Michael Jellison

Michael Jellison

Michael Jellison

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

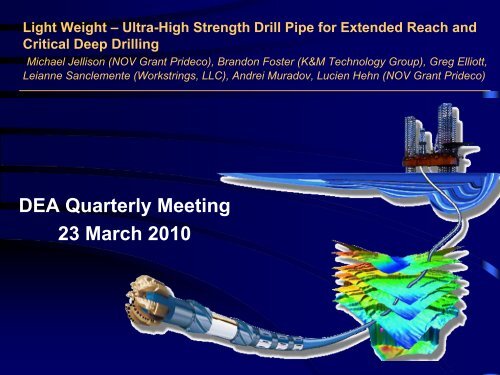

Light Weight – Ultra-High Strength Drill Pipe for Extended Reach and<br />

Critical Deep Drilling<br />

<strong>Michael</strong> <strong>Jellison</strong> (NOV Grant Prideco), Brandon Foster (K&M Technology Group), Greg Elliott,<br />

Leianne Sanclemente (Workstrings, LLC), Andrei Muradov, Lucien Hehn (NOV Grant Prideco)<br />

DEA Quarterly Meeting<br />

23 March 2010

Light Weight – Ultra-High Strength Drill Pipe for Extended Reach and Critical Deep Drilling<br />

<strong>Jellison</strong>, Foster, Elliott, Sanclemente, Muradov, Hehn<br />

• Background<br />

• Comparison with Aluminum & Titanium Drill Pipe<br />

• Metallurgical Development<br />

• Field History<br />

• Third Generation Double-Shouldered Connection<br />

• Example ERD Design<br />

• Performance Properties – Collapse<br />

Considerations<br />

• Conclusions<br />

Outline<br />

2

Light Weight – Ultra-High Strength Drill Pipe for Extended Reach and Critical Deep Drilling<br />

<strong>Jellison</strong>, Foster, Elliott, Sanclemente, Muradov, Hehn<br />

Strength to weight ratio comparisons of many steel grades to nonsteel<br />

alternative materials including steel tool joints attached<br />

Drill Pipe<br />

Type<br />

Grade<br />

Yield<br />

Strength<br />

(psi)<br />

Tube OD<br />

(in.)<br />

Tube ID<br />

(in.)<br />

Tube<br />

C.S.A.<br />

(in 2 )<br />

Tube<br />

Tensile<br />

Strength<br />

(lbf)<br />

Joint<br />

Length<br />

(ft)<br />

Joint Air<br />

Weight<br />

(lbf) 3<br />

Joint Strength<br />

to Joint Weight<br />

(lbf/lbf)<br />

%<br />

Improvement<br />

to S-135<br />

Cost<br />

Compared<br />

to S-135<br />

Titanium Ti 6Al-4V 120,000 5.875 5.153 6.254 750,421 46.24 741 1,013 37% ≈ 7 - 10X<br />

Steel UD-165 165,000 5.875 5.153 6.254 1,031,829 46.24 1,145 901 22% NA<br />

Aluminum 1 Al-Zn-Mg II 2 69,618 5.787 4.764 8.477 590,175 46.24 717 823 12% ≈ 1.5 - 2.5X<br />

Steel V-150 150,000 5.875 5.153 6.254 938,026 46.24 1,145 819 11% NA<br />

Steel Z-140 140,000 5.875 5.153 6.254 875,491 46.24 1,145 765 4% NA<br />

Steel S-135 135,000 5.875 5.153 6.254 844,224 46.24 1,145 737 0% 1X<br />

Aluminum 1 Al-Zn-Mg IV 2 50,763 5.787 4.764 8.477 430,335 46.24 717 600 -19% ≈ 1.5 - 2.5X<br />

Aluminum 1 AI-Cu-Mg-Si-Fe III 2 49,312 5.787 4.764 8.477 418,034 46.24 717 583 -21% ≈ 1.5 - 2.5X<br />

Aluminum 1 Al-Cu-Mg I 2 47,137 5.787 4.764 8.477 399,596 46.24 717 557 -24% ≈ 1.5 - 2.5X<br />

Notes:<br />

1 = Aluminum drill pipe design (drill pipe with protector thickening) from ISO 15546 Petroleum and natural gas industries — Aluminum alloy drill pipe<br />

2 = Aluminum drill pipe grades from ISO 15546 Petroleum and natural gas industries — Aluminum alloy drill pipe<br />

3 = includes weight of steel tool joints<br />

3

Light Weight – Ultra-High Strength Drill Pipe for Extended Reach and Critical Deep Drilling<br />

<strong>Jellison</strong>, Foster, Elliott, Sanclemente, Muradov, Hehn<br />

High Strength Drill Pipe Manufactured to Date<br />

960,000<br />

900,000<br />

939,413<br />

840,000<br />

780,000<br />

720,000<br />

660,000<br />

600,000<br />

Z-140<br />

V-150<br />

540,000<br />

480,000<br />

420,000<br />

415,381<br />

360,000<br />

300,000<br />

240,000<br />

180,000<br />

120,000<br />

60,000<br />

0<br />

Jan-97<br />

Jul-97<br />

Jan-98<br />

Jul-98<br />

Jan-99<br />

Jul-99<br />

Jan-00<br />

Jul-00<br />

Jan-01<br />

Jul-01<br />

Jan-02<br />

Jul-02<br />

Jan-03<br />

Jul-03<br />

Jan-04<br />

Jul-04<br />

Jan-05<br />

Jul-05<br />

Jan-06<br />

Jul-06<br />

Jan-07<br />

Jul-07<br />

Jan-08<br />

Jul-08<br />

Jan-09<br />

4

Light Weight – Ultra-High Strength Drill Pipe for Extended Reach and Critical Deep Drilling<br />

<strong>Jellison</strong>, Foster, Elliott, Sanclemente, Muradov, Hehn<br />

Metallurgical Development<br />

Grade Size Impact 1 Impact 2 Impact 3 Average Elong. Yield UTS Yield/UTS<br />

(ft‐lbs) (ft‐lbs) (ft‐lbs) (ft‐lbs) (%) (ksi) (ksi) (%)<br />

S135 (NS1) 3/4 76 78 75 76 20.2 147.4 160.8 92<br />

V150 3/4 60 62 65 63 26.5 158.0 171.3 92<br />

UD165 3/4 46 47 47 47 24.4 169.0 174.0 97<br />

† Tests carried out in -20 ◦ C (-4 ◦ F).<br />

CTOD CTOD CTOD CTOD CTOD<br />

B 1 2 3 average average Yield UTS<br />

Grade Type (mm) (mm) (mm) (mm) (mm) (inch) (ksi) (ksi)<br />

S135 (NS1) BxB, L‐C 18.00 0.150 0.160 0.150 0.153 0.0060 147.4 160.8<br />

V150 BxB, L‐C 18.00 0.079 0.094 0.088 0.087 0.0034 158.0 171.3<br />

UD165 BxB, L‐C 18.00 0.090 0.090 0.090 0.090 0.0035 169.0 174.0<br />

†CTOD tests carried out in three-point bending at 0 ◦ C (32 ◦ F).<br />

5

Light Weight – Ultra-High Strength Drill Pipe for Extended Reach and Critical Deep Drilling<br />

<strong>Jellison</strong>, Foster, Elliott, Sanclemente, Muradov, Hehn<br />

S-N plot for fatigue testing program comparing UD-165 with V-150.<br />

6

Light Weight – Ultra-High Strength Drill Pipe for Extended Reach and Critical Deep Drilling<br />

<strong>Jellison</strong>, Foster, Elliott, Sanclemente, Muradov, Hehn<br />

Field History<br />

• 30 joints of 5” 0.500” wall thickness UD-165 drill pipe deployed to Patterson UTI Rig<br />

#30 in South Texas and successfully run in two wells in combination with 5” 19.50#<br />

S-135 NC50 drill pipe. Wells in this area typically range in depth from 16,000 to<br />

17,000 ft.<br />

• First use was not planned. Rig did not have sufficient pipe to reach TD and topped<br />

out the string with 12 joints of UD-165 pipe. (Additional 5” S-135 drill pipe readily<br />

available; decision made to run UD-165 early.) Drill pipe performed as expected with<br />

no unusual running or handling issues experienced.<br />

• Second case history was a re-entry well in same South Texas area. Well kicked off<br />

at 3,450 ft and a total of 13,274 ft was drilled to an MD of 16,724 ft with max<br />

inclination angle of 23 deg. Average RPM’s were 65 running with a mud motor and<br />

12,000 to 15,000 lb WOB. Penetration rates averaged 30 – 35 ft/hr with rotary table<br />

and 15 – 20 ft/hr in sliding mode with mud motor drilling. Visual inspection revealed<br />

no unusual or unexpected conditions and pipe showed typical signs of normal use.<br />

• Since then 5-7/8” 0.500” wall thickness UD-165 pipe manufactured and awaiting field<br />

trials.<br />

• First lot of light weight 5-7/8” 0.300” wall thickness UD-165 drill pipe currently being<br />

processed for evaluation and field trials. In addition, there are plans to build two<br />

ultra-high capacity 6-5/8” UD-165 landing strings this year.<br />

7

Light Weight – Ultra-High Strength Drill Pipe for Extended Reach and Critical Deep Drilling<br />

<strong>Jellison</strong>, Foster, Elliott, Sanclemente, Muradov, Hehn<br />

3 rd Gen. Double-Shouldered Connection<br />

2 nd Gen. Double-Shouldered<br />

Connection<br />

≈ 13 revolutions<br />

Starting Thread<br />

Starting Thread 1<br />

3 rd Gen. Double-Shouldered<br />

Connection<br />

≈ 4 revolutions<br />

Starting Thread 2<br />

8

Light Weight – Ultra-High Strength Drill Pipe for Extended Reach and Critical Deep Drilling<br />

<strong>Jellison</strong>, Foster, Elliott, Sanclemente, Muradov, Hehn<br />

Cumulative footage by delivery date<br />

(as of January 1, 2009)<br />

450,000<br />

Total: 417,250 ft<br />

400,000<br />

350,000<br />

300,000<br />

250,000<br />

200,000<br />

150,000<br />

100,000<br />

50,000<br />

0<br />

Sep-06 Jan-07 May-07 Sep-07 Jan-08 May-08 Sep-08 Jan-09 May-09<br />

9

Light Weight – Ultra-High Strength Drill Pipe for Extended Reach and Critical Deep Drilling<br />

<strong>Jellison</strong>, Foster, Elliott, Sanclemente, Muradov, Hehn<br />

Footage by connection size and material grade<br />

(as of January 1, 2009)<br />

220,000<br />

210,000<br />

200,000<br />

190,000<br />

180,000<br />

170,000<br />

160,000<br />

150,000<br />

140,000<br />

130,000<br />

120,000<br />

110,000<br />

100,000<br />

90,000<br />

80,000<br />

70,000<br />

60,000<br />

50,000<br />

40,000<br />

30,000<br />

20,000<br />

10,000<br />

0<br />

15,704<br />

72,038<br />

14,000<br />

SS-105<br />

S-135<br />

Z-140<br />

V-150<br />

31,205<br />

20,000<br />

56,020<br />

141,998<br />

57,047<br />

9,237<br />

380 390 485 525 550 585<br />

10

Light Weight – Ultra-High Strength Drill Pipe for Extended Reach and Critical Deep Drilling<br />

<strong>Jellison</strong>, Foster, Elliott, Sanclemente, Muradov, Hehn<br />

Estimated Cost Savings<br />

Rig Type<br />

Day Rate (1)<br />

(USD)<br />

Spread Rate (2)<br />

(USD)<br />

Cost per sec.<br />

of time saved<br />

(USD)<br />

Min. Est. Time<br />

Savings per<br />

Well (3)<br />

(hr)<br />

Min. Est. Cost<br />

Savings per<br />

Well (3)<br />

(USD)<br />

Semisub 7,500' WD $ 214,439 $ 428,878 $ 4.96 7.22 $ 128,996<br />

Drillship 3,000' WD $ 191,244 $ 382,489 $ 4.43 5.50 $ 87,676<br />

Jackup 350' WD $ 123,798 $ 247,597 $ 2.87 4.49 $ 46,323<br />

Jackup 200' WD $ 82,743 $ 165,487 $ 1.92 4.43 $ 30,566<br />

Inland barge $ 43,863 $ 87,726 $ 1.02 4.36 $ 15,924<br />

Notes:<br />

(1) Average rig day rates from www.rigzone.com as of 31 July 2006.<br />

(2) Spread rate assumes 2X rig day rate.<br />

(3) Time and cost savings assumes mininum number of trips (one bit run per casing/liner size) for 20,000 ft typical well from the mud line with four casing strings and one liner.<br />

11

Light Weight – Ultra-High Strength Drill Pipe for Extended Reach and Critical Deep Drilling<br />

<strong>Jellison</strong>, Foster, Elliott, Sanclemente, Muradov, Hehn<br />

Example uERD Design<br />

12

Light Weight – Ultra-High Strength Drill Pipe for Extended Reach and Critical Deep Drilling<br />

<strong>Jellison</strong>, Foster, Elliott, Sanclemente, Muradov, Hehn<br />

13

Drillstring Design Grade Tooljoints 1 Adj Wt.<br />

(lb/ft)<br />

Makeup<br />

(k ft-lbs)<br />

Tube Limitations Mechanical Load<br />

Torque 2 Tension 2 Torque 3 Tension 4 SPP 5<br />

(k ft-lbs) (kips) (k ft-lbs) (kips) (psi)<br />

Stretch 6<br />

(ft)<br />

5⅞” 0.361” wall RII (45,000’) S135 7⅛”x4” 27.85 66 75 600 75 770 6,500 75<br />

5⅞” 0.361” wall RII (45,000’) S135 7”x4½” 26.06 62 75 600 70 730 6050 72<br />

5⅞” 0.361” wall RIII (45,000’) S135 7”x4½” 24.61 62 75 600 66 690 5950 67<br />

5⅞” 0.500” wall RII (10,000’)<br />

5⅞” 0.361” wall RII (35,000’)<br />

S135<br />

S135<br />

7⅛”x4”<br />

7”x4¼”<br />

34.83<br />

26.41<br />

66<br />

57<br />

95<br />

75<br />

805<br />

600<br />

73<br />

53<br />

800<br />

360<br />

6,500 65<br />

5⅞” 0.415” wall RII (10,000’)<br />

5⅞” 0.300” wall RII (35,000’)<br />

UD165<br />

UD165<br />

7⅛”x4”<br />

7”x4¼”<br />

30.78<br />

23.32<br />

66<br />

57<br />

102<br />

78<br />

832<br />

617<br />

65<br />

48<br />

710<br />

320<br />

6,100 67<br />

5⅞” 0.361” wall RII (10,000’)<br />

5⅞” 0.300” wall RII (35,000’)<br />

UD165<br />

UD165<br />

7”x4½”<br />

7”x4½”<br />

25.94<br />

22.84<br />

62<br />

62<br />

90<br />

78<br />

733<br />

617<br />

63<br />

46<br />

660<br />

320<br />

5,800 70<br />

5⅞” 0.361” wall RII (10,000’)<br />

5⅞” 0.300” wall RIII (35,000’)<br />

UD165<br />

UD165<br />

7”x4½”<br />

7”x4½”<br />

25.94<br />

21.38<br />

62<br />

62<br />

90<br />

78<br />

733<br />

617<br />

60<br />

44<br />

630<br />

300<br />

5,700 65<br />

5⅞” 0.361” wall RII (10,000’)<br />

5⅞” 0.250” wall RII (35,000’)<br />

UD165<br />

UD165<br />

7⅛”x4”<br />

7”x4¼”<br />

27.85<br />

20.71<br />

66<br />

57<br />

90<br />

67<br />

733<br />

520<br />

58<br />

42<br />

640<br />

295<br />

5,800 72<br />

5⅞” 0.361” wall RII (10,000’)<br />

5⅞” 0.250” wall RII (35,000’)<br />

UD165<br />

UD165<br />

7⅛”x4”<br />

7”x4½”<br />

27.85<br />

20.32<br />

66<br />

62<br />

90<br />

67<br />

733<br />

520<br />

57<br />

41<br />

630<br />

290<br />

5,700 69<br />

5⅞” 0.361” wall RII (10,000’)<br />

5⅞” 0.250” wall RIII (35,000’)<br />

UD165<br />

UD165<br />

7”x4½”<br />

7”x4½”<br />

26.40<br />

18.76<br />

62<br />

62<br />

90<br />

67<br />

733<br />

520<br />

53<br />

39<br />

520<br />

240<br />

5,500 64<br />

5⅞” 0.500” wall RII (45,000’) Group III 7 7”x4¼” 17.11 57 35 294 35 365 7100 82<br />

5⅞” 0.361” wall RII (15,000’)<br />

5⅞” 0.500” wall RII (30,000’)<br />

S135<br />

Group III 7<br />

7”x4¼”<br />

7”x4¼”<br />

26.41<br />

17.11<br />

57<br />

57<br />

75<br />

35<br />

600<br />

294<br />

45<br />

25<br />

520<br />

170<br />

6,800 59<br />

5⅞” 0.361” wall RII (45,000’) Ti-6Al-4V 7”x4¼” 18.16 57 66 530 45 460 6,200 82

Light Weight – Ultra-High Strength Drill Pipe for Extended Reach and Critical Deep Drilling<br />

<strong>Jellison</strong>, Foster, Elliott, Sanclemente, Muradov, Hehn<br />

Difference in side forces for Range II vs. Range III<br />

In order to manage side<br />

force below 2,000 lbs per<br />

tool joint, the upper<br />

±10,000’ of the string<br />

should be Range II<br />

15

Light Weight – Ultra-High Strength Drill Pipe for Extended Reach and Critical Deep Drilling<br />

<strong>Jellison</strong>, Foster, Elliott, Sanclemente, Muradov, Hehn<br />

Mechanical performance properties of various<br />

drill pipe tubes (100% of API Premium Class)<br />

Drillpipe Tube Grade Torque<br />

(k ft-lbs)<br />

Tension<br />

(kips)<br />

Burst<br />

(psi)<br />

Collapse<br />

(psi)<br />

5⅞” 0.500” wall S135 106 895 18380 14820<br />

5⅞” 0.415” wall S135 93 757 15258 9368<br />

5⅞” 0.361” wall S135 83 666 13270 6200<br />

5⅞” 0.361” wall UD165 101 815 16220 6600<br />

5⅞” 0.300” wall UD165 87 686 13480 3700<br />

5⅞” 0.250” wall UD165 75 578 11230 2090*<br />

5⅞” 0.500” wall Al Group III 49 ksi 39 327 6710 6460<br />

5⅞” 0.361” wall Ti 120 ksi 74 592 11800 5880<br />

*Note on 0.250” wall steel: 2100 psi collapse load is equivalent to 3100’ (>30 stands) of evacuated drill<br />

pipe in 13.0 ppg fluid. Reduced collapse strength will require a.) diligent inspection of tubes to better<br />

than premium class (“New” drill pipe tubes are rated to 3940 psi collapse) and b.) modified tripping<br />

procedures (i.e. fill pipe more frequently on trips to reduce differential load to ±1,000 psi).<br />

16

Light Weight – Ultra-High Strength Drill Pipe for Extended Reach and Critical Deep Drilling<br />

<strong>Jellison</strong>, Foster, Elliott, Sanclemente, Muradov, Hehn<br />

Conclusions<br />

• New drill pipe material grade that combines ultra-high strength<br />

with excellent fracture toughness has been developed.<br />

• This new drill pipe can help expand the extended reach<br />

drilling envelop by enabling drill strings with excellent strength<br />

to weight properties.<br />

• Combining the UD-165 material with light weight, thinner wall<br />

drill string designs can reduce torque and drag loads while<br />

providing high axial tension capacities and torsional strengths<br />

necessary to drill the next generation of ERD wells.<br />

• The ultra-high strength material is also well suited to landing<br />

string applications where the loading demands to run longer<br />

and heavier casing strings in deep-water continue to increase.<br />

• The authors anticipate that innovative drilling professionals<br />

may also discover additional critical drilling applications that<br />

can benefit from this new drill pipe technology.<br />

17

Light Weight – Ultra-High Strength Drill Pipe for Extended Reach and Critical Deep Drilling<br />

<strong>Jellison</strong>, Foster, Elliott, Sanclemente, Muradov, Hehn<br />

Light Weight UD-165 DP Ready for Field Use<br />

• NOV Grant Prideco has produced 175 joints<br />

of 5-7/8” t=0.285 UD-165 drill pipe.<br />

• 95 joints have the eXtreme Torque ® XT-57<br />

connection<br />

• 80 joints with TurboTorque TT-585<br />

• All pipe has internal plastic coating and<br />

Platinum casing-friendly hardband (3/32”<br />

raised) on both pin and box.<br />

• This drill pipe is ready for field application.<br />

Questions?<br />

18