Maintenance & Reliability News - Maintenance Journal

Maintenance & Reliability News - Maintenance Journal

Maintenance & Reliability News - Maintenance Journal

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Drive Asset Performance and<br />

Deliver Stakeholder Value:<br />

Four Powerful Opportunities to Maximize Uptime and<br />

Minimize Costs with MRO Analytics<br />

Andy Hill, CEO, Oniqua MRO Analytics<br />

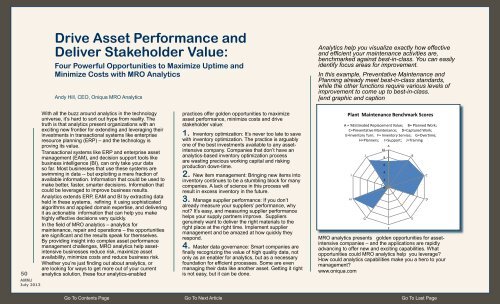

Analytics help you visualize exactly how effective<br />

and efficient your maintenance activities are,<br />

benchmarked against best-in-class. You can easily<br />

identify focus areas for improvement.<br />

In this example, Preventative <strong>Maintenance</strong> and<br />

Planning already meet best-in-class standards,<br />

while the other functions require various levels of<br />

improvement to come up to best-in-class.<br />

[end graphic and caption<br />

50<br />

AMMJ<br />

July 2013<br />

With all the buzz around analytics in the technology<br />

universe, it’s hard to sort out hype from reality. The<br />

truth is that analytics present organizations with an<br />

exciting new frontier for extending and leveraging their<br />

investments in transactional systems like enterprise<br />

resource planning (ERP) – and the technology is<br />

proving its value.<br />

Transactional systems like ERP and enterprise asset<br />

management (EAM), and decision support tools like<br />

business intelligence (BI), can only take your data<br />

so far. Most businesses that use these systems are<br />

swimming in data -- but exploiting a mere fraction of<br />

available information. Information that could be used to<br />

make better, faster, smarter decisions. Information that<br />

could be leveraged to improve business results.<br />

Analytics extends ERP, EAM and BI by extracting data<br />

held in these systems, refining it using sophisticated<br />

algorithms and applied domain expertise, and delivering<br />

it as actionable information that can help you make<br />

highly effective decisions very quickly.<br />

In the field of MRO analytics – analytics for<br />

maintenance, repair and operations – the opportunities<br />

are significant and the results speak for themselves.<br />

By providing insight into complex asset performance<br />

management challenges, MRO analytics help assetintensive<br />

businesses reduce risk, maximize asset<br />

availability, minimize costs and reduce business risk.<br />

Whether you’re just finding out about analytics, or<br />

are looking for ways to get more out of your current<br />

analytics solution, these four analytics-enabled<br />

practices offer golden opportunities to maximize<br />

asset performance, minimize costs and drive<br />

stakeholder value:<br />

1. Inventory optimization: It’s never too late to save<br />

with inventory optimization. The practice is arguably<br />

one of the best investments available to any assetintensive<br />

company. Companies that don’t have an<br />

analytics-based inventory optimization process<br />

are wasting precious working capital and risking<br />

production down-time.<br />

2. New item management: Bringing new items into<br />

inventory continues to be a stumbling block for many<br />

companies. A lack of science in this process will<br />

result in excess inventory in the future.<br />

3. Manage supplier performance: If you don’t<br />

already measure your suppliers’ performance, why<br />

not? It’s easy, and measuring supplier performance<br />

helps your supply partners improve. Suppliers<br />

genuinely want to deliver the right materials to the<br />

right place at the right time. Implement supplier<br />

management and be amazed at how quickly they<br />

respond.<br />

4. Master data governance: Smart companies are<br />

finally recognizing the value of high quality data, not<br />

only as an enabler for analytics, but as a necessary<br />

foundation for efficient processes. Some are even<br />

managing their data like another asset. Getting it right<br />

is not easy, but it can be done.<br />

Plant <strong>Maintenance</strong> Benchmark Scores<br />

A = %Estimated Replacement Value; B= Planned Work;<br />

C=Preventative <strong>Maintenance</strong>; D=Captured Work;<br />

E=Inventory Turn; F= Inventory Service; G=Overtime;<br />

H=Planners; I=Support; J=Training<br />

A<br />

10<br />

I<br />

H<br />

J<br />

G<br />

MRO analytics presents golden opportunities for assetintensive<br />

companies – and the applications are rapidly<br />

advancing to offer new and exciting capabilities. What<br />

opportunities could MRO analytics help you leverage?<br />

How could analytics capabilities make you a hero to your<br />

management?<br />

www.oniqua.com<br />

8<br />

6<br />

4<br />

2<br />

0<br />

F<br />

B<br />

E<br />

C<br />

D<br />

Go To Contents Page<br />

Go To Next Article<br />

Go To Last Page