The Nickel Advantage - Nickel in Stainless Steel - Eurometaux

The Nickel Advantage - Nickel in Stainless Steel - Eurometaux

The Nickel Advantage - Nickel in Stainless Steel - Eurometaux

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 2<br />

Corrosion Resistance<br />

<strong>Nickel</strong> contributes<br />

to corrosion “<br />

resistance.<br />

”<br />

Stress Corrosion Crack<strong>in</strong>g <strong>The</strong>re are many different types of stress corrosion crack<strong>in</strong>g<br />

(SCC). Austenitic sta<strong>in</strong>less steels have very good stress corrosion crack<strong>in</strong>g reistance <strong>in</strong><br />

hydrogen sulphide environments, such as are found <strong>in</strong> the natural gas sector. Austenitic<br />

sta<strong>in</strong>less steels and more recently duplex sta<strong>in</strong>less steels have shown excellent long term<br />

performance and guidel<strong>in</strong>es for their use can be found <strong>in</strong> standards such as NACE<br />

MR0175/ISO 15156.<br />

Chloride stress corrosion crack<strong>in</strong>g has been studied for years, and many people are familiar<br />

with the “Copson Curve,” derived from test<strong>in</strong>g <strong>in</strong> aggressive boil<strong>in</strong>g magnesium chloride. It<br />

has shown that the ferritic sta<strong>in</strong>less steels without a nickel addition are superior to the<br />

standard sta<strong>in</strong>less steels with 6-12% nickel. Alloys with more than 45% nickel were found<br />

to be virtually immune to crack<strong>in</strong>g <strong>in</strong> magnesium chloride. In practice, most other chloride<br />

solutions are far less aggressive than the magnesium chloride, and while grades such as 304<br />

and 316L are generally avoided, the sta<strong>in</strong>less alloys with 6% molybdenum have sufficient<br />

resistance <strong>in</strong> most cases, as do the duplex sta<strong>in</strong>less steels.<br />

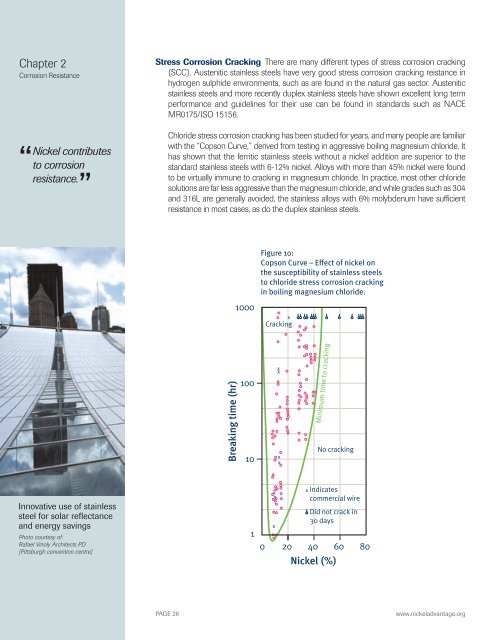

Figure 10:<br />

Copson Curve – Effect of nickel on<br />

the susceptibility of sta<strong>in</strong>less steels<br />

to chloride stress corrosion crack<strong>in</strong>g<br />

<strong>in</strong> boil<strong>in</strong>g magnesium chloride.<br />

1000<br />

Crack<strong>in</strong>g<br />

Break<strong>in</strong>g time (hr)<br />

100<br />

10<br />

M<strong>in</strong>imum time to crack<strong>in</strong>g<br />

No crack<strong>in</strong>g<br />

Innovative use of sta<strong>in</strong>less<br />

steel for solar reflectance<br />

and energy sav<strong>in</strong>gs<br />

Photo courtesy of:<br />

Rafael V<strong>in</strong>oly Architects PD<br />

[Pittsburgh convention centre]<br />

1<br />

Indicates<br />

commercial wire<br />

Did not crack <strong>in</strong><br />

30 days<br />

0 20 40 60 80<br />

<strong>Nickel</strong> (%)<br />

PAGE 26<br />

www.nickeladvantage.org