2004 Issue 3 - Raytheon

2004 Issue 3 - Raytheon

2004 Issue 3 - Raytheon

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

technology<br />

today<br />

HIGHLIGHTING RAYTHEON’S TECHNOLOGY<br />

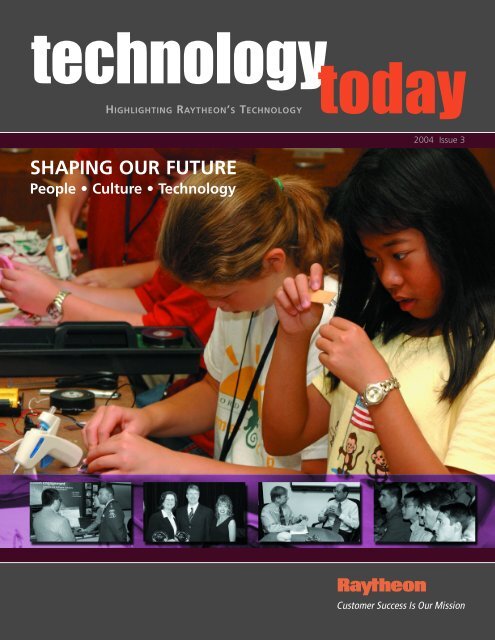

SHAPING OUR FUTURE<br />

People • Culture • Technology<br />

<strong>2004</strong> <strong>Issue</strong> 3

A Message from Greg Shelton<br />

Vice President of Engineering,<br />

Technology, Manufacturing & Quality<br />

or<br />

Ask Greg on line<br />

at: http://www.ray.com/rayeng/<br />

2 <strong>2004</strong> ISSUE 3<br />

This issue of technology today kicks off with a feature on cognitive computing/cognitive systems. Wow,<br />

what a difference a career makes. When I was in college, I did a project on an artificial intelligence<br />

(AI) game that, given a set of rule-based assumptions, would “learn” strategy. It was a small project of<br />

four pawns on each side of the board. The program took three boxes of punch cards; remember, there<br />

were no memory sticks back then. The game required several iterations before I got it right, and I got<br />

complaints from the mainframe (IBM 360) guys that I was hogging computer time (I ran my runs at<br />

1:00–3:00 a.m.).<br />

Since that early experience with AI, I have watched technology grow and compute power following<br />

Moore's law. I have seen systems based on genetic programming, artificial intelligence and neural<br />

networks evolve into useful products that are just now beginning to affect our lives.<br />

Today we are working towards cognitive systems. Does that bring back any thoughts to the over-fifty<br />

crowd? Could we be on the verge of generating a “HAL 9000” from 2001: A Space Odyssey? When the<br />

film was first released 40 years ago, 2001 was so far off, and the concept of a “thinking computer” was<br />

just science-fiction. But only a few years after the fictionalized 2001, the Cassini probe en route to<br />

Saturn spotted two "shepherd" moons which keep one of the planet's rings in check through their<br />

gravitational influence. We are a few years behind in generating the HAL 9000, but it does not quite<br />

seem like science fiction now! Think about it: Within the next 10 years, the technology advances we<br />

are working on today could birth a much kinder, gentler HAL 9000... I hope.<br />

Alas, so much for the sci-fi mind-wandering. Back in technology today, you hear us say “our technology<br />

is as good as our people,” and this will become startlingly clear as you read our several spotlights on<br />

people and how they relate to our future. For example, <strong>Raytheon</strong>’s dedication to K-16 education is<br />

highlighted to show you how we are committed to supporting education as students discover the wonders<br />

of math and science. A diverse and educated pool of bright young minds in the fields of engineering<br />

and science is a key to keeping this company at the leading edge of technology.<br />

Throughout this issue, you will also see profiles of our five technology areas as well as engineering,<br />

manufacturing, technology and quality (ETMQ, for short) professionals — their accomplishments,<br />

career paths and visions. They are shining reasons why we emphasize the importance of our employees<br />

and how we rely on our people — you — who shape the future of this company and the future of the<br />

industry itself.<br />

Speaking of leading-edge technology, make sure you flip to “Tech Talk,” a feature we will be publishing<br />

in national magazines to spotlight key programs and technologies across <strong>Raytheon</strong>. Keep a lookout for<br />

Tech Talk, both on www.ray.com and in the trades.<br />

Last, but certainly not least, is the addition of our international patents awards. Look for these roundthe-globe<br />

achievements where we list the quarterly U.S. patent awards. If there’s any question about<br />

whether or not <strong>Raytheon</strong> is leading the way in the electronics and aerospace industries, this list —<br />

and this issue of technology today — should make it clear. Are people our strongest asset? Of course.<br />

If they weren’t, the person in the office next to you would be named HAL.<br />

Sincerely,<br />

Greg

TECHNOLOGY TODAY<br />

technology today is published<br />

quarterly by the Office of Engineering,<br />

Technology, Manufacturing & Quality<br />

Vice President Greg Shelton<br />

Managing Editor Jean Scire<br />

Editors Mardi Scalise, Lee Ann Sousa<br />

Art Director Debra Graham<br />

Photography Jon Black, Rob Carlson,<br />

Roy Chamberline, Mike McGravey,<br />

Tom Morris, Ken Ulbrich<br />

Publication Coordinator Carol Danner<br />

Contributors<br />

Michael Adlerstein<br />

Linda Ban<br />

Duncan Crawford<br />

John Evers<br />

Tim Fitzgerald<br />

Jocelyn Hicks-Garner<br />

Cathy Ibrahim<br />

Alan Jost<br />

Jay Lala<br />

Peter Matthewson<br />

Mason Nakamura<br />

Dan Nash<br />

Amy Ochs<br />

Jill Pate<br />

Alan Silver<br />

Mark Warner<br />

INSIDE THIS ISSUE<br />

An Interview with Dr. Ronald Brachman 4<br />

Profiles: Jay Lala and Pete Bata 9<br />

<strong>Raytheon</strong> UK World Class Technologies<br />

Eye on Technology<br />

10<br />

Architecture & Systems Integration 12<br />

RF Systems 13<br />

EO/Lasers 14<br />

Processing 15<br />

Materials & Structures 16<br />

Technology Strategy Integration Offsite 17<br />

Spring Symposia 18<br />

Leadership Perspective – Peter Pao 19<br />

Systems and Software Technology Conference 20<br />

Excellence in Technology Awards 21<br />

Quality Excellence and Excellence in Operations Awards 22<br />

IPDS Program Planning Tool 24<br />

IPDS Upgrades 26<br />

T2: Tech Talk 27<br />

CMMI Accomplishments 28<br />

Design for Six Sigma 30<br />

DD(X) Team receives SPC Excellence Award 31<br />

DesignCamp 32<br />

U.S. Patent Recognition 33<br />

International Patent Recognition 34<br />

Interactive online technology today 36<br />

Future Events 36<br />

EDITOR’S NOTE<br />

The end of the summer is quickly upon us and, as my three children return to school, I think about<br />

what I can do to encourage them and their friends to be excited about learning, especially about<br />

math and science. I talk to so many children, especially girls, who think that they’re not good in<br />

math and science, or that it’s not “cool.”<br />

I often visit classrooms and am troubled that many students do not know anything about engineering<br />

or the exciting opportunities that are available to them. We all need to play a part in<br />

changing this perception by showing our children that they can actually enjoy math and science,<br />

and that they are more competent than they think — simply point out how they are often more<br />

computer savvy and can run the electronics in the house better than us! The motto in my home is based on the Henry<br />

Ford quote: “Either you think you can or you can’t; either way, you’re right.”<br />

I had the opportunity (yes, I must admit, my job is a lot of fun) to visit UMass Lowell’s DesignCamp, a hands-on experience<br />

for students. <strong>Raytheon</strong> was integral in this math and science educational initiative by getting the camp started<br />

with a major grant and continued sponsorship. The children were excited and couldn’t wait to share with us what they<br />

were learning and how much fun they were having. It’s no small declaration to say our children of today are the<br />

future of tomorrow, which is why we decided to put children on the cover of this issue, especially since <strong>Raytheon</strong> is<br />

focused on promoting technical literacy for all, from pre-K to grade 16.<br />

I am excited about new developments with technology today. One is the introduction of “Eye on Technology,” a new<br />

section that will feature where we were, where we are and where we are going in our five key technology areas.<br />

Another is the new online interactive version of technology today for which many of you were integral in providing<br />

feedback and ideas. Thirdly, with editors Mardi Scalise and Lee Ann Sousa, we are continuing to grow and work to<br />

provide you with an invaluable resource you can use every day.<br />

Jean Scire, Managing Editor<br />

jtscire@raytheon.com<br />

We welcome your comments and suggestions; go to technology<br />

today via www.ray.com/rayeng and visit the Interact section, or<br />

email us at techtodayeditor@raytheon.com.<br />

<strong>2004</strong> ISSUE 3 3

An interview with Dr. Ronald Brachman,<br />

DARPA/IPTO Director<br />

On Feb. 6, <strong>2004</strong>,<br />

Dr. Ronald Brachman,<br />

director of the Information<br />

Processing Technology Office,<br />

sat down in his office at<br />

DARPA in Arlington, Va. for an<br />

interview with Dr. Jaynarayan<br />

Lala, engineering fellow in IDS<br />

and a former IPTO program<br />

manager. The discussion yielded<br />

topics ranging from the origins<br />

of cognitive computing to<br />

DARPA’s vision of Cognitive<br />

Systems to where we might<br />

expect major breakthroughs.<br />

LALA: What are the origins of cognitive<br />

computing? And, do you prefer the term<br />

“cognitive computing” or “cognitive<br />

systems”?<br />

BRACHMAN: Generally, we’ve been using<br />

the term “cognitive systems.” We are very<br />

interested in building computational systems<br />

that are substantially more versatile<br />

and adaptive, and less prone to surprise<br />

from unanticipated circumstances — in<br />

other words, more intelligent — than the<br />

ones we have now. A word that naturally<br />

comes to mind when we think about our<br />

aspirations is “cognitive”: We are most<br />

excited about emulating the kinds of capabilities<br />

that humans uniquely have that<br />

involve thinking: solving complex problems,<br />

4 <strong>2004</strong> ISSUE 3<br />

making decisions and learning. Together<br />

these amount to the very definition of the<br />

notion of cognition. So, you can call what<br />

we are doing “cognitive computing,” “cognitive<br />

systems” or, as our office BAA names<br />

it, “cognitive information processing technology.”<br />

We are trying to take notions that,<br />

in the natural world, exemplify cognition<br />

and marry them with work in computer science.<br />

We’ve tended to use “cognitive systems”<br />

to emphasize the fact that we not<br />

only care about the “cognitive” part but<br />

also about building fully integrated, functional<br />

systems.<br />

There are different ways to think about<br />

the origins of this kind of thinking. In the<br />

bigger picture, great thinkers have been<br />

contemplating artificial cognition for centuries<br />

— all the way back at least to<br />

Aristotle. The late 17th century philosopher<br />

Leibniz believed that thinking was a<br />

mechanical process that could be captured<br />

in a formal, computational way. Leibniz,<br />

one of the inventors of the mathematical<br />

calculus that we all know and love from<br />

high school, contemplated the notion of a<br />

“calculus of thought,” computing with<br />

symbols in a way that would be analogous<br />

to the differential calculus’s way of computing<br />

with numbers. Subsequently, at the end<br />

of 19th century, Gottlob Frege made a critical<br />

invention: a mathematical system that<br />

allowed the formal computation of logical<br />

conclusions. We have come to think of this<br />

as formal logic — a symbolic system that<br />

supports the mechanization of reasoning.<br />

Most of us are at least passively familiar<br />

with the kind of computation that Frege’s<br />

logic allows; perhaps the easiest way to<br />

think of classical logic is through syllogisms<br />

like “All men are mortal; Socrates is a man;<br />

therefore, Socrates is mortal.” We can see<br />

that, for a very long time, philosophers and<br />

mathematicians have toyed with the idea of<br />

“thinking” as a mechanical process. But<br />

until recently, none of them had machines<br />

on which they could test their ideas and<br />

help them see the incredible implications of<br />

their visions of mechanized reasoning.<br />

Once the digital computer came into being,<br />

modern thinkers could begin to see the<br />

tremendous implications of the dreams of<br />

Aristotle, Leibniz, Frege and others. In the<br />

1950s when the technical field of Artificial<br />

Intelligence got its start, people like John<br />

McCarthy started to think about using formal<br />

logic to allow computing machines to<br />

reason. So, in a more narrow view, the<br />

notion of an artificial cognitive system really<br />

started to take shape in the middle of the<br />

20th century. And since then, once mechanized<br />

reasoning was first implemented,<br />

researchers in the field started looking at<br />

the consequences of more richly emulating<br />

human thought, including the implications<br />

of looking at psychology from an information-processing<br />

point of view. Researchers<br />

branched out and began trying to understand<br />

the many different ways that people<br />

think, well beyond the very simple kind of<br />

deductive reasoning you can get from strict<br />

use of Frege’s classical logic.<br />

From a DARPA perspective, the cognitive<br />

systems initiative started with Tony Tether,<br />

the agency’s director. In 2001, Tony was<br />

looking for a new computation flag to<br />

raise, something more cohesive and visionary<br />

than the IT agenda then in place at<br />

DARPA. He brainstormed with a few trusted

colleagues, and together they came up<br />

with the idea of a cognitive systems thrust<br />

as a major new focus for work in IT and<br />

computer science. Tony believes, as do all<br />

of us in IPTO, that serious progress in this<br />

area could create a revolution in computing<br />

as significant and broad-reaching as the<br />

Internet, which is probably the office’s<br />

greatest and most well-known prior<br />

achievement. Tony invited me and my<br />

deputy director, Zach Lemnios, to join<br />

DARPA in 2002, and handed us the charter<br />

to make the general idea real. Given the<br />

history of the office, including early work in<br />

the 1960s by J.C.R. Licklider, the first IPTO<br />

Director, I suggested we change the name<br />

of the office back to IPTO (it was previously<br />

ITO) and, with that inspiration, we were off<br />

and running.<br />

LALA: How do you see AI as being related<br />

to cognitive computing? What breakthroughs<br />

do you believe have taken place<br />

to allow a revolutionary advance in cognitive<br />

systems?<br />

BRACHMAN: In its history, DARPA has<br />

had times when it put major efforts into<br />

Artificial Intelligence. Licklider’s earliest<br />

agenda for the office (in the early 1960s)<br />

involved “man-machine symbiosis” with a<br />

vision of intelligence as machines as partners<br />

for human users. There was a lot of<br />

work done in AI on planning in the 1990s<br />

that ultimately became very successful in<br />

supporting military logistics. In the 1980s<br />

and early ‘90s there was the Strategic<br />

Computing Initiative’s emphasis on rulebased<br />

systems, with three major applications,<br />

including a “Pilot’s Associate.”<br />

People may want to know why DARPA is<br />

tackling this once again. First, in its early<br />

years, raw computing power was a serious<br />

limitation for AI. But Moore’s Law over the<br />

last 10 years has qualitatively changed the<br />

landscape of the way people do AI work.<br />

In addition, during the 1990s, which some<br />

people call the “decade of the brain,”<br />

there was a tremendous amount of investment<br />

by NIH to do research in neuroscience.<br />

In fact, our understanding of the<br />

brain and natural reasoning, thinking, and<br />

learning mechanisms has changed substantially<br />

because of this investment. Third,<br />

there have been substantial developments<br />

over this time in traditional AI where new<br />

technologies, such as machine learning,<br />

have proven that, in some application<br />

areas, they scale and are real. There have<br />

been many other types of AI and related<br />

technologies that have become practically<br />

and even commercially viable. NASA, for<br />

example, has done some wonderful work,<br />

putting very rich and complex models of<br />

system behavior and goals on board spacecraft<br />

and allowing the Deep Space 1 mission<br />

to test out fully autonomous operation. So<br />

much new technology and understanding<br />

now exists over the expert-systems period<br />

of 15 years ago that it would be a mistake<br />

not to see how far it can now take us with<br />

respect to machine cognition.<br />

LALA: Could the Mars rover “Spirit” have<br />

diagnosed its own problems if it had something<br />

like cognition?<br />

BRACHMAN: In principle, there are classes<br />

of problems that could occur in scenarios<br />

like we saw with Spirit, where the right<br />

kind of self-aware software — one that<br />

could examine the physical state of the<br />

machine it was running on and even some<br />

of the software itself — could deal with<br />

unforeseen problems in very intelligent<br />

ways. In other words, you could get some<br />

interesting behavior if a program could<br />

“step back” from the problem and do<br />

some reasoning about the variance<br />

between its current state and its expected<br />

state. I already mentioned briefly ways in<br />

which NASA itself has explored the role of<br />

intelligent processing, a certain amount of<br />

self-awareness and multi-level reasoning in<br />

“It’s essential that humans are<br />

fault-tolerant. This type of<br />

reasoned response to problems<br />

would be a very powerful<br />

type of capability to have<br />

in computational systems.”<br />

autonomy trials on some of its missions.<br />

Since that work was still very experimental,<br />

it could not have made its way onto the<br />

current generation of Mars rovers, but<br />

there is hope that it will play an important<br />

role in a Mars mission in 2009.<br />

LALA: So, fault tolerance is a necessary<br />

condition?<br />

BRACHMAN: Yes, but we want to interpret<br />

“tolerance” very broadly. There are<br />

many ways that fault tolerance can be built<br />

into computational systems, but we see a<br />

whole new level of capability being made<br />

possible by creating explicit models and<br />

allowing reasoning — and learning — to<br />

help with diagnosis, recovery and even system<br />

improvement over time. Note that the<br />

same is true in natural systems. It’s essential<br />

that humans are fault-tolerant. Sometimes<br />

our bodies heal themselves, continuing to<br />

operate while repairs are in progress, and<br />

sometimes it takes groups of humans,<br />

thinking, solving problems and designing<br />

cures and vaccines, to deal with a problem.<br />

Continued on page 6<br />

<strong>2004</strong> ISSUE 3 5

BRACHMAN INTERVIEW<br />

Continued from page 5<br />

This type of reasoned response to problems<br />

would be a very powerful type of capability<br />

to have in computational systems.<br />

LALA: What are the DARPA-hard problems<br />

you think must be solved for cognitive<br />

computing to advance significantly?<br />

BRACHMAN: If you think about characteristics<br />

of natural intelligent systems, it is<br />

clear that we are multi-faceted, multidimensional<br />

systems. I don’t know whether<br />

major successes along independent, indi-<br />

vidual technology paths (e.g., vision,<br />

speech, planning, default reasoning, etc.)<br />

will simply add up, or whether it’s the<br />

interaction between the pieces that is really<br />

critical. So, we are investing in work in<br />

both dimensions. Clearly, if something is<br />

going to be cognitive, it has to apply<br />

knowledge to make judgments and decisions.<br />

That’s really the essence of being<br />

cognitive: to know things, to reason and to<br />

use that knowledge to influence your activities.<br />

So, at the core what we want is<br />

robust, multi-dimensional reasoning by<br />

machine. Some great formal reasoning<br />

technology already exists, but there are<br />

some very challenging problems still out<br />

there having to do with the scale of human<br />

knowledge, the use of background knowledge<br />

and “context,” “common-sense reasoning,”<br />

defaults, model-based reasoning<br />

and other things. Another area that is<br />

absolutely critical is learning. You can have<br />

a very clever machine that makes good<br />

decisions, but if it makes a mistake and<br />

repeats that mistake over and over again<br />

(and you see this with our PCs all the time),<br />

it just appears stupid. Our belief is that<br />

learning is as essential as reasoning to build<br />

cognitive machines. And an essential part<br />

6 <strong>2004</strong> ISSUE 3<br />

of real reasoning and learning is the connection<br />

of the entity to the world. It has to<br />

be “situated” somewhere and deal with<br />

inputs and outputs that come from the rest<br />

of the universe. We don’t want to construct<br />

an isolated “brain in a bottle.” So,<br />

it’s very important to look at the intersection<br />

of reasoning and learning at the core<br />

and perception at the periphery — taking<br />

in inputs through multiple sensor modalities.<br />

One of the interesting things about<br />

the future of cognitive systems is that we<br />

could imagine sensor modalities that are<br />

quite different from what natural systems<br />

have. People don’t use LADAR and infrared<br />

and inertial sensors in the way robots do.<br />

You could have broader sensor suite in an<br />

artificial system than in a natural one, and<br />

that might give you a lot more powerful<br />

capability.<br />

And on the flip-side of perception, we<br />

want to build systems that can take action.<br />

It is one thing to decide something or to<br />

create a formal, logical plan, but no intellectual<br />

plan survives contact with the real<br />

world. Things go wrong; sensors are imperfect;<br />

other agents do surprising things. We<br />

need to include actions, observation and<br />

re-planning in our research agenda. Of<br />

course, such actions could be in cyberspace;<br />

they don’t have to be physical.<br />

Another given is that the real world<br />

involves multiple reasoning entities. We<br />

have to take communication, collaboration,<br />

team and adversary activity into account.<br />

Certainly the military is heavily dependent<br />

on the performance of teams, both formal<br />

and informal. We have to take into<br />

account communication and coordination<br />

among multiple, independently reasoning,<br />

autonomous systems, whether they are<br />

humans or robots.<br />

Last point here: We could and need to<br />

make great strides in each of these areas<br />

independently, and that’s how research<br />

tends to go. However, we believe that it’s<br />

critically important that we look at architectures<br />

and issues of integration of the various<br />

components.<br />

LALA: What new applications do you feel<br />

will be enabled as a result of advances in<br />

cognitive computing?<br />

BRACHMAN: Virtually everything that<br />

matters in the Department of Defense and<br />

in the world in general — almost every-<br />

thing we do, everyday — depends on computing<br />

equipment. “Network-centric” warfare<br />

is the envisioned future of our military<br />

services. DARPA is very much engaged in<br />

support for visions such as the Army’s<br />

Future Combat Systems. We need to<br />

attend to the capability of the core platform<br />

on which all these future visions are<br />

going to be built. We want to pursue a<br />

radically different approach to large software<br />

systems, where the systems could<br />

ultimately be much more responsible for<br />

their own success. If you could understand<br />

the requirements for the first release of a<br />

system well enough to have them articulated<br />

to the system explicitly, then you’ve<br />

decided what the requirements were for<br />

the second generation, maybe you could<br />

avoid sending 500 programmers back to<br />

the lab and to design the next release and<br />

actually discuss changes with the system<br />

itself, advising it as to how you’d like to<br />

see it increase its own capabilities. Perhaps<br />

we can ultimately teach software systems<br />

the same way we teach humans and leave<br />

a great deal of the burden on the system<br />

as to how to assimilate and implement its<br />

new capabilities. A system that is more<br />

capable would not only be able to maintain

itself better in the field and prevent being<br />

taken down by contingencies and attacks<br />

by an adversary, but such systems might<br />

even improve and change their missions<br />

when they’re already deployed. This is a<br />

pretty radical vision but, the way I see it,<br />

something this extreme is urgently needed<br />

or we will simply be buried by the cost<br />

and complexity of the software we are<br />

producing (not to mention its growing<br />

fragility and vulnerability because of this<br />

complexity).<br />

LALA: Where do you think the initial<br />

breakthroughs will come?<br />

BRACHMAN: There is always a tension in<br />

a situation like ours, between knowing<br />

how to solve the core problems and longterm<br />

challenges, and feeling that there is<br />

low-hanging fruit to be harvested just by<br />

applying the right idea to the right problem.<br />

We are exploring both of those,<br />

although it is important to remember that<br />

DARPA is one of the few places that can<br />

really focus on the critical, long-term issues<br />

that are almost — but, not quite —impos-<br />

sible, and that is our primary responsibility.<br />

One place I hope to see some early breakthroughs<br />

is in a program that has just<br />

begun: “Self-Regenerative Systems.” In this<br />

program, we’ve created four technology<br />

thrusts that are trying to remove critical<br />

roadblocks in the way of building a software<br />

system that would be able to survive<br />

even successful attacks or failures and, not<br />

only survive, but always maintain 100 percent<br />

of critical functionality and grow back<br />

full functionality after an attack. I love this<br />

program because it has very significant<br />

work in hardcore computer science, complemented<br />

by a potentially critical contribution<br />

from reasoning and learning. It really<br />

exemplifies our view of the future of com-<br />

putational systems augmented by cognitive<br />

information processing.<br />

Another area that we’re exploring that<br />

should have some early payoffs is the application<br />

of reasoning and learning to the<br />

management of networks. The grand goal<br />

is to invent a virtual space that would be<br />

applied to large-scale distributed networks<br />

that would parallel the data plane and the<br />

control plane — a “knowledge plane” —<br />

that would have a global view of everything<br />

in this very distributed computing<br />

fabric. Such a system might, by observation<br />

of things going on in different places and<br />

reasoning about past experience, be proactive<br />

about, for example, distributed denialof-service<br />

attacks; or it might be able to do<br />

management of access or even network<br />

resources in a cognitive way where the<br />

tasking could come at a high level. It<br />

wouldn’t have to be reprogrammed by network<br />

engineers, and you wouldn’t need as<br />

many professional network managers who<br />

are watching the network traffic and making<br />

changes to parameters.<br />

Other areas in which we are seeking relatively<br />

short term gains have to do with<br />

applying state-of-the-art learning algorithms<br />

to robotic locomotion and navigation.<br />

You’re aware, I’m sure, of the DARPA<br />

Grand Challenge. While a very exciting<br />

event, the Challenge showed us how much<br />

more research needs to be done in dealing<br />

with autonomous navigation in natural terrain.<br />

We’re looking at some learning capabilities<br />

for leading robotic vehicles through<br />

a course by a human and then having it<br />

learn through experience how to navigate<br />

the course and get over different types of<br />

barriers. This work will be embodied in our<br />

new “Learning Applied to Ground Robots”<br />

program. I can envision results from this<br />

program supporting programs like FCS in<br />

less than five years.<br />

Finally, I think I can say that we’ve already<br />

seen some interesting potential breakthroughs<br />

in our Personalized Assistant that<br />

“There is always a tension…<br />

between knowing how to<br />

solve the core problems<br />

and long-term challenges,<br />

and feeling that there is<br />

low-hanging fruit to<br />

be harvested.”<br />

Learns (PAL) program. Our researchers have<br />

created some new machine learning algorithms<br />

that, in some early tests, seem to be<br />

doing better than the very best prior algorithms<br />

— by taking background knowledge<br />

into account. We are very excited about<br />

these results and the promise of more<br />

learning breakthroughs.<br />

LALA: What else can you tell us about PAL?<br />

BRACHMAN: When you make a system<br />

operate in a way that begins to look cognitive<br />

and you look at how it might work<br />

with a war fighter or a commander, what<br />

seems obvious is that the best way to think<br />

of it is as an assistant. It would likely have<br />

a significant degree of autonomy so as not<br />

to be a constant burden to its user, but<br />

you’d want it to be advisable and take<br />

guidance from its supervisor. You’d like it<br />

to use some common sense, be aware of<br />

the mission and be personalized over time<br />

to the needs of the user. The ideal that<br />

Continued on page 8<br />

<strong>2004</strong> ISSUE 3 7

BRACHMAN INTERVIEW<br />

Continued from page 7<br />

comes to mind is an executive assistant or<br />

a chief of staff. Typically, the more people<br />

work together, the better they work as a<br />

team, making each of them more independently<br />

effective, so the idea of building<br />

an integrated artificial assistant has motivated<br />

us. In that image, we’ve created<br />

Personalized Assistant that Learns (PAL).<br />

What we’re trying to do in PAL is focus<br />

on each of the elements that I mentioned<br />

earlier — learning, reasoning, perception,<br />

communication and action — but, most<br />

importantly, on the integration of those,<br />

and then tackling the real-world complex<br />

tasks that an executive assistant would be<br />

asked to tackle. For example, this means<br />

not just looking at how well the system<br />

parses a visual image of a conference room<br />

or a calendar, but how it integrates what it<br />

sees and hears with what it knows about<br />

the mission, what is going on in a meeting<br />

and what the action items and outcomes are.<br />

The PAL program is really our office centerpiece,<br />

and it’s very ambitious. The idea of<br />

building an artificial chief of staff or an<br />

assistant applies all over the military.<br />

Recently, a visiting Marine talked about<br />

how useful it would be to augment or<br />

replace a radio operator in a tank or in a<br />

unit. It’s a very critical yet tedious position<br />

for a person and ranges from boring, low<br />

levels of activity to high-stress, chaotic,<br />

time-critical activities — seems like the perfect<br />

place to consider a cognitive computer<br />

assistant. We’ve observed activities in an air<br />

operations center training setting where<br />

you can see how the JFAC could use assistance<br />

in coordinating the activities of all<br />

the people that report to him, prioritizing<br />

activities, riding herd over people to make<br />

8 <strong>2004</strong> ISSUE 3<br />

“Recently, a visiting Marine<br />

talked about how useful it<br />

would be to augment or<br />

replace a radio operator<br />

in a tank or in a unit.”<br />

sure their activities have been completed,<br />

simply remembering conversations from<br />

the past so you could have the information<br />

ready at hand in the future, keeping things<br />

from falling between the cracks — all of<br />

the things that an excellent assistant does.<br />

LALA: How can one measure progress in<br />

this field?<br />

BRACHMAN: In some limited technical<br />

areas, like learning, you can set up very<br />

careful and quantitative evaluations. You<br />

can draw learning curves and show that<br />

how you want to push them ahead a certain<br />

distance. You can show the speed of<br />

learning and competitiveness between multiple<br />

learning algorithms. But when you are<br />

trying to build an artificial executive assis-<br />

tant, think about how we evaluate such<br />

people in the real world. It tends to be subjective;<br />

it’s complex and multi-dimensional,<br />

and there is no one dimension of what<br />

they do that is the most important. We<br />

may want to look at ways in which learning<br />

and reasoning and other types of performance<br />

are measured in humans by psychologists<br />

and educators. There may be<br />

some good ideas there that can help us.<br />

Nevertheless, we’re at the very beginning<br />

of this. Many people are familiar with what<br />

is called the Turing Test that Alan Turing<br />

invented 50 years ago, which is a way of<br />

trying to determine whether a computer is<br />

actually intelligent, but that’s totally inade-<br />

quate for the purposes we have. It’s not<br />

quantitative; it doesn’t involve taking any<br />

actions, and it doesn’t involve learning<br />

from experience.<br />

LALA: How do you keep a long-term<br />

research effort like this going long enough<br />

to succeed?<br />

BRACHMAN: We don’t know whether<br />

we can succeed. We think the probabilities<br />

are reasonable, but DARPA doesn’t work<br />

on things that are guaranteed success. So<br />

what we are trying to do is think about<br />

meaningful, exciting and compelling problems<br />

with some intermediate results that<br />

will show our successors that there is<br />

promise here. What we’re dealing with<br />

here is a very-long-term vision. So we’re<br />

going to build some small things that build<br />

on past history, and we’re going to do<br />

some ambitious, long-term things that<br />

address the vision directly and hope that<br />

the portfolio is very strong by the time we<br />

leave. Things have been going very well<br />

with this initiative, in large part because we<br />

have very strong support from the director<br />

of the agency.<br />

LALA: Is there anything else you would<br />

like to add?<br />

BRACHMAN: I should conclude with<br />

one very important thought. DARPA lives<br />

and breathes through its program managers.<br />

The success of any of these efforts<br />

and the longevity of projects really depends<br />

on getting excellent technical people who<br />

really understand the field and understand<br />

how to put together a vision, to sell it and<br />

manage it. We really are critically dependent<br />

on these people coming in from the<br />

community and helping turn exciting<br />

visions into reality. •

PROFILE: Jay LALA<br />

Upon earning his Sc.D. in Instrumentation from MIT,<br />

Jay Lala embarked on an impressive 25-year career<br />

at Draper Laboratory where he designed and developed<br />

fault-tolerant computers for mission- and safety-critical<br />

applications. These included the swim-bywire<br />

ship control computer for the SEAWOLF nuclear<br />

attack submarine and the flight-critical computer to<br />

control all on-board functions of NASA X-38 crew<br />

return vehicle. In 1999, Jay joined DARPA as a<br />

Program Manager (PM) under the Interagency<br />

Personnel Agreement (IPA) before coming to<br />

<strong>Raytheon</strong> in 2003.<br />

Started in the late ‘90s, DARPA’s Information<br />

Assurance & Survivability program provided<br />

Jay with an opportunity to achieve his<br />

vision of integrating the two previously distinct and parallel disciplines of fault<br />

tolerance and computer security. Working at DARPA enabled Jay to change the<br />

security paradigm from prevention and detection to intrusion tolerance.<br />

“Intrusion tolerance moves from the classical computer and network security<br />

approach of prevention — where you build all types of forts and moats to keep<br />

attackers out — to intrusion tolerance where you design systems that, even<br />

when some parts fail or are successfully attacked, continue to operate and<br />

degrade gracefully to perform all the mission-critical functions correctly,” he<br />

explained. Even though Jay served only four years at DARPA, a congressionally<br />

mandated term-limit for IPAs, he was awarded the Office of Secretary of<br />

Defense Medal for Exceptional Public Service for his many contributions to<br />

improving the security of our nation’s networks.<br />

PROFILE: Pete BATA<br />

Pete Bata has always enjoyed working with customers, building relationships<br />

that enable <strong>Raytheon</strong> to provide them with the best solutions. After graduating<br />

from the University of Colorado with a BS aerospace engineering, Pete joined<br />

<strong>Raytheon</strong> as a test engineer in Aurora, Colo.<br />

He then moved into systems engineering working on a large satellite command<br />

and control system. When the system was complete, Pete went to the customer<br />

site in Washington, D.C. where he spent three years working directly with the<br />

customer on installation of the system. “The knowledge I gained working directly<br />

with the customer was invaluable,” Pete said. “I was able to see how the customer<br />

used the system and what their needs where. This is where you learn the<br />

importance of Mission Assurance and what the customer needs really are.”<br />

With the experience he gained in the field, Pete returned to a lead systems<br />

engineering role on a satellite system in Aurora.At the same time, Pete earned<br />

his MS in Aerospace Engineering and participated in the Engineering<br />

Leadership Development Program (ELDP), a two-year leadership program that<br />

focuses on developing highly capable engineering leaders by providing crossfunctional,<br />

leadership and business training.<br />

Through the ELDP, Pete became aware of an exciting opportunity in the<br />

Business Development office of Advanced Technology. This position would<br />

enable him to leverage his experience working with the customer, but also challenged<br />

him to step outside his comfort zone by directly working with DARPA<br />

learning the latest technologies. “This opportunity provided me with the visibility<br />

of the depth and breadth of, not only <strong>Raytheon</strong>’s technology capabilities and<br />

strengths, but also our competitors. I work directly with the customer and our<br />

partners on new solutions for the next-generation battle space.”<br />

Pete is working with DARPA on military solutions for the war fighter and is<br />

particularly proud of the “Integrated Solution” team concept that he was integral<br />

in developing. This concept brings together technologists, domain experts,<br />

DARPA empowered Jay to carry out his vision by providing substantial<br />

resources and a highly streamlined execution environment. He was thrilled with<br />

his experience at DARPA. “DARPA is a unique agency in the world where new<br />

blood is constantly brought in from outside, and the PMs are trusted with enormous<br />

funds to accomplish their vision,” Jay said. “The knowledge gained from<br />

working with top-notch principal investigators, as well as the visibility into a<br />

broad swath of the latest science and technology, was invaluable.”<br />

Now located at Customer Integration Center at IDS in the Crystal City offices of<br />

Arlington, Va., Jay’s current position demonstrates Customer Focused Marketing<br />

at its best. He has built solid relationships with his DARPA peers, now<br />

<strong>Raytheon</strong>’s customers. He understands our customer needs and has a thorough<br />

comprehension of the science and technology landscape that enables him to<br />

provide state-of-the-art solutions. Since joining IDS, Jay has been integral to<br />

several key wins and will continue to work with customers to help ensure that<br />

our commitments are met and delivered as promised.<br />

Jay’s background and experiences in fault tolerant computers, as well as changing<br />

a mindset from prevention to intrusion tolerance, is closely aligned with<br />

<strong>Raytheon</strong>’s pursuit of Mission Assurance. “We are well-prepared for Mission<br />

Assurance. We have the IPDS, <strong>Raytheon</strong> Six Sigma TM and CMMI ® processes,”<br />

he said. “Our systems architectures need to be consistent with the mapping<br />

of Mission Assurance requirements so that we design the ability to perform<br />

missions from the ground-up early in the design cycle.”<br />

For more information, contact Jay at Jay_Lala@raytheon.com<br />

customers and partners in a workshop-styled setting. Each workshop focuses<br />

on a critical mission area — such as urban warfare, space control or, most<br />

recently, improvised explosive devices (IEDs) — in which the problem is<br />

defined, gaps and needs are identified, and solutions are generated. The end<br />

result is growth with new program wins.<br />

As a result of the IED workshop, 10 new potential solutions were developed.<br />

“The objectives of the workshop were to frame the IED problem and generate<br />

a number of system concepts that address the current needs and gaps,”<br />

explained Pete. “We focused on solutions with potential for rapid implementation<br />

in Iraq to save U.S. lives. We are now in the process of refining<br />

these concepts for presentation to DARPA and the services.”<br />

Pete is planning to return to the businesses, leading a program<br />

or function where he can utilize the knowledge and skills<br />

gained by working in the D.C. office, and where he can work<br />

directly with our customers and partners. “I encourage<br />

everyone in Engineering to seek new and exciting opportunities<br />

outside of their comfort zone,” he urged. “These stretch<br />

assignments are invaluable to career growth and<br />

development. I have learned so much about our<br />

great company that I could not have learned while<br />

working on a single program or within a business.<br />

Now I can apply that knowledge and insight to<br />

provide One Company solutions leveraging<br />

the strong relationships I have built within<br />

the customer community.”<br />

For more information on the IED<br />

workshop, visit http://www.ray.com/<br />

feature/ied_workshop, or email Pete at<br />

pdbata@raytheon.com<br />

<strong>2004</strong> ISSUE 3 9

Air Traffic Management<br />

Systems (ATMS)<br />

RSL has become a major supplier of<br />

Monopulse Secondary Surveillance Radars<br />

(MSSR) around the world. The company<br />

pioneered this technology after World<br />

War II, installing the first Secondary<br />

Radar at London’s Heathrow airport in<br />

the early 1950s.<br />

Today, approximately 300 <strong>Raytheon</strong> MSSR<br />

systems have been installed in 34 countries,<br />

and customers include the United States<br />

Federal Aviation Administration and the<br />

United Kingdom Civil Aviation Authority.<br />

Automatic Dependent<br />

Surveillance–Broadcast (ADS-B)<br />

The next generation of cooperative Air<br />

Traffic Management Systems (ATMS) surveillance<br />

technology is called ADS-B. This<br />

system utilizes positional information from<br />

aircraft navigation systems,<br />

and broadcasts<br />

it to receivers on<br />

the ground or<br />

to other aircraft.<br />

Received messages<br />

provide situational<br />

awareness of the location<br />

and intent of aircraft in the vicinity.<br />

The sky has become increasingly congested<br />

and the number of transmissions has<br />

increased, RSL Harlow, England has developed<br />

decoding technology that allows reli-<br />

10 <strong>2004</strong> ISSUE 3<br />

able signal reception despite “garbling” of the<br />

signals. RSL’s demonstration of the ADS-B<br />

receiver shows potential customers the power<br />

of this innovative new decoding technology.<br />

Flight Planning Systems<br />

The RSL Northern Ireland Systems and<br />

Software Center (NISSC) has been working<br />

as a fully integrated part of the P1<br />

program — along with the <strong>Raytheon</strong><br />

facility in Marlborough, Mass. — to supply<br />

the ATM solution for the German civil<br />

aviation authority (DFS). The system provides<br />

advanced functions such as precise<br />

trajectory calculation and flight-plan-based<br />

conflict prediction that allows a safe<br />

introduction of flexible and dynamic<br />

airspace utilization concepts.<br />

P1 system at Langen control center. Picture<br />

courtesy of DFS Deutsche Flugsicherung GmbH.<br />

System Integration<br />

Airborne STand Off Radar (ASTOR)<br />

Thirteen Engineers from RSL are on site at<br />

Greenville, Texas to support the development<br />

and integration of the first ASTOR<br />

aircraft and to transition the design authority<br />

for the platform to the UK. Four production<br />

aircraft have now been delivered to<br />

RSL in Broughton, Wales for assembly. The<br />

aircraft are being extensively modified to<br />

incorporate the dual-mode radar antenna,<br />

data link antennas, SATCOM system and<br />

the Defensive Aids Group. In addition, the<br />

aircraft has been equipped with a comprehensive<br />

mission system, which permits the<br />

control of the radar, mission flight plan and<br />

communications systems.<br />

RSL has all necessary approval<br />

capabilities to allow us to<br />

undertake further upgrade<br />

programs associated with<br />

the integration of varied<br />

systems on many platform types.<br />

Successor Identify Friend or Foe<br />

(SIFF)<br />

RSL’s Airborne and Naval platform integration<br />

teams have, as part of the SIFF<br />

program, introduced new IFF transponders<br />

and interrogators into 11 different aircraft<br />

types and are integrating eight more. They<br />

have also successfully introduced the system<br />

to four different classes of ships. This<br />

complex process includes integration with<br />

the naval combat system highway and<br />

ships’ primary sensors.

Electronic Systems<br />

Digital GPS Anti-Jam Technology<br />

GPS systems are vulnerable to<br />

interference and deliberate<br />

countermeasures. RSL<br />

manufactures a range of<br />

systems that offer aircraft a high<br />

level of protection against a wide<br />

range of jamming scenarios.<br />

To date, 2,400 systems have been<br />

delivered to customers<br />

around<br />

the world. The<br />

next-generation<br />

fully digital solution<br />

is currently<br />

under development at RSL and is designed<br />

to offer better jamming cancellation performance,<br />

more flexible modes of operation<br />

and simultaneous protection of both<br />

GPS frequency bands.<br />

Power and Control Electronics<br />

The RSL facility in Glenrothes, Scotland is<br />

a leader in the supply of power and<br />

control systems.<br />

Motor Drives and Controls<br />

Our Power and Control Motor Drive team<br />

designs and develops Direct Current (DC)<br />

brushless motor drive solutions for aerospace<br />

and defense applications. Leadingedge<br />

algorithm design techniques — such<br />

as Space Vector Pulse Width Modulation<br />

(PWM) and Field Oriented Control, along<br />

with position control loops around the<br />

inner torque control loop — are used to<br />

produce high performance.<br />

Semiconductor Products<br />

RSL’s wafer fabrication facility (Fab) was<br />

involved in the early pioneering and development<br />

of non-volatile Complementary<br />

Metal Oxide Semiconductors (CMOS).<br />

When combined with analog and digital<br />

circuitry, the non-volatile elements can<br />

store system and calibration data.<br />

Encryption devices, fusing, fire detector<br />

sensor elements, transponders and security<br />

devices have benefited from this technology.<br />

One application couples an RSL ASIC<br />

with a micro electro mechanical sensor<br />

(MEMS) element to provide the sensor<br />

interface, calibration and signal conditioning<br />

functions used in automotive vehicle<br />

stability control and braking systems.<br />

The Fab is a “flexible foundry” where<br />

low-volume and unconventional projects<br />

can be accommodated. This has enabled<br />

solutions for obsolescence issues on older<br />

military systems where ASICs have been<br />

remanufactured from original design<br />

databases, reducing the need for<br />

system re-engineering and qualification.<br />

Silicon carbide processing techniques are<br />

also being developed for use in power and<br />

high-frequency applications to support<br />

higher-density power solutions and better<br />

microwave components.<br />

Hybrid Microcircuits<br />

RSL develops and manufactures hybrids for<br />

use in power conversion and motor drives.<br />

Package materials and technologies are optimized<br />

to maintain the thermal and electrical<br />

performance required within size constraints<br />

such as low profile and small outline.<br />

Martin Stevens is the chief<br />

architect of the ADS-B<br />

demonstration system and<br />

the new decoding technology<br />

developed to underpin<br />

RSL’s entry into the emerging<br />

ADS-B market.<br />

His family has a long history with RSL,<br />

beginning with his grandfather, Walter,<br />

who joined the company in 1933 (then<br />

trading as Cossor). Walter was involved in<br />

development of the original Chain Home<br />

HF radar system for defense of the UK<br />

during World War II and, later, as Works<br />

Manager where he was instrumental in<br />

bringing the business to the Harlow site.<br />

Martin’s father, Michael, worked in the<br />

business for 40 years and was the chief<br />

innovator for Monopulse Secondary<br />

Surveillance Radar, now a standard RSL<br />

product. Some of Michael’s MSSR patents<br />

protecting the technology are still in force.<br />

As a result of the 1961 merger with<br />

Cossor, Michael became part of <strong>Raytheon</strong>.<br />

Martin, in turn, has been with RSL for 17<br />

years, during which he has developed<br />

Mode-S Secondary Radar Interrogators and<br />

Identification Friend or Foe technology.<br />

His family history and his own accomplishments<br />

have served as an ideal background<br />

for Martin’s role in RSL’s present-day challenge<br />

of developing superior new technology<br />

and implementing this technology into<br />

products to address a new market for RSL.<br />

RSL’s hybrid facility<br />

recently achieved<br />

Qualified<br />

Manufacturers<br />

Listing (QML)<br />

accreditation, one of only two sites in the<br />

UK to receive such an endorsement. The<br />

team also supports long-running defense<br />

programs that are running into component<br />

obsolescence and, in some cases, system<br />

upgrades driven by obsolescence. •<br />

Peter Matthewson<br />

peter.matthewson@raytheon.co.uk<br />

<strong>2004</strong> ISSUE 3 11

Microwave<br />

Semiconductor<br />

Technology:<br />

An Overview<br />

The Transistor<br />

In 1947, few appreciated the tremendous<br />

impact of Bardeen, Brittain and Schockley’s<br />

point contact transistor invention. Early<br />

transistors were built using Germanium, but<br />

Silicon quickly became the preferred material<br />

due mostly to Silicon’s purity and chemical<br />

properties. Silicon is the most widely<br />

used transistor material today, particularly<br />

in computers and consumer electronics, but<br />

it is not adequate for applications where<br />

there is a tradeoff between speed and power.<br />

Frequencies of operation in <strong>Raytheon</strong> communication<br />

and radar products range from<br />

5 GHz to 100 GHz. This range includes the<br />

microwave bands (10 GHz, 15 GHz and 20<br />

GHz) as well as the millimeter bands (35 GHz,<br />

44 GHz and 94 GHz). These high frequencies<br />

can be compared with state-of-the-art<br />

Pentium ® microprocessors operating at 2.5<br />

GHz using Si technology.<br />

Advanced Materials<br />

<strong>Raytheon</strong> RF applications have proven best<br />

served by compound semiconductors that<br />

combine elements from columns III and V of<br />

the periodic table. So far, Gallium Arsenide<br />

(GaAs) has been the key material for<br />

microwave applications.<br />

<strong>Raytheon</strong>’s commitment to this technology<br />

through a robust R&D effort has resulted in<br />

important material and design innovations,<br />

which enable high power transmit transistors<br />

and low-noise receive transistors operating<br />

in the microwave and mm-wave<br />

bands. Basic material designs are based on<br />

various crystalline combinations of Gallium,<br />

Arsenic, Aluminum, Indium and Phosphorus.<br />

Today, development of Gallium Nitride<br />

(GaN) transistors is one of the most important<br />

of <strong>Raytheon</strong>’s R&D activities. GaN, like<br />

the other materials, is a III-V compound<br />

semiconductor, but it is more ionic, so transistors<br />

made from GaN have a much higher<br />

operating voltage and power density compared<br />

with transistors made from GaAs. The<br />

advantage in power generation will have a<br />

significant impact on <strong>Raytheon</strong>’s future<br />

solid-state systems and will result in a competitive<br />

advantage for the company.<br />

Transistor Fabrication Technology<br />

Even with the most advanced material technology<br />

it is necessary to fabricate transistors<br />

with sub-micron features to achieve the<br />

Figure 1<br />

desired frequency response. Figure 1 is an<br />

electron micrograph of a GaN FET showing<br />

the structure of a transistor. Electrons flow<br />

from the source to the drain electrodes, but<br />

must first flow under the gate where the<br />

flow is modulated by a low power signal.<br />

<strong>Raytheon</strong> has made many contributions to<br />

transistor fabrication technology, and is<br />

continuing to enhance its fabrication techniques<br />

while attaining high performance,<br />

reproducibility, reliability and high yield.<br />

Monolithic Integration and Modules<br />

The discussion of transistor technology<br />

inevitably leads to a discussion of the circuits<br />

that surround them. For microwave<br />

devices, one cannot simply use ordinary<br />

resistors, capacitors and inductors since the<br />

dimensions of such components are on the<br />

order of the wavelength of the microwaves.<br />

Instead, structures must at least be printed<br />

on the circuit board and, further, printing<br />

the circuit components directly on the same<br />

semiconductor chip as the transistors themselves.<br />

In the 1980s and 90s, this technique<br />

developed into a process for chips called<br />

“Microwave Monolithic Integrated Circuits”<br />

(MMICs). With assistance from the Defense<br />

Advanced Research Projects Agency<br />

(DARPA), <strong>Raytheon</strong> continues to be at the<br />

forefront of this technology. As the company<br />

grew through acquisition of Hughes and<br />

Texas Instruments Defense Group, expert<br />

chip-design centers were added to <strong>Raytheon</strong>’s<br />

repertoire. <strong>Raytheon</strong> RF Components in<br />

Andover, Mass. presently provides the capability<br />

to manufacture MMICs. Typically, MMIC<br />

chips are sent to <strong>Raytheon</strong>’s Advanced Product<br />

Center in Dallas, Texas for assembly into<br />

hardware necessary for <strong>Raytheon</strong> products.<br />

YESTERDAY…TODAY…TOMORROW<br />

Power Amplifier<br />

GaAs MMIC<br />

Mixed Signal (Digital<br />

and RF) GaAs MMIC<br />

Constant improvement in measurement and<br />

modeling techniques of today’s advanced<br />

MMICs is necessary. To produce a successful<br />

monolithic circuit design, one must have an<br />

accurate model of the transistor over a wide<br />

variety of bias, operating powers and temperatures.<br />

Transistor data is gathered by<br />

advanced techniques and extensive analysis.<br />

The resulting models must be maintained<br />

for various fabrication processes. Using the<br />

models, powerful circuit simulation software<br />

tools are used to evaluate various circuit<br />

designs to achieve the desired performance<br />

in the MMIC. Following a trend toward<br />

higher frequencies and smaller chips, circuit<br />

layouts are often analyzed with sophisticated<br />

electromagnetic simulation software.<br />

Such analysis reveals interaction between<br />

elements that can adversely affect designs.<br />

What About the Future?<br />

There are several frontiers for MMIC<br />

research and development: use of new<br />

materials such as GaN; use of special coatings<br />

which eliminate the need for sealed<br />

modules; use of direct interconnects which<br />

eliminate the need for bond wires and associated<br />

pads; reducing the size and cost of<br />

MMIC chips; and incorporation of multiple<br />

functions — transmit, receive, digital control,<br />

digital conversion — on a single MMIC.<br />

Widening and deepening of these tributaries<br />

is an ongoing process within <strong>Raytheon</strong><br />

and involve many disciplines — ranging<br />

from basic physics and materials to circuit<br />

design, packaging, thermal designs and<br />

manufacturing expertise. However, in contrast<br />

to tributaries, elements of MMIC technology<br />

cannot flow independently, but must<br />

be coordinated with a guiding vision aimed<br />

at low-cost and high-performance applications<br />

in <strong>Raytheon</strong> systems. •<br />

Michael G. Adlerstein<br />

<strong>2004</strong> ISSUE 3 13<br />

RF SYSTEMS

EO/LASERS<br />

Seeing the Enemy First:*<br />

The United States Army takes its<br />

armored vehicles’ infrared eyes<br />

to another level*<br />

In the days of Vietnam, the U.S. military<br />

realized the advantage of owning the night<br />

through infrared imaging. Unfortunately,<br />

the cost of ownership in those early years<br />

was extremely high. Each IR system design<br />

was unique so that there could be no<br />

advantage of cost through scale, and logistics<br />

were a nightmare.<br />

However, <strong>Raytheon</strong> and the Army recognized<br />

the value of infrared technology and<br />

together developed a set of building blocks<br />

— called “common modules” — from<br />

which a variety of systems could be constructed.<br />

These modules could be built in<br />

large quantities and at a much lower cost<br />

than previously achievable, and logistics<br />

were greatly simplified.<br />

With government sponsorship and internal<br />

investment, <strong>Raytheon</strong> continued to improve<br />

technology to develop<br />

Figure 1<br />

(in the mid-1990s) a second-generation of<br />

common modules, now called “horizontal<br />

technology integration.” This technology<br />

consisted of system-unique (A-kits) and<br />

common (HTI-B kits) components.<br />

In addition to remarkably high resolution<br />

allowing vehicle commanders<br />

and gunners to see targets as far as<br />

their weapons can shoot, secondgeneration<br />

FLIRs (assembled from<br />

these modules) doubled the effective<br />

range of the target-acquisition sights —<br />

used by the commander and gunner on<br />

the Abrams and Bradley combat systems —<br />

compared to first-generation “commonmodule”<br />

FLIRs.*<br />

<strong>Raytheon</strong> developed and fielded every firstand<br />

second-generation EO/IR sensor for the<br />

U.S. Army’s ground combat systems:<br />

Abrams, Bradley, TOW, Javelin and LRAS3<br />

(see Figure 1). These high-performance,<br />

highly reliable systems were critical to success<br />

in both Gulf Wars and in Afghanistan.<br />

Now, during Operation Iraqi Freedom, our<br />

customers call our systems “Combat<br />

Multipliers” and say “They are the<br />

reason many young men and women have<br />

come home.” The Stryker Brigade’s Mobile<br />

Gun System, Long Range Reconnaissance<br />

vehicle and Anti Tank Guided Missile vehicle,<br />

deployed with the 4ID — Bradley and<br />

Abrams armor and cavalry components —<br />

US Army Illustration<br />

Figure 2. In a dual-band third generation FLIR<br />

image of a hand, the long-wave band the hand is<br />

obscured by a sheet of plastic, top, but the mid-wave<br />

band, bottom, the whole hand is detected. In the<br />

second image, a silicon ball is opaque in the longwave,<br />

top, but acts as a lens in the midwave, bottom.<br />

are all equipped with <strong>Raytheon</strong> high performance<br />

second-generation EO/IR systems.<br />

<strong>Raytheon</strong> is continuing its lead in the EO/IR<br />

sensor arena with the development of thirdgeneration<br />

EO/IR. The Dual Band Focal<br />

Plane Array Manufacturing (DBFM) and the<br />

Multi-Function Staring Sensor Suite (MFS3)<br />

programs are currently under contract with<br />

the Night Vision and Electronic Sensors<br />

Directorate (NVESD).<br />

In addition, the Army is developing thirdgeneration<br />

FLIRs to provide identification<br />

at detection ranges of current systems.<br />

Technological breakthroughs have afforded<br />

much greater resolution and the use of<br />

multiple colors (see Figure 2).<br />

The systems operate in both the mid- and<br />

long-wave infrared spectral bands, which<br />

are the best frequencies for detecting IR<br />

radiation within the atmosphere. The Army<br />

predominantly uses long-wave ISR sensors<br />

because they are better than mid-wave sensors<br />

at seeing through smoke and dust. The<br />

HTI second-generation FLIR operates in the<br />

long-wave (8 to 12 micron) band. Mid-wave<br />

(3 to 5 micron) IR sensors offer higher resolution<br />

for better target identification at long<br />

ranges. A third-generation dual-band FLIR<br />

would offer the benefits of both and provide<br />

a higher probability of recognizing targets<br />

hidden by camouflage or foliage.* •<br />

Alan Silver<br />

asilver@raytheon.com<br />

* From an article by Glenn W. Goodman, Jr. in the<br />

June <strong>2004</strong> ISR Journal.<br />

14 <strong>2004</strong> ISSUE 3 YESTERDAY…TODAY…TOMORROW

High-Performance<br />

Processing<br />

now comes in a tiny<br />

little package<br />

<strong>Raytheon</strong> has been developing and<br />

deploying systems to meet critical U.S.<br />

Government needs for decades. Many of<br />

these systems support stringent timelines<br />

and require extremely high-performance<br />

processing. The underlying technologies<br />

that support these systems have evolved<br />

over the years, and <strong>Raytheon</strong> has adapted<br />

to the changing environment to take<br />

advantage of these technologies.<br />

An example that can illustrate the dramatic<br />

shift in the underlying technology base is a<br />

product line in Intelligence and Information<br />

Systems (IIS) that has been building signal<br />

processing systems since the late ‘60s.<br />

These systems are ground-based and<br />

deployed in standard data center environments.<br />

Because of this, they can easily leverage<br />

emerging commercial technologies.<br />

In the early ‘80s, these systems proposed<br />

using digital signal processing techniques<br />

to achieve significant performance<br />

improvements, but the required processing<br />

was more than anyone had ever deployed.<br />

Back then, more than 16 fully configured<br />

Cray computers would have been required<br />

(see Figure 1). Based upon early IRAD prototypes,<br />

<strong>Raytheon</strong> set out to develop a<br />

cost-effective solution based on custom<br />

hardware designs and Application Specific<br />

Integrated Circuit (ASICs).<br />

Figure 1. First generation processor was a custom<br />

hardware solution employing 24" x 24" boards.<br />

First Generation Processor<br />

Processing 13 GFLOPS RAM 1536 MB<br />

Circuit Cards 227 Power 48 kW<br />

Racks 4 FLOPS in HW 95%<br />

ASIC Types 14 FLOPS in SW 5%<br />

As illustrated in the table above, the performance<br />

may seem trivial compared with<br />

today’s systems, but it was a very challenging<br />

project for its time. It provided critical<br />

strategic information to <strong>Raytheon</strong> customers<br />

and was in operation until 2003.<br />

Figure 2. Second generation processor used COTS<br />

supercomputer technology.<br />

With DoD demanding increased capacity,<br />

Operation Desert Shield and Desert Storm<br />

showed the importance of this system and,<br />

in response to a congressional mandate,<br />

<strong>Raytheon</strong> was asked to double the capacity.<br />

Challenges, as well as opportunities,<br />

began to appear a decade after the first<br />

system was built. Component obsolescence<br />

made rebuilding an identical copy unrealistic,<br />

but Moore’s law had made massively<br />

parallel Commercial Off The Shelf (COTS)<br />

computers feasible. <strong>Raytheon</strong> had been<br />

prototyping algorithms on these machines<br />

and was ready to meet the challenge.<br />

<strong>Raytheon</strong> purchased one of the first Cray<br />

T3Es, similar to the one shown in Figure 2.<br />

A liquid cooled machine housed 160 central<br />

processing units (CPUs), and this allsoftware<br />

version of the system produced<br />

identical output to the hardware system. It<br />

was delivered on schedule and provided<br />

the increased capacity needed to support<br />

the war fighter. It was taken out of operation<br />

last year at the same time the original<br />

system was de-commissioned.<br />

YESTERDAY…TODAY…TOMORROW<br />

What replaced these systems was made<br />

possible by the inevitable march of CPU<br />

technology. Now, 20 years after the<br />

original contract was signed, processing<br />

capacity of a single CPU chip has increased<br />

more than 8,000 times. This means that<br />

a quad-CPU system with a field programmable<br />

gate array (FPGA) accelerated<br />

peripheral component interface (PCI) card<br />

can do the job. Systems, similar to the Sun<br />

V440 (see Figure 3) have been delivered<br />

and continue to be deployed to meet<br />

increasing demands.<br />

Figure 3. Today’s processor uses inexpensive entry<br />

level servers with embedded FPGA cards.<br />

The future promises dramatic performance<br />

increases. Analog Optical Signal Processing<br />

(AOSP), a DARPA program, illustrates one<br />

possibility. Using optical signal processing,<br />

AOSP hopes to provide 2,500 times the<br />

performance of the original system in a<br />

package the size of a VHS cassette.<br />

Again, <strong>Raytheon</strong> continues to explore new<br />

technologies to bring down the cost of<br />

these systems which, in turn, allows an<br />

exponential rise in mission effectiveness<br />

over time. •<br />

Duncan Crawford<br />

Duncan_L_Crawford@raytheon.com<br />

<strong>2004</strong> ISSUE 3 15<br />

PROCESSING

<strong>2004</strong> Technology Strategy<br />

Integration Offsite<br />

From July 12-15, more<br />

than 100 <strong>Raytheon</strong><br />

employees from<br />

six businesses — IDS, IIS, NCS, MS, RTSC<br />

and SAS — gathered at HRL Laboratories,<br />

LLC in Malibu, Calif. for the <strong>2004</strong><br />

Technology Strategy Integration Offsite.<br />

At the annual event, business leaders set<br />

out how to integrate <strong>Raytheon</strong>’s business<br />

strategy technology needs into <strong>Raytheon</strong>’s<br />

global technology strategy. Each business<br />

defines their strategy carefully aligned with<br />

the Strategic Business Areas. Technology<br />

area directors integrate the technology<br />

needs from the businesses into a technology<br />

strategy for investment opportunities to<br />

leverage independent research and development<br />

investment to shape our customers’<br />

technology vision while increasing<br />

contract research and development (CRAD)<br />

bookings. Strategic alliances and make/buy<br />

decisions are realized by leveraging technology<br />

investment across all of <strong>Raytheon</strong>.<br />

“<strong>Raytheon</strong> is a solutions company, and<br />

technology is our foundation,” said Dr.<br />

Peter Pao, vice president of Technology.<br />

“In the technology integration meeting, we<br />

identify the technologies we need to provide<br />

our customers with unparalleled capabilities,<br />

and we establish our technology<br />

acquisition strategy.”<br />

To include the entire portfolio of technologists<br />

across the company, representatives<br />

were on hand from the Advanced Product<br />

Center, <strong>Raytheon</strong> Vision Systems, <strong>Raytheon</strong><br />

RF Components and HRL Laboratories, LLC,<br />

along with the strategic business areas of<br />

Missile Defense, Precision Engagement,<br />

Intelligence, Surveillance & Reconnaissance<br />

and Homeland Security.<br />

Dr. Paul G. Kaminski, <strong>Raytheon</strong> Strategic<br />

Advisory Board member, attended to<br />

provide an independent view of the<br />

<strong>Raytheon</strong> technology strategy<br />

developments.<br />

Technical directors from each business —<br />

Nick Uros, David N. Martin, Kevin Riley, Reo<br />

Yoshitani, and Winthrop Smith and Martt<br />

Harding for IIS technical director Lynwood<br />

Givens — presented their respective business<br />