

Portes outils<br />

Attaco<br />

Mango<br />

Shank<br />

Portes outils<br />

Attaco<br />

Mango<br />

Blade fi xing bolt<br />

vis de fi xation de cassette<br />

vite di montaggio<br />

tornillo de montaje<br />

Blade<br />

Cassette<br />

Lama<br />

Cartucho<br />

External Grooving<br />

Gorges exterieur<br />

Scanalatura esterna<br />

Ranurado externo<br />

Blade<br />

Application (0°)<br />

KGDR-T KGDL-T<br />

Right hand KGDR YES NO<br />

Shank<br />

Left hand KGDL NO YES<br />

Blade<br />

Application (90°)<br />

KGDR-T KGDL-T<br />

Right hand KGDSR NO YES<br />

Shank<br />

Left hand KGDSL YES NO<br />

Combination of Shank & Blade (for Face Grooving)<br />

Combinaison des portes outils et casettes (Pour usinage gorges frontales)<br />

Combinazione di attacco e lama (per scanalatura frontale)<br />

Combinación de mango y cartucho (para ranurado externo, transversal y corte)<br />

0° seperate type<br />

Cassette type 0°<br />

0° a lama<br />

Tipo modular a 0°<br />

(R) Right-hand<br />

(R) Type Droite<br />

(R) Destro<br />

(R) Derecho<br />

Shank: Left-hand<br />

Portes outils: Type Gauche<br />

Attacco: Sinistro<br />

Mango: Izquierdo<br />

0° seperate type<br />

Cassette type 90°<br />

90° a lama<br />

Tipo modular a 90°<br />

Shank: Right-hand<br />

Portes outils: Type Droite<br />

Attacco: Destro<br />

Mango: Derechoecho<br />

(L) Left-hand<br />

(L) Type Gauche<br />

(L) Sinistro<br />

(L) Izquierdo<br />

Blade: Right-hand<br />

Cassette: Type Droite<br />

Lama: Destro<br />

Cartucho: Derecho<br />

Shank: Right-hand<br />

Portes outils: Type Droite<br />

Attacco: Destro<br />

Mango: Derecho<br />

Blade: Right-hand<br />

Cassette: Type Droite<br />

Lama: Destro<br />

Cartucho: Derecho<br />

Right-hand<br />

Type Droite<br />

Destro<br />

Derecho<br />

Face Grooving<br />

Gorges frontales<br />

Scanalatura Frontale<br />

Ranurado frontal<br />

Blade<br />

Application (0°)<br />

KGDFR-T KGDFL-T<br />

Right hand KGDL YES NO<br />

Shank<br />

Left hand KGDR NO YES<br />

Blade: Left-hand<br />

Cassette: Type Gauche<br />

Lama: Sinistro<br />

Cartucho: Izquierdo<br />

Blade<br />

Application (90°)<br />

KGDFR-T KGDFL-T<br />

Right hand KGDSR YES NO<br />

Shank<br />

Left hand KGDSL NO YES<br />

4

H2°<br />

Classifi cation of usage<br />

P Carbon steel, Alloy steel ●<br />

M Stainless Steel<br />

K Cast iron<br />

● Applicable Inserts<br />

Continuous - Interruption / 1st Choice)<br />

N Non-ferrous Material<br />

(Grooving & Traversing) Continuous - Interruption / 2nd Choice)<br />

S Titanium alloy<br />

●Continuous / 1st Choice)<br />

Hard materials (under 40HRC)<br />

H<br />

Hard materials (over 40HRC)<br />

Dimension (mm)<br />

<br />

Angle<br />

Cermet MEGACOAT Carbide<br />

Shape<br />

Description<br />

W<br />

rε<br />

Right-hand Insert shown<br />

tolerance<br />

M L H θ<br />

GDM 2420N-020GM 2.4<br />

0.2 1.95<br />

● ● ●<br />

3020N-020GM 0.2<br />

● ● ●<br />

3.0 2.3<br />

3020N-040GM 0.4 ● ● ●<br />

rε<br />

±0.03<br />

4020N-020GM<br />

0.2<br />

● ● ●<br />

L<br />

rε<br />

4020N-040GM 4.0<br />

0.4 3.3<br />

● ● ●<br />

20 4.3<br />

4020N-080GM 0.8 - ● ● ●<br />

5020N-040GM 0.4<br />

● ● ●<br />

5.0 4.2<br />

5020N-080GM 0.8 ● ● ●<br />

±0.04<br />

6020N-040GM 0.4<br />

● ● ●<br />

6.0 5.2<br />

6020N-080GM 0.8 ● ● ●<br />

General Purpose 2-edge<br />

8030N-080GM 8.0 ±0.05 0.8 6 30 5.5 ● ●<br />

GDMS 2220N-020GM 2.2<br />

0.2 1.75<br />

● ● ●<br />

3020N-040GM 3.0 ±0.03 0.4 2.3 ● ● ●<br />

L<br />

4020N-040GM 4.0 0.4 3.3 20 4.3 - ● ● ●<br />

5020N-080GM 5.0<br />

0.8 4.2 ● ● ●<br />

±0.04<br />

General Purpose 1-edge<br />

6020N-080GM 6.0 0.8 5.2 ● ● ●<br />

GDM 2420N-020GL 2.4<br />

0.2 1.95<br />

● ● ●<br />

1.5°<br />

rε<br />

3020N-020GL<br />

0.2<br />

● ● ●<br />

3.0<br />

2.3<br />

3020N-040GL ±0.03 0.4 ● ● ●<br />

1.5°<br />

L<br />

4020N-020GL<br />

0.2 20 4.3 - ● ● ●<br />

4.0<br />

3.3<br />

4020N-040GL 0.4 ● ● ●<br />

5020N-040GL 5.0<br />

0.4 4.2 ● ● ●<br />

±0.04<br />

Low feed 2-edge<br />

6020N-040GL 6.0 0.4 5.2 ● ● ●<br />

GDG 2520N-020GS 2.5<br />

2.0<br />

● ● ● ●<br />

rε<br />

3020N-020GS 3.0 0.2 2.3 ● ● ● ●<br />

3520N-020GS 3.5 2.8 ● ● ● ●<br />

L<br />

20 4.3<br />

4020N-040GS 4.0 ±0.02 3.3 - ● ● ● ●<br />

20°<br />

5020N-040GS 5.0 4.2 ● ● ● ●<br />

0.4<br />

6020N-040GS 6.0 5.2 ● ● ● ●<br />

Low cutting force 2-edge<br />

8030N-040GS 8.0 6.0 30 5.5 ● ● ● ●<br />

GDM 3020N-150R-CM 3.0<br />

1.5 2.3<br />

● ● ●<br />

rε<br />

±0.03<br />

20<br />

4020N-200R-CM 4.0 2.0 3.3 ● ● ●<br />

L<br />

4.3 -<br />

5020N-250R-CM 5.0<br />

2.5 4.2<br />

● ● ●<br />

±0.04<br />

21<br />

2-edge<br />

6020N-300R-CM 6.0 3.0 5.2 ● ● ●<br />

Grooving & Traversing<br />

Grooving<br />

Full-R / Copying<br />

W<br />

W<br />

2°<br />

2°<br />

W±0.02<br />

W<br />

M<br />

M<br />

M<br />

M<br />

M<br />

H<br />

H 2° 2°<br />

W<br />

rε<br />

H<br />

2°<br />

H<br />

TN90<br />

PR1225<br />

PR1215<br />

GW15<br />

Grooving & Traversing<br />

High feed 2-edge<br />

W±0.031.5°<br />

1.5°<br />

M<br />

L<br />

M<br />

L<br />

rε<br />

rε<br />

1.5°<br />

rε<br />

1.5°<br />

H<br />

W±0.03<br />

GDM 2020N-020PH 2.0<br />

0.2 1.5<br />

● ●<br />

3020N-030PH 3.0 ±0.03 0.3 2.3 20<br />

-<br />

● ●<br />

4020N-030PH 4.0 0.3 3.3 ● ●<br />

4.3<br />

GDMS 2020N-020PH 2.0<br />

0.2 1.5<br />

● ●<br />

3020N-030PH 3.0 ±0.03 0.3 2.3 20 -<br />

● ●<br />

High feed 1-edge<br />

H<br />

4020N-030PH 4.0 0.3 3.3 ● ●<br />

Standard Item<br />

Insert setting angle of KGD/KGM toolholder<br />

Combination of KGD/KGM toolholder and Insert<br />

New KGD type (0°) Conventional KGM type (5°)<br />

GDM<br />

Insert<br />

GMM<br />

0°<br />

5°<br />

Toolholder<br />

KGD YES NO<br />

KGM (YES) YES<br />

5

● Applicable Inserts<br />

(Cut-Off PM Chipbreaker)<br />

Shape<br />

Right-hand Insert shown<br />

Classifi cation of usage<br />

Continuous - Interruption / 1st Choice<br />

Continuous - Interruption / 2nd Choice<br />

Description<br />

P<br />

M<br />

K<br />

N<br />

S<br />

H<br />

Carbon steel, Alloy steel<br />

Stainless Steel<br />

Cast iron<br />

Non-ferrous Material<br />

Titanium alloy<br />

Hard materials (under 40HRC)<br />

Hard materials (over 40HRC)<br />

Dimension (mm)<br />

<br />

Angle<br />

Cermet MEGACOAT<br />

W<br />

rε<br />

tolerance<br />

M L H θ<br />

TN90<br />

PR1225<br />

PR1215<br />

3°<br />

W±0.03<br />

3°<br />

M<br />

L<br />

rε<br />

rε<br />

GDM 2020N-020PM 2.0<br />

0.2 1.5<br />

● ●<br />

2520N-020PM 2.5 0.2 1.95 ● ●<br />

±0.03<br />

20<br />

-<br />

3020N-025PM 3.0 0.25 2.3 ● ●<br />

H<br />

2-edge<br />

4020N-030PM 4.0 0.3 3.3 ● ●<br />

3°<br />

W±0.03<br />

3°<br />

M<br />

L<br />

θ<br />

rε<br />

GDM 2020R-020PM-6D 2.0<br />

0.2 1.5<br />

● ●<br />

2520R-020PM-6D 2.5 ±0.03 0.2 1.95 20 6° ● ●<br />

Cut-off<br />

2-edge<br />

H<br />

3020R-025PM-6D 3.0 0.25 2.3 4.3<br />

● ●<br />

M<br />

L<br />

3° 3°<br />

W±0.03<br />

rε<br />

GDMS 2020N-020PM 2.0<br />

0.2 1.5<br />

● ●<br />

3020N-025PM 3.0 ±0.03 0.25 2.3 20 -<br />

● ●<br />

1-edge<br />

H<br />

4020N-030PM 4.0 0.3 3.3 ● ●<br />

M<br />

L<br />

θ<br />

3° 3°<br />

W±0.03<br />

rε<br />

GDMS 2020R-020PM-6D 2.0<br />

0.2 1.5<br />

● ●<br />

3020R-025PM-6D 3.0 ±0.03 0.25 2.3 20 6° ● ●<br />

1-edge<br />

H<br />

4020R-030PM-6D 4.0 0.3 3.3 ● ●<br />

When grooving with PM chipbreaker (for cut-off), bottom cutting shape is not fl at. (see Right Fig.)<br />

Bottom cutting shape of PM<br />

chipbreaker<br />

Standard Item<br />

● Indication of Insert Description<br />

Tolerance<br />

M-Class<br />

G-Class<br />

Edge Width<br />

20 2mm<br />

30 3mm<br />

40 4mm<br />

G D M S 30 20 N - 025 GM<br />

Hand<br />

R Right-hand<br />

L Left-hand<br />

N No Hand<br />

Chipbreaker (grooving, cut-off)<br />

GMGrooving & Traversing<br />

PMCut-off<br />

CMCopying<br />

Lead Angle<br />

<br />

- 6D<br />

Series<br />

GD Grooving, Cut-off<br />

GDFFace grooving<br />

No. of Corners<br />

No Indication: 2-edge<br />

S: 1-edge<br />

Insert Length<br />

20 20mm<br />

30 30mm<br />

Corner-R<br />

020 0.2mm<br />

030 0.3mm<br />

150R- 1.5mm (Full R)<br />

Chipbreaker (Face Grooving)<br />

GMGeneral Purpose<br />

DMDeep Grooving<br />

Recommended tightenting torque: 6.5 Nm (8 Nm for 8mm width)<br />

Couple de serrage : 6,5 Nm (8 Nm pour une largeur de 8 mm)<br />

Coppia di serraggio: 6.5 Nm (8 Nm per larghezza di 8 mm)<br />

Par de apriete recomendado: 6.5 Nm (8Nm para anchura de 8mm)<br />

Insert clamp bolt<br />

Correct<br />

Incorrect<br />

Insert mounting part<br />

Toolholder’s surface for<br />

fi xing the insert’s back end<br />

6

KGD type (Monoblock type)<br />

F1<br />

W<br />

T<br />

B<br />

A<br />

h<br />

L2<br />

L3<br />

H2 H3<br />

L1<br />

H1<br />

Right-hand shown<br />

Toolholder Dimensions<br />

Width<br />

<br />

2<br />

Max. Grooving<br />

Depth<br />

<br />

6<br />

10<br />

17<br />

2.4 17<br />

3<br />

4<br />

5<br />

6<br />

6<br />

10<br />

20<br />

10<br />

20<br />

Description<br />

Standard Dimension (mm) W (mm)<br />

R L H1=h H2 H3 B L1 L2 L3 F1 A T MIN MAX<br />

Clamp Bolt<br />

KGD$ 1616H-2T06 ● ● 16 4.0 16 100 27.7 28.0 15.2<br />

HH5X16<br />

2020K-2T06 ● ● 20<br />

20 125 28.0 19.2 6<br />

-<br />

-<br />

2525M-2T06 ● ● 25 25 150 28.0 24.2 HH5X25<br />

KGD$ 1616H-2T10 ● ● 16 4.0 16 100 30.2 30.5 15.2<br />

HH5X16<br />

2020K-2T10 ● ● 20<br />

20 125 30.5 19.2 10<br />

-<br />

-<br />

1.7 2.0 3.0<br />

2525M-2T10 ● ● 25 25 150 30.5 24.2 HH5X25<br />

KGD$ 1616H-2T17 ● ● 16 4.0 16 100 31.2 31.5 15.2<br />

2012K-2T17 ● ● 20<br />

12 125<br />

11.2<br />

2020K-2T17 ● ● -<br />

20 125 32.5 - 19.2<br />

KGD$ 1616H-3T10 ● ● 16 4.0 16 100 30.2 30.5 14.8<br />

HH5X16<br />

2020K-3T10 ● ● 20<br />

20 125<br />

18.8 10<br />

-<br />

30.5 -<br />

2.4 3.0 4.0<br />

2525M-3T10 ● ● 25 25 150 23.8 HH5X25<br />

9.5<br />

KGD$ 1616H-3T20 ● ● 16 4.0 16 100 34.2 34.5 14.8<br />

17<br />

HH5X16<br />

2525M-2T17 ● ● 25 25 150 24.2 HH5X25<br />

KGD$ 2012K-2.4T17 ● ● 12 125<br />

11.0<br />

20 - 32.5 -<br />

2020K-2.4T17 ● ● 20 125 19.0<br />

Spare parts<br />

Wrench<br />

LW-4<br />

2.0 17 2.4 3.0 HH5X16 LW-4<br />

KGD$ 1616H-3T06 ● ● 16 4.0 16 100 27.7 28.0 14.8<br />

HH5X16<br />

2020K-3T06 ● ● 20<br />

20 125 28.0 18.8 6<br />

-<br />

-<br />

2525M-3T06 ● ● 25 25 150 28.0 23.8 HH5X25<br />

2012K-3T20 ● ● 12 125<br />

10.8<br />

20 34.5<br />

2020K-3T20 ● ● -<br />

20 125 - 18.8<br />

20<br />

HH5X16<br />

2525M-3T20 ● ● 25 25 150 35.5 23.8 HH5X25<br />

KGD$ 2020K-4T10 ● ● 20<br />

20 125<br />

18.3<br />

HH5X16<br />

30.5<br />

10<br />

2525M-4T10 ● ● 25 25 150 23.3 HH5X25<br />

KGD$ 2020K-4T20 ● ● 20 -<br />

20 125 34.5 - 18.3<br />

2525M-4T20 ● ● 25 25 150 35.5 23.3<br />

25 KGD$ 2525M-4T25 ● ● 25 25 150 40.5 23.3 25<br />

10<br />

17<br />

8 25<br />

KGD$ 2020K-5T10 ● ● 20<br />

20 125<br />

17.8<br />

30.5<br />

2525M-5T10 ● ● 25 25 150 22.8<br />

KGD$ 2020K-5T17 ● ● 20 -<br />

20 125 - 17.8<br />

37.5<br />

2525M-5T17 ● ● 25 25 150 22.8<br />

25 KGD$ 2525M-5T25 ● ● 25 25 150 40.5 22.8 25<br />

15 KGD$ 2525M-6T15 ● ● 25<br />

25 150 32.5 22.4 15<br />

-<br />

-<br />

5.3<br />

30 KGD$ 2525M-6T30 ● ● 25 25 150 45.5 22.4 30<br />

3.4<br />

4.4<br />

20<br />

10<br />

17<br />

4.0 5.0<br />

5.0 6.0<br />

HH5X16<br />

HH5X25<br />

HH5X16<br />

HH5X25<br />

LW-4<br />

LW-4<br />

LW-4<br />

6.0 6.0 HH5X25 LW-4<br />

KGD$ 2525M-8T25 ● ● 25 7.0 25 150<br />

43.3 44.2 22.0 6.0 25 8.0 8.0 HH6X25 LW-5<br />

3232P-8T25 ● ● 32 - 32 170 - 29.0<br />

T dimension shows the maximum grooving depth. (When using 2-edge insert with toolholder T=20/25, set the grooving depth under 18mm due to interfere.)<br />

Standard Item<br />

7

KGD-S type (0°seperate type)<br />

T<br />

h<br />

W<br />

F1<br />

B<br />

L2<br />

H1<br />

H3<br />

A<br />

H2<br />

L1<br />

Right-hand shown<br />

Toolholder Dimensions (shank and blade)<br />

Shank Angle<br />

0°<br />

Width<br />

Max. Grooving<br />

Depth<br />

Shank size<br />

<br />

2 17<br />

3<br />

4<br />

5<br />

10<br />

20<br />

10<br />

20<br />

25<br />

10<br />

25<br />

Shank<br />

Description<br />

<br />

20 KGD$2020-C<br />

Blade<br />

Description<br />

<br />

Assembled<br />

Description<br />

Standard<br />

KGD$ 2020X-2T17S ● ● 20 12<br />

Dimension (mm)<br />

W<br />

(mm)<br />

R L H1=h H2 H3 B L1 L2 L3 F1 A T MIN MAX<br />

20 122<br />

25 KGD$2525-C KGD$-2T17-C 2525X-2T17S ● ● 25 7 25 147 40 28.4<br />

32 KGD$3232-C - - - 32 - 32 167 35.4<br />

20 KGD$2020-C<br />

KGD$ 2020X-3T10S ● ● 20 12 20 115<br />

25 KGD$2525-C KGD$-3T10-C 2525X-3T10S ● ● 25 7 25 140 33 28.0<br />

32 KGD$3232-C 3232X-3T10S ● ● 32 - 32 160 35.0<br />

20 KGD$2020-C<br />

KGD$ 2020X-3T20S ● ● 20 12 20 125<br />

25 KGD$2525-C KGD$-3T20-C 2525X-3T20S ● ● 25 7 25 150 43 28.0<br />

32 KGD$3232-C 3232X-3T20S ● ● 32 - 32 170 35.0<br />

20 KGD$2020-C<br />

KGD$ 2020X-4T10S ● ● 20 12 20 115<br />

25 KGD$2525-C KGD$-4T10-C 2525X-4T10S ● ● 25 7 25 140 33 27.5<br />

32 KGD$3232-C 3232X-4T10S ● ● 32 - 32 160 34.5<br />

11.6<br />

-<br />

20 KGD$2020-C<br />

KGD$ 2020X-4T20S ● ● 20 12 20 125<br />

22.5<br />

25 KGD$2525-C KGD$-4T20-C 2525X-4T20S ● ● 25 7 25 150 43 27.5<br />

32 KGD$3232-C 3232X-4T20S ● ● 32 - 32 170 34.5<br />

20 KGD$2020-C<br />

KGD$ 2020X-4T25S ● ● 20 12 20 130<br />

25 KGD$2525-C KGD$-4T25-C 2525X-4T25S ● ● 25 7 25 155 48 27.5<br />

32 KGD$3232-C 3232X-4T25S ● ● 32 - 32 175 34.5<br />

20 KGD$2020-C<br />

KGD$ 2020X-5T10S ● ● 20 12 20 115<br />

25 KGD$2525-C KGD$-5T10-C 2525X-5T10S ● ● 25 7 25 140 33 27.0<br />

32 KGD$3232-C 3232X-5T10S ● ● 32 - 32 160 34.0<br />

20 KGD$2020-C<br />

KGD$ 2020X-5T25S ● ● 20 12 20 130<br />

25 KGD$2525-C KGD$-5T25-C 2525X-5T25S ● ● 25 7 25 155 48 27.0<br />

32 KGD$3232-C 3232X-5T25S ● ● 32 - 32 175 34.0<br />

23.4<br />

23.0<br />

23.0<br />

22.5<br />

22.5<br />

22.0<br />

22.0<br />

1.7 17 2.0 3.0<br />

2.4<br />

3.4<br />

4.4<br />

10<br />

20<br />

10<br />

20<br />

25<br />

10<br />

25<br />

3.0 4.0<br />

4.0 5.0<br />

5.0 6.0<br />

Standard Item<br />

Note) 1. In case of normal mounting position, toolholder body may interfere with tool presetter<br />

2. Toolholder description and blade description are printed on toolholder body (Assembled description is not indicated).<br />

3. T dimension shows the maximum grooving depth (When using 2-edge insert with toolholder T=20/25, set the grooving depth under 18mm due to interfere).<br />

La cote T indique la profondeur maximale de rainurage (lorsque vous utilisez des plaquettes à 2 arètes de coupe avec des portes outils dont la cote T est égale à 20/25 mm, la<br />

profondeur maximum de rainurage sera de 18 mm).<br />

T indica la distanza dall’utensile al fi lo tagliente. (Quando si utilizza l’inserto bilaterale, con valori di T=20/25; causa interferenza, impostare la profondità al di sotto dei 18mm).<br />

La cota T muestra la máxima profundidad de ranura. (Si se usa plaquita de 2 puntas con el portaherramientas T=20/25, hace ranura por debajo de 18mm debido a interferencia)<br />

8

KGDS-S type (90°seperate type)<br />

T<br />

L3<br />

B<br />

L2<br />

L1<br />

h<br />

A<br />

H2 H3<br />

H1<br />

Right-hand shown<br />

Toolholder Dimensions (shank and blade)<br />

Shank Angle<br />

Width<br />

Max. Grooving<br />

Depth<br />

Shank size<br />

<br />

2 17<br />

Toolholder<br />

Description<br />

<br />

Blade<br />

Description<br />

<br />

Assembled<br />

Description<br />

Standard<br />

20 KGDS$2020-C<br />

- - - 20 12 20 125<br />

KGD -2T17-C<br />

25 KGDS$2525-C - - - 25 7 25 150<br />

Dimension (mm)<br />

W<br />

(mm)<br />

R L H1=h H2 H3 B L1 L2 L3 F1 A T MIN MAX<br />

56.7<br />

1.7 17 2.0 3.0<br />

3<br />

10<br />

20<br />

20 KGDS$2020-C<br />

KGDS$ 2020X-3T10S ● ● 20 12 20 125<br />

KGD -3T10-C<br />

25 KGDS$2525-C 2525X-3T10S ● ● 25 7 25 150<br />

20 KGDS$2020-C<br />

- - - 20 12 20 125<br />

KGD -3T20-C<br />

25 KGDS$2525-C - - - 25 7 25 150<br />

49.7<br />

10<br />

2.4<br />

59.7 20<br />

3.0 4.0<br />

90°<br />

4<br />

10<br />

20<br />

20 KGDS$2020-C<br />

- - - 20 12 20 125<br />

KGD -4T10-C<br />

25 KGDS$2525-C - - - 25 7 25 150<br />

11.6<br />

20 KGDS$2020-C<br />

- - - 20 12 20 125<br />

KGD -4T20-C<br />

25 KGDS$2525-C - - - 25 7 25 150<br />

27.7<br />

49.7<br />

10<br />

-<br />

59.7 3.4 20<br />

4.0 5.0<br />

25<br />

20 KGDS$2020-C<br />

- - - 20 12 20 125<br />

KGD -4T25-C<br />

25 KGDS$2525-C - - - 25 7 25 150<br />

64.7 25<br />

5<br />

10<br />

25<br />

20 KGDS$2020-C<br />

- - - 20 12 20 125<br />

KGD -5T10-C<br />

25 KGDS$2525-C - - - 25 7 25 150<br />

20 KGDS$2020-C<br />

- - - 20 12 20 125<br />

KGD -5T25-C<br />

25 KGDS$2525-C - - - 25 7 25 150<br />

49.7<br />

10<br />

4.4<br />

64.7 25<br />

5.0 6.0<br />

Standard Item<br />

Note) 1. In case of normal mounting position, toolholder body may interfere with tool presetter<br />

2. Toolholder description and blade description are printed on toolholder body. (Assembled description is not indicated.)<br />

3. T dimension shows the maximum grooving depth. (When using 2-edge insert with toolholder T=20/25, set the grooving depth under 18mm due to interfere.)<br />

La cote T indique la profondeur maximale de rainurage (lorsque vous utilisez des plaquettes à 2 arètes de coupe avec des portes outils dont la cote T est égale à 20/25 mm, la<br />

profondeur maximum de rainurage sera de 18 mm).<br />

T indica la distanza dall’utensile al fi lo tagliente. (Quando si utilizza l’inserto bilaterale, con valori di T=20/25; causa interferenza, impostare la profondità al di sotto dei 18mm).<br />

La cota T muestra la máxima profundidad de ranura. (Si se usa plaquita de 2 puntas con el portaherramientas T=20/25, hace ranura por debajo de 18mm debido a interferencia)<br />

9

0°seperate type shape<br />

Right-hand Shown<br />

Shank Description<br />

Standard<br />

Dimension(mm)<br />

R L L B H1<br />

H1 B<br />

KGD$ 2020-C ● ● 104 20 20<br />

2525-C ● ● 129 25 25<br />

L<br />

3232-C ● ● 149 32 32<br />

90°seperate type shape<br />

Right-hand Shown<br />

Shank Description<br />

Standard<br />

Dimension(mm)<br />

R L L B H1<br />

L<br />

H1 B<br />

KGDS$ 2020-C ● ● 122 20 20<br />

2525-C ● ● 147 25 25<br />

Blade shape<br />

Right-hand Shown<br />

A<br />

Blade Description<br />

Standard<br />

Dimension(mm)<br />

R L L T W<br />

T KGD$ -2T17-C ● ● 51.2 17.2 1.7<br />

-3T10-C ● ● 44.2 10.2 2.4<br />

-3T20-C ● ● 53.2 20.2 2.4<br />

-4T10-C ● ● 44.2 10.2 3.4<br />

-4T20-C ● ● 54.2 20.2 3.4<br />

-4T25-C ● ● 59.2 25.2 3.4<br />

-5T10-C ● ● 44.2 10.2 4.4<br />

L<br />

-5T25-C ● ● 59.2 25.2 4.4<br />

41.5<br />

Standard Item<br />

Spare parts<br />

Spare parts<br />

Clamp bolt (For Insert Clamp) Fixing bolt(For Blade) Wrench<br />

Assembled Description<br />

KGD$S BH6X10TR SB-60120TR LTW-25<br />

Setting the blade (Seperate-type toolholder)<br />

Recommended tightening torque: 8 Nm<br />

Couple de serrage : 8 Nm<br />

Coppia di serraggio: 8 Nm<br />

Par de apriete recomendado: 8 Nm<br />

Insert clamp bolt<br />

Blade<br />

Serration joint<br />

Blade<br />

No gap between<br />

blade and shank<br />

Shank<br />

Blade fixing bolt<br />

Shank<br />

10

Recommended Cutting Conditions (Grooving, Cut-off)<br />

Workpiece Material<br />

Carbon Steel<br />

Chipbreaker<br />

GM<br />

Vc (m/min)<br />

Cermet MEGACOAT Carbide Carbide<br />

TN90 PR1225 PR1215 GW15<br />

<br />

100~220 80~200 100~200<br />

Alloy Steel<br />

GL<br />

<br />

PM 80~200 70~180 80~180<br />

Stainless Steel<br />

PH<br />

<br />

CM 70~180 60~150 60~150<br />

Cast Iron<br />

GS<br />

<br />

- -<br />

100~200<br />

Aluminium<br />

GS<br />

- - -<br />

Brass - - -<br />

Recommended Cutting Conditions (f, ap)<br />

Grooving<br />

Width (mm)<br />

Width (mm)<br />

Width (mm)<br />

8<br />

5~6<br />

3~4<br />

CM chipbreaker [ Recommended max. a.p. for pulling up ]<br />

ap (mm) Max.<br />

Description<br />

Description of Toolholder<br />

KGD…-2T… KGD…-3T… KGD…-4T… KGD…-5T… KGD…-6T…<br />

GDM 3020N-150R-CM 0.24 0.20 - - -<br />

4020N-200R-CM - 0.24 0.20 - -<br />

5020N-250R-CM - - 0.30 0.20 -<br />

6020N-300R-CM - - - 0.30 0.25<br />

ap<br />

Tips about external turning<br />

Point (I) (Traversing after grooving)<br />

1) Over 0.5mm of groove depth : For Roughing (Refer to fi g 1)<br />

Before traversing, pull the tool back by 0.1mm after grooving.<br />

(Put the load on edge from single direction.)<br />

fig 1<br />

Pull back the tool by 0.1mm<br />

before traversing<br />

(over 0.5mm of groove depth :<br />

For Roughing)<br />

2) Less 0.5mm of groove depth : For Finishing (Refer to fi g 2)<br />

Available to traverse continuously after grooving.<br />

(Dwell motion is not required)<br />

Point (II)<br />

1) In case of expanding groove width (Refer to fi g. 3)<br />

Please program to make steps at each pass.<br />

fig 2<br />

Traversing continuously after<br />

grooving<br />

(Less 0.5mm of groove depth :<br />

For Finishing)<br />

2) For fi nishing<br />

(Leave the material more than 0.5mm total to get bettter chip control.)<br />

Note; if machining without centering:<br />

If feeding the tool towards the tailstock, please reduce in this case<br />

the feedrate for more accurracy.<br />

0.1mm<br />

fig 3<br />

Descriptions of seperate type toolholder and indication of setting up to machine.<br />

Description of Clamp bolt<br />

Description of Shank<br />

Description of Fixing bolt<br />

Description of Blade<br />

Lot number of Shank<br />

Lot number of Blade<br />

No gap here<br />

12

KGDF Face grooving tool<br />

GDFM/GDFMS<br />

Grooving & Traversing<br />

Deep Grooving, Traversing<br />

2-edge<br />

2-edge<br />

1-edge<br />

Shape<br />

M<br />

M<br />

M<br />

L<br />

L<br />

L<br />

Classifi cation of usage<br />

Continuous - Interruption / 1st Choice)<br />

Continuous - Interruption / 2nd Choice)<br />

●Continuous / 1st Choice)<br />

2°<br />

2°<br />

W<br />

2°<br />

W<br />

2°<br />

2°<br />

rε<br />

rε<br />

W<br />

2°<br />

H<br />

H<br />

H<br />

rε<br />

Description<br />

P Carbon steel, Alloy steel ●<br />

M Stainless Steel<br />

K Cast iron<br />

N Non-ferrous Material<br />

S Titanium alloy<br />

H<br />

Hard materials (under 40HRC)<br />

Hard materials (over 40HRC)<br />

W<br />

tolerance<br />

Dimension (mm) Cermet MEGACOAT<br />

rε M L H<br />

GDFM 3020N-030GM 3.0<br />

0.3 2.3<br />

● ● ●<br />

±0.03<br />

4020N-040GM 4.0<br />

3.3 ● ● ●<br />

20 4.3<br />

5020N-040GM 5.0<br />

0.4 4.2 ● ● ●<br />

±0.04<br />

6020N-040GM 6.0 5.2 ● ● ●<br />

GDFM 3020N-030DM 3.0<br />

0.3 2.3<br />

● ● ●<br />

±0.03<br />

4020N-040DM 4.0<br />

3.3 ● ● ●<br />

20 4.3<br />

5020N-040DM 5.0<br />

0.4 4.2 ● ● ●<br />

±0.04<br />

6020N-040DM 6.0 5.2 ● ● ●<br />

GDFMS 3020N-030DM 3.0<br />

0.3 2.3<br />

● ● ●<br />

±0.03<br />

4020N-040DM 4.0<br />

3.3 ● ● ●<br />

20 4.3<br />

5020N-040DM 5.0<br />

0.4 4.2 ● ● ●<br />

±0.04<br />

6020N-040DM 6.0 5.2 ● ● ●<br />

TN90<br />

PR1225<br />

PR1215<br />

See page 6 for indication of insert description<br />

Standard Item<br />

Comparison of chip control (GM chipbreaker)<br />

Vc=150m/min f =0.05~ 0.1mm/rev<br />

GDFM5020N-040GM SCM415 Wet<br />

Face grooving (Ø62)<br />

0.05 0.08 0.1<br />

Shoulder grooving<br />

<br />

Width of cut (mm)<br />

1.0<br />

0.5<br />

Traversing<br />

0.1 0.15 0.2<br />

f (mm/rev)<br />

0.8<br />

ap<br />

(mm)<br />

0.5<br />

0.2<br />

0.05 0.1<br />

f (mm/rev)<br />

0.15<br />

13

KGDF type<br />

T<br />

L1<br />

h H3 F1<br />

W<br />

L2<br />

H2<br />

H1 B<br />

Left-hand shown<br />

H1<br />

L2<br />

F1<br />

B<br />

W<br />

H3<br />

h<br />

H2<br />

Right-hand shown<br />

T<br />

L1<br />

Toolholder Dimensions<br />

Shank Angle<br />

Width<br />

Shank size<br />

Max. Grooving<br />

Depth<br />

Face<br />

Grooving<br />

Dia.<br />

øD(mm)<br />

Shank<br />

Description<br />

<br />

Blade<br />

Description<br />

<br />

Assembled<br />

Description<br />

Standard<br />

MIN MAX<br />

25 30<br />

KGDF$ -25-3A-C KGDF$ 2020X25-3AS ● ●<br />

13 30 40 -30-3A-C 2020X30-3AS ● ●<br />

40 50 -40-3A-C 2020X40-3AS ● ●<br />

50 65 -50-3B-C 2020X50-3BS ● ●<br />

65 85 -65-3B-C 2020X65-3BS ● ●<br />

15<br />

20 85 110 KGD 2020-C<br />

-85-3B-C 2020X85-3BS ● ●<br />

110 145 -110-3B-C 2020X110-3BS ● ●<br />

22<br />

50 65 -50-3C-C 2020X50-3CS ● ●<br />

65 85 -65-3C-C 2020X65-3CS ● ●<br />

25<br />

85 110 -85-3C-C 2020X85-3CS ● ●<br />

110 145 -110-3C-C 2020X110-3CS ● ●<br />

25 30<br />

KGDF$ -25-3A-C KGDF$ 2525X25-3AS ● ●<br />

13 30 40 -30-3A-C 2525X30-3AS ● ●<br />

40 50 -40-3A-C 2525X40-3AS ● ●<br />

50 65 -50-3B-C 2525X50-3BS ● ●<br />

65 85 -65-3B-C 2525X65-3BS ● ●<br />

15<br />

0° 3 25 85 110 KGD 2525-C<br />

-85-3B-C 2525X85-3BS ● ●<br />

110 145 -110-3B-C 2525X110-3BS ● ●<br />

22<br />

50 65 -50-3C-C 2525X50-3CS ● ●<br />

65 85 -65-3C-C 2525X65-3CS ● ●<br />

25<br />

85 110 -85-3C-C 2525X85-3CS ● ●<br />

110 145 -110-3C-C 2525X110-3CS ● ●<br />

25 30<br />

KGDF$ -25-3A-C - - -<br />

13 30 40 -30-3A-C - - -<br />

40 50 -40-3A-C - - -<br />

50 65 -50-3B-C - - -<br />

65 85 -65-3B-C - - -<br />

15<br />

32 85 110 KGD 3232-C<br />

-85-3B-C - - -<br />

110 145 -110-3B-C - - -<br />

22<br />

50 65 -50-3C-C - - -<br />

65 85 -65-3C-C - - -<br />

25<br />

85 110 -85-3C-C - - -<br />

110 145 -110-3C-C - - -<br />

Dimension (mm)<br />

W<br />

(mm)<br />

R L H1=h H2 H3 B L1 L2 F1 T W<br />

20 12 11.6 20<br />

25 7 11.6 25<br />

32 - 11.6 32<br />

118 36<br />

13<br />

120 38 15<br />

24.5<br />

127 45 22<br />

130 48 25<br />

143 36<br />

13<br />

145 38 15<br />

29.5<br />

152 45 22<br />

155 48 25<br />

163 36<br />

13<br />

165 38 15<br />

36.5<br />

172 45 22<br />

175 48 25<br />

3<br />

Standard Item<br />

14

Toolholder Dimensions<br />

Shank Angle<br />

Width<br />

Shank size<br />

Max. Grooving<br />

Depth<br />

Face<br />

Grooving<br />

Dia.<br />

øD(mm)<br />

Shank<br />

Description<br />

<br />

Blade<br />

Description<br />

<br />

Assembled<br />

Description<br />

Standard<br />

Dimension (mm)<br />

W<br />

(mm)<br />

R L H1=h H2 H3 B L1 L2 F1 T W<br />

MIN MAX<br />

13 25 35<br />

KGDF$ -25-4A-C KGDF$ 2020X25-4AS ● ●<br />

118 36<br />

13<br />

15<br />

35 50 -35-4B-C 2020X35-4BS ● ●<br />

50 70 -50-4B-C 2020X50-4BS ● ●<br />

70 100 -70-4B-C 2020X70-4BS ● ●<br />

100 150 -100-4B-C 2020X100-4BS ● ●<br />

150 220 -150-4B-C 2020X150-4BS ● ●<br />

120 38 15<br />

20<br />

220 ∞ KGD 2020-C<br />

-220-4B-C 2020X220-4BS ● ●<br />

20 12 11.6 20<br />

24.5<br />

35 50 -35-4C-C 2020X35-4CS ● ●<br />

50 70 -50-4C-C 2020X50-4CS ● ●<br />

25<br />

70 100 -70-4C-C 2020X70-4CS ● ●<br />

100 150 -100-4C-C 2020X100-4CS ● ●<br />

150 220 -150-4C-C 2020X150-4CS ● ●<br />

220 ∞ -220-4C-C 2020X220-4CS ● ●<br />

130 48 25<br />

13 25 35<br />

KGDF$ -25-4A-C KGDF$ 2525X25-4AS ● ●<br />

143 36<br />

13<br />

15<br />

35 50 -35-4B-C 2525X35-4BS ● ●<br />

50 70 -50-4B-C 2525X50-4BS ● ●<br />

70 100 -70-4B-C 2525X70-4BS ● ●<br />

100 150 -100-4B-C 2525X100-4BS ● ●<br />

150 220 -150-4B-C 2525X150-4BS ● ●<br />

145 38 15<br />

0° 4<br />

25<br />

220 ∞ KGD 2525-C<br />

-220-4B-C 2525X220-4BS ● ●<br />

25 7 11.6 25<br />

29.5<br />

4<br />

35 50 -35-4C-C 2525X35-4CS ● ●<br />

50 70 -50-4C-C 2525X50-4CS ● ●<br />

25<br />

70 100 -70-4C-C 2525X70-4CS ● ●<br />

100 150 -100-4C-C 2525X100-4CS ● ●<br />

150 220 -150-4C-C 2525X150-4CS ● ●<br />

220 ∞ -220-4C-C 2525X220-4CS ● ●<br />

155 48 25<br />

13 25 35<br />

KGDF$ -25-4A-C - - -<br />

163 36<br />

13<br />

15<br />

35 50 -35-4B-C - - -<br />

50 70 -50-4B-C - - -<br />

70 100 -70-4B-C - - -<br />

100 150 -100-4B-C - - -<br />

150 220 -150-4B-C - - -<br />

165 38 15<br />

32<br />

220 ∞ KGD 3232-C<br />

-220-4B-C - - -<br />

32 - 11.6 32<br />

36.5<br />

35 50 -35-4C-C - - -<br />

50 70 -50-4C-C - - -<br />

25<br />

70 100 -70-4C-C - - -<br />

100 150 -100-4C-C - - -<br />

150 220 -150-4C-C - - -<br />

220 ∞ -220-4C-C - - -<br />

175 48 25<br />

Standard Item<br />

15

Toolholder Dimensions<br />

Shank Angle<br />

Width<br />

0° 5<br />

Shank size<br />

Max. Grooving<br />

Depth<br />

Face<br />

Grooving<br />

Dia.<br />

øD(mm)<br />

MIN MAX<br />

20<br />

25<br />

32<br />

Shank<br />

Description<br />

<br />

Blade<br />

Description<br />

<br />

Assembled<br />

Description<br />

Standard<br />

Dimension (mm)<br />

W<br />

(mm)<br />

R L H1=h H2 H3 B L1 L2 F1 T W<br />

25 35<br />

KGDF$ -25-5B-C KGDF$ 2020X25-5BS ● ●<br />

35 50 -35-5B-C 2020X35-5BS ● ●<br />

50 75 -50-5B-C 2020X50-5BS ● ●<br />

15 75 115 -75-5B-C 2020X75-5BS ● ●<br />

120 38 15<br />

115 180 -115-5B-C 2020X115-5BS ● ●<br />

180 235 -180-5B-C 2020X180-5BS ● ●<br />

235 ∞ -235-5B-C 2020X235-5BS ● ●<br />

20 25 35 -25-5C-C 2020X25-5CS ● ● 125 43 20<br />

35 50 -35-5C-C 2020X35-5CS ● ●<br />

KGD 2020-C<br />

50 75 -50-5C-C 2020X50-5CS ● ●<br />

20 12 11.6 20<br />

24.5<br />

25<br />

75 115 -75-5C-C 2020X75-5CS ● ●<br />

115 180 -115-5C-C 2020X115-5CS ● ●<br />

130 48 25<br />

180 235 -180-5C-C 2020X180-5CS ● ●<br />

235 ∞ -235-5C-C 2020X235-5CS ● ●<br />

75 115 -75-5D-C - - -<br />

32<br />

115 180 -115-5D-C - - -<br />

180 235 -180-5D-C - - -<br />

137 55 32<br />

235 ∞ -235-5D-C - - -<br />

25 35<br />

KGDF$ -25-5B-C KGDF$ 2525X25-5BS ● ●<br />

35 50 -35-5B-C 2525X35-5BS ● ●<br />

50 75 -50-5B-C 2525X50-5BS ● ●<br />

15 75 115 -75-5B-C 2525X75-5BS ● ●<br />

145 38 15<br />

115 180 -115-5B-C 2525X115-5BS ● ●<br />

180 235 -180-5B-C 2525X180-5BS ● ●<br />

235 ∞ -235-5B-C 2525X235-5BS ● ●<br />

20 25 35 -25-5C-C 2525X25-5CS ● ● 150 43 20<br />

35 50 -35-5C-C 2525X35-5CS ● ●<br />

KGD 2525-C<br />

50 75 -50-5C-C 2525X50-5CS ● ●<br />

25 7 11.6 25<br />

29.5<br />

25<br />

75 115 -75-5C-C - - -<br />

115 180 -115-5C-C - - -<br />

155 48 25<br />

180 235 -180-5C-C - - -<br />

235 ∞ -235-5C-C - - -<br />

75 115 -75-5D-C 2525X75-5DS ● ●<br />

32<br />

115 180 -115-5D-C 2525X115-5DS ● ●<br />

180 235 -180-5D-C 2525X180-5DS ● ●<br />

162 55 32<br />

235 ∞ -235-5D-C 2525X235-5DS ● ●<br />

25 35<br />

KGDF$ -25-5B-C - - -<br />

35 50 -35-5B-C - - -<br />

50 75 -50-5B-C - - -<br />

15 75 115 -75-5B-C - - -<br />

165 38 15<br />

115 180 -115-5B-C - - -<br />

180 235 -180-5B-C - - -<br />

235 ∞ -235-5B-C - - -<br />

20 25 35 -25-5C-C - - - 170 43 20<br />

35 50 -35-5C-C - - -<br />

KGD 3232-C<br />

50 75 -50-5C-C - - -<br />

32 - 11.6 32<br />

36.5<br />

25<br />

75 115 -75-5C-C - - -<br />

115 180 -115-5C-C - - -<br />

175 48 25<br />

180 235 -180-5C-C - - -<br />

235 ∞ -235-5C-C - - -<br />

75 115 -75-5D-C - - -<br />

32<br />

115 180 -115-5D-C - - -<br />

180 235 -180-5D-C - - -<br />

182 55 32<br />

235 ∞ -235-5D-C - - -<br />

5<br />

Standard Item<br />

16

Toolholder Dimensions<br />

Shank Angle<br />

Width<br />

0° 5<br />

Shank size<br />

Max. Grooving<br />

Depth<br />

Face<br />

Grooving<br />

Dia.<br />

øD(mm)<br />

MIN MAX<br />

20<br />

25<br />

32<br />

Shank<br />

Description<br />

<br />

Blade<br />

Description<br />

<br />

Assembled<br />

Description<br />

Standard<br />

Dimension (mm)<br />

W<br />

(mm)<br />

R L H1=h H2 H3 B L1 L2 F1 T W<br />

25 35<br />

KGDF$ -25-6B-C KGDF$ 2020X25-6BS ● ●<br />

35 50 -35-6B-C 2020X35-6BS ● ●<br />

50 75 -50-6B-C 2020X50-6BS ● ●<br />

15 75 115 -75-6B-C 2020X75-6BS ● ●<br />

120 38 15<br />

115 180 -115-6B-C 2020X115-6BS ● ●<br />

180 235 -180-6B-C 2020X180-6BS ● ●<br />

235 ∞ -235-6B-C 2020X235-6BS ● ●<br />

20 25 35 -25-6C-C 2020X25-6CS ● ● 125 43 20<br />

35 50 -35-6C-C 2020X35-6CS ● ●<br />

KGD 2020-C<br />

50 75 -50-6C-C 2020X50-6CS ● ●<br />

20 12 11.6 20<br />

24.5<br />

25<br />

75 115 -75-6C-C 2020X75-6CS ● ●<br />

115 180 -115-6C-C 2020X115-6CS ● ●<br />

130 48 25<br />

180 235 -180-6C-C 2020X180-6CS ● ●<br />

235 ∞ -235-6C-C 2020X235-6CS ● ●<br />

75 115 -75-6D-C - - -<br />

32<br />

115 180 -115-6D-C - - -<br />

180 235 -180-6D-C - - -<br />

137 55 32<br />

235 ∞ -235-6D-C - - -<br />

25 35<br />

KGDF$ -25-6B-C KGDF$ 2525X25-6BS ● ●<br />

35 50 -35-6B-C 2525X35-6BS ● ●<br />

50 75 -50-6B-C 2525X50-6BS ● ●<br />

15 75 115 -75-6B-C 2525X75-6BS ● ●<br />

145 38 15<br />

115 180 -115-6B-C 2525X115-6BS ● ●<br />

180 235 -180-6B-C 2525X180-6BS ● ●<br />

235 ∞ -235-6B-C 2525X235-6BS ● ●<br />

20 25 35 -25-6C-C 2525X25-6CS ● ● 150 43 20<br />

35 50 -35-6C-C 2525X35-6CS ● ●<br />

KGD 2525-C<br />

50 75 -50-6C-C 2525X50-6CS ● ●<br />

25 7 11.6 25<br />

29.5<br />

25<br />

75 115 -75-6C-C - - -<br />

115 180 -115-6C-C - - -<br />

155 48 25<br />

180 235 -180-6C-C - - -<br />

235 ∞ -235-6C-C - - -<br />

75 115 -75-6D-C 2525X75-6DS ● ●<br />

32<br />

115 180 -115-6D-C 2525X115-6DS ● ●<br />

180 235 -180-6D-C 2525X180-6DS ● ●<br />

162 55 32<br />

235 ∞ -235-6D-C 2525X235-6DS ● ●<br />

25 35<br />

KGDF$ -25-6B-C - - -<br />

35 50 -35-6B-C - - -<br />

50 75 -50-6B-C - - -<br />

15 75 115 -75-6B-C - - -<br />

165 38 15<br />

115 180 -115-6B-C - - -<br />

180 235 -180-6B-C - - -<br />

235 ∞ -235-6B-C - - -<br />

20 25 35 -25-6C-C - - - 170 43 20<br />

35 50 -35-6C-C - - -<br />

KGD 3232-C<br />

50 75 -50-6C-C - - -<br />

32 - 11.6 32<br />

36.5<br />

25<br />

75 115 -75-6C-C - - -<br />

115 180 -115-6C-C - - -<br />

175 48 25<br />

180 235 -180-6C-C - - -<br />

235 ∞ -235-6C-C - - -<br />

75 115 -75-6D-C - - -<br />

32<br />

115 180 -115-6D-C - - -<br />

180 235 -180-6D-C - - -<br />

182 55 32<br />

235 ∞ -235-6D-C - - -<br />

6<br />

Standard Item<br />

17

Indication of KGDF unit description<br />

Assembled description<br />

(Assembled description is not marked)<br />

Shank (shank description is marked)<br />

Blade (Blade description is marked)<br />

Right-hand Left-hand Right-hand<br />

Left-hand Right-hand Left-hand<br />

R-hand Blade for L-hand shank, L-hand Blade for R-hand shank.<br />

Assembled description is shown on the package only, but not on product itself.<br />

Indication of Assembled Description for KGDF series<br />

Hand of Blade<br />

Right-hand<br />

Left-hand<br />

Shank size of tool holder<br />

<br />

<br />

<br />

<br />

KGDF R 2020X 25 -<br />

Width<br />

<br />

<br />

<br />

<br />

Symbol of<br />

assembled holder<br />

Indicate the<br />

Unit Description<br />

3 A S<br />

What is ØD Min. and Max.?<br />

It indicates the available range for the 1st plunging.<br />

Outside diameter of the groove is shown.<br />

Face Grooving Dia.(Out side)<br />

MIN: minimum (Shown in the description)<br />

MAX: maximum (Refer to the spec chart)<br />

Series<br />

Min.Bore Dia. (Face grooving)<br />

grooving depth<br />

KGDF Face grooving<br />

Min. diameter (outside of groove) for<br />

the first plumging.<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

For 2-edge type insert<br />

For 1-edge type insert<br />

For 1-edge type insert<br />

øD(MAX)<br />

øD(MIN)<br />

Refer max. diameter (outside of groove)<br />

to "ØD (mm)" in the chart for holder spec.<br />

Limit of Traversing toward center<br />

Traversing towards the center causes the toolholder to interfere with the groove wall depending on the initial cut´s diameter.<br />

d<br />

D<br />

Interference<br />

Limitation of groove expansion<br />

Description<br />

KGDF$<br />

2020X25-3AS<br />

2525X25-3AS<br />

2020X25-4AS<br />

2525X25-4AS<br />

2020X25-5AS<br />

2525X25-5AS<br />

2020X25-6AS<br />

2525X25-6AS<br />

ø <br />

ød<br />

<br />

<br />

<br />

<br />

<br />

over<br />

No<br />

remaining<br />

Boss<br />

Spare parts<br />

Spare parts<br />

Clamp bolt (For Insert Clamp) Fixing bolt(For Blade) Wrench<br />

Unit Description<br />

KGDF$S BH6X10TR SB-60120TR LTW-25<br />

18

KGDF (90° seperate type)<br />

Shank and Blade<br />

Shank Angle<br />

Width<br />

Shank size<br />

Max. Grooving<br />

Depth<br />

Face<br />

Grooving<br />

Dia.<br />

øD(mm)<br />

Shank<br />

Description<br />

<br />

Blade<br />

Description<br />

<br />

Shank Angle<br />

Width<br />

Shank size<br />

Max. Grooving<br />

Depth<br />

Face<br />

Grooving<br />

Dia.<br />

øD(mm)<br />

Shank<br />

Description<br />

<br />

Blade<br />

Description<br />

<br />

90°<br />

MIN MAX<br />

25 30<br />

KGDF$ -25-3A-C<br />

13 30 40 -30-3A-C<br />

40 50 -40-3A-C<br />

50 65 -50-3B-C<br />

65 85 -65-3B-C<br />

15<br />

20<br />

KGDS$2020-C<br />

85 110 -85-3B-C<br />

110 145 -110-3B-C<br />

22<br />

50 65 -50-3C-C<br />

65 85 -65-3C-C<br />

25<br />

3<br />

25 30<br />

KGDF$ -25-3A-C<br />

85<br />

110<br />

110<br />

145<br />

-85-3C-C<br />

-110-3C-C<br />

13 30 40 -30-3A-C<br />

40 50 -40-3A-C<br />

50 65 -50-3B-C<br />

65 85 -65-3B-C<br />

15<br />

25<br />

KGDS$2525-C<br />

85 110 -85-3B-C<br />

110 145 -110-3B-C<br />

22<br />

50<br />

65<br />

65<br />

85<br />

-50-3C-C<br />

-65-3C-C<br />

25<br />

85 110 -85-3C-C<br />

110 145 -110-3C-C<br />

13 25 35<br />

KGDF$ -25-4A-C<br />

35 50 -35-4B-C<br />

50 70 -50-4B-C<br />

15<br />

70 100 -70-4B-C<br />

100 150 -100-4B-C<br />

150 220 -150-4B-C<br />

20 220 ∞ KGDS$2020-C<br />

-220-4B-C<br />

35 50 -35-4C-C<br />

50 70 -50-4C-C<br />

25<br />

100 150 -100-4C-C<br />

70 100 -70-4C-C<br />

150 220 -150-4C-C<br />

4<br />

220 ∞ -220-4C-C<br />

13 25 35<br />

KGDF$ -25-4A-C<br />

35 50 -35-4B-C<br />

50 70 -50-4B-C<br />

15<br />

70 100 -70-4B-C<br />

100 150 -100-4B-C<br />

150 220 -150-4B-C<br />

25 220 ∞ KGDS$2525-C<br />

-220-4B-C<br />

35 50 -35-4C-C<br />

50 70 -50-4C-C<br />

25<br />

70 100 -70-4C-C<br />

100 150 -100-4C-C<br />

150 220 -150-4C-C<br />

220 ∞ -220-4C-C<br />

90°seperate type<br />

Blade : Right-hand<br />

Shank : Right-hand<br />

Right-hand<br />

Shank and blades of KGDF seperate type (90°) are soldseperately. Please purchase<br />

individually and assemble them into a set.<br />

Les manches et les cassettes des outils KGDF (90 °) Sont vendues séparément. Acheter<br />

séparément Les éléments et les assembler en un ensemble; S’il vous plait.<br />

Attacco e lame dell’utensile tipo KGDF (90°), vengono venduti separatamente.<br />

Mango y cartuchos del KGDF tipo modular (90º) se venden por separado. Por favor,<br />

pídalos por separado y móntelos para hacer el conjunto.<br />

MIN MAX<br />

25 35<br />

KGDF$ -25-5B-C<br />

35 50 -35-5B-C<br />

50 75 -50-5B-C<br />

15 75 115 -75-5B-C<br />

115 180 -115-5B-C<br />

180 235 -180-5B-C<br />

235 ∞ -235-5B-C<br />

20 25 35 -25-5C-C<br />

20<br />

KGDS$2020-C<br />

35<br />

50<br />

50<br />

75<br />

-35-5C-C<br />

-50-5C-C<br />

25<br />

75 115 -75-5C-C<br />

115 180 -115-5C-C<br />

180 235 -180-5C-C<br />

235 ∞ -235-5C-C<br />

75 115 -75-5D-C<br />

32<br />

115<br />

180<br />

180<br />

235<br />

-115-5D-C<br />

-180-5D-C<br />

90° 5<br />

235 ∞ -235-5D-C<br />

25 35<br />

KGDF$ -25-5B-C<br />

35 50 -35-5B-C<br />

50 75 -50-5B-C<br />

15 75 115 -75-5B-C<br />

115 180 -115-5B-C<br />

180 235 -180-5B-C<br />

235 ∞ -235-5B-C<br />

20 25 35 -25-5C-C<br />

25<br />

KGDS$2525-C<br />

35<br />

50<br />

50<br />

75<br />

-35-5C-C<br />

-50-5C-C<br />

25<br />

75 115 -75-5C-C<br />

115 180 -115-5C-C<br />

180 235 -180-5C-C<br />

235 ∞ -235-5C-C<br />

75 115 -75-5D-C<br />

32<br />

115 180 -115-5D-C<br />

180 235 -180-5D-C<br />

235 ∞ -235-5D-C<br />

25 35<br />

KGDF$ -25-6B-C<br />

35 50 -35-6B-C<br />

50 75 -50-6B-C<br />

15 75 115 -75-6B-C<br />

115 180 -115-6B-C<br />

180 235 -180-6B-C<br />

235 ∞ -235-6B-C<br />

20 25 35 -25-6C-C<br />

20<br />

KGDS$2020-C<br />

35<br />

50<br />

50<br />

75<br />

-35-6C-C<br />

-50-6C-C<br />

25<br />

75 115 -75-6C-C<br />

115 180 -115-6C-C<br />

180 235 -180-6C-C<br />

235 ∞ -235-6C-C<br />

75 115 -75-6D-C<br />

32<br />

115<br />

180<br />

180<br />

235<br />

-115-6D-C<br />

-180-6D-C<br />

90° 6<br />

235 ∞ -235-6D-C<br />

25 35<br />

KGDF$ -25-6B-C<br />

35 50 -35-6B-C<br />

50 75 -50-6B-C<br />

15 75 115 -75-6B-C<br />

115 180 -115-6B-C<br />

180 235 -180-6B-C<br />

235 ∞ -235-6B-C<br />

20 25 35 -25-6C-C<br />

25<br />

KGDS$2525-C<br />

35<br />

50<br />

50<br />

75<br />

-35-6C-C<br />

-50-6C-C<br />

25<br />

75 115 -75-6C-C<br />

115 180 -115-6C-C<br />

180 235 -180-6C-C<br />

235 ∞ -235-6C-C<br />

75 115 -75-6D-C<br />

32<br />

115 180 -115-6D-C<br />

180 235 -180-6D-C<br />

235 ∞ -235-6D-C<br />

Right-hand Blade for Right-hand shank, Left-hand Blade for Left-hand shank.<br />

Insert clamp bolt (BH6x10TR)/Blade fi xing bolt(SB-60120TR) come with tool holder.<br />

19

Blade Dimensions<br />

41.5<br />

L<br />

Shape<br />

Indication of blade for face grooving<br />

T<br />

Right-hand Shown<br />

A<br />

Blade<br />

Description<br />

Standard<br />

Dimension (mm)<br />

Face Grooving<br />

Dia.<br />

øD (mm)<br />

Width<br />

<br />

R L L T A MIN MAX W<br />

KGDF$ -25-3A-C ● ●<br />

25 30<br />

-30-3A-C ● ● 47.35 13<br />

30 40<br />

-40-3A-C ● ● 40 50<br />

-50-3B-C ● ●<br />

50 65<br />

-65-3B-C ● ● 65 85<br />

49.35 15<br />

-85-3B-C ● ● 2 85 110 3<br />

-110-3B-C ● ● 110 145<br />

-50-3C-C ● ● 50 65<br />

56.35 22<br />

-65-3C-C ● ● 65 85<br />

-85-3C-C ● ● 85 110<br />

59.35 25<br />

-110-3C-C ● ● 110 145<br />

KGDF$ -25-4A-C ● ● 47.35 13<br />

25 35<br />

-35-4B-C ● ●<br />

35 50<br />

-50-4B-C ● ● 50 70<br />

-70-4B-C ● ● 70 100<br />

49.35 15<br />

-100-4B-C ● ● 100 150<br />

-150-4B-C ● ● 150 220<br />

-220-4B-C ● ● 3 220 ∞ 4<br />

-35-4C-C ● ●<br />

35 50<br />

-50-4C-C ● ● 50 70<br />

-70-4C-C ● ● 70 100<br />

59.35 25<br />

-100-4C-C ● ● 100 150<br />

-150-4C-C ● ● 150 220<br />

-220-4C-C ● ● 220 ∞<br />

KGDF$ -25-5B-C ● ●<br />

25 35<br />

-35-5B-C ● ● 35 50<br />

-50-5B-C ● ● 50 75<br />

-75-5B-C ● ● 49.35 15<br />

75 115<br />

-115-5B-C ● ● 115 180<br />

-180-5B-C ● ● 180 235<br />

-235-5B-C ● ● 235 ∞<br />

-25-5C-C ● ● 54.35 20 25 35<br />

-35-5C-C ● ●<br />

35 50<br />

4<br />

-50-5C-C ● ● 50 75<br />

5<br />

-75-5C-C ● ● 75 115<br />

59.35 25<br />

-115-5C-C ● ● 115 180<br />

-180-5C-C ● ● 180 235<br />

-235-5C-C ● ● 235 ∞<br />

-75-5D-C ● ●<br />

75 115<br />

-115-5D-C ● ● 115 180<br />

66.35 32<br />

-180-5D-C ● ● 180 235<br />

-235-5D-C ● ● 235 ∞<br />

KGDF$ -25-6B-C ● ●<br />

25 35<br />

-35-6B-C ● ● 35 50<br />

-50-6B-C ● ● 50 75<br />

-75-6B-C ● ● 49.35 15<br />

75 115<br />

-115-6B-C ● ● 115 180<br />

-180-6B-C ● ● 180 235<br />

-235-6B-C ● ● 235 ∞<br />

-25-6C-C ● ● 54.35 20 25 35<br />

-35-6C-C ● ●<br />

35 50<br />

5<br />

-50-6C-C ● ● 50 75<br />

6<br />

-75-6C-C ● ● 75 115<br />

59.35 25<br />

-115-6C-C ● ● 115 180<br />

-180-6C-C ● ● 180 235<br />

-235-6C-C ● ● 235 ∞<br />

-75-6D-C ● ●<br />

75 115<br />

-115-6D-C ● ● 115 180<br />

66.35 32<br />

-180-6D-C ● ● 180 235<br />

-235-6D-C ● ● 235 ∞<br />

Applicable<br />

Inserts<br />

<br />

GDFM 3020N-030GM<br />

GDFM 3020N-030DM<br />

GDFMS 3020N-030DM<br />

GDFM 4020N-040GM<br />

GDFM 4020N-040DM<br />

GDFMS 4020N-040DM<br />

GDFM 5020N-040GM<br />

GDFM 5020N-040DM<br />

GDFMS 5020N-040DM<br />

GDFM 6020N-040GM<br />

GDFM 6020N-040DM<br />

GDFMS 6020N-040DM<br />

Shank<br />

Description<br />

<br />

KGD<br />

•••-C<br />

KGDS$•••-C<br />

Standard Item<br />

Hand of Blade<br />

Width<br />

Symbol<br />

Right-hand<br />

Left-hand<br />

<br />

<br />

<br />

<br />

Shank Height for 20mm/25mm<br />

square shank<br />

KGDF R - 25 - 3 A - C<br />

Series<br />

Min.Bore Dia. (Face grooving)<br />

grooving depth<br />

KGDF Face grooving<br />

Indicates available outside<br />

groove dia. for the 1st plunging.<br />

<br />

<br />

For 2-edge type insert<br />

For 1-edge type insert<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

For 1-edge type insert<br />

20

Recommended Cutting Conditions (Face grooving)<br />

Vc (m/min)<br />

Workpiece Material<br />

Cermet<br />

MEGACOAT Carbide<br />

Coolant<br />

Carbon Steel<br />

Alloy Steel<br />

Stainless Steel<br />

TN90 PR1225 PR1215<br />

<br />

100~220 80~200 100~200<br />

<br />

80~200 70~180 80~180<br />

<br />

70~180 60~150 60~150<br />

Cast Iron - -<br />

<br />

100~200<br />

Aluminium - - -<br />

Brass - - -<br />

Chipbreaker Selection (Face grooving)<br />

Yes<br />

1st. Recommendation2nd. Recommendation<br />

Application<br />

Shallow Grooving (under 10mm)<br />

Deep Grooving (over 10mm)<br />

Narrow Grooving<br />

Wide Grooving<br />

Narrow Grooving<br />

Wide Grooving<br />

Single plunging<br />

Multiple<br />

plunging<br />

Plunging<br />

<br />

Traversing<br />

Single plunging<br />

Multiple<br />

plunging<br />

Plunging<br />

<br />

Traversing<br />

GM<br />

General Purpose<br />

DM<br />

Deep Grooving<br />

GM<br />

General Purpose<br />

Please try DM chip-breaker when experiencing unstable chip evacuation with GM for plunging.<br />

Recommended Cutting Conditions (f, ap)<br />

Grooving<br />

Traversing<br />

Shoulder Grooving<br />

GM Chipbreaker<br />

Workpiece Material: Steel<br />

GM Chipbreaker<br />

Workpiece Material: Steel<br />

GM Chipbreaker<br />

Workpiece Material: Steel<br />

Width (mm)<br />

6<br />

5<br />

4<br />

3<br />

ap<br />

(mm)<br />

3.0<br />

2.0<br />

1.0<br />

4mm<br />

3mm<br />

W=6mm<br />

5mm<br />

Width (mm)<br />

6<br />

5<br />

4<br />

3<br />

0.05 0.10 0.15 0.20 0.25<br />

f (mm/rev)<br />

0.05 0.10 0.15 0.20 0.25 0.30<br />

f (mm/rev)<br />

0.05 0.10 0.15 0.20 0.25 0.30<br />

f (mm/rev)<br />

DM Chipbreaker<br />

Workpiece Material: Steel<br />

DM Chipbreaker<br />

Workpiece Material: Steel<br />

6<br />

3.0<br />

Width (mm)<br />

5<br />

4<br />

3<br />

ap<br />

(mm)<br />

2.0<br />

1.0<br />

5mm<br />

4mm<br />

3mm<br />

W=6mm<br />

0.05 0.10 0.15 0.20 0.25<br />

f (mm/rev)<br />

0.05 0.10 0.15 0.20 0.25 0.30<br />

f (mm/rev)<br />

DM Chipbreaker Max. Depth of Cut: Edge width x 0.3<br />

21

Tips about face grooving<br />

1) Toolholder Selection<br />

Check available Min and Max diameter as<br />

well as width and depth.<br />

2) Feed rate<br />

Set proper feed rate to form continiuous chips<br />

for steel machining.<br />

3) Expand groove width (Plunging, Traversing)<br />

Recommended traversing from outside to inside to get<br />

better chip evacuation.<br />

f<br />

Plunging<br />

Traversing<br />

<br />

f<br />

f<br />

<br />

4) Traversing<br />

A: ap over 0.5mm<br />

Plunging<br />

Pull back the tool by 0.1mm<br />

Traversing<br />

<br />

<br />

<br />

<br />

<br />

When widening the groove width, apply the<br />

"Step Turning".<br />

The widened groove and side walls should be<br />

finished last<br />

0.1mm<br />

<br />

B: ap under 0.5mm<br />

Plunging<br />

Traversing<br />

After plunging, traversing can start directly<br />

without pulling back.<br />

<br />

<br />

<br />

<br />

22

Case studies<br />

20Cr4 (Grooving)<br />

Free cutting Steel (Cut-off)<br />

Gear<br />

<br />

<br />

<br />

<br />

<br />

<br />

10<br />

<br />

ø24<br />

ø35<br />

Sleeve<br />

<br />

<br />

<br />

<br />

<br />

<br />

ø10<br />

ø33<br />

<br />

GM Chipbreaker<br />

<br />

Competitor K<br />

(PVD Coated Carbide)<br />

250pcs/edge<br />

1500pcs/edge<br />

6 times longer<br />

tool life<br />

PM Chipbreaker<br />

<br />

Competitor L<br />

(PVD Coated Carbide)<br />

250pcs/edge, capable<br />

of further machining<br />

250pcs/edge, with chipping<br />

Results<br />

·KGD-type and GM chipbreaker (PR1225)<br />

improved tool life to 6 times of Comp. K.<br />

·No burned chips and good chip control.<br />

Results<br />

·KGD-type and PM chipbreaker (PR1225) showed good edge condition after machining<br />

same number of workpieces as Comp. L.<br />

·Available for further machining. (Comp. L caused chipping)<br />

Competitor K<br />

GM Chipbreaker<br />

34CrMo4 (Copying)<br />

35CrMo4 (Face Grooving)<br />

Ball Stud<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

ø13<br />

ø20<br />

Piston<br />

<br />

Grooving)<br />

<br />

Traversing)<br />

Traversing)<br />

<br />

<br />

<br />

<br />

・・・<br />

18<br />

ø25<br />

ø55<br />

GM Chipbreaker<br />

<br />

800pcs/edge<br />

2 times longer<br />

tool life<br />

GM Chipbreaker<br />

<br />

40pcs/edge, capable<br />

of further machining<br />

Conventional A<br />

400pcs/edge<br />

Conventional B<br />

40pcs/edge, with chipping<br />

Results<br />

· Resolve issues such as chip-bite and tangled chips due to its surperior chip evacuation<br />

performance<br />

Resolve breakage of edge caused by chips.<br />

·Doubled tool life by reducing damage on the<br />

edge.<br />

Results<br />

· KGDF + GM chipbreaker improved chip evacuatoin compared to B.<br />

(Resolved frequent breakage of holder.)<br />

· Smaller wear on the edge provided by MEGACOAT make the tool life longer.<br />

(Lower running cost by longer tool life)<br />

KYOCERA Fineceramics GmbH<br />

Cutting Tool Division<br />

Hammfelddamm 6, 41460 Neuss, Germany<br />

Phone: +49 (0) 2131 1637-115<br />

Fax: +49 (0) 2131 1637-152<br />

www.kyocera.de / www.kyocera.eu<br />

ceratip@kyocera.de<br />

KYOCERA Fineceramics SAS.<br />

Cutting Tool Division<br />

Parc Tertiaire Silic, 21 Rue de Villeneuve<br />

BP 90439, 94528 Rungis Cedex, France<br />

Phone: +33 (0) 1 41 73 73 40 Fax: +33 (0) 1 56 72 18 94<br />

www.kyocera.fr<br />

KYOCERA Fineceramics GmbH Poland Branch Office<br />

Cutting Tool Division<br />

Leg. ul.Europejska 4, 55-220, Jelcz-Laskowice, Poland<br />

Phone: +48-(0) 71-381-12-15 Fax: +48-(0) 71-381-12-16<br />

www.kyocera.eu<br />

KYOCERA Fineceramics GmbH Italy Branch Office<br />

Cutting Tool Division<br />

Via Torino 51, 20123 Milan, Italy<br />

Phone: +39-02 00620 845 Fax: +39-02 00620 848<br />

www.kyocera.it<br />

KYOCERA Fineceramics GmbH Spain Branch Office<br />

Cutting Tool Division<br />

Avenida Manacor 4, 28290 Las Matas, Madrid, Spain<br />

Phone: +34-91-631-83-92-802 Fax: +34-91-631-82-19<br />

www.kyocera.es

![2012 - DRC Magic Drill - [ENG FRA ITA ESP] - 02.indd - Kyocera](https://img.yumpu.com/49215477/1/184x260/2012-drc-magic-drill-eng-fra-ita-esp-02indd-kyocera.jpg?quality=85)

![2012 - MEC series [GER ENG PL RUS].indd - Kyocera](https://img.yumpu.com/44428724/1/184x260/2012-mec-series-ger-eng-pl-rusindd-kyocera.jpg?quality=85)

![2012 - MEW - [ENG FRA ITA ESP].indd - Kyocera](https://img.yumpu.com/39423422/1/184x260/2012-mew-eng-fra-ita-espindd-kyocera.jpg?quality=85)