environment impact evaluation of a new type continuous mixing

environment impact evaluation of a new type continuous mixing

environment impact evaluation of a new type continuous mixing

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

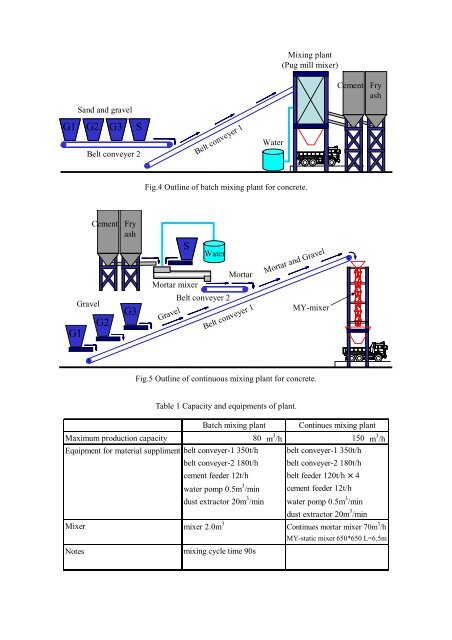

Mixing plant(Pug mill mixer)CementFryashSand and gravelG1 G2 G3 SBelt conveyer 2Belt conveyer 1WaterFig.4 Outline <strong>of</strong> batch <strong>mixing</strong> plant for concrete.CementGravelG2G1FryashG3SMortar mixerGravelWaterMortarBelt conveyer 2Belt conveyer 1Mortar and GravelMY-mixerFig.5 Outline <strong>of</strong> <strong>continuous</strong> <strong>mixing</strong> plant for concrete.Table 1 Capacity and equipments <strong>of</strong> plant.Batch <strong>mixing</strong> plant Continues <strong>mixing</strong> plantMaximum production capacity 80 m 3 /h 150 m 3 /hEquipment for material suppliment belt conveyer-1 350t/h belt conveyer-1 350t/hbelt conveyer-2 180t/h belt conveyer-2 180t/hcement feeder 12t/h belt feeder 120t/h 4water pomp 0.5m 3 /mindust extractor 20m 3 /mincement feeder 12t/hwater pomp 0.5m 3 /mindust extractor 20m 3 /minMixermixer 2.0m 3 Continues mortar mixer 70m 3 /hMY-static mixer 650*650 L=6.5mNotes<strong>mixing</strong> cycle time 90s