oliver valves power industry

oliver valves power industry

oliver valves power industry

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ASME B31.1 VALVES<br />

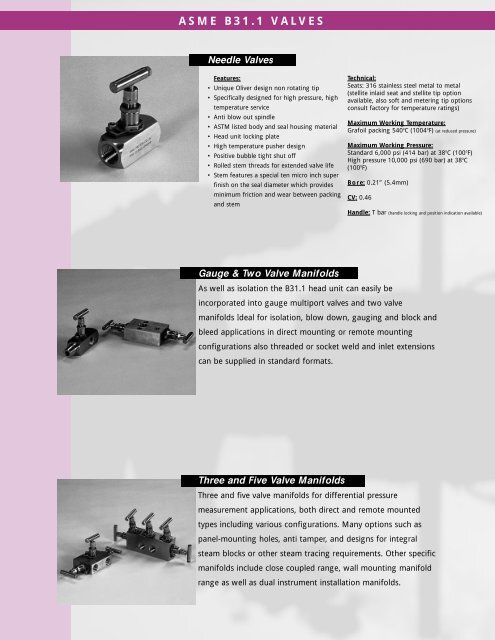

Needle Valves<br />

Features:<br />

• Unique Oliver design non rotating tip<br />

• Specifically designed for high pressure, high<br />

temperature service<br />

• Anti blow out spindle<br />

• ASTM listed body and seal housing material<br />

• Head unit locking plate<br />

• High temperature pusher design<br />

• Positive bubble tight shut off<br />

• Rolled stem threads for extended valve life<br />

• Stem features a special ten micro inch super<br />

finish on the seal diameter which provides<br />

minimum friction and wear between packing<br />

and stem<br />

Technical:<br />

Seats: 316 stainless steel metal to metal<br />

(stellite inlaid seat and stellite tip option<br />

available, also soft and metering tip options<br />

consult factory for temperature ratings)<br />

Maximum Working Temperature:<br />

Grafoil packing 540 0 C (1004 0 F) (at reduced pressure)<br />

Maximum Working Pressure:<br />

Standard 6,000 psi (414 bar) at 38 0 C (100 0 F)<br />

High pressure 10,000 psi (690 bar) at 38 0 C<br />

(100 0 F)<br />

Bore: 0.21” (5.4mm)<br />

CV: 0.46<br />

Handle: T bar (handle locking and position indication available)<br />

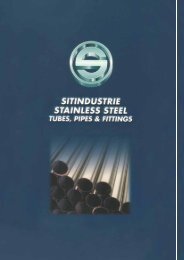

Gauge & Two Valve Manifolds<br />

As well as isolation the B31.1 head unit can easily be<br />

incorporated into gauge multiport <strong>valves</strong> and two valve<br />

manifolds Ideal for isolation, blow down, gauging and block and<br />

bleed applications in direct mounting or remote mounting<br />

configurations also threaded or socket weld and inlet extensions<br />

can be supplied in standard formats.<br />

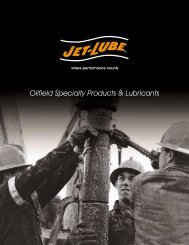

Three and Five Valve Manifolds<br />

Three and five valve manifolds for differential pressure<br />

measurement applications, both direct and remote mounted<br />

types including various configurations. Many options such as<br />

panel-mounting holes, anti tamper, and designs for integral<br />

steam blocks or other steam tracing requirements. Other specific<br />

manifolds include close coupled range, wall mounting manifold<br />

range as well as dual instrument installation manifolds.