Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

It’s no cliché, it’s our people who make us great<br />

Brian Jessel BMW Achievements:<br />

• First in Canada for New Car Sales -<br />

4 consecutive years in a row<br />

• First in Canada for Pre-owned<br />

sales - 2 consecutive years<br />

in a row<br />

• First retailer in BC to be<br />

QMA certified<br />

• First retailer in Western Canada<br />

to offer Express Service<br />

96 brianJESSEL SUMMER 2007<br />

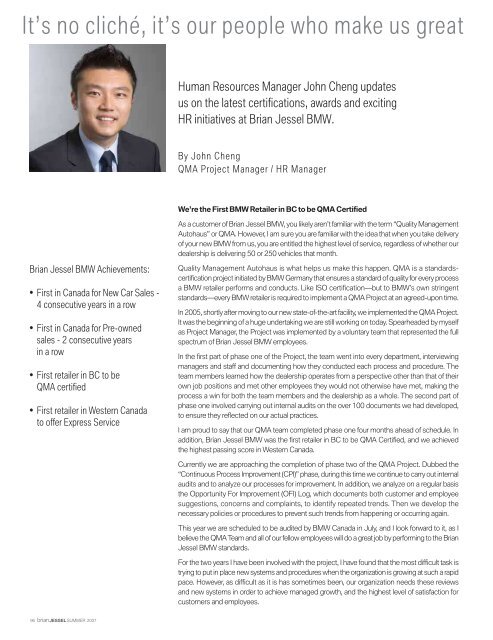

Human Resources Manager John Cheng updates<br />

us on the latest certifications, awards and exciting<br />

HR initiatives at Brian Jessel BMW.<br />

By John Cheng<br />

QMA Project Manager / HR Manager<br />

We’re the First BMW Retailer in BC to be QMA Certified<br />

As a customer of Brian Jessel BMW, you likely aren’t familiar with the term “Quality Management<br />

Autohaus” or QMA. However, I am sure you are familiar with the idea that when you take delivery<br />

of your new BMW from us, you are entitled the highest level of service, regardless of whether our<br />

dealership is delivering 50 or 250 vehicles that month.<br />

Quality Management Autohaus is what helps us make this happen. QMA is a standardscertification<br />

project initiated by BMW Germany that ensures a standard of quality for every process<br />

a BMW retailer performs and conducts. Like ISO certification—but to BMW’s own stringent<br />

standards—every BMW retailer is required to implement a QMA Project at an agreed-upon time.<br />

In 2005, shortly after moving to our new state-of-the-artfacility, we implemented the QMA Project.<br />

It was the beginning of a huge undertaking we are still working on today. Spearheaded by myself<br />

as Project Manager, the Project was implemented by a voluntary team that represented the full<br />

spectrum of Brian Jessel BMW employees.<br />

In the first part of phase one of the Project, the team went into every department, interviewing<br />

managers and staff and documenting how they conducted each process and procedure. <strong>The</strong><br />

team members learned how the dealership operates from a perspective other than that of their<br />

own job positions and met other employees they would not otherwise have met, making the<br />

process a win for both the team members and the dealership as a whole. <strong>The</strong> second part of<br />

phase one involved carrying out internal audits on the over 100 documents we had developed,<br />

to ensure they reflected on our actual practices.<br />

I am proud to say that our QMA team completed phase one four months ahead of schedule. In<br />

addition, Brian Jessel BMW was the first retailer in BC to be QMA Certified, and we achieved<br />

the highest passing score in Western Canada.<br />

Currently we are approaching the completion of phase two of the QMA Project. Dubbed the<br />

“Continuous Process Improvement (CPI)” phase, during this time we continue to carry out internal<br />

audits and to analyze our processes for improvement. In addition, we analyze on a regular basis<br />

the Opportunity For Improvement (OFI) Log, which documents both customer and employee<br />

suggestions, concerns and complaints, to identify repeated trends. <strong>The</strong>n we develop the<br />

necessary policies or procedures to prevent such trends from happening or occurring again.<br />

This year we are scheduled to be audited by BMW Canada in July, and I look forward to it, as I<br />

believe the QMA Team and all of ourfellow employees will do a great job by performing to the Brian<br />

Jessel BMW standards.<br />

For the two years I have been involved with the project, I have found that the most difficult task is<br />

trying to put in place new systems and procedures when the organization is growing at such a rapid<br />

pace. However, as difficult as it is has sometimes been, our organization needs these reviews<br />

and new systems in order to achieve managed growth, and the highest level of satisfaction for<br />

customers and employees.<br />

<strong>The</strong> reason Brian Jessel BMW successfully maintains a balance<br />

between leading changes and managing growth is because, as a team,<br />

we are not only open to change, but implement changes successfully.<br />

I can assure our customers and employees that as part of this process,<br />

we will never stop in pursuing the ultimate customer and employee<br />

satisfaction.<br />

I would like to recognize the following QMA Members for their<br />

outstanding efforts and performance: Carol Anderson, Jim Krahn, Tim<br />

Van Dyke, Elaine Harley, Denna Matthews, Kenneth Lee, Steve Lavides,<br />

Tina Lalonde, Kristin Codrington, Tess Erickson, Brooke Waddell and<br />

Breanne Yip.<br />

Strengthening Employee Satisfaction<br />

“To inspire ourteam at Brian Jessel BMW to constantly exceed<br />

our customers’ expectations when dealing with every aspect<br />

of their motoring needs.”<br />

– Mission Statement, Brian Jessel BMW.<br />

Customer satisfaction is Brian Jessel BMW’s mission, and employee<br />

satisfaction is my department’s mission primary. I believe that without<br />

employee satisfaction, employees will not able to take good care of our<br />

customers. <strong>The</strong>refore, the HR Department has one mission: to take<br />

great care of our over 140 staff at the dealership.<br />

Fostering a culture of satisfied employees always involves interesting<br />

dynamics, as human beings are complex, with unique emotions,<br />

personalities and distinct characteristics. As complicated as we might be,<br />

however, the simplest way to achieve employee satisfaction is to always<br />

listen to what each person has to say.<br />

For example, I was once chatting with a member of our Service Wash<br />

Staff. I asked him if there was anything he wanted or needed in order to<br />

improve his satisfaction as an employee. I thought for sure he would<br />

say—as would most of us—that he’d like to be paid more. To my<br />

surprise, he replied that what he really needed were waterproof shoes<br />

and uniforms. I discovered that his colleagues shared his opinion, so we<br />

wasted no time in getting them all everything they needed for their work.<br />

From this experience, I learned that creating satisfaction is as simple as<br />

asking the right questions, listening to the answers you receive, and<br />

then—most importantly—acting on what you’ve heard.<br />

On the other hand, I do have to admit that with 140-plus staff my to-do<br />

list is long, and sometimes it may take a while for an employee to see<br />

their suggestions implemented. In order to stay credible with our staff, I<br />

have to always do my best to make sure everyone’s needs and<br />

suggestions are acknowledged and followed up.<br />

Another critical element in creating employee satisfaction lies in emplyee<br />

recognition. For the first time ever, at our 2006 Christmas party our<br />

Departmental Managers handed out Loyalty Appreciation Plagues to<br />

employees who have been with Brian Jessel BMW for 5, 10, 15 and<br />

20 years.<br />

In addition, we gave out ourfirst-annual Employee of<strong>The</strong> Year Award. All<br />

employees were able to nominate a fellow coworker whom they believe<br />

deserve the ultimate recognition. <strong>The</strong> nomination yielded three finalists:<br />

Elaine Harley, Office Manager; Travis MacFarlane, Journeyman<br />

brianJESSEL SUMMER 2007 97