ARKU InfoMAX UK 16 - ARKU Maschinenbau GmbH

ARKU InfoMAX UK 16 - ARKU Maschinenbau GmbH

ARKU InfoMAX UK 16 - ARKU Maschinenbau GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Levelers like pearls on a string<br />

<strong>ARKU</strong> is extending its assembly capacity and taking on new staff – New market potential thanks<br />

to HiCap PLUS high-capacity levelers with cassette-change-system<br />

Baden-Baden – 2007 was a<br />

record-breaking year for the<br />

German machinery and plant<br />

manufacturing industry. According<br />

to the German Engineering<br />

Federation (VDMA), the sector<br />

experienced a turnover increase<br />

of about 13 percent. Doubledigit<br />

growth rates have not been<br />

seen since 1969. The sector had<br />

more good news with the<br />

creation of 50,000 new jobs during<br />

the past year. In 2008, the<br />

industry is filled with optimism<br />

rooted in forecasts for an additional<br />

5 percent growth and<br />

10,000 more new jobs. (Source<br />

VDMA)<br />

<strong>ARKU</strong> has kept up with the<br />

German machinery and plant<br />

manufacturing industry in 2007.<br />

The German machine builder<br />

saw order intake and turnover<br />

grow by more than 15 percent.<br />

<strong>ARKU</strong> also had considerable<br />

personal growth.<br />

Full order books and an increasing<br />

demand for high-capacity<br />

levelers marked the start of the<br />

new year for <strong>ARKU</strong>! In<br />

Baden-Baden, precision levelers<br />

are being produced nearly non-<br />

stop. The range extends from<br />

small levelers for the clock and<br />

watch industry to the great<br />

juggernauts for thick flame-cut<br />

parts. From feeder straighteners<br />

in press lines, to high-capacity<br />

levelers for steel service<br />

centers, the assembly shop is<br />

busier than ever. With 1,000<br />

square meters of expansion<br />

completed in 2003, plans for<br />

<strong>InfoMAX</strong><br />

Parts Levelers · Cut-to-length and punching lines · Press feeding lines · Coil preparation lines for roll formers<br />

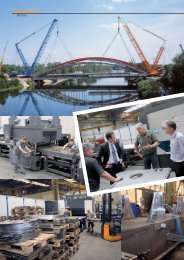

A high-capacity leveler HiCap PLUS with cassette changing-system in the final assembly.<br />

Levelers – as far as the eye can see.<br />

more expansion are being painstakingly<br />

forged to meet higher<br />

production demand.<br />

A large percentage of the levelers<br />

currently being assembled<br />

in Baden-Baden will replace old<br />

levelers in existing plants.<br />

Older levelers are often unable<br />

to achieve the increased tolerance<br />

requirements or process<br />

high-strength material. The<br />

integration of a new leveler into<br />

an existing coil line can be an<br />

excellent alternative to replacing<br />

the whole line. The latest development<br />

ot the German leveling<br />

specialist is the HiCap PLUS<br />

high-capacity leveler. The new<br />

range is equipped with a special<br />

cassette-change-system.<br />

This makes it possible to use cassettes<br />

with sets of leveling rollers<br />

with different diameters. As a<br />

result, a wider range of sheet<br />

thickness can be covered. This<br />

is particularly effective when<br />

processing high-strength sheets.<br />

Cut-to-length lines previously<br />

equipped with two levelers in<br />

tandem – to cover a wider<br />

range of sheet thickness – can<br />

now get by with one leveler.<br />

Therefore the user saves<br />

valuable space and investment<br />

costs.<br />

The <strong>ARKU</strong> HiCap PLUS highperformance<br />

leveler shown in<br />

the picture will be used in<br />

the company HFS' newly extended<br />

service centre in Hagen,<br />

Germany.<br />

You will find more information<br />

on the Internet at www.arku.com,<br />

www.hfs-hagen.de<br />

Customer-portrait:<br />

Palfinger AG<br />

<strong>ARKU</strong> <strong>Maschinenbau</strong> <strong>GmbH</strong> · Siemensstraße 11 · 76532 Baden-Baden · Germany · Phone: +49 (0) 7221/ 50 09-0 · Fax +49 (0) 7221/ 50 09-11 · E-mail: info@arku.com · www.arku.com<br />

Austria<br />

Page 4<br />

No. 31 · <strong>16</strong> th year, April 2008<br />

After <strong>16</strong> years and 40 total<br />

issues in German, English<br />

and French, we have given<br />

the InfoMax a dynamic<br />

new look!<br />

We have revitalized our<br />

customer magazine to suit<br />

the reading habits of today's<br />

internet generation while<br />

becoming more colourful at<br />

the same time.<br />

We have maintained the<br />

style of the presentation –<br />

short and to the point for<br />

high-speed readers.<br />

We look forward to receiving<br />

your comments at<br />

marketing@arku.de<br />

We hope the InfoMax will<br />

inspire you to new ideas!<br />

<strong>ARKU</strong> President Albert Reiss<br />

Quotation<br />

Truth is<br />

what stands<br />

the test of<br />

experience<br />

(Albert Einstein)

<strong>InfoMAX</strong><br />

FlatMaster<br />

levels flame-cut parts<br />

in France<br />

Nearly 80 percent of Devillers parts<br />

will be processed on the FlatMaster<br />

Special precision leveler<br />

for aircraft industry<br />

<strong>ARKU</strong> EcoMaster special leveler<br />

for aircraft sheet metal parts goes to China<br />

<strong>ARKU</strong>-Ticker<br />

An <strong>ARKU</strong> FlatMaster 120<br />

used at Devillers.<br />

Mr. Albert Reiss, <strong>ARKU</strong> President,<br />

in the middle of the HAIG delegation in Baden-Baden.<br />

Hericourt – Devillers Oxycoupage<br />

is one of the largest flamecutting<br />

companies in France.<br />

They currently employ more<br />

than 500 people in plants in<br />

France and Poland. The flamecutting<br />

specialist processes more<br />

than 65,000 tons of material<br />

each year. Officials of Devillers<br />

say they expect that number to<br />

increase to more than 100,000<br />

tons for 2009. This was one of<br />

several reasons why Devillers<br />

purchased a FlatMaster 120 in<br />

2007.<br />

The FlatMaster levels flame-cut<br />

parts up to 35 mm in thickness.<br />

Harbin – During a recent trip to<br />

China, <strong>ARKU</strong> Sales Engineer,<br />

Jürgen Metz visited Harbin Aircraft<br />

Industry (Group) Co., Ltd.<br />

(HAIG) with representatives of<br />

another interested company to<br />

show them the EcoMaster.<br />

The specialist in aircraft employs<br />

about 27,000 people. As a<br />

supplier to world renowned<br />

aviation enterprises: Boeing and<br />

Airbus, HAIG has become an<br />

important supporter in the<br />

aviation enterprise of China.<br />

The aircraft industry requires the<br />

use of specific high strength and<br />

light weight materials. These<br />

materials have to be processed<br />

in a cooled status. As a result of<br />

the low temperature, condensation<br />

develops on the sheet<br />

metal part to be processed. With<br />

a standard leveler, this creates<br />

a high risk of corrosion. The<br />

Mr. Scheidecker <strong>ARKU</strong> Representative in France with Mrs. Devillers<br />

and several other visitors at the <strong>ARKU</strong> booth of TolExpo, Paris.<br />

For Devillers, that means nearly<br />

80 percent of their parts will be<br />

processed on the FlatMaster.<br />

Devillers chose <strong>ARKU</strong> because of<br />

the ability of the FlatMaster 120<br />

to level such a wide range of<br />

sheet metal thickness. The<br />

precision leveler can handle<br />

sheet metal parts ranging from<br />

3 mm to 35 mm thick.<br />

Quick change of the leveling<br />

rollers provides another advantage.<br />

Dirt and material residues<br />

accumulating in the leveling unit<br />

during daily production need to<br />

be cleaned.<br />

Thorough cleaning of the leveling<br />

and backup rollers provides<br />

<strong>ARKU</strong> EcoMaster for aircraft sheet metal parts in process at Harbin Aircraft Industry<br />

(Group) Co., Ltd.<br />

EcoMaster for aircraft parts<br />

was designed especially for this<br />

application. It has anticorrosive<br />

elements which produce consistent<br />

good leveling results –<br />

especially in the case of cooled<br />

intricate sheet metal parts.<br />

User friendly and easy to<br />

operate, the EcoMaster fit<br />

consistent leveling results and<br />

prevents damage caused by contamination<br />

of the leveling unit.<br />

When frequent changes are<br />

required, considerable time<br />

savings are achieved with the<br />

RollerPickup.<br />

With the quick change of the<br />

leveling rollers, the leveler has<br />

not to be dismounted for days<br />

and is ready for the next shift<br />

within a few hours. Devillers<br />

Oxycoupage is convinced by the<br />

FlatMaster. Due to this <strong>ARKU</strong><br />

will deliver a second <strong>ARKU</strong><br />

FlatMaster in April to Devillers<br />

plant in Poland.<br />

smoothly into the production<br />

environment of HAIG.<br />

HAIG chose to invest in the<br />

EcoMaster after seeing a high<br />

number of references from the<br />

aircraft industry and great time<br />

savings when compared to<br />

manual straightening.<br />

www.hafei.com<br />

Hanover waits!<br />

The sheet metal world returns to Hanover again this autumn. EuroBlech 2008 will be held at<br />

the Hanover Exhibition Center October 21 st –25 th . <strong>ARKU</strong> will be back with more new surprises.<br />

Not to give away any of the surprises now, but the <strong>ARKU</strong> exhibition bar will be serving up<br />

refreshing fruit cocktails for interested visitors again.

Training workshop<br />

on leveling for <strong>ARKU</strong><br />

representatives<br />

<strong>ARKU</strong> CompactFeed<br />

helps to form fineblanking<br />

system solution!<br />

Franck Hirschmann with operator Roy and<br />

Senior Supervisor, Dave Jackson of Feintool System Parts, Cincinnati, OH-USA –<br />

in front of an <strong>ARKU</strong> coil line with precision leveler.<br />

KAIZEN<br />

KAIZEN has been an important part of the <strong>ARKU</strong> company philosophy<br />

since 2005. In 2007, in assembly and logistics a presentable success was<br />

experienced. During the 5S campaign, <strong>ARKU</strong> achieved a target rate of 96%.<br />

Baden-Baden – Remaining true<br />

to the company creed, „Anyone<br />

who no longer wants to be better<br />

is no longer any good,“ training<br />

and development plays a<br />

key role at <strong>ARKU</strong>. The German<br />

Cincinnati – Founded in<br />

1959, and now in its 50 th year<br />

developing fineblanking and<br />

forming technology and systems,<br />

Feintool is the global market<br />

leader in total solutions for<br />

presses, tools and peripheral systems.<br />

Feintool has technology<br />

centers on three continents –<br />

production and sales facilities in<br />

Europe, the U.S.A. and Japan<br />

and a network of representatives<br />

worldwide.<br />

With more than 2000 fineblanking<br />

systems in use around the world,<br />

their goal is to provide advanced<br />

technology solutions for maximum<br />

benefit to the customer.<br />

„<strong>ARKU</strong> helps us achieve our<br />

goal to help customers meet<br />

machine builder helps to train<br />

representatives worldwide to<br />

better answer the customers'<br />

questions.<br />

<strong>ARKU</strong> offers many training<br />

courses, both internal and external,<br />

to share its knowledge,<br />

new product information and<br />

current industry topics with new<br />

employees, representatives and<br />

customers. The leveling training<br />

course for the Polish <strong>ARKU</strong> representatives<br />

– POL-WELT from<br />

Katowice – being run by sales<br />

engineer Patric Jobst is a good<br />

example. The leveling specialist<br />

shares his experience with the<br />

Polish delegation and familiar-<br />

Mr. Ganczarek - General Manager of the<br />

Polish <strong>ARKU</strong> representation in discussion<br />

with Sales Engineers Andreas Hellriegel,<br />

Patric Jobst and leveling specialist<br />

Johannes Schmitt.<br />

A Feintool System Parts operator listens to Franck Hirschmann,Vice-President <strong>ARKU</strong> Coil Systems, Cincinnati, OH-USA.<br />

their production requirements,“<br />

said Lars Reich, Vice President,<br />

Feintool Equipment Corporation,<br />

Cincinnati, OH-USA.<br />

„They integrate seamlessly into<br />

our production equipment. They<br />

are plug-n-play.“<br />

During a long and successful partnership<br />

with <strong>ARKU</strong>, Feintool<br />

has integrated several <strong>ARKU</strong><br />

CompactFeed press feeding<br />

lines into fineblanking presses.<br />

<strong>ARKU</strong>'s automation concepts<br />

help reduce coil change times to<br />

less than five minutes with<br />

the CompactFeed straightener<br />

feeder.The jaw opening straightening<br />

unit allows quick implementation<br />

of new strips into the<br />

feeder straightener.<br />

<strong>InfoMAX</strong><br />

izes them with <strong>ARKU</strong> technology.<br />

Using practical examples<br />

in the leveling center demonstrates<br />

the results levelers are capable<br />

of achieving; a successful<br />

combination of theory and practice.<br />

The presentation on basic<br />

principles of roller leveling is<br />

also a favorite of customers.<br />

There is always a selection of<br />

machines available for trial purposes<br />

in the leveling center at<br />

Baden-Baden. Besides internal<br />

seminars and training courses<br />

for <strong>ARKU</strong> customers, leveling<br />

trials with customer-specific<br />

parts are also held here. The<br />

leveling center is available<br />

specifically for this purpose.<br />

If you are interested in<br />

training courses, please contact<br />

service@arku.de<br />

„The advanced technology of<br />

the <strong>ARKU</strong> CompactFeed line<br />

also makes roller changes and<br />

cleaning quick and easy,“ said<br />

Dave Jackson, Production Floor<br />

Senior Supervisor, Feintool<br />

System Parts, Cincinnati, OH-<br />

USA. „They listen to our ideas<br />

and design the system to meet<br />

our needs.“<br />

Feintool offers their customers<br />

competitive advantages in today's<br />

highly competitive market<br />

place – from material feed to the<br />

finished quality part. <strong>ARKU</strong> is<br />

proud of the long lasting partnership<br />

with Feintool.<br />

www.feintool-USA.com<br />

www.feintool.com<br />

<strong>ARKU</strong> on Trade fairs in Russia and Poland<br />

From May 26 th –31 st <strong>ARKU</strong> will exhibit at the Metalloobrabotka 2008 –<br />

international exhibition for Equipment, Instruments and Tools for the Metal-<br />

Working Industry – in Moscow. Already from June 9 th –12 th the leveling specialist<br />

will again present a FlatMaster at the Mach Tool 2008 in Posen, Poland.

Friedrichsbad<br />

Traditional bathing<br />

experience in<br />

Baden-Baden<br />

The Friedrichsbad fits very<br />

well with the broad range of<br />

culture and tradition in Baden-<br />

Baden. Not only is the architecture<br />

very impressive, but it<br />

is also rich in history. Built<br />

between 1869 and 1877, its<br />

origins trace all the way back<br />

to the Roman Empire. The<br />

twelve hot springs that supply<br />

Personality<br />

Andreas<br />

Hellriegel<br />

Since summer 2002, Andreas<br />

Hellriegel strengthens the<br />

<strong>ARKU</strong> Team. He joined<br />

<strong>ARKU</strong> after completing his<br />

academic studies in industrial<br />

engineering at the university<br />

of applied science in Karls-<br />

the Friedrichsbad today are the<br />

same ones used by the Romans<br />

2000 years ago. Known for its<br />

health benefits, the Roman and<br />

Irish bathing cultures were<br />

combined in the Friedrichsbad<br />

to create a harmonized integrated<br />

bathing concept. The<br />

unique combination of vapour<br />

bath and thermal-bath; along<br />

with the monumental architecture<br />

of the Friedrichsbad often<br />

served as a source of inspiration<br />

to visitors.<br />

More information is available<br />

at: www.carasana.com<br />

ruhe, Germany. The young industrial<br />

engineer has completed<br />

an 18 month trainee<br />

program and then worked in<br />

marketing. Hellriegel moved<br />

to the sales department in<br />

early 2006 where his first concern<br />

was Key-Accounts.<br />

Today he is part of <strong>ARKU</strong><br />

sales force with emphasis on<br />

parts levelers and cut-to-length<br />

lines.<br />

Andreas is not only a wellknown<br />

team player at work.<br />

In his leisure time, he is a<br />

passionate handball player.<br />

Though it takes nearly an hour<br />

to get to Nordheim from<br />

Baden-Baden, whenever time<br />

permits, he continues to be a<br />

loyal team-mate to his long<br />

time team there.<br />

For more than 75 years, the<br />

name Palfinger has been synonymous<br />

with innovative lifting,<br />

loading and handling solutions<br />

at the hub of the distribution<br />

chain. Headquartered in Salzburg,<br />

Austria, Palfinger is a multi-national<br />

company with production<br />

and assembly sites in Europe,<br />

North and South America and in<br />

Asia. More than 1500 sales-andservice<br />

offices in over 125 coun-<br />

tries on all 5 continents provides<br />

easy access for all customers.<br />

Established in1932,the company<br />

has a long history as a leader<br />

among international manufacturers<br />

of hydraulic lifting,<br />

loading and handling systems.<br />

Richard Palfinger originally<br />

founded a repair and fitter's<br />

workshop for agricultural trailers,<br />

tippers and vehicle bodies, but<br />

it didn't take long before<br />

Palfinger built its first crane.<br />

In 1964 the Austrian specialist<br />

laid the foundation for a new era<br />

by focusing on hydraulic truck<br />

loading cranes. Palfinger is recognized<br />

as the world leader in the<br />

knuckle-boom loading crane<br />

market. With about 150 models,<br />

and a market share of 30 percent,<br />

the PALFINGER Group is not<br />

only the market leader, but also<br />

highly regarded as the leader in<br />

technology for the industry. In<br />

the portable lifts market, the<br />

CRAYLER product is also a<br />

world leader for PALFINGER.<br />

Palfinger AG<br />

FlatMaster provides flat flame-cut parts in<br />

Bulgaria and Slovenia<br />

Over the years the product line<br />

has grown steadily with products<br />

like the RATCLIFF and<br />

MBB tail-lifts, and the BISON<br />

truck mounted aerial work platform.<br />

Innovation, globalization,<br />

service and product diversification<br />

are the strategic pillars<br />

of the corporate mission. As a<br />

result, continuous product improvement,<br />

easy access for customers<br />

on all continents and<br />

Johannes Schmitt,<strong>ARKU</strong> leveling specialist with Mr. Drdak of the Palfinger AG during leveling trials.<br />

freedom from regional economic<br />

fluctuations is assured.<br />

Serving the customer is top priority<br />

for Palfinger. Their primary<br />

mission is to help customers all<br />

around the world succeed by<br />

developing products and services<br />

to deliver “perfect service”<br />

to the customer. Dealers and<br />

customers from all over the world<br />

can meet at the new Service and<br />

Demonstration Center where<br />

they receive first-hand training<br />

and the latest information on<br />

products, services and the company.<br />

This is a perfect example<br />

of the company's commitment<br />

to serving the customer first.<br />

In 2007 <strong>ARKU</strong> delivered two<br />

FlatMaster parts levelers to the<br />

Palfinger Group. These two precision<br />

levelers for flame-cut<br />

parts are used in manufacturing<br />

plants in Bulgaria and Slowenia.<br />

They provide on-site accuracy<br />

in flatness of the flame-cut parts<br />

needed for the production of<br />

lifting, loading and handling<br />

solutions. <strong>ARKU</strong> is proud to<br />

have the confidence of the<br />

Palfinger Group.<br />

PALFINGER AG<br />

Franz-Wolfram-Scherer-<br />

Straße 24<br />

A-5101 Bergheim/ Salzburg<br />

Austria<br />

www.palfinger.com<br />

PK 42502 performance sets new standards for the loading of containers<br />

or heavy machinery.<br />

Masthead | Publisher: <strong>ARKU</strong> <strong>Maschinenbau</strong> <strong>GmbH</strong> · Responsible: Albert Reiss, President · Coordination: Susanne Grossmann · Layout: Rommel & Frank · Print: Koelblin-Fortuna-Druck <strong>GmbH</strong>