The Nickel Advantage - Nickel in Stainless Steel - Eurometaux

The Nickel Advantage - Nickel in Stainless Steel - Eurometaux

The Nickel Advantage - Nickel in Stainless Steel - Eurometaux

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Chapter 1:<br />

Overview of nickel-conta<strong>in</strong><strong>in</strong>g<br />

sta<strong>in</strong>less steels<br />

Structural stability is a<br />

major reason for their<br />

widespread use at<br />

high temperatures.<br />

“<br />

”<br />

Call Outs <strong>in</strong> Italics <strong>in</strong><br />

Medium<br />

Chapter 3<br />

High Temperature<br />

At elevated, as well as at lower, temperatures, a material is selected on the basis of its properties,<br />

and usually there are compromises. At elevated temperatures, properties of <strong>in</strong>terest to the<br />

designer <strong>in</strong>clude mechanical ones, such as yield and tensile strength, creep strength or creep<br />

rupture, ductility, thermal fatigue, and thermal shock resistance. Physical properties of possible<br />

<strong>in</strong>terest <strong>in</strong>clude thermal expansion, thermal conductivity, and electrical conductivity. Properties<br />

that show environmental resistance <strong>in</strong>clude oxidation, carburization, sulphidation and nitrid<strong>in</strong>g.<br />

Fabrication properties <strong>in</strong>clude weldability and formability. Other properties such as wear, gall<strong>in</strong>g<br />

and reflectivity may also need to be considered.<br />

<strong>The</strong>se properties are of <strong>in</strong>terest at all the temperatures to which the material is subjected, and<br />

it is especially important to look at potential changes to properties dur<strong>in</strong>g service life. <strong>The</strong><br />

structural stability of austenitic sta<strong>in</strong>less steels is a major reason for their widespread use at<br />

high temperatures.<br />

In general, austenitic sta<strong>in</strong>less steels rema<strong>in</strong> strong at elevated temperatures, at least compared<br />

with other materials. Figure 11 compares the short-time high-temperature yield and tensile<br />

strengths of some austenitic and ferritic sta<strong>in</strong>less steels at various temperatures. At temperatures<br />

below about 540° C (1,000° F), the differences are not that large. Above that temperature, the<br />

strength levels drop off rapidly on the ferritic grades. Some special ferritic sta<strong>in</strong>less steels can be<br />

alloyed for <strong>in</strong>creased high-temperature strength.<br />

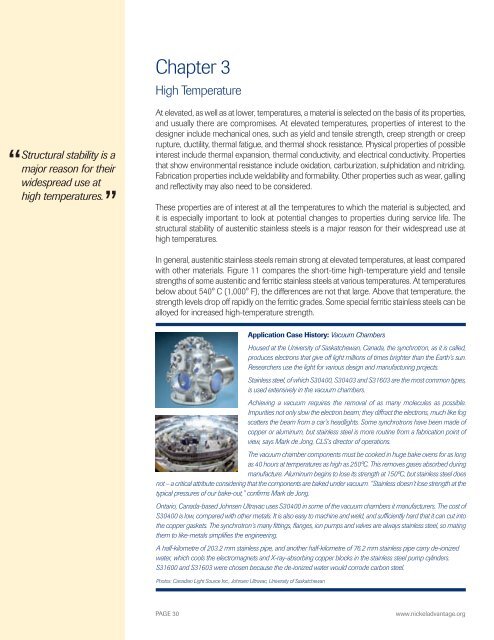

Application Case History: Vacuum Chambers<br />

Housed at the University of Saskatchewan, Canada, the synchrotron, as it is called,<br />

produces electrons that give off light millions of times brighter than the Earth’s sun.<br />

Researchers use the light for various design and manufactur<strong>in</strong>g projects.<br />

Sta<strong>in</strong>less steel, of which S30400, S30403 and S31603 are the most common types,<br />

is used extensively <strong>in</strong> the vacuum chambers.<br />

Achiev<strong>in</strong>g a vacuum requires the removal of as many molecules as possible.<br />

Impurities not only slow the electron beam; they diffract the electrons, much like fog<br />

scatters the beam from a car’s headlights. Some synchrotrons have been made of<br />

copper or alum<strong>in</strong>um, but sta<strong>in</strong>less steel is more rout<strong>in</strong>e from a fabrication po<strong>in</strong>t of<br />

view, says Mark de Jong, CLS’s director of operations.<br />

<strong>The</strong> vacuum chamber components must be cooked <strong>in</strong> huge bake ovens for as long<br />

as 40 hours at temperatures as high as 250ºC. This removes gases absorbed dur<strong>in</strong>g<br />

manufacture. Alum<strong>in</strong>um beg<strong>in</strong>s to lose its strength at 150ºC, but sta<strong>in</strong>less steel does<br />

not – a critical attribute consider<strong>in</strong>g that the components are baked under vacuum. “Sta<strong>in</strong>less doesn’t lose strength at the<br />

typical pressures of our bake-out,” confirms Mark de Jong.<br />

Ontario, Canada-based Johnsen Ultravac uses S30400 <strong>in</strong> some of the vacuum chambers it manufacturers. <strong>The</strong> cost of<br />

S30400 is low, compared with other metals. It is also easy to mach<strong>in</strong>e and weld, and sufficiently hard that it can cut <strong>in</strong>to<br />

the copper gaskets. <strong>The</strong> synchrotron’s many fitt<strong>in</strong>gs, flanges, ion pumps and valves are always sta<strong>in</strong>less steel, so mat<strong>in</strong>g<br />

them to like-metals simplifies the eng<strong>in</strong>eer<strong>in</strong>g.<br />

A half-kilometre of 203.2 mm sta<strong>in</strong>less pipe, and another half-kilometre of 76.2 mm sta<strong>in</strong>less pipe carry de-ionized<br />

water, which cools the electromagnets and X-ray-absorb<strong>in</strong>g copper blocks <strong>in</strong> the sta<strong>in</strong>less steel pump cyl<strong>in</strong>ders.<br />

S31600 and S31603 were chosen because the de-ionized water would corrode carbon steel.<br />

Photos: Canadian Light Source Inc., Johnsen Ultravac, University of Saskatchewan<br />

PAGE 30<br />

www.nickeladvantage.org