Surface Finishing - The Hong Kong Polytechnic University

Surface Finishing - The Hong Kong Polytechnic University

Surface Finishing - The Hong Kong Polytechnic University

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

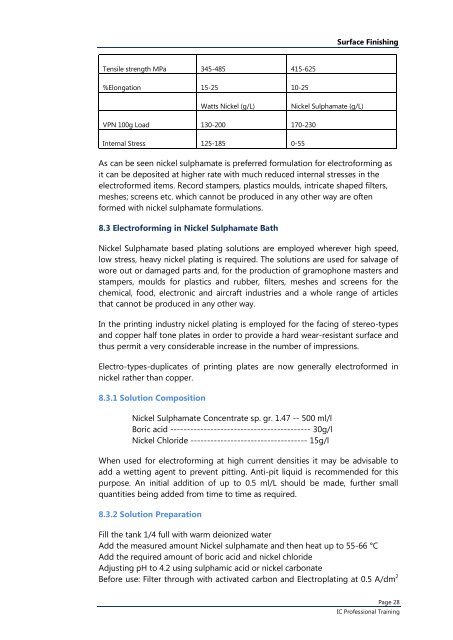

<strong>Surface</strong> <strong>Finishing</strong>Tensile strength MPa 345-485 415-625%Elongation 15-25 10-25Watts Nickel (g/L)Nickel Sulphamate (g/L)VPN 100g Load 130-200 170-230Internal Stress 125-185 0-55As can be seen nickel sulphamate is preferred formulation for electroforming asit can be deposited at higher rate with much reduced internal stresses in theelectroformed items. Record stampers, plastics moulds, intricate shaped filters,meshes; screens etc. which cannot be produced in any other way are oftenformed with nickel sulphamate formulations.8.3 Electroforming in Nickel Sulphamate BathNickel Sulphamate based plating solutions are employed wherever high speed,low stress, heavy nickel plating is required. <strong>The</strong> solutions are used for salvage ofwore out or damaged parts and, for the production of gramophone masters andstampers, moulds for plastics and rubber, filters, meshes and screens for thechemical, food, electronic and aircraft industries and a whole range of articlesthat cannot be produced in any other way.In the printing industry nickel plating is employed for the facing of stereo-typesand copper half tone plates in order to provide a hard wear-resistant surface andthus permit a very considerable increase in the number of impressions.Electro-types-duplicates of printing plates are now generally electroformed innickel rather than copper.8.3.1 Solution CompositionNickel Sulphamate Concentrate sp. gr. 1.47 -- 500 ml/lBoric acid ------------------------------------------ 30g/lNickel Chloride ----------------------------------- 15g/lWhen used for electroforming at high current densities it may be advisable toadd a wetting agent to prevent pitting. Anti-pit liquid is recommended for thispurpose. An initial addition of up to 0.5 ml/L should be made, further smallquantities being added from time to time as required.8.3.2 Solution PreparationFill the tank 1/4 full with warm deionized waterAdd the measured amount Nickel sulphamate and then heat up to 55-66 °CAdd the required amount of boric acid and nickel chlorideAdjusting pH to 4.2 using sulphamic acid or nickel carbonateBefore use: Filter through with activated carbon and Electroplating at 0.5 A/dm 2Page 28IC Professional Training