The Nickel Advantage - Nickel in Stainless Steel - Eurometaux

The Nickel Advantage - Nickel in Stainless Steel - Eurometaux

The Nickel Advantage - Nickel in Stainless Steel - Eurometaux

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Chapter 2<br />

Corrosion Resistance<br />

“<br />

Austenitic sta<strong>in</strong>less<br />

steels are very useful<br />

<strong>in</strong> hydrogen sulphide<br />

environments.<br />

”<br />

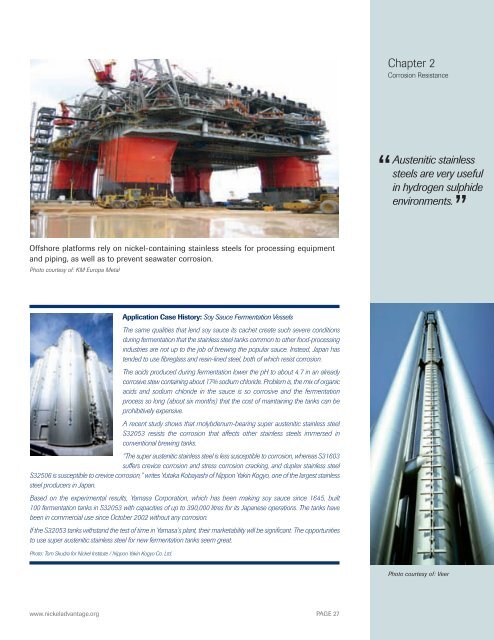

Offshore platforms rely on nickel-conta<strong>in</strong><strong>in</strong>g sta<strong>in</strong>less steels for process<strong>in</strong>g equipment<br />

and pip<strong>in</strong>g, as well as to prevent seawater corrosion.<br />

Photo courtesy of: KM Europa Metal<br />

Application Case History: Soy Sauce Fermentation Vessels<br />

<strong>The</strong> same qualities that lend soy sauce its cachet create such severe conditions<br />

dur<strong>in</strong>g fermentation that the sta<strong>in</strong>less steel tanks common to other food-process<strong>in</strong>g<br />

<strong>in</strong>dustries are not up to the job of brew<strong>in</strong>g the popular sauce. Instead, Japan has<br />

tended to use fibreglass and res<strong>in</strong>-l<strong>in</strong>ed steel, both of which resist corrosion.<br />

<strong>The</strong> acids produced dur<strong>in</strong>g fermentation lower the pH to about 4.7 <strong>in</strong> an already<br />

corrosive stew conta<strong>in</strong><strong>in</strong>g about 17% sodium chloride. Problem is, the mix of organic<br />

acids and sodium chloride <strong>in</strong> the sauce is so corrosive and the fermentation<br />

process so long (about six months) that the cost of ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g the tanks can be<br />

prohibitively expensive.<br />

A recent study shows that molybdenum-bear<strong>in</strong>g super austenitic sta<strong>in</strong>less steel<br />

S32053 resists the corrosion that affects other sta<strong>in</strong>less steels immersed <strong>in</strong><br />

conventional brew<strong>in</strong>g tanks.<br />

“<strong>The</strong> super austenitic sta<strong>in</strong>less steel is less susceptible to corrosion, whereas S31603<br />

suffers crevice corrosion and stress corrosion crack<strong>in</strong>g, and duplex sta<strong>in</strong>less steel<br />

S32506 is susceptible to crevice corrosion,” writes Yutaka Kobayashi of Nippon Yak<strong>in</strong> Kogyo, one of the largest sta<strong>in</strong>less<br />

steel producers <strong>in</strong> Japan.<br />

Based on the experimental results, Yamasa Corporation, which has been mak<strong>in</strong>g soy sauce s<strong>in</strong>ce 1645, built<br />

100 fermentation tanks <strong>in</strong> S32053 with capacities of up to 390,000 litres for its Japanese operations. <strong>The</strong> tanks have<br />

been <strong>in</strong> commercial use s<strong>in</strong>ce October 2002 without any corrosion.<br />

If the S32053 tanks withstand the test of time <strong>in</strong> Yamasa’s plant, their marketability will be significant. <strong>The</strong> opportunities<br />

to use super austenitic sta<strong>in</strong>less steel for new fermentation tanks seem great.<br />

Photo: Tom Skudra for <strong>Nickel</strong> Institute / Nippon Yak<strong>in</strong> Kogyo Co. Ltd.<br />

Photo courtesy of: Veer<br />

www.nickeladvantage.org PAGE 27