Table of Contents - Rainbow Precision Products, Inc.

Table of Contents - Rainbow Precision Products, Inc.

Table of Contents - Rainbow Precision Products, Inc.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

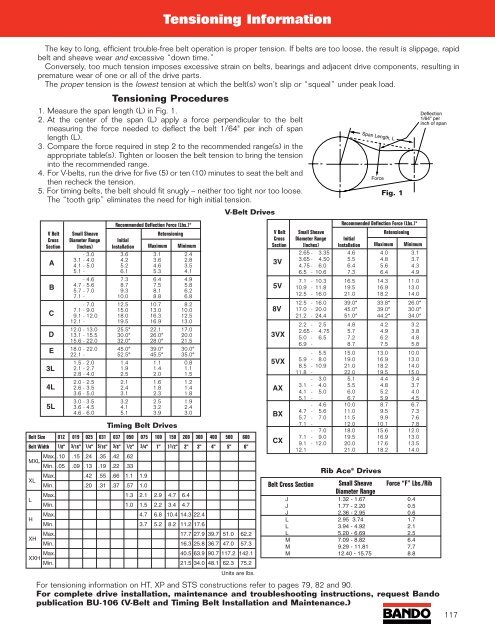

Tensioning InformationThe key to long, efficient trouble-free belt operation is proper tension. If belts are too loose, the result is slippage, rapidbelt and sheave wear and excessive “down time.”Conversely, too much tension imposes excessive strain on belts, bearings and adjacent drive components, resulting inpremature wear <strong>of</strong> one or all <strong>of</strong> the drive parts.The proper tension is the lowest tension at which the belt(s) won’t slip or “squeal” under peak load.Tensioning Procedures1. Measure the span length (L) in Fig. 1.2. At the center <strong>of</strong> the span (L) apply a force perpendicular to the beltmeasuring the force needed to deflect the belt 1/64" per inch <strong>of</strong> spanlength (L).3. Compare the force required in step 2 to the recommended range(s) in theappropriate table(s). Tighten or loosen the belt tension to bring the tensioninto the recommended range.4. For V-belts, run the drive for five (5) or ten (10) minutes to seat the belt andthen recheck the tension.5. For timing belts, the belt should fit snugly – neither too tight nor too loose.The “tooth grip” eliminates the need for high initial tension.Span Length, LV-Belt DrivesRecommended Deflection Force (Lbs.)*Recommended Deflection Force (Lbs.)*V Belt Small Sheave RetensioningV Belt Small Sheave RetensioningCross Diameter Range InitialCross Diameter Range InitialSection (<strong>Inc</strong>hes) Installation Maximum MinimumSection (<strong>Inc</strong>hes) Installation Maximum Minimum- 3.0 3.6 3.1 2.42.65 - 3.35 4.6 4.0 3.13.1 - 4.0 4.2 3.6 2.83.65 - 4.50 5.5 4.8 3.7A3V4.1 - 5.0 5.2 4.6 3.54.75 - 6.0 6.4 5.6 4.35.1 - 6.1 5.3 4.16.5 - 10.6 7.3 6.4 4.9B- 4.6 7.3 6.4 4.97.1 - 10.3 16.5 14.3 11.04.7 - 5.6 8.7 7.5 5.85V 10.9 - 11.8 19.5 16.9 13.05.7 - 7.0 9.3 8.1 6.27.1 - 10.0 8.8 6.812.5 - 16.0 21.0 18.2 14.0- 7.0 12.5 10.7 8.212.5 - 16.0 39.0* 33.8* 26.0*7.1 - 9.0 15.0 13.0 10.08V 17.0 - 20.0 45.0* 39.0* 30.0*C 9.1 - 12.0 18.0 16.3 12.521.2 - 24.4 51.0* 44.2* 34.0*12.1 - 19.5 16.9 13.02.2 - 2.5 4.8 4.2 3.212.0 - 13.0 25.5* 22.1 17.02.65 - 4.75 5.7 4.9 3.8D 13.1 - 15.5 30.0* 26.0* 20.03VX 5.0 - 6.5 7.2 6.2 4.815.6 - 22.0 32.0* 28.0* 21.56.9 - 8.7 7.5 5.8E 18.0 - 22.0 45.0* 39.0* 30.0*22.1 - 52.5* 45.5* 35.0*- 5.5 15.0 13.0 10.05.9 - 8.0 19.0 16.9 13.01.5 - 2.0 1.4 1.1 0.85VX8.5 - 10.9 21.0 18.2 14.03L 2.1 - 2.7 1.9 1.4 1.12.8 - 4.0 2.5 2.0 1.511.8 - 22.0 19.5 15.0- 3.0 5.1 4.4 3.42.0 - 2.5 2.1 1.6 1.24L 2.6 - 3.5 2.4 1.8 1.43.1 - 4.0 5.5 4.8 3.7AX3.6 - 5.0 3.1 2.3 1.84.1 - 5.0 6.0 5.2 4.05.1 - 6.7 5.9 4.53.0 - 3.5 3.2 2.5 1.95L 3.6 - 4.5 4.1 3.2 2.4- 4.6 10.0 8.7 6.74.6 - 6.0 5.1 3.9 3.04.7 - 5.6 11.0 9.5 7.3BX5.7 - 7.0 11.5 9.9 7.6Timing Belt Drives7.1 - 12.0 10.1 7.8- 7.0 18.0 15.6 12.0Belt Size 012 019 025 031 037 050 075 100 150 200 300 400 500 6007.1 - 9.0 19.5 16.9 13.0CX 9.1 - 12.0 20.0 17.6 13.5Belt Width 1/8" 3/16" 1/4" 5/16" 3/8" 1/2" 3/4" 1" 11/2" 2" 3" 4" 5" 6"12.1 21.0 18.2 14.0Max. .10 .15 .24 .35 .42 .62MXLMin. .05 .09 .13 .19 .22 .33Rib Ace ® DrivesMax. .42 .55 .66 1.1 1.9XLMin. .20 .31 .37 .57 1.0Belt Cross Section Small Sheave Force “F” Lbs./RibDiameter RangeMax. 1.3 2.1 2.9 4.7 6.4LJ 1.32 - 1.67 0.4Min. 1.0 1.5 2.2 3.4 4.7J 1.77 - 2.20 0.5HMax. 4.7 6.8 10.4 14.3 22.4J 2.36 - 2.95 0.6L 2.95 3.74 1.7Min. 3.7 5.2 8.2 11.2 17.6L 3.94 - 4.92 2.1XHMax. 17.7 27.9 39.7 51.0 62.2L 5.20 - 6.69 2.5M 7.09 - 8.82 6.4Min. 16.3 25.8 36.7 47.0 57.3M 9.29 - 11.81 7.7Max. 40.5 63.9 90.7 117.2 142.1M 12.40 - 15.75 8.8XXHMin. 21.5 34.0 48.1 62.3 75.2Units are lbs.For tensioning information on HT, XP and STS constructions refer to pages 79, 82 and 90.For complete drive installation, maintenance and troubleshooting instructions, request Bandopublication BU-106 (V-Belt and Timing Belt Installation and Maintenance.)117ForceFig. 1Deflection1/64" perinch <strong>of</strong> span