yacht and shipbuilding - Hamel

yacht and shipbuilding - Hamel

yacht and shipbuilding - Hamel

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1. PlAte: en Aw - 5059<br />

hAmel metAAl<br />

<strong>Hamel</strong> metaal has been a supplier to Dutch industry for more than 70 years as<br />

a stock-holding wholesaler of ferrous <strong>and</strong> non-ferrous metals. <strong>Hamel</strong> metaal has<br />

an extensive range of stock in copper, brass, bronze, aluminium, stainless steel,<br />

steel <strong>and</strong> plastic. In addition, a special supply programme has been developed for<br />

the ship <strong>and</strong> luxury <strong>yacht</strong>-building industry, including (Alustar) <strong>shipbuilding</strong> plates<br />

<strong>and</strong> profiles, cunifer, duplex <strong>and</strong> high-grade metals. All products can be customised<br />

<strong>and</strong> delivered exactly to your specifications.<br />

<strong>Hamel</strong> metaal provides fast delivery according to any required certification<br />

(EN-10204-2.2, 3.1, 3.2, Germanischer Lloyd, Lloyd’s Register, DNV, RINA etc.)<br />

We are pleased to present our aluminium programme for the luxury <strong>yacht</strong> <strong>and</strong><br />

<strong>shipbuilding</strong> industries.<br />

This brochure covers the following items:<br />

1. Alustar ® > Product range, chemical composition, mechanical properties,<br />

corrosion resistance <strong>and</strong> welding<br />

2. Other plate > Product range, chemical composition, mechanical properties<br />

3. Profiles > Product range, special profiles<br />

4. Processing > The various processing options for plate <strong>and</strong> profile<br />

5. Certification > Information on the various certification documents<br />

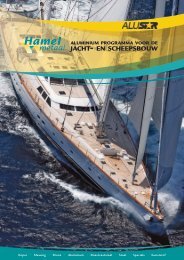

Alustar ® was originally developed out of catamaran building in New Zeal<strong>and</strong> <strong>and</strong> Australia. Due to the unique composition of<br />

this new alloy EN AW - 5059, it is possible to construct stronger <strong>and</strong> yet lighter (approx. 20%) than with other comparable<br />

aluminium alloys available on the market, such as EN AW - 5083. In addition, this alloy is considerably stronger after welding<br />

(up to approx. 28%) <strong>and</strong> has a very high corrosion resistance combined with higher ductility.<br />

Alustar ® has also since found its way into the sailing <strong>and</strong> luxury <strong>yacht</strong> building industry. Because of the high final strength<br />

after welding <strong>and</strong> the good deformability, it is possible to design even more innovative <strong>and</strong> efficient hulls, which in turn have<br />

a positive influence on the speed <strong>and</strong> form of a (sailing) <strong>yacht</strong> as well as fuel consumption.<br />

Alustar ® is ideally suited for the construction of ferryboats <strong>and</strong> other vehicles for which the weight of the construction must be kept<br />

to a minimum. This allows one to remain competitive with other forms of transport <strong>and</strong> tunnel links. By making use of thinner<br />

material, it is possible to achieve large savings on fuel costs as well as higher speeds by retaining the strength of thicker variants.<br />

Alustar ® is also used in the defence industry for its strong ballistic properties.