yacht and shipbuilding - Hamel

yacht and shipbuilding - Hamel

yacht and shipbuilding - Hamel

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ASSOrtment<br />

Alustar ® en Aw - 5059 (AlMg5,5MnZnZr) thickness: 3 4 5 6 8 10 12 15 16 20 25 30 35 40<br />

6000*2000 mm x x x x x x x x x x x x x x<br />

8000*2000 mm x x x x x x<br />

ChemiCAl COmPOSitiOn<br />

meChAniCAl PrOPertieS<br />

Other sizes <strong>and</strong> thickness on request.<br />

Alloy Simax Femax Cumax mn mg Crmax Zn Zr ti<br />

en Aw - 5059 Alustar ® (AlMg5.5MnZnZr) 0.45 0.50 0.25 0.6-1.2 5.0-6.0 0.25 0.4-0.9 0.05-0.25 -<br />

According to en 485-2 temper thickness tensile strength yield strength elongation bendradius *<br />

mm rmMpa rmMpa rp0,2Mpa min.<br />

min. max. min. A 50mm A (%) 180º<br />

≥ 3 - 6.0 330 380 160 24 - 1.5t<br />

Alustar ® 0 / H111 6.0 - 12.5 330 380 160 24 - 4.0t<br />

en Aw - 5059 12.5 - 40 330 380 160 - 24 -<br />

(AlMg5.5MnZnZr) ≥ 3 - 6.0 370 - 270 10 - 3.0t<br />

H116 / 6.0 - 12.5 370 - 270 10 - 6.0t<br />

H321 12.5 - 20 370 - 270 - 10 -<br />

20 - 40 360 - 260 - 10 -<br />

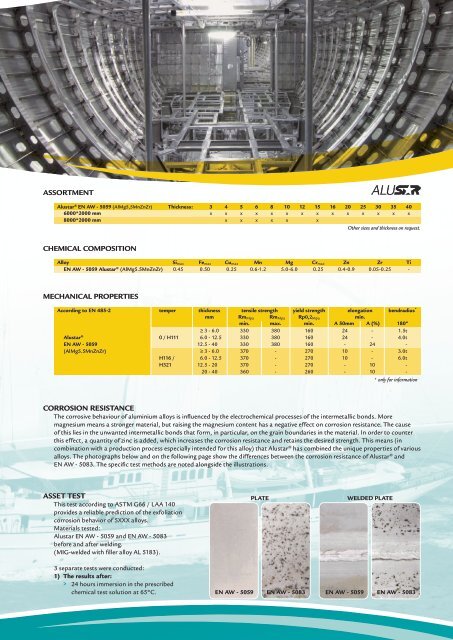

COrrOSiOn reSiStAnCe<br />

The corrosive behaviour of aluminium alloys is influenced by the electrochemical processes of the intermetallic bonds. More<br />

magnesium means a stronger material, but raising the magnesium content has a negative effect on corrosion resistance. The cause<br />

of this lies in the unwanted intermetallic bonds that form, in particular, on the grain boundaries in the material. In order to counter<br />

this effect, a quantity of zinc is added, which increases the corrosion resistance <strong>and</strong> retains the desired strength. This means (in<br />

combination with a production process especially intended for this alloy) that Alustar ® has combined the unique properties of various<br />

alloys. The photographs below <strong>and</strong> on the following page show the differences between the corrosion resistance of Alustar ® <strong>and</strong><br />

EN AW - 5083. The specific test methods are noted alongside the illustrations.<br />

ASSet teSt<br />

This test according to ASTM G66 / LAA 140<br />

provides a reliable prediction of the exfoliation<br />

corrosion behavior of 5XXX alloys.<br />

Materials tested:<br />

Alustar EN AW - 5059 <strong>and</strong> EN AW - 5083<br />

before <strong>and</strong> after welding.<br />

(MIG-welded with filler alloy AL 5183).<br />

3 separate tests were conducted:<br />

1) the results after:<br />

> 24 hours immersion in the prescribed<br />

chemical test solution at 65°C.<br />

PlAte welDeD PlAte<br />

* only for information<br />

en Aw - 5059 en Aw - 5083 en Aw - 5059 en Aw - 5083