You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

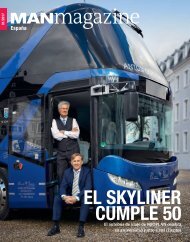

1/<strong>2015</strong><br />

Great Britain<br />

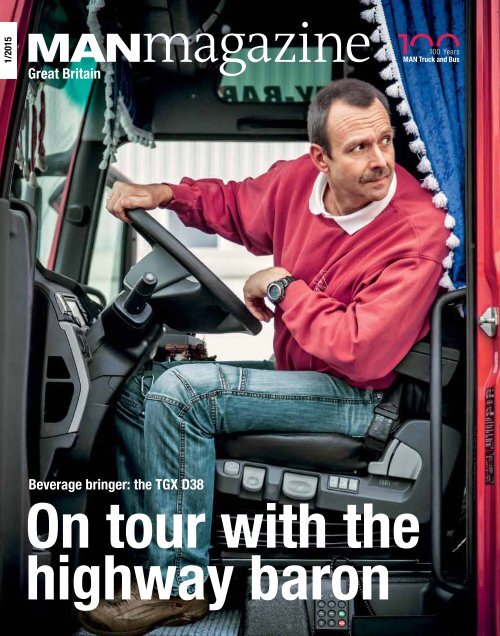

Beverage bringer: the TGX D38<br />

On tour with the<br />

highway baron

man magazine<br />

1/<strong>2015</strong><br />

Explore much<br />

more of<br />

on your tablet.<br />

digitally<br />

Great Britain<br />

for Android<br />

Simply<br />

download the<br />

app for free:<br />

for ios<br />

1/<strong>2015</strong><br />

Great Britain<br />

The best of MAN’s world<br />

Beverage bringer: the TGX D38<br />

On tour with the<br />

highway baron<br />

masthead<br />

MAN magazine is published twice a year<br />

in 16 languages.<br />

published by MAN Corporate Communications<br />

Andreas Lampersbach (V.i.S.d.P.),<br />

Ungererstraße 69, 80805 Munich, Germany<br />

Responsible editor & project manageR<br />

Joachim Kelz, Tel.: +49. 89. 1580-1175,<br />

magazin@man.eu, www.man.eu<br />

EDITORIAL, GREAT BRITAIN Verity Cullum<br />

Publisher C3 Creative Code and Content GmbH,<br />

Heiligegeistkirchplatz 1, 10178 Berlin, Germany<br />

Tel.: +49. 30. 44032-0, www.c3.co,<br />

Shareholders of C3 Creative Code and Content GmbH<br />

are the Burda Gesellschaft mit beschränkter Haftung<br />

(limited liability company), Offenburg, and the KB Holding<br />

GmbH, Berlin, with 50% each. Sole shareholder of<br />

the Burda Gesellschaft mit beschränkter Haftung is the<br />

Hubert Burda Media Holding Kommanditgesellschaft<br />

(limited partnership), Offenburg. Shareholders of<br />

KB Holding GmbH are Mr. Lukas Kircher (managing<br />

director, Berlin) and Mr. Rainer Burkhardt (managing<br />

director, Berlin) with 50% each.<br />

Editors & Authors Klaus-Peter Hilger (resp.),<br />

Yasmine Sailer (dep.). Freelance authors: Tobias Birzer,<br />

Alexandra Grossmann, Dr. Wolfgang Hörner, Martin<br />

Kaluza, Marcus Schick, André Schmidt-Carré<br />

international Editors Patricia Preston<br />

(resp., freelance editor), Asa. C. Tomash<br />

MANAgiNg editor Sara Austen<br />

Concept Stefan Lemle, A New Kind<br />

(freelance contributor)<br />

Graphics Micheline Pollach, Andrea Hüls, Christian<br />

Kühn, Anna-Sophie Werner (freelance contributor)<br />

graphics editor Elke Latinovic,<br />

André Kirsch (freelance contributor)<br />

cover image Christian Grund<br />

productioN C3 Creative Code and Content GmbH<br />

printing Gotteswinter und Aumaier GmbH,<br />

Joseph-Dollinger-Bogen 22, 80807 Munich, Germany<br />

reproduction permitted with reference.<br />

Any changes must be coordinated with the editors.<br />

advertising service Zeitzeichen Vertriebs GmbH,<br />

Radka Neumann, Tel.: +49. 8323. 99 84 630,<br />

radkaneumann@zeitzeichen.de<br />

Copyright ©<strong>2015</strong> MAN and C3 Creative Code and<br />

Content GmbH<br />

04<br />

12<br />

COVER STORY<br />

The MAN TGX D38 proves<br />

its prowess during beverage<br />

transport runs.<br />

06<br />

18 28<br />

content<br />

04 The sandman<br />

Peter Meyer shuttles tourists around<br />

Fraser Island in a converted MAN truck.<br />

06 Ready for the future<br />

The key milestones of MAN’s century-old<br />

tradition in commercial vehicle production<br />

12 Fluid run<br />

One of the first delivered MAN TGX D38<br />

models transports beverages and more.<br />

18 Under ground<br />

Reporting for mine duty, an MAN truck<br />

travels underground in pieces.<br />

24 Update for a better line<br />

During a test run, the MAN TGX<br />

EfficientLine 2 proves its efficiency.<br />

28 On location<br />

News from the british MAN-Market<br />

32 Systematic safety<br />

A wide range of MAN assistance systems<br />

improves the safety of truck traffic.<br />

What are the highlights of MAN’s century-old<br />

experience in commercial vehicle<br />

design and manufacturing? How is the new<br />

TGX D38 received by customers? And how is a<br />

four-axle truck hauled into a deep mine? This<br />

third issue of <strong>MANmagazine</strong> offers answers to<br />

these and other interesting questions. It reflects<br />

the world of MAN: a world shaped by<br />

technology, with fascinating topics drawn<br />

from the realm of trucks and buses.<br />

We hope you enjoy this edition of <strong>MANmagazine</strong>.<br />

You can also download the digital<br />

tablet version for free, which is available on<br />

iOS and Android.<br />

Photo: APPLE INC. Pr<br />

02<br />

03

man magazine<br />

1/<strong>2015</strong><br />

my man<br />

The sandman<br />

Find more images<br />

of Peter Meyer in<br />

action on Fraser<br />

Island in the app.<br />

Peter Meyer, 44, works as a ranger on Fraser<br />

Island. The Australian with German roots uses<br />

an all-wheel truck with a bus body to show visitors<br />

the island, which is made up entirely of<br />

sand, located off Australia’s eastern coast. His<br />

MAN vehicle never navigates a surfaced road.<br />

Is your MAN a serial vehicle? It’s an MAN<br />

driver’s cab saddled by a bus body. The vehicle<br />

has 28 seats and an MAN engine with 280 hp.<br />

We had it converted to an all-wheel drive.<br />

You drive on sand all day. How does that<br />

impact the machine? While operating on soft<br />

sand, you must maintain an extremely high<br />

engine speed, always approaching the red<br />

zone. Sand seeps in through all the cracks,<br />

while salt water, salt-laden air and mud will<br />

destroy any machine in the long run. I have<br />

been here for 20 years and have driven many<br />

different vehicles. Those coming from MAN<br />

are definitely the most enduring!<br />

As a driver, what do you need to watch<br />

out for? If you stop in the wrong place, the<br />

truck is simply going to sink. Just unladen,<br />

these vehicles weigh 13 tonnes – which makes<br />

tyre pressure all the more important! I drive<br />

with a pressure of 2.75 bar, while 7.6 or 7.9 bar<br />

would be standard on asphalt roads. This is<br />

done to enlarge the tyre footprint and thus<br />

float over the sand, rather than digging yourself<br />

into a hole. Quite a few inexperienced<br />

private sightseers come here with their expensive<br />

all-wheel vehicles, believing that they<br />

can drive anywhere. Ultimately, they get<br />

stuck – and I will pull them out again.<br />

Beach buggy: The 280-hp<br />

MAN vehicle never comes<br />

in contact with a tarred road.<br />

Photos: Martin Kaluza<br />

Australian ranger: For two decades,<br />

Peter Meyer has been driving tourists<br />

across the island on behalf of Fraser<br />

Explorer Tours.<br />

Road of sand: The beach serves as<br />

Fraser Island’s motorway – with the<br />

maximum permissible speed being<br />

80 kilometres per hour.<br />

04<br />

05

man magazine<br />

1/<strong>2015</strong><br />

Ready for<br />

the future<br />

1915<br />

Looking back on a history<br />

of more than 250 years,<br />

the MAN Group celebrates<br />

yet another significant<br />

anniversary in <strong>2015</strong>: The<br />

history of commercial<br />

vehicle construction at<br />

MAN began a century ago.<br />

An overview of the most<br />

important milestones.<br />

E<br />

ntered into the trade register of<br />

the City of Nuremberg on 21 June<br />

1915 was a new company, namely<br />

“Lastwagenwerke M.A.N.-Saurer”. The company<br />

had been established as a joint venture<br />

between Maschinenfabrik Augsburg-Nürnberg<br />

AG and Saurer, a Swiss producer of commercial<br />

vehicles. Soon thereafter, the first MAN-<br />

Saurer three-tonne truck left the joint factory<br />

in Lindau, Germany, on Lake Constance, followed<br />

by the first buses used as long-distance<br />

coaches by the Imperial Post Office, and transporting<br />

passengers as well as letters and<br />

parcels. This was the beginning of commercial<br />

vehicle construction at MAN, a success story<br />

that has not only decisively shaped the history<br />

of the company itself. With its advanced and<br />

often revolutionary innovations, MAN has significantly<br />

influenced the development of<br />

trucks and buses for the last 100 years – an endeavour<br />

that continues to this very day.<br />

Production shifted to the MAN plant in<br />

Nuremberg in 1916 and the company traded<br />

as “M.A.N. Lastwagenwerke” following the departure<br />

of Sauer two years later. In 1924, MAN<br />

presented the first truck with a direct dieselinjection<br />

engine – which formed the basis for<br />

the triumphant deployment of diesel engines<br />

in truck construction. It saved up to 75% of<br />

operating costs compared with the gasoline<br />

engines common at the time. Back then,<br />

economy and efficiency were already two<br />

1924<br />

In cooperation with the Saurer company, MAN<br />

builds the first trucks and buses in Lindau in<br />

southern Germany. One year later, production<br />

moves to MAN’s plant in Nuremberg. MAN develops the first vehicle<br />

engine with direct diesel<br />

injection. This launches the<br />

triumphant success story of<br />

diesel engines in trucks –<br />

which continues until today.<br />

1951<br />

The first German truck<br />

engine with exhaust turbocharging<br />

achieves a 35%<br />

performance improvement<br />

over conventional truck<br />

engines: the six-cylinder<br />

engine MAN 1546 GT with<br />

175 hp instead of 130 hp.<br />

1961<br />

With the 750 HO, MAN introduces the first bus with<br />

a modular chassis for city and regional buses as<br />

well as travel coaches to the market.<br />

1897<br />

Together with MAN<br />

engineers, Rudolf<br />

Diesel develops the<br />

first diesel engine.<br />

1932<br />

With 140 hp, the MAN<br />

S1H6 is the world’s most<br />

powerful diesel truck.<br />

A year later, MAN even<br />

markets a truck model<br />

with 150 hp.<br />

Photos: Historical Archive MAN <strong>Truck</strong> & Bus<br />

1951<br />

The MAN truck F8 with its V8<br />

180-hp engine becomes a flagship<br />

of Germany’s emerging “economic<br />

miracle” period.<br />

1955<br />

The production of trucks, buses and<br />

tractors moves from Nuremberg to<br />

the new plant in Munich. The first<br />

truck coming off the production line<br />

is an MAN 515 L1. Engine production<br />

remains in Nuremberg.<br />

06<br />

07

man magazine<br />

1/<strong>2015</strong><br />

essential development targets of MAN, objectives<br />

that still apply today. That same year,<br />

MAN produced the first low-floor bus with a<br />

specially designed low-frame chassis. Until<br />

then, buses previously built by MAN had been<br />

based on a truck chassis.<br />

In 1928, MAN presented its first threeaxle<br />

truck, which became the precursor of all<br />

subsequent heavy-duty trucks made by MAN.<br />

In 1932, the S1H6 truck was equipped with a<br />

D4086 diesel engine that delivered 140 hp –<br />

then considered the most powerful diesel<br />

truck in the world. The next technical milestone<br />

was reached in 1937 with the development<br />

of an extremely fuel-efficient directinjection<br />

diesel engine and the introduction<br />

of the all-wheel drive.<br />

<strong>Truck</strong>s were much in demand during reconstruction<br />

work after World War II. In the<br />

1950s, the MAN F8 with its 180-hp V8 motor<br />

advanced to the flagship of the economic<br />

miracle period experienced by a still-young<br />

Federal Republic of Germany. As early as 1951,<br />

MAN was already demonstrating its level<br />

of innovation when it introduced the first<br />

German truck engine with exhaust gas turbocharging.<br />

The six-cylinder engine achieved<br />

175 hp with an 8.72-litre displacement, a<br />

remarkable performance increase of 35%. In<br />

1955, MAN moved truck and bus production<br />

to its new site in Munich. The Nuremberg<br />

plant evolved into the centre of competence<br />

for engine production.<br />

MAN also repeatedly proved its innovative<br />

powers in bus construction. In 1961,<br />

the company introduced the market to the<br />

750 HO, the first bus in modular design.<br />

Different structure variants were mounted<br />

on a standardised chassis for regular line<br />

service and regional buses, as well as longdistance<br />

travel coaches.<br />

140<br />

horsepower<br />

In 1932, MAN’s S1H6 with its 140-hp<br />

engine was the world’s strongest diesel<br />

truck. Issued one year later was an even<br />

more powerful version with 150 hp.<br />

Photos: Historical Archive MAN <strong>Truck</strong> & Bus<br />

When acquiring Büssing Automobilwerke<br />

and the company’s plant in Salzgitter in 1971,<br />

MAN adopted Büssing’s specialised underfloor<br />

engine technology as well as the specific<br />

Büssing logo for its own corporate identity.<br />

The stylised Brunswick Lion has since decorated<br />

the radiator grille of all commercial<br />

vehicles made by MAN. In the late 1970s, MAN<br />

began a collaboration with VW in the lighttruck<br />

segment, with the G-series’ six- and<br />

eight-tonne trucks jointly produced until<br />

1993. Today, MAN is part of the VW Group.<br />

the show horses of MAN have always<br />

remained the short-hooded trucks for<br />

construction work and heavy-duty forwardcontrolled<br />

trucks for long-distance transport<br />

– including the 19.280 type that was the first<br />

MAN truck to receive the “<strong>Truck</strong> of the Year”<br />

award in 1978. Numerous awards followed,<br />

such as for the MAN F90 introduced in 1986<br />

and recognised as “<strong>Truck</strong> of the Year” the following<br />

year. Especially the generous driver’s<br />

cab of the F90 left a lasting impression. Then<br />

as today, driver ergonomics and comfort have<br />

always been of major concern for MAN designers.<br />

The most successful truck model of<br />

the 1990s was the F2000. The heavy-duty series<br />

already featured standard engines with<br />

electronic injection control back in 1994.<br />

MAN buses also had their milestones. In<br />

1992, MAN presented the Lion’s Star, a travel<br />

coach that would shape the names of all MAN<br />

bus generations to come. With drag coefficient<br />

value of 0.41, the long-distance highdecker<br />

was especially aerodynamic and therefore<br />

fuel-efficient.<br />

New innovations marked the entry into a<br />

new millennium. In 2000, the “<strong>Truck</strong>nology<br />

Generation Type A”, or TGA series, set new<br />

standards in terms of comfort and ergonomics,<br />

as well as new technologies such as the<br />

“The past and<br />

present success of<br />

MAN is defined by<br />

industry expertise,<br />

customer focus and<br />

innovative drive.”<br />

Henning Stibbe, Head of the Historical Archive,<br />

MAN <strong>Truck</strong> & Bus<br />

1977<br />

Start of a collaboration with Volkswagen<br />

Nutzfahrzeuge to develop a light vehicle<br />

range from 6 to 10 tonnes gross weight.<br />

Production of the so-called VW-MAN joint<br />

series begins in 1979.<br />

1986<br />

MAN introduces the F90 series, with a<br />

completely new driver’s cab, to the market.<br />

1992<br />

The travel coach MAN Lion’s Star<br />

enters the market and is named<br />

“Coach of the Year”.<br />

2000<br />

The presentation of the <strong>Truck</strong>nology Generation TGA<br />

is the starting point of a major product campaign.<br />

1971<br />

MAN acquires the ÖAF and<br />

Büssing Automobilwerke.<br />

The Büssing lion is adopted<br />

in MAN’s logo.<br />

1978<br />

MAN receives the “<strong>Truck</strong> of the<br />

Year” award for the first time,<br />

with the 19.280 model.<br />

2001<br />

MAN acquires the brands<br />

NEOPLAN, ERF and Star.<br />

08<br />

09

man magazine<br />

1/<strong>2015</strong><br />

MAN TipMatic or MAN Comfort-Shift for optimised<br />

gear changing. Acquiring the NEOPLAN<br />

brand in 2001 strengthened MAN’s position in<br />

the premium travel-coach segment.<br />

Introducing the D20 engines with common<br />

rail injection in 2004 was a real milestone<br />

in engine technology. MAN was the<br />

first commercial vehicle manufacturer to<br />

convert all its engines to this economical and<br />

environmentally friendly, electronically controlled<br />

injection method. MAN also modernised<br />

the light and medium series by introducing<br />

the TGL and the TGM in 2005. Meeting<br />

Euro 4, the exhaust gas standard at the time,<br />

could be achieved through a combination of<br />

exhaust gas recycling and particle filters<br />

without any additives such as AdBlue. Two<br />

years later, two models were to succeed the<br />

TGA in the heavy-duty series: While the TGX<br />

is designed for long-distance transport, the<br />

TGS operates in the areas of traction and<br />

heavy-duty distribution. Both MAN models<br />

received the “<strong>Truck</strong> of the Year” award for the<br />

seventh time – an industry record.<br />

In 2010, MAN began serial production of a<br />

city bus with a hybrid drive, the Lion’s City<br />

Hybrid. Due to its innovative hybrid drive,<br />

this vehicle saves up to 30% in fuel. The model<br />

quickly became a huge success and received<br />

the ÖkoGlobe Award in 2011 and the Green Bus<br />

Award in 2012 for its sustainable concept.<br />

The development of resource-saving and<br />

environmentally friendly vehicles has<br />

always been one of the main objectives of<br />

MAN <strong>Truck</strong> & Bus. Meeting the latest exhaust<br />

gas standard Euro 6 was a challenge met by<br />

MAN in 2012 with its latest generation of TG<br />

vehicles. These fulfil the strictest requirements<br />

with maximum fuel efficiency. In the<br />

autumn of 2014, MAN introduced the latest<br />

engine generation D38, representing the<br />

“This century-old<br />

success story<br />

wrote the basis<br />

for a future filled<br />

with ideas and an<br />

innovative spirit.”<br />

Dr. Georg Pachta-Reyhofen,<br />

Chief Executive Officer, MAN SE<br />

current culmination of 100 years of engine<br />

development for commercial vehicles. Utilising<br />

a two-stage turbocharger, the frugal Euro<br />

6 diesel engines reach up to 640 hp.<br />

driving factors in today’s product development<br />

include sustainability and corporate<br />

climate goals, as well as policy frameworks<br />

and the limited availability of fossil fuels.<br />

MAN is therefore investigating the advanced<br />

development of various alternative drive concepts.<br />

In future, hybrid drives in commercial<br />

vehicles will be part of the drive concept in all<br />

application areas. Urban buses already use a<br />

serial diesel/electric hybrid drive. As for the<br />

commercial vehicles sector, MAN introduced<br />

the TGX Hybrid at the 2014 IAA exhibit as a<br />

concept vehicle for a TCO-optimised truck hybrid<br />

drive in long-distance transport. An allelectrically-operated<br />

heavy truck with Range<br />

Extender for operating in urban environs, the<br />

Metropolis research vehicle conceptualised<br />

by MAN is currently in its test phase.<br />

Compressed natural gas (CNG) and biogas<br />

are already available as alternatives. Engines<br />

suitable for CNG can also run on biogas in an<br />

almost CO 2 -neutral manner, as exemplified<br />

by the new Lion’s City GL CNG natural gas articulated<br />

vehicle that won the “Bus of the Year<br />

<strong>2015</strong>” award. The established range of natural<br />

gas city buses will be supplemented by trucks<br />

with a CNG drive in 2016.<br />

Future-forecast analysts investigate global<br />

megatrends and define the direction for developing<br />

future vehicle generations. In its predevelopment,<br />

MAN is working on vehicles that<br />

no longer require a driver for certain activities,<br />

such as safety vehicles securing motorway<br />

construction sites. These and other entirely<br />

new ideas will serve MAN <strong>Truck</strong> & Bus in<br />

continuously driving the advancement of<br />

state-of-the-art commercial vehicles in future.<br />

250 years of<br />

MAN history<br />

While MAN has built commercial vehicles for<br />

a century, the historical roots of today’s MAN<br />

Group can be traced back to three starting<br />

points: the founding of the St. Antony ironworks<br />

in Oberhausen in 1758 as well as the<br />

Sandersche Maschinenfabrik in 1840 and<br />

the establishment of the Eisengießerei und<br />

Maschinenfabrik Klett & Comp in Nuremberg<br />

in 1841. In 1878, the St. Antony ironworks<br />

merged with two other ironworks in the Ruhr<br />

area to form the “Gutehoffnungshütte” (GHH),<br />

while the two southern German predecessor<br />

companies merged to form Maschinenfabrik<br />

Augsburg-Nürnberg AG in 1898 – abbreviated<br />

to the name MAN. From 1893 to 1897, Rudolf<br />

Diesel developed the first diesel engine in this<br />

Augsburg factory, which provided the basis<br />

for later engine generations in MAN’s<br />

commercial vehicle construction. In 1921,<br />

MAN and GHH merged to form the company<br />

still existing today, which has been part of<br />

the VW Group since 2011.<br />

2005<br />

2010<br />

The market launch of the TGL<br />

and TGM models in the light- and<br />

medium-weight class from<br />

7.5 to 26 tonnes completes the<br />

MAN <strong>Truck</strong>nology Generation.<br />

The MAN Hybrid<br />

city bus enters<br />

series production.<br />

2014<br />

The new D38 Euro 6 engines are<br />

offered for the MAN TGX series with<br />

520 hp to 640 hp.<br />

2004<br />

Introduction of the D20 Common Rail<br />

engine series offers an entirely new,<br />

electronically controlled injection<br />

technology.<br />

2007<br />

In the heavy-duty truck series, the TGA<br />

develops into the MAN TGS and TGX models.<br />

Both are awarded the “<strong>Truck</strong> of the Year<br />

2008” title by trade journalists.<br />

Photos: Historical Archive MAN <strong>Truck</strong> & Bus<br />

2011<br />

Return of a<br />

legend: The<br />

double-decker<br />

NEOPLAN<br />

Skyliner re-enters<br />

the market.<br />

2012<br />

Premiere: Euro-6 compliant MAN TG vehicles<br />

in the TGL, TGM, TGS and TGX series<br />

<strong>2015</strong><br />

The articulated natural gas Lion’s City<br />

GL CNG is named “Bus of the Year”.<br />

10<br />

11

man magazine<br />

1/<strong>2015</strong><br />

Flagship: With the TGX D38, the beverage<br />

hauler Tiger-Trans has added a new and<br />

efficient powerhouse to its vehicle fleet.<br />

Full speed ahead in<br />

beverage logistics: The<br />

efficient transport of bottles<br />

is heavy-duty work, yet the<br />

TGX D38 meets even<br />

the toughest challenges.<br />

12fluid run<br />

Photos: Christian Grund<br />

13

man magazine<br />

1/<strong>2015</strong><br />

High-tech truck: The new TGX D38<br />

acquired by Tiger-Trans features 560 hp<br />

and highly sophisticated technology.<br />

140 000<br />

kilometres<br />

Wolfgang Müller covers many thousand<br />

kilometres with his truck every year and<br />

frequently under full load. This requires<br />

powerful vehicles such as the TGX D38.<br />

S<br />

haking her feathery pillows vigorously<br />

on this January day, the<br />

fairy tale figure Mother Hulda<br />

probably meant well. Rays of morning sun<br />

sparkle on the snow and the road winds its<br />

way through the distant countryside, akin to a<br />

widely curved strip of asphalt. Bare, knotted<br />

orchard trees form narrow lines, while the<br />

horizon is confined by snow-covered Alpine<br />

peaks reaching for the sky. Wolfgang Müller is<br />

underway in the Lake Constance region and<br />

today covers the distance between Kißlegg<br />

and Meckatz. “This is where other people come<br />

for a holiday,” he observes. The 47-year-old<br />

professional driver transports beverage pallets<br />

to the Meckatz Brewery with his truck of 16.5<br />

metres and 40 tonnes – a job for heavyweights.<br />

Wolfgang Müller has been steering this<br />

brand-new, bright-red TGX D38 for a fortnight,<br />

christening it the “highway baron”. It’s the<br />

flagship of his employer, the beverage logistics<br />

company Tiger-Trans in Neukirch. The<br />

truck is MAN’s latest top model, with Tiger-<br />

Trans being among the first customers to receive<br />

one. “It definitely needed a special<br />

name,” says Müller, “after all, this vehicle of<br />

40 tonnes puts a whacking 560 hp and stateof-the-art<br />

technology on the road.” Performance<br />

and technical sophistication are required<br />

for this job, as the considerable load of<br />

56 beverage pallets finds room on the jumbosized<br />

tractor trailer with dual-level loading.<br />

“This is actually the largest beverage transporter<br />

in its class,” explains Müller. He proudly<br />

reports that driver colleagues repeatedly<br />

ask about his spectacular high-tech rig whenever<br />

he stops at service stations.<br />

“all of our drivers have their own vehicle,”<br />

comments Udo Hunstiger, 46. Together<br />

with his brother Jürgen, he has been managing<br />

the beverage hauler Tiger-Trans since<br />

1989. The company fleet comprises 21 trucks.<br />

In the spring, when beverage demand tends<br />

to experience a seasonal drop, Tiger-Trans<br />

also transports plants from Tuscany and wine<br />

from all over Italy. “In the case of both our<br />

beverage and plant shipments, we practically<br />

Photos: Christian Grund<br />

Powerful: The TGX D38 offers maximum<br />

torque of 2,700 newton metres as fully<br />

available in all gears.<br />

“MAN technology<br />

simplifies life for<br />

us drivers.”<br />

Wolfgang Müller, truck driver with Tiger-Trans<br />

Reliable partner: Wolfgang Müller spends<br />

numerous long hours with his vehicle and<br />

considers the TGX “a brilliant piece of work”.<br />

14<br />

15

man magazine<br />

no time at all,” marvels Müller. “Those MAN<br />

developers have truly created something extraordinary.”<br />

Especially the torque is “nothing<br />

short of brilliant”, he says. “At 70 kilometres<br />

per hour I drive in 12th gear. The machine<br />

pulls anything within a speed range of 900 to<br />

around 1,300 rpm. That’s where cubic capacity<br />

and the two-phase engine turbocharging<br />

make a perceptible difference.” Müller considers<br />

the GPS-controlled EfficientCruise® system<br />

that recognises road topography to generate<br />

a forecasting and intelligent shift strategy<br />

a “great service”. “All it needs is a little nudge,”<br />

he reports. Especially when on the motorway,<br />

he would not want to do without.<br />

On arrival in Meckatz, Müller manoeuvres<br />

his beverage transporter into the delivery hall<br />

beneath the historic brewery building. He<br />

raises the side walls of his huge tractor trailer<br />

as if they were angel wings, with forklifts already<br />

zooming in to rapidly pull the beverage<br />

Full load: The TGX D38 is the most<br />

powerful truck in the Tiger-Trans fleet.<br />

“The drivers and<br />

their vehicles<br />

are our essential<br />

business card.”<br />

Udo Hunstiger, Managing Director of Tiger-Trans<br />

always operate under full loads,” explains<br />

Hunstiger. Especially when crossing the Alps,<br />

powerful traction vehicles such as the TGX<br />

are “a real blessing”, he says.<br />

Udo Hunstiger knows what he is talking<br />

about, as he occasionally takes a seat behind<br />

the wheel himself. “My father always used to<br />

say that you can recognise a company by its<br />

vehicle,” remembers Hunstiger. “Our drivers<br />

and their vehicles are the essential business<br />

card when interacting with our customers.”<br />

Drivers enjoying their trucks and appreciating<br />

their driving experience results in a boost<br />

for motivation and customer satisfaction.<br />

“We effectively are working with precisely<br />

that combination,” concludes Hunstiger.<br />

Wolfgang Müller has been on the road on<br />

behalf of Tiger-Trans for 12 years. Every year,<br />

he covers a distance of around 140,000 kilometres.<br />

Sophisticated automotive technology<br />

“simplifies life for us drivers” – which is noticeable<br />

en route to the Meckatz brewery.<br />

While pulling off on an incline of 9%, the retarder<br />

gently brakes the 40-tonne truck on the<br />

descent, a bend to the right, another to the left<br />

and then all uphill again. “In mountainous<br />

terrain, I merely need two gears, which takes<br />

pallets off the truck. These are replaced by<br />

beer cases and barrels for a beverage wholesaler<br />

on Lake Constance. While the forklift<br />

operators get the job done, Wolfgang Müller<br />

sums up his first handling impressions: “Especially<br />

the efficiency of the TGX D38 was a positive<br />

surprise,” he says. “While my old tractor<br />

rig used an average 37 litres of diesel for 100<br />

kilometres, it’s come down to 30 litres, with as<br />

little as 28.5 litres, depending on the trailer’s<br />

tyre size. That makes quite a difference.”<br />

About 20 minutes later, Wolfgang Müller’s<br />

beverage transporter has been loaded up with<br />

beer. He checks the load status on the cab’s display:<br />

9.3 tonnes on the drive axles, 16 tonnes<br />

on the trailer. All in perfect order. Müller starts<br />

up the engine and turns on the radio. It’s back<br />

onto the country roads. Powerful and surprisingly<br />

quiet, the 40-tonner hums on its way.<br />

Müller takes a deep breath: “What a great day.<br />

For me, there’s no better job than this.”<br />

A video about the TGX D38 at Tiger-Trans is<br />

available on > www.man.eu/discovermantgxd38ontour<br />

In the app: Accompany<br />

Wolfgang Müller’s tour<br />

with his new TGX D38.<br />

Photos: Christian Grund<br />

Redefining regional:<br />

Conti Hybrid<br />

The ever-increasing demands of today’s transport<br />

market require a new level of versatility for commercial<br />

vehicles. With its innovative technical features, the new<br />

Conti Hybrid tire line is equally at home on city streets,<br />

motorways or uneven roads – and offers the highest<br />

mileage and best fuel consumption in its class*.<br />

By driving down your overall costs, the cutting-edge<br />

Conti Hybrid range is redefining regional, mile after<br />

mile after mile.<br />

GENERATION 3.<br />

DRIVEN BY YOUR NEEDS.<br />

* valid for Conti Hybrid 17.5“ and 19.5“<br />

Conti Hybrid<br />

HS3<br />

Conti Hybrid<br />

HD3<br />

Conti Hybrid<br />

HT3<br />

For further information, visit<br />

www.continental-truck-tires.com<br />

16

man magazine<br />

1/<strong>2015</strong><br />

In the depths of the Bernburg mine, salt is extracted far beneath the<br />

ground. This operation requires vehicles that can easily cope with the<br />

challenging terrain – such as the Euro 6 HydroDrive by MAN. Before<br />

it can go into service at the bottom of the pit, however, the truck is<br />

dismantled and transported below in its individual components.<br />

Under<br />

ground<br />

O<br />

nce the iron door slides into<br />

place, a bucking elevator hurtles<br />

down to a depth of 500 metres<br />

below ground, with ears subjected to the same<br />

kind of pressure as experienced in a plane at<br />

altitude. Once arrived down under, the world<br />

has changed entirely: Neon light illuminates<br />

the outer area, an assortment of jeeps awaits.<br />

Traversing the mine in all directions is a labyrinth<br />

of passages and tunnels. While seemingly<br />

an impenetrable tangle of paths, it is indeed<br />

an established road network for the crew that<br />

works here every day. At a balmy 25°C, a refreshing<br />

scent lies in the air: salt. It is a universal<br />

sensation – everything here consists of salt.<br />

Walls and ceilings glitter in places, generally<br />

Photo: Jörg Gläscher<br />

Pit operations: At the<br />

Bernburg salt mine, MAN’s<br />

push-off dumpers are the<br />

service vehicle of choice.<br />

18<br />

19

man magazine<br />

1/<strong>2015</strong><br />

1<br />

white or grey. In areas where other sediments<br />

have accumulated, streaks of rusty red, brown<br />

or even blue shimmer through. The floor is<br />

smooth and hard: To facilitate the employment<br />

of heavy equipment, specific road construction<br />

is implemented by using finely grated<br />

salt and water. Salt is in the air, inhaled and<br />

soon enough even the visitor’s skin will taste<br />

of it. Salt dust covers machinery, tools and vehicles.<br />

“Due to the low humidity in here, salt<br />

does no harm,” says Volker Grzeschuchna.<br />

“Yet if you brought this jeep back up to the<br />

surface, it would immediately start rusting<br />

and fall apart in a couple of days.”<br />

Grzeschuchna heads M+E Underground<br />

Technology at the European Salt Company<br />

(Esco) in Bernburg an der Saale. The East<br />

German mine has been sourced for salt since<br />

1912 and covers about 25 square kilometres.<br />

Grzeschuchna is below ground every day to<br />

ensure smooth operations. His responsibilities<br />

cover not only all electrical equipment,<br />

cables, power supply, lighting and the conveyor<br />

belts, but also the vehicle fleet with its massively<br />

heavy mining machinery and the fouraxle<br />

unloading tippers and three-axle roll-off<br />

skip loaders supplied by MAN that were<br />

hauled down to the tunnel in piece parts.<br />

“Moving the new vehicles down here was<br />

a real adventure,” recalls Uwe Müller, Works<br />

Manager at Gress + Zapp Bernburg. The com-<br />

2<br />

“It’s much more costefficient<br />

for us to convert<br />

MAN vehicles.”<br />

Volker Grzeschuchna, Head of M+E Technology at Esco<br />

The truck’s journey into the<br />

depths: 1 Dismantling: The<br />

vehicle is taken apart above<br />

ground. 2 On the hook:<br />

descent to the mine through<br />

a narrow shaft. 3 Full focus:<br />

A staff member manoeuvres<br />

the trucks parts via a joystick.<br />

4 Arrival: The individual parts<br />

are received at the bottom of<br />

the mine.<br />

Photos: Jörg Gläscher<br />

Precision manoeuvre: When<br />

lowering the four-axle chassis,<br />

every centimetre counts.<br />

4<br />

400<br />

kilograms<br />

MAN’s HydroDrive system offers more<br />

traction in off-road conditions. In<br />

addition, trucks with HydroDrive are 400<br />

kilos lighter and lower than conventional<br />

all-wheel vehicles and therefore ideally<br />

suited for work underground.<br />

3<br />

pany is one of MAN’s service partners and<br />

specialised in the transport and maintenance<br />

of trucks underground. “We had to dismantle<br />

the truck, get the individual parts down<br />

below and then reassemble them.” Three<br />

mechanics worked for a week to take the vehicle<br />

apart. “Stowing the parts in boxes and lowering<br />

them down on a hook was not really an<br />

issue,” says Müller, “yet the driver’s cab, the<br />

body structure and especially the three-axle<br />

chassis proved a much bigger challenge. It’s<br />

more than eight metres long, with a width<br />

just a few centimetres less than the diameter<br />

of the transport shaft. That took us three attempts.”<br />

Once below, the vehicle was reassembled<br />

during the course of two weeks until<br />

ready for its first mission. Müller remains unperturbed<br />

by the fact that the truck delivery<br />

was not exactly an easy exercise – and Esco<br />

has ordered four more dump loaders and one<br />

skip load vehicle from MAN: “It’s much more<br />

cost-effective for us to convert MAN dumpers<br />

than to purchase special mining equipment,”<br />

says Grzeschuchna. The vehicles are optimally<br />

equipped for tackling subterranean assignments.<br />

“Those drivers’ cabs come with an automatic<br />

fire-extinguishing system and a filtered<br />

ventilation system, for example,” says<br />

Thomas Triller, Sales Manager at MAN. The<br />

ceiling heights in the tunnels, explains Triller,<br />

are rarely a problem, but sometimes still a<br />

rather tight fit: “With its operating height of<br />

3.35 metres, the vehicle can cope with the required<br />

ceiling heights.”<br />

To safely steer their machinery, the drivers<br />

receive specific instruction lessons by<br />

Heinrich Degenhart. “We first work through<br />

the theoretical part before going down the<br />

mine,” says the ProfiDrive trainer. Below<br />

ground, standard driving techniques are<br />

practised, including those for dump load<br />

trucks, explains the expert. One of the challenges:<br />

“We are navigating tunnels where the<br />

terrain becomes rather slick and slippery. In<br />

some places, the salt has been compacted into<br />

a surface as smooth as glass.” After one day of<br />

20<br />

21

man magazine<br />

Pit vehicle: The MAN roll-off<br />

dumper truck with HydroDrive<br />

is a reliable team member in the<br />

Bernburg salt mine.<br />

T ECHNOLOGY<br />

Ready to roll: It takes two weeks to<br />

reassemble the truck at the bottom of<br />

the pit before it can go into service.<br />

DRIVE AND<br />

REST TIME<br />

60% LESS<br />

INFRINGEMENTS<br />

C<br />

extracted for salt. The truck therefore carries<br />

M<br />

a load of construction backfill materials to<br />

Y<br />

the upper edge of the pit and pushes it down<br />

CM<br />

– and repeats this action until the cavity is<br />

filled. As there is no overhead clearance for<br />

MY<br />

tipping, the mixture is pushed off the vehi-<br />

CY<br />

cle. “The process resembles a sort of press,”<br />

CMY<br />

says Triller. “There is a prop under hydraulic<br />

K<br />

“MAN’s Hydro-Drive<br />

improves driving<br />

safety on any unsurfaced<br />

terrain.”<br />

Thomas Triller, Sales Manager at MAN<br />

training, the men are qualified to operate the<br />

vehicles. When ordering its roll-off skip loaders,<br />

Esco specifically chose vehicles with<br />

HydroDrive, as additional traction at the<br />

front axle is an option when needed. “This<br />

means improved driving safety on unsurfaced<br />

terrain often found underground,” explains<br />

Triller. In addition, the HydroDrive<br />

truck is lower than a conventional all-wheel<br />

vehicle – a considerable advantage and safety<br />

factor in the narrow tunnels down under. And<br />

with its weight reduced by up to 400 kilos, it<br />

also consumes less fuel. In mine operations,<br />

the HydroDrive roll-off skip loaders are responsible<br />

for safety-related tasks, such as the<br />

pressure inside the loader walls, which pushes<br />

the material out the back of the vehicle as<br />

if on a rail.”<br />

Down below now, a gigantic wheel loader<br />

rolls up and drives its shovel blades under<br />

lumps of salt taller than a human figure. The<br />

pit resembles a cathedral: 30 metres high,<br />

with glittering walls reflecting the visible sediment<br />

deposits that are 250 million years old.<br />

Lumbering and groaning, the wheeler rolls<br />

away and tips the salt blocks into the gorge of<br />

a shredder, where the saline substance is broken<br />

down and deposited on a conveyor belt. It<br />

will eventually find its way up, above the surface<br />

and into the light of day, to find use as<br />

gritting or table salt.<br />

CHOOSE THE MAN STANDARD TACHOGRAPH<br />

CHOOSE THE SE5000 EXAKT DUO<br />

The SE5000 Exakt ‘One Minute Rule’ tachograph now comes with Duo<br />

Developed in consultation with drivers, new Duo technology is a decision support tool that gives real-time updates on driving<br />

and rest time – removing all the hassle and confusion away from drivers. This free of charge tool helps them optimise their<br />

time on the road and adapt to any changes in their journey, as well as helping them to stay legal, avoiding costly fines*. Duo<br />

Technology has been shown to reduce infringements by an average of 60%**, making the SE5000 Exakt Duo the tachograph<br />

for a better, more efficient fleet.<br />

Watch the spectacular<br />

truck transport below<br />

the ground in the app.<br />

transport of spare parts and explosives. Other<br />

customers also appreciate the advantages offered<br />

by the MAN HydroDrive: 11,000 vehicles<br />

have been sold since 2005.<br />

The four-axle dump loader, on the other<br />

hand, is assigned to fill in the pits no longer<br />

Grzeschuchna is satisfied. Business is<br />

going well, further acquisitions are in the<br />

pipeline. “The MAN dump loader has performed<br />

well in the test phase. We’ll probably<br />

be ordering more vehicles before the end of<br />

this year.”<br />

Photos: Jörg Gläscher<br />

Get the SE5000 Exakt Duo now at your nearest MAN dealer or for more information<br />

†<br />

and for the chance<br />

to win an iPad mini go to www.SE5000.com/MAN<br />

22<br />

*Provides a guide according to 561/2006.<br />

** By implementing unique screens in the latest SE5000 to provide extra information to drivers, infringements in a sample of real data taken from 108 drivers, examined over<br />

180 days using any digital tachograph prior to April 2012 for 90 days, followed by an SE5000 Rev 7.4 or 7.5 for 90 days, showed 60% reduction in actual infringements.

man magazine<br />

1/<strong>2015</strong><br />

update<br />

Hanover<br />

for a<br />

better<br />

In terms of efficiency, MAN set a new<br />

milestone in long-distance transport<br />

with the TGX EfficientLine 2. Taking<br />

it on a comparative test drive across<br />

Europe with the predecessor model<br />

strongly proved the point.<br />

Irún<br />

Orléans<br />

Nîmes<br />

Munich<br />

Piacenza<br />

Valencia<br />

line<br />

Santa<br />

Elena<br />

J<br />

ourneying from Munich up to<br />

Hanover, yet not on a direct route<br />

but rather via Austria, Italy, France,<br />

Spain and Belgium: This test drive of 5,271 kilometres<br />

was designed to prove the efficiency of<br />

the new MAN TGX EfficientLine 2. After eight<br />

days and having scaled 31,075 elevation metres,<br />

it became evident that the test drive had been<br />

a complete success. Just in time for the new<br />

model presentation at the <strong>2015</strong> IAA Commercial<br />

Vehicles trade fair last autumn, MAN sent<br />

the new TGX and its predecessor, the Efficient<br />

Line 1, on a comparative test run across Europe.<br />

“While the EfficientLine of the first generation<br />

is already a very economical vehicle, the new<br />

model saves another significantly increased<br />

amount of fuel,” sums up MAN ProfiDrive<br />

trainer Willibald Pfeffer, who sat behind the<br />

wheel of the new truck. An expert from<br />

Germany’s technical control association TÜV<br />

Süd supervised the trip from an escort vehicle.<br />

Despite challenging topographics – with 46%<br />

of the distance being uphill – the technical inspection<br />

expert registered a frugal average<br />

The app contains<br />

a video of the<br />

comparative test<br />

drive across Europe.<br />

From experts for pros<br />

MAN ProfiDrive trainers instruct truck and<br />

coach drivers how to operate their vehicles<br />

in an optimised fashion. Besides advanced<br />

theoretical training, test drive centres in<br />

25 countries also offer practical and<br />

hands-on training sessions, with the goal<br />

of making daily driving routines even safer<br />

and more economical. Each year, about<br />

4,000 truck and coach drivers attend the<br />

MAN ProfiDrive training courses.<br />

Photo: MAN<br />

Changes in altitude: 46% of the chosen<br />

route was uphill to thoroughly test<br />

the GPS EfficientCruise control system.<br />

24<br />

25

man magazine<br />

1/<strong>2015</strong><br />

Touring Europe: The test drive<br />

covered five countries.<br />

suitable pace within the range of a speed<br />

preference selected by the driver a well as an<br />

adjustable, four-stage speed tolerance. “The<br />

cruise control system accelerates sooner<br />

than the driver would and likewise also cuts<br />

back at an earlier stage,” reports Pfeffer. “The<br />

technology gets it right, however: The truck<br />

took every hilltop at precisely the preset<br />

speed, and the system is very easy to operate.<br />

It’s certainly impressive.”<br />

In addition, the MAN engineers designed<br />

the system to prevent any unpleasant cogging<br />

of the truck when drawing off the accelerator.<br />

“The vehicle steps off the gas just as any qualified<br />

good driver would do,” states Pfeffer. To<br />

further reduce diesel consumption, the<br />

engine has an extra torque of 200 newton metres<br />

in the upper gears, which keeps revolu-<br />

tions low and maximises economy. Due to<br />

higher pulling power, the driver can remain in<br />

the higher gear range longer, thus reducing<br />

shift-ins and the resulting temporary traction<br />

losses, such as on moderate motorway ascents.<br />

“Ultimately, it’s the overall tally of innovations<br />

that leads to an improved fuel economy<br />

over the predecessor model,” says Pfeffer.<br />

Incidentally, slipstreaming did not play a<br />

role on the test drive. To not skew the comparative<br />

study results, the two TGX trucks<br />

always rolled with about 45 minutes between<br />

them. Still, both reached their destination at<br />

the IAA Commercial Vehicles trade fair in<br />

Hanover just in time.<br />

See the fuel efficiency champion in the interactive<br />

web special > www.man.eu/efficientline2<br />

“The vehicle steps<br />

off the gas just<br />

as any qualified<br />

driver would do.”<br />

Willibald Pfeffer, MAN ProfiDrive trainer<br />

Hand in hand: The driver selects the<br />

speed parameters, the Efficient-<br />

Cruise calculates the best speed to<br />

optimise consumption.<br />

Fuel savings: Despite topographically challenging conditions,<br />

the TGX EfficientLine 2 consumed merely 30.17 litres of diesel<br />

per 100 kilometres.<br />

6.57 %<br />

fuel savings<br />

The technical standards agency TÜV<br />

Süd documented and escorted the test<br />

drive of both EfficientLine models.<br />

The new truck proved even more<br />

economical in fuel consumption than<br />

the previous vehicle generation.<br />

consumption of 30.17 litres of diesel per 100<br />

kilometres for the new EfficientLine 2 –<br />

around two litres less than the comparison vehicle<br />

with the identical weight.<br />

The test convoy with two trucks and an<br />

escort vehicle each had set out from the MAN<br />

<strong>Truck</strong> Forum in Munich, heading south for<br />

the Brenner Pass. Moving past Piacenza in<br />

northern Italy and the French Côte d’Azur,<br />

the tour continued in a total of eight stages to<br />

Andalusia, across the mountain ranges of the<br />

Sierra Nevada, through France and Belgium,<br />

and finally to Hanover. “We deliberately<br />

picked a route with large altitude differences,”<br />

says Pfeffer. After all, the new GPS-based<br />

cruise control was to prove its capabilities:<br />

The system detects the topography of the<br />

road ahead with any inclines or descents, initiates<br />

consumption-optimised speed adjustments,<br />

and appropriately suppresses shift-ins<br />

of the MAN Tipmatic during uphill gradients.<br />

Due to GPS signal utilization, position<br />

and direction of the truck are determined on<br />

documented material with areal terrain data<br />

for ascents and declines. This factors in<br />

impact variables such as current load and<br />

engine revolutions, thereby calculating a<br />

Photos: proxenos.de(2), MAN<br />

Professionals at the wheel: MAN<br />

ProfiDrive trainers take a seat in the<br />

driver cabs of the test trucks.<br />

26<br />

27

man magazine<br />

1/<strong>2015</strong><br />

Traditional outing for all road haulage<br />

industry friends: In early May,<br />

<strong>Truck</strong>fest provides entertainment for<br />

engine power fans and families alike.<br />

Elegantly efficient<br />

transport solution<br />

The customised TGM carrier is a<br />

highlight in terms of both capacity<br />

and appearance.<br />

A leading machinery business was more<br />

than just satisfied with the efforts of MAN<br />

<strong>Truck</strong> & Bus <strong>UK</strong> to prepare for a crucial road<br />

show. Based in Crick, Northampton, Hako Machines<br />

Ltd approached MAN to solve a logisti-<br />

Playful<br />

Platform<br />

cal problem: Having recently launched the<br />

new Citymaster 1600 road sweeper – which<br />

weighs in at a hefty 3 tonnes – Hako Machines<br />

required a vehicle with the capacity to transport<br />

two of these machines for a product demonstration<br />

tour.<br />

Paul Allen, Demonstration Manager at<br />

Hako Machines Ltd, speaks enthusiastically<br />

about the MAN TGM 18.290 truck solution as it<br />

was presented by MAN <strong>Truck</strong> & Bus <strong>UK</strong>: “We<br />

were delighted to have taken delivery of this<br />

brand new custom-made vehicle. In order to<br />

launch and present some extraordinary new<br />

machinery, we needed a truck just like this to<br />

transport our product all across the country<br />

for the road show.” In terms of the technical<br />

challenge, Allen explains that “although our<br />

previous truck had a beavertail ramp, we<br />

encountered problems getting some of our<br />

heavier machinery in and out. So I approached<br />

MAN <strong>Truck</strong> & Bus Northampton to see what<br />

they could do for us.”<br />

Scott Munton, Sales Executive at MAN<br />

<strong>Truck</strong> & Bus <strong>UK</strong>, enlisted the help of tail lift<br />

manufacturer Dhollandia, as well as Kurt<br />

Hobbs Coachworks Ltd, to create the perfect<br />

truck for Hako Machines. “We had a cantilever<br />

full-closure tail lift incorporated in the vehicle.<br />

Although it was capable of lifting up to 6<br />

tonnes, it also needed to be large enough to<br />

cope with the sheer size of the utility machine,<br />

so we secured additional aluminium flip-over<br />

extensions to the truck.” This solution worked<br />

perfectly. “We finished the MAN TGM with<br />

beautiful Alcoa wheels and striking silver<br />

paintwork with colour coding to the arches<br />

and bumpers. As the vehicle was for the sales<br />

demonstration unit, we felt that the appearance<br />

was also important.”<br />

Hako Machines Ltd finalised a three-year<br />

contract hire with a full repair and maintenance<br />

package through MAN Financial Services,<br />

including telematics and a forward-facing<br />

camera. “The truck is just clocking up the miles<br />

and due to the vehicle's sheer workload, we decided<br />

it needed coverage,” says Hako's Paul<br />

Allen. “The Gold repair and maintenance package<br />

was the right option for us.” Allen also<br />

praises the customer support experience: “The<br />

services we received were excellent. MAN listened<br />

to our problem and came up with a quick<br />

and efficient solution in no time. This TGM is<br />

just what we needed – we would definitely go<br />

back to MAN <strong>Truck</strong> & Bus Northampton.”<br />

Returning to <strong>Truck</strong>fest<br />

Peterborough in <strong>2015</strong>, MAN<br />

<strong>Truck</strong> & Bus <strong>UK</strong> surprised<br />

its visitors with numerous<br />

sporting challenges.<br />

Pitting their skills against threetime<br />

British champion and current<br />

titleholder Mat Summerfield,<br />

would-be truck racers put their<br />

driving to the test on a Brands Hatch circuit in<br />

a MAN D38 cab. “MAN <strong>Truck</strong>ers World” hosted<br />

a race simulator where up to nine people<br />

raced live, head-to-head and against the track<br />

time set by the pro driver. Keith Sims, operations<br />

director for MAN dealers HRVS Group<br />

Ltd, a main sponsor to Summerfield <strong>Truck</strong>sport,<br />

joked that “it was great for Mat to take<br />

on some ‘proper’ drivers“. In the self-contained<br />

Performance Zone for racers, each ergonomic<br />

simulator featured a monitor for the<br />

D38’s cockpit view of the circuit. Best times<br />

were shown on a leader board and winners<br />

were invited back to claim their prize. Mat<br />

Summerfield attended the two-day event with<br />

his race truck for the <strong>2015</strong> season: a MAN TGX<br />

fitted with a 1,200-hp race engine and the very<br />

latest Canbus driver information system.<br />

Champion darts player and winner of eight<br />

major titles James Wade – who is sponsored by<br />

MAN <strong>Truck</strong> and Bus <strong>UK</strong> – took on all comers for<br />

a nine-dart challenge on the second event day.<br />

In addition to these celebrity appearances,<br />

MAN <strong>Truck</strong> & Bus <strong>UK</strong> displayed a range of topof-the-range<br />

TGXs, 8x4s and rigid vehicles at<br />

the popular and fun bank holiday event.<br />

<strong>Truck</strong> driver crisis as<br />

youngsters shun industry<br />

MAN <strong>Truck</strong> & Bus research reveals the<br />

image issues of logistics and transport.<br />

According to a study conducted for the<br />

leading truck manufacturer MAN, the <strong>UK</strong>’s<br />

freight haulage industry is facing the biggest<br />

crisis in its history as it fails to attract young<br />

people to the sector. Fears are growing that a<br />

mere shortage of truck drivers will turn into<br />

a massive void as the majority of them heads<br />

for retirement while school-leavers turn their<br />

backs on the profession. Simon Elliott, Managing<br />

Director of MAN <strong>Truck</strong> & Bus <strong>UK</strong>, emphasises<br />

that the national industry must<br />

work closely with the <strong>UK</strong> Government to find<br />

solutions that not only shake up Heavy<br />

Goods Vehicle (HGV) training, but also tackle<br />

the poor image the industry has amongst<br />

school-leavers.<br />

Simon Elliott, Managing Director of MAN<br />

<strong>Truck</strong> & Bus <strong>UK</strong>, encourages young people<br />

to take a closer look at his industry.<br />

28<br />

29

man magazine<br />

1/<strong>2015</strong><br />

60 %<br />

of drivers are 45+<br />

As HGV-certified drivers enter retirement<br />

age, there is a massive shortage of<br />

younger freight professionals to replace<br />

them.<br />

MAN commissioned research that<br />

surveyed 1,000 young people aged 16 to<br />

30 looking at career choices at an early<br />

age. Of the 1,000 candidates, only 3.4%<br />

were advised to follow a career in road<br />

transport and logistics, while the majority<br />

were pointed in the direction of careers<br />

in media, retail, and professional<br />

services such as law and accountancy.<br />

In its recent budget, the <strong>UK</strong> government<br />

vowed to work with freight firms to<br />

find an industry-led solution to the<br />

shortage, including possible funding for<br />

support and training. Elliott acknowledges<br />

that “becoming a HGV 1 driver is not<br />

cheap. It can cost thousands of pounds<br />

which acts as a major barrier to young<br />

people interested in becoming truck<br />

drivers.” When asked if a careers advisor<br />

had ever suggested driving a truck for a<br />

living, 88% replied no, while 25% of those<br />

questioned said they would indeed consider<br />

it as a career option. The truck and<br />

bus manufacturer MAN had commissioned<br />

its study to explore what young<br />

people think about the industry at a time<br />

MAN supports initiatives to strengthen the<br />

appeal of transport and logistics careers.<br />

of rapid expansion due to the explosion<br />

of online shopping. Elliott comments<br />

that “the Freight Transport Association<br />

has predicted a shortfall of 45,000 to<br />

60,000 truck drivers. We wanted to know<br />

why and our findings not only make for<br />

interesting reading but look at the advice<br />

given to young people from an early age.”<br />

The MAN executive adds that the shortage<br />

coincides, of all things, with a time of<br />

rapid freight transport growth. “Our research<br />

showed that 93% of women and<br />

86% of men shop online. This trend is not<br />

going to abate, so how will these items be<br />

delivered in the future? We asked our<br />

panel what their delivery expectations<br />

were for online purchases and 80% said<br />

they expected delivery within 48 hours<br />

of ordering. I think we’ve got some work<br />

ahead of us to meet these expectations in<br />

the future!”<br />

MAN’s research also underlines a<br />

warning issued in <strong>2015</strong> by the All-Party<br />

Parliamentary Group for Integrated<br />

Transport Strategy. The “Barriers to Youth<br />

Employment in the Freight Transport<br />

Sector” report claims there are entrenched<br />

obstacles to attracting people<br />

aged 16 to 24 to the logistics industry. The<br />

report revealed that just 2% of all HGV<br />

drivers are under the age of 25, while 60%<br />

are older than 45.<br />

Off the docks for delivery: MAN vehicles<br />

distribute and transport a wide range of goods.<br />

More MAN power for<br />

transport expert<br />

DJB Haulage experienced a power boost<br />

from its new fleet of MAN TGX 26.480 6x2 tractor<br />

units. A member of the ADMP Group that<br />

includes Willmotts Transport, based in Somerset,<br />

the company chose the increased power of<br />

the TGX 480 backed by an excellent package<br />

through MAN Finance to renew its fleet.<br />

Group Transport Director Andy Tuck explained:<br />

“We have been running some Euro 5<br />

trucks on ’12 plates and as the time for their renewal<br />

came along we chose the TGX models ,<br />

with the last three being Euro 6-compliant.<br />

The drivers are very happy with them – especially<br />

as we have upgraded from the 440-hp to<br />

the 480-hp units, which are pulling heavy<br />

loads. The higher torque gives them lots of<br />

power, whether they are moving 30-tonne containers<br />

in Southampton or china clay or scrap<br />

over here in Somerset.” Tuck also mentions his<br />

company’s long history with MAN, with 18 vehicles<br />

operating in Southampton and 12 tractors<br />

in Somerset. The contracts with MAN<br />

Finance, the repair and maintenance, and the<br />

latest Microlise <strong>Truck</strong>nology telematics all<br />

made MAN an attractive choice once more.<br />

Roy Osborne, Sales Territory Manager for<br />

MAN, added: “We are glad to have offered<br />

such an attractive deal and to maintain our<br />

long-standing relationship with DJB. It is good<br />

to hear that the drivers are pleased with the<br />

extra torque, and I am sure they will also enjoy<br />

the comfort of their TGX BMS XXL cabs.”<br />

For the DJB haulage provider, MAN Finance<br />

services and telematics certainly add up to an<br />

appealing and competitive MAN solution.<br />

Booming business and<br />

brand loyalty<br />

A civil engineering giant turned to MAN<br />

<strong>Truck</strong> & Bus <strong>UK</strong> to satisfy its demand for fleet<br />

expansion. M J Church, a leading civil engineering,<br />

earthworks and waste management<br />

contractor based in Chippenham, took delivery<br />

of six TGS 8x4 rigid tippers and one hook<br />

loader to help meet growing customer orders.<br />

The vehicles were purchased from the MAN<br />

<strong>Truck</strong>s To Go programme, which cuts lead<br />

times on new trucks.<br />

Director Tom Church explains that “while<br />

we already have a long-standing relationship<br />

with MAN, the availability of these trucks was<br />

a major factor in our ordering. They were in<br />

production and ready to go as soon as we<br />

needed them. That was necessary, since we<br />

didn’t have a long lead time.” Church adds:<br />

“We were looking to replace some units of our<br />

fleet, but this order became an expansion due<br />

to our sheer work volume.” MAN sales executive<br />

Mike Bull says that “M J Church is a real<br />

ambassador for the MAN brand. They are loyal<br />

SRC Aggregates chose MAN vehicles<br />

to expand its mixer fleet in the future.<br />

and repeatedly have purchased our products.”<br />

Tom Church remembers that “our former<br />

transport manager Dave Bell, who sadly<br />

passed away in November 2014, was always<br />

keen on MAN, which is why we know the<br />

brand well. We have tested a range of Euro 6<br />

units – and it had to be MAN once more. Fuel<br />

efficiency and Ad Blue usage are impressive.”<br />

The feedback of drivers also counts: According<br />

to Church, they are all happy with the MAN<br />

vehicles, praising sturdiness and reliability.<br />

“We currently have a number of major civil<br />

engineering projects, including work at RAF<br />

Lyneham and a big contract working on the<br />

M3 motorway, so these vehicles will all be<br />

rolled out and put to immediate use.”<br />

Construction power from MAN<br />

Specialising in the construction of agricultural<br />

reservoirs, a thriving aggregates<br />

firm has invested £260,000 in MAN vehicles<br />

to support its expanding business. Essexbased<br />

SRC Aggregates launched a new readymix<br />

concrete plant in December 2014 and<br />

purchased two new MAN 6x4 mixers and an<br />

MAN TGS 32.360 8x4 mixer chassis fitted with<br />

a Hymix P8000 mixer body for use at the<br />

opening. MAN won the contract due to its efficient<br />

lead times and the relationship the<br />

firm developed with sales manager Mark<br />

Richmond at the Essex-based MAN dealer.<br />

SRC Aggregate’s transport manager, Clint<br />

Layzell, said: “We have recently expanded our<br />

business to include ready-mixed concrete,<br />

“We tested a range<br />

of Euro 6 units –<br />

and it had to be<br />

MAN once more.”<br />

Tom Church, Director M J Church<br />

The civil engineering<br />

company M J Church<br />

purchased MAN units<br />

to meet growing<br />

customer demand.<br />

and MAN was the obvious choice for us as the<br />

lead times on the vehicles we required were<br />

efficient and the terms of service were excellent.”<br />

The first two mixers are fitted with<br />

Utranazz bodies. Layzell added: “In the interest<br />

of speed we have worked with the MAN<br />

dealer in Witham and opted to go with the<br />

Hymix body for the third one. The service we<br />

received was second to none.” SRC Aggregates<br />

already operates a fleet of 41 tippers, trucks<br />

and grabs. According to Lyzell, SRC had been<br />

so impressed with the MAN vehicles so far<br />

that the company decided to use them for its<br />

mixer fleet: “With the successful launch of<br />

our ready-mix concrete, we will definitely expand<br />

our fleet of mixers over the next year.”<br />

30<br />

31

man magazine<br />

1/<strong>2015</strong><br />

Systematic safety<br />

ACC<br />

Adaptive Cruise Control<br />

(ACC) monitors and<br />

continuously maintains the<br />

distance to other vehicles.<br />

EBA<br />

Should the driver fail to<br />

recognise a hazardous<br />

situation in due time,<br />

the Emergency Braking<br />

Assistant (EBA) automatically<br />

initiates an emergency<br />

braking process.<br />

Human beings behind the wheel are the<br />

most important safety factor in road traffic.<br />

MAN supports the work of drivers with a wide<br />

range of innovative assistance systems.<br />

LGS<br />

The Lane Guard Assistant<br />

(LGS) monitors the road<br />

markings and issues a<br />

warning to the driver<br />

when crossing without<br />

indicating.<br />

esp<br />

The Electronic Stability<br />

Programme (ESP)<br />

intervenes as soon as<br />

the vehicle threatens to<br />

skid and applies the<br />

brakes to individual<br />

wheels as needed.<br />

Illustration: www.how2.expert<br />

L<br />

arger than anything else on the<br />

road, trucks and buses are fascinating<br />

high-tech machines. While<br />

their massive sizes alone award them a special<br />

status, it also moves the operators of trucks<br />

and buses into the spotlight in terms of safety<br />

and responsibility. MAN, however, does not<br />

leave drivers to their own devices, but rather<br />

offers them support through a range of intelligent<br />

assistance systems. In addition to the<br />

passive safety features of all MAN vehicles,<br />

these systems relieve drivers in both daily<br />

driving routines as well as critical situations,<br />

and help to avoid or at least reduce risks.<br />

Many innovations celebrated in the past<br />

as safety milestones have since become standard<br />

– including the Anti-Blocking System<br />

(ABS) and Traction Control System (TCS).<br />

Among more recent additions, the Electronic<br />

Stability Programme (ESP) is the most widely<br />

known. As soon as a vehicle threatens to start<br />

skidding, ESP immediately intervenes – and<br />

much faster than even an experienced truck<br />

or bus driver could manage. The system<br />

reduces the drive momentum and applies the<br />

brakes to individual wheels as needed to stabilise<br />

the vehicle. After all, 44% of all singlevehicle<br />

truck accidents, can be avoided with<br />

ESP. Especially the monotonous solitude during<br />

long hauls or at night represents a particular<br />

challenge to drivers, and here MAN has already<br />

rendered support for several years with<br />

its Lane Guard Assistant (LGS). A video camera<br />

continuously monitors the road markings.<br />

Should they be crossed without signalling,<br />

a warning beep alerts the driver. Avoiding<br />

hazardous situations has entirely different<br />

32<br />

33

man magazine<br />

1/<strong>2015</strong><br />

Foresightful<br />

assistance: The<br />

Emergency Braking<br />

Assistant (EBA)<br />

intervenes preventively<br />

(visual warning signal<br />

in yellow), should the<br />

driver fail to activate<br />

the brake in time.<br />

GOOD BRAKING. BETTER DRIVING. INTARDER!<br />

Good braking means better driving. Better driving means driving more economically, safely, and more environmentally<br />

friendly. The ZF-Intarder hydrodynamic hydraulic brake allows for wear-free braking without fading, relieves<br />

the service brakes by up to 90 percent, and in doing so, reduces maintenance costs. Taking into account the vehicle’s<br />

entire service life, the Intarder offers a considerable savings potential ensuring quick amortization. In addition, the<br />

environment benefits from the reduced brake dust and noise emissions. Choose the ZF-Intarder for better performance<br />

on the road. www.zf.com/intarder<br />

aspects as well, however. Active Roll Stabilisation<br />

or Continuous Damping Control (CDC),<br />

for example, reduces dangerous moments of<br />

inertia torque – which can occur in case of varying<br />

load weights or vehicles with a high gravity<br />

centre that can cause considerable lateral<br />

forces during braking or swerving manoeuvres.<br />

In just split seconds, CDC adjusts the<br />

damping of each individual shock absorber to<br />

reduce the roll movement. The outcome for<br />

the driver includes shorter braking distances,<br />

more direct steering and improved safety.<br />

yet interacting with other drivers can<br />

also result in risky situations – which is why<br />

Adaptive Cruise Control (ACC) is such a popular<br />

assistance system. “Especially the avoidance<br />

of rear-end collisions is of vital importance<br />

to us,” states Rudolf Ebner, responsible<br />

for Purchasing at the Quehenberger Group<br />

based in Austria. When placing a large order<br />

with MAN, Quehenberger had requested that<br />

the purchased TGX models be mainly<br />

equipped with the SafetyPackage. ACC not<br />

only maintains a constant speed, but reduces<br />

it automatically if the vehicle in front slows<br />

down. To this end, the distance is monitored<br />

through a radar sensor. This system is closely<br />

interlinked with the Emergency Braking<br />

Assistant (EBA) and the Emergency Stop Signal<br />

(ESS), which not only indicates an emergency<br />

braking event to other road users through<br />

pulsing indicator lights, but also automatically<br />

activates the warning flashers when a vehicle<br />

stops, to avoid rear-end collisions. EBA will<br />

soon be mandatory for commercial vehicles,<br />

is already available from MAN and will actually<br />

reach second-generation status, after further<br />

development, in summer <strong>2015</strong>. Whereas<br />

the area in front of a vehicle had been controlled<br />

by radar so far, a video system is now<br />

being added to improve the accuracy of analysis,<br />

and make automatic emergency braking<br />

even more effective. Road safety is not just a<br />

matter of human lives and safety, however,<br />

but also plays an economic role, explains<br />

Rudolf Ebner: “Due to the numerous assistance<br />

systems on board our vehicles, we not<br />

only pay lower insurance premiums, but also<br />

experience less downtime and greater vehicle<br />

availability due to accident prevention.”<br />

Despite modern technology, driving competence<br />

and a sense of responsibility are still<br />

expected of bus and truck operators. MAN<br />