yacht and shipbuilding - Hamel

yacht and shipbuilding - Hamel

yacht and shipbuilding - Hamel

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

hardness (HV 5)<br />

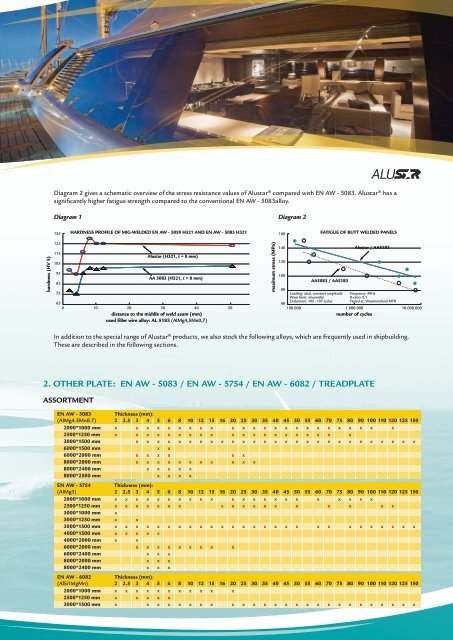

Diagram 2 gives a schematic overview of the stress resistance values of Alustar ® compared with EN AW - 5083. Alustar ® has a<br />

significantly higher fatigue strength compared to the conventional EN AW - 5083alloy.<br />

Diagram 1 Diagram 2<br />

135<br />

125<br />

115<br />

105<br />

95<br />

85<br />

75<br />

In addition to the special range of Alustar ® products, we also stock the following alloys, which are frequently used in <strong>shipbuilding</strong>.<br />

These are described in the following sections.<br />

2. Other PlAte: en Aw - 5083 / en Aw - 5754 / en Aw - 6082 / treADPlAte<br />

ASSOrtment<br />

HARDNESS PROFILE OF MIG-WELDED EN AW - 5059 H321 AND EN AW - 5083 H321<br />

Alustar (H321, t = 8 mm)<br />

AA 5083 (H321, t = 8 mm)<br />

65<br />

0 10 20 30 40 50<br />

distance to the middle of weld seam (mm)<br />

used filler wire alloy: AL 5183 (AlMg4,5Mn0,7)<br />

maximum stress (MPa)<br />

FATIGUE OF BUTT WELDED PANELS<br />

AA5083 / AA5183<br />

Alustar / AA5183<br />

Loading: axial, constant amplitude Frequency: 40Hz<br />

Wave form: sinusoidal R-ratio: 0.1<br />

Endurance: 105 - 107 cycles Tested at: Westmorel<strong>and</strong> MTR<br />

100.000 1.000.000 10.000.000<br />

number of cycles<br />

en Aw - 5083 thickness (mm):<br />

(AlMg4.5Mn0.7) 2 2.5 3 4 5 6 8 10 12 15 16 20 25 30 35 40 45 50 55 60 70 75 80 90 100 110 120 125 150<br />

2000*1000 mm x x x x x x x x x x x x x x x x x x x x x x x x<br />

2500*1250 mm x x x x x x x x x x x x x x x x x x x x<br />

3000*1500 mm x x x x x x x x x x x x x x x x x x x x x x x x x x x<br />

6000*1500 mm x x<br />

6000*2000 mm x x x x x x<br />

8000*2000 mm x x x x x x x x x x x<br />

8000*2400 mm x x x x x<br />

8000*2500 mm x x x x<br />

en Aw - 5754 thickness (mm):<br />

(AlMg3) 2 2.5 3 4 5 6 8 10 12 15 16 20 25 30 35 40 45 50 55 60 70 75 80 90 100 110 120 125 150<br />

2000*1000 mm x x x x x x x x x x x x x x x x x x x x x x<br />

2500*1250 mm x x x x x x x x x x x x x x x x x x<br />

3000*1000 mm x<br />

3000*1250 mm x x<br />

3000*1500 mm x x x x x x x x x x x x x x x x x x x x x x x x x x x<br />

4000*1500 mm x x x x x<br />

4000*2000 mm x x<br />

6000*2000 mm x x x x x x x x x<br />

6000*2400 mm x x x<br />

8000*2000 mm x x x<br />

8000*2400 mm x x x<br />

en Aw - 6082 thickness (mm):<br />

(AlSi1MgMn) 2 2.5 3 4 5 6 8 10 12 15 16 20 25 30 35 40 45 50 55 60 70 75 80 90 100 110 120 125 150<br />

2000*1000 mm x x x x x x x x x x x<br />

2500*1250 mm x x x x x<br />

3000*1500 mm x x x x x x x x x x x x x x x x x x x x x x x x x x