SYSTEM KAN-therm KAN-therm SYSTEM - broen-sei

SYSTEM KAN-therm KAN-therm SYSTEM - broen-sei

SYSTEM KAN-therm KAN-therm SYSTEM - broen-sei

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

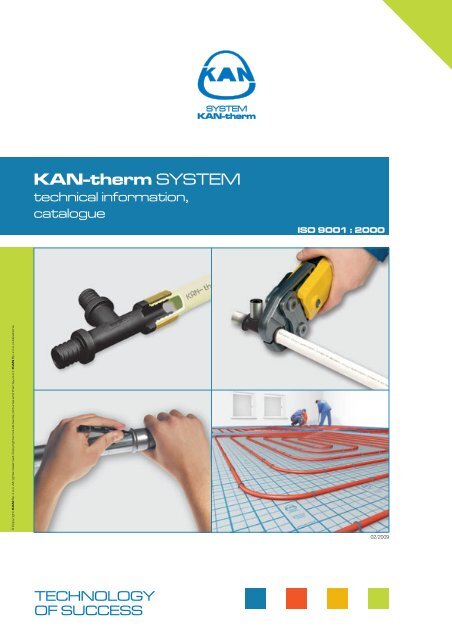

<strong>SYSTEM</strong> <strong>KAN</strong>-<strong>therm</strong> <strong>KAN</strong>-<strong>therm</strong><strong>SYSTEM</strong>informacja technical information,techniczna,katalog catalogueISO 9001 : 2000© Copyright <strong>KAN</strong> Sp. z o.o. All rights reserved. Copyrights include texts, pictures and their lay-out in <strong>KAN</strong> Sp. z o.o. publications.02/2009TECHNOLOGYOF SUCCESS

ContentsPage <strong>KAN</strong>-<strong>therm</strong> Push <strong>SYSTEM</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 <strong>KAN</strong>-<strong>therm</strong> Press <strong>SYSTEM</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 <strong>KAN</strong>-<strong>therm</strong> <strong>SYSTEM</strong> - manifolds, cabinets and supplementary elements . . . . . . . . . . . . . . . . . . . . . . . . . . .53 <strong>KAN</strong>-<strong>therm</strong> Steel <strong>SYSTEM</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71 <strong>KAN</strong>-<strong>therm</strong> Inox <strong>SYSTEM</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93 The underfloor heating of <strong>KAN</strong>-<strong>therm</strong> <strong>SYSTEM</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119 <strong>KAN</strong>-<strong>therm</strong> <strong>SYSTEM</strong> - fastening systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153 Additional information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .161Order Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .168This catalogue is valid from February 1st, 2009 and replaces all its previous editions.<strong>KAN</strong> Sp. z o.o. reserves the right to change contents of this catalogue.© Copyright <strong>KAN</strong> Sp. z o.o. All rights reserved. Copyrights include texts, pictures and their lay-out in <strong>KAN</strong> Sp. z o.o. publications.

<strong>KAN</strong>-<strong>therm</strong> Push SystemISO 9001 : 2000TECHNOLOGYOF SUCCESS

ContentsPage<strong>KAN</strong>-<strong>therm</strong> Push System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3<strong>KAN</strong>-<strong>therm</strong> Push System - modern technology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5<strong>KAN</strong>-<strong>therm</strong> Push System - long-lasting technology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5<strong>KAN</strong>-<strong>therm</strong> Push System - optimal technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5<strong>KAN</strong>-<strong>therm</strong> Push System - safe technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5PE-RT pipes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6PE-Xc pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6PE-RT and PE-Xc pipes operation parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7PE-RT and PE-Xc pipes' physical properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7Transport and storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7Push connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8Push connections assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9Push tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11Screwed connections for PE-RT and PE-Xc pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12<strong>KAN</strong>-<strong>therm</strong> Push System - screwed connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12Screwed connections for PE-RT and PE-Xc pipes - screw joint connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13Connections of the fittings with nickel plated tubes with radiator fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<strong>KAN</strong>-<strong>therm</strong> Push System - for water and heating systems up to 10 bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14<strong>KAN</strong>-<strong>therm</strong> Push System - for water and heating systems up to 6 bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20<strong>KAN</strong>-<strong>therm</strong> Push System - for water systems under pressure of 10 bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25<strong>KAN</strong>-<strong>therm</strong> System - screw fittings for pipes PE-Xc and PE-RT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30<strong>KAN</strong>-<strong>therm</strong> System - Push tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32This catalogue is valid from February 1st, 2009 and replaces all its previous editions.<strong>KAN</strong> Sp. z o.o. reserves the right to change contents of this catalogue.© Copyright <strong>KAN</strong> Sp. z o.o. All rights reserved. Copyrights include texts, pictures and their lay-out in <strong>KAN</strong> Sp. z o.o. publications.

1 <strong>KAN</strong>-<strong>therm</strong> Push System<strong>KAN</strong>-<strong>therm</strong> Push System Catalog consists of two sections: technical section, assortment section.The technical section contains all necessary information for making orders as well as for system assembly on site. Moredetails can be found in "<strong>KAN</strong>-<strong>therm</strong> System Designer and Contractor's Handbook."The assortment section of <strong>KAN</strong>-<strong>therm</strong> Push System is divided into 3 chapters presenting various assortmentgroups depend from the type of installation (heating, drinking) and parameters of work (10 or 6 bars).Chapters are concerned with Push connector system for PE-Xc and PE-RT pipes. Each chapter contains a completeassortment (pipes and connectors) in system type order (heating or water) and required operation parameters (10 or 6 bar).Such an order of elements considerably facilitates proper choice of pipes and connectors for particular application(heating/water systems, operation parameters: 6/10 bar)When choosing PE-Xc, PE-RT pipes and Push connector (chapters 1-3) for a given system type, you should chooseelements from the same chapter respectively.Chapter 1<strong>KAN</strong>-<strong>therm</strong> Push System for water and heating systems up to 10 bar (general-purpose 10 bar) - they are PE-Xcpipes in series of diameters 12×2, 14×2, 18×2.5, 25×3.5, 32×4.4 with diffusion barrier, together with proper connectors,designed for water and heating systems up to 10 bar.Chapter 2<strong>KAN</strong>-<strong>therm</strong> Push System for water and heating systems up to 6 bar (general-purpose 6 bar) - they are PE-Xcand PE-RT pipes in series of diameters 12×2, 14×2, 18×2, 25×3.5, 32×4.4 with diffusion barrier, together with properconnectors, designed for water and heating systems up to 6 bar.Chapter 3<strong>KAN</strong>-<strong>therm</strong> Push System for water systems up to 10 bar - they are PE-Xc and PE-RT pipes in series ofdiameters 12×2, 14×2, 18×2.5, 25×3.5, 32×3.4 without diffusion barrier, together with proper connectors, designed for watersystems up to 10 bar.- 3 -

2 <strong>KAN</strong>-<strong>therm</strong> Push System - technical information<strong>KAN</strong>-<strong>therm</strong> Push System is a complete installation system consisting of PE-Xc or PE-RT polyethylene pipes andPPSU or brass fittings in diameter range of ∅12-32 mm.O-Ring-free and leakproof connections in <strong>KAN</strong>-<strong>therm</strong> Push System are obtained by sliding a brass sleeve over afitting and a pipe. The connections do not require additional seals, e.g. teflon tape and tow. Manifolds and installationcabinets complement the system.<strong>KAN</strong>-<strong>therm</strong> Push System has been designed on the basis of "quick assembly - long-lasting effect" principle,which enables to accelerate considerably investment and finishing works.<strong>KAN</strong>-<strong>therm</strong> Push System - modern technologyThe newest generation of materials (PPSU - phenylene polysulfone) used in production of connectors ensure: 100% corrosion resistance, total neutrality towards drinking water, fittings' durability higher than pipes' durability, high mechanical strength.PPSU connector production technology practically excludes any latent defects.<strong>KAN</strong>-<strong>therm</strong> Push System - long-lasting technology<strong>KAN</strong>-<strong>therm</strong> Push System, because of perfect design of its elements and their mutual matching, provides: over 50-year-long life, high temperature operation - T work = 80°C (working), T max = 90°C (maximum, heat source should have a safety deviceagainst temperature rise above that value) and 6 bar working pressure for pipes with EVOH layer, and 10 bar for pipeswithout EVOH layer, extremely durable PPSU joints whose maximum operation parameters are limited by pipe durability, 100% corrosion free regardless of water quality.<strong>KAN</strong>-<strong>therm</strong> Push System - optimal technology<strong>KAN</strong>-<strong>therm</strong> Push System allows to choose optimal technical and economic solutions because: Push joints can be concealed in floors; it is compatible with systems made of different materials; it enables to make economical distribution systems.<strong>KAN</strong>-<strong>therm</strong> Push System - safe technology<strong>KAN</strong>-<strong>therm</strong> Push System guarantees full assembly and operation safety: Push PPSU connectors have technical approval AT/2000-02-0914 and positive hygienic assessmentPZH HK/W/0055/02/2005; PE-RT pipes have technical approval AT/2003-02-1399 and positive hygienic assessment PZH HK/W0462/01/2008; PE-Xc pipes have technical approval AT/2003-02-1317 and positive hygienic assessment PZH HK/W/0764/01/2007; the system has a 10-year guarantee.- 5 -

2 <strong>KAN</strong>-<strong>therm</strong> Push System - technical informationPE-RT and PE-Xc pipes operation parametersPE-RT and PE-Xc pipes according to AT/2003-02-1399 (PE-RT) and AT/2003-02-1317 (PE-Xc) approvals can operate:System type andapplication classExternalPE-RT, PE-Xcpipe diameter[mm]Wallthickness[mm]EVOH layerPipe series SOperation parametersP work(2)[bar]T work/T max[°C]Central heating systemsclass 5(for class 4 floor heatingT work/T max - 60/70°CCold water system* not available for PE-RT pipes1)PE-Xc general-purpose pipes that can be applied in hot and cold water system (P max = 10 bar, T max = 80°C), central heating (P max = 10 bar, T max = 90°C).2)In class 4.5 working pressure for PE-RT pipes equals 6 bar.Attention:In Poland, separate regulations concerning maximum operation parameters apply: central heating system 90°C and 6 bar, floor heating 60°C and 6 bar (in the above mentioned approvals for central heatingsystem max pressure 6 bar is given); hot water system 60°C and 10 bar (at draw-off points max 6 bar PN 92/B-01706);Working temperature T work in particular classes should be considered as designed temperature, maximum temperature T maxas temperature before exceeding; systems should be secured.PE-RT and PE-Xc pipes' physical properties12 2,0 yes 2,50 10 80/9014 1) 2,0 yes 3,00 10 80/9018 2,0 yes 4,00 8 80/9018 1) 2,5 yes 3,10 10 80/9025 1) 3,5 yes 3,07 10 80/9032* 1) 4,4 yes 3,14 10 80/9014 2,0 no 3,00 10 2018 2,5 no 3,10 10 2025 3,5 no 3,07 10 2032 4,4 no 3,14 10 20Hot water system 1, (2) 18 2,5 no 3,10 10 60,(70)/8025 3,5 no 3,07 10 60,(70)/8014 2,0 no 3,00 10 60,(70)/8032 4,4 no 3,14 10 60,(70)/80No. Properties Unit of measure Value1 Thermal conductivity [W/mK] 0,412 Coefficient of linear expansion:20°C [K -1 ] 1,4×10 -4100°C [K -1 ] 2,0×10 -43 Density of material [g/cm³] 0,944 Internal pipe roughness (absolute) [mm] 0,0055 Limiting working temperatures:PE-RT [°C] -40 ÷ 90PE-Xc [°C] -40 ÷ 956 E Module [N/mm²] 600Transport and storagePE-RT and PE-Xc pipes are delivered in 25, 50, 200 m rolls in carton packages. They can be stored in different temperatures,also low ones (below 0°C). Because of vulnerability to UV rays pipes should be protected against direct, long-lastingexposure to sunlight.- 7 -

<strong>KAN</strong>-<strong>therm</strong> Push System - technical information 2Push connectionsMaking Push connection consists in sliding a brass sleeve over a pipe and a fitting using hand or hydraulic press.1. Connector for Push connections (PPSU tee),2. brass sleeve for Push connections,3. PE-RT or PE-Xc pipe.Fittings for Push connections: elbows and tees, elbows, tees and other fittings with copper pipe, nickel plated ∅15 mm, connectors, screw joints, male and female joints, tap connectors, special fittings.In the case of using brass fittings in highly corrosive water systems it is advised to apply nickel fittings (MN).Attention:During the assembly of PPSU fittings the purity must be kept and contact with chemical substances must be avoided.Brass sleeves for Push connections:letter „A”grooveRing for PE-Xc and PE-RT pipes with diffusion barrier is marked with aletter "A".Ring for PE-Xc and PE-RT pipes without diffusion barrier has a"groove" on its external surface.- 8 -

2 <strong>KAN</strong>-<strong>therm</strong> Push System - technical informationPush connections assembly1. Cut PE-RT or PE-Xc pipe of required length using shears. Cutperpendicularly to pipe axis.2. Put sleeve on the pipe with innerly beveled end from the fittingside. Carefully choose proper sleeve as there are different sleevesfor pipes with and without diffusion barrier.3. Expanding the pipe using expanding tool should be performed inthree phases. First two expansions not full, then rotate theexpanding tool through 30° and 15° against the pipe. The thirdexpansion is full.4. Insert the fitting into the pipe up to the last bead on the fitting.5. Slide the sleeve using hand or hydraulic press with foot-operateddrive. Fittings can be gripped only at flanges.Do not slide two sleeves at the same time..6. The connection is ready for pressure test.- 9 -

<strong>KAN</strong>-<strong>therm</strong> Push System - technical information 2Attention:For assembly of fittings made of PPSU plastic you have to use, from the fitting side, black inserts marked with a letter T (12,14, 18 or 25) and from the sleeve side straight nickel inserts. Plastic fitting should be supported against the flange directlyadjacent to stub pipe on which a sleeve is slid.straight nickel insertstraight black insertIn the case of PPSU fitting of ∅32 mm in diameter assembly use, from the fitting side, straight nickel insert ∅25 mm, and apress jaw from the sleeve side.straight nickel insert ∅25mmpress jawAssemble brass elements using straight nickel inserts.straight nickel insert- 10 -

2 <strong>KAN</strong>-<strong>therm</strong> Push System - technical informationPush toolsHydraulic Push tool with foot-operated drive - case set.214683751. Hydraulic Push tool with foot drive.2. Expanding tool for pipes PE-Xc and PE-RT.3. Cutter for pipes PE-Xc and PE-RT.4. Expanding head (12×2; 14×2; 18×2;18×2,5; 25×3,5; 32×4,4)5. Insert set (12, 14, 18, 25) - 2 pcs.6. Insert set (T12, T14; T18; T25) - 1 pcs.7. Allen's key.8. Tool case.Mechanical hand Push tool - case set.834512761. Manual mechanical Push tool2. Expanding tool for pipes PE-Xc and PE-RT.3. Cutter for pipes PE-Xc and PE-RT.4. Expanding head (12×2; 14×2; 18×2;18×2,5; 25×3,5; 32×4,4)5. Insert set (12, 14, 18, 25) - 2 pcs.6. Insert set (T12, T14, T18, T25)) - 1 pcs.7. Jaws for manual mechanical Push tool indiameter range 12-18 mm and 25-32 mm.8. Tool case.- 11 -

<strong>KAN</strong>-<strong>therm</strong> Push System - screwed connections 3Screwed connections for PE-RT and PE-Xc pipesRules for making a screwed connection:1. Screw in connector body into fitting with screw thread sealing.2. Place nut and ring on the pipe.3. Slide the pipe on the connector body and screw on the nut clamping the ring.1. Fitting - female tee.2. Straight male connector (body).3. Compression ring.4. Clamping nut.5. PE-RT or PE-Xc pipe.Insert the compression ring on the pipe and the ring edge should be 0.5 to 1 mm distant from the pipe edge. The pipeshould be slid to the end of connector body. The connection can be considered as dismountable provided after exiting thepipe, by the connector body the used end of pipe is cut off and a new connection is made.It is not allowed to rotate the fitting against the pipe during and after the assembly or use any pastes to make the sliding ofpipe onto the connector body easier.Screwed connectors operate with: fittings with internal threads, e.g. elbows, tees, tap connectors, manifolds without nipples (without accesories); fixtures with internal threads.Connections of that type: should be sealed by hemp (threads) with addition of pastes, in the case of internal brass threads making sure there is noexcess tow; internal brass threads (cylindrical thread contour) should not be connected with pipe external threads (conical threadcontour) because of danger of brass fracture; apply a rule that connectors and fittings with internal threads should not be connected with elements which are notincluded in <strong>KAN</strong>-<strong>therm</strong> System. should not be concealed in floors.- 12 -

3 <strong>KAN</strong>-<strong>therm</strong> Push System - screwed connectionsScrewed connections for PE-RT and PE-Xc pipes - screw joint connectionsScrew joint connections are a variation of screwed connections.1. Fitting female tee.2. Straight male connector (body).3. Compression ring.4. Clamping nut.5. PERT or PEXc pipe.The basic element of such connections are screw joints which have an O-Ring between the connector and the fitting. Screwjoint connections operate with: fitting series 9012 with external threads; manifolds with special nipples; radiator combined valves.Screw joint connections are characterized by the cone and an O-Ring between the connector and the fitting. Connections ofthat type are self-sealing and additional sealing should not be applied, e.g. teflon tape or tow. Connections of that typeshould be located in easily accessible places.Connections of the fittings with nickel plated tubes with radiator fittingsIn order to make esthetical radiator connection in <strong>KAN</strong>-<strong>therm</strong> System, in case of the floor and wall connections, therecan be found in the <strong>KAN</strong> offer, special performance of the fitting with nickel plated pipes.Nickel plated elbows and tees can be connected with the radiator valves and directly with VK radiators via elements: union adapter for copper tube 15G¾", code 9023.08, union adapter for copper tube 15G½", code K-609010, compression adapter for copper tube 15G¾",code 629201N, straight female nipple body G½", code 9001.35.All connections of this kind are self-sealed and do not require additional sealing elements.- 13 -

<strong>KAN</strong>-<strong>therm</strong> Push System - for water and heating systems up to 10 bar 4<strong>KAN</strong> -<strong>therm</strong> pipe PE-Xc acc. to DIN 16892/93 with EVOH layer acc. to DIN 4726 - for Push and screwfittingsSize Pipe length in coil/on palette Code Price €/m Group∅12×2 200/4000 0.2144 C∅14×2 200/4000 0.2145 C∅18×2,5 200/3000 0.9119 C∅25×3,5 50/1000 0.9127 C∅32×4,4 25/500 0.9133 C<strong>KAN</strong> -<strong>therm</strong> Push straight male connectorSize Pcs. in one bag/box Code Price €/pcs. Group∅12×2 G½" 10/150 9014.580 A∅14×2 G½" 10/150 9006.37K A** ∅14×2 G½" (MN) 10/150 9006.37KC A∅18×2,5 G½" 10/150 9006.39K A** ∅18×2,5 G½" (MN) 10/150 9006.39C A∅25×3,5 G½" 10/100 9014.98 A** ∅25×3,5 G½" (MN) 10/100 9014.98C A∅25×3,5 G¾" 10/100 9014.220 A** ∅25×3,5 G¾" (MN) 10/100 9014.220C A∅32×4,4 G1'' 5/50 9019.030 A** ∅32×4,4 G1'' (MN) 5/50 9019.030C A(MN) - brass fitting, nickel plated<strong>KAN</strong> -<strong>therm</strong> Push straight female connectorSize Pcs. in one bag/box Code Price €/pcs. Group∅12×2 G½" 10/150 9014.590 A∅14×2 G½" 10/150 9014.270 A** ∅14×2 G½" (MN) 10/150 9014.270C A∅18×2,5 G½" 10/150 9014.290 A** ∅18×2,5 G½" (MN) 10/150 9014.290C A∅25×3,5 G¾" 5/70 9014.300 A** ∅25×3,5 G¾" (MN) 5/70 9014.300C A∅32×4,4 G1'' 5/50 9019.040 A** ∅32×4,4 G1'' (MN) 5/50 9019.040C A(MN) - brass fitting, nickel platedDon't join them with conical external threads (e.g. R½").<strong>KAN</strong> -<strong>therm</strong> Push union adapterSize Pcs. in one bag/box Code Price €/pcs. Group∅18×2,5 G½" 20/200 9014.250 A** ∅18×2,5 G½" (MN) 20/200 9014.250C A(MN) - brass fitting, nickel platedPush eurocone adapter can be used for manifold type 40 (see p. 62) and male tees and elbows.<strong>KAN</strong> -<strong>therm</strong> Push couplingSize Pcs. in one bag/box Code Price €/pcs. Group∅12×2/∅12×2 50/700 9014.610 A∅14×2/∅14×2 50/500 9006.06 A** ∅14×2/∅14×2 (MN) 50/500 9006.06C A∅18×2,5/∅18×2,5 20/400 9006.08 A** ∅18×2,5/∅18×2,5 (MN) 20/400 9023.07 A∅25×3,5/∅25×3,5 10/100 9006.10 A** ∅25×3,5/∅25×3,5 (MN) 10/100 9006.10C A∅32×4,4/∅32×4,4 5/60 9019.050 A** ∅32×4,4/∅32×4,4 (MN) 5/60 9019.050C A(MN) - brass fitting, nickel plated<strong>KAN</strong> -<strong>therm</strong> Push reducing couplingSize Pcs. in one bag/box Code Price €/pcs. Group∅14×2/∅12×2 50/500 9016.250 A∅18×2,5/∅14×2 20/400 9019.130 A** ∅18×2,5/∅14×2 (MN) 20/400 9019.130C A∅25×3,5/∅18×2,5 20/200 9006.11CN A** ∅25×3,5/∅18×2,5 (MN) 20/200 9006.11C A∅32×4,4/∅25×3,5 5/70 9019.120 A** ∅32×4,4/∅25×3,5 (MN) 5/70 9019.120C A(MN) - brass fitting, nickel platedCoupling is used for repair purposes (re-boring faults) as well as for joining of long pipe sections.- 14 -* stock-out goods catalog net prices - no discount** on request (delivery date about 2 weeks) Push sliding sleeve not included

4 <strong>KAN</strong>-<strong>therm</strong> Push System - for water and heating systems up to 10 bar<strong>KAN</strong> -<strong>therm</strong> Push teeSize Pcs. in one bag/box Code Price €/pcs. Group∅12×2/∅12×2/∅12×2 (P) 20/200 9014.650 A∅14×2/∅14×2/∅14×2 (P) 10/100 9018.250 A∅14×2/∅14×2/∅14×2 (MN) 20/200 9006.16B A∅18×2,5/∅18×2,5/∅18×2,5 (P) 10/80 9018.020 A∅18×2,5/∅18×2,5/∅18×2,5 (MN) 10/150 9006.18B A∅25×3,5/∅25×3,5/∅25×3,5 (P) 5/40 9018.030 A∅25×3,5/∅25×3,5/∅25×3,5 (MN) 5/60 9006.20B A∅32×4,4/∅32×4,4/∅32×4,4 (P) 2/20 9018.69 A(P) - PPSU fitting, (MN) - brass fitting, nickel plated<strong>KAN</strong> -<strong>therm</strong> Push reducing teeSize Pcs. in one bag/box Code Price €/pcs. Group∅14×2/∅12×2/∅12×2 (P) 20/200 9014.570 A∅14×2/∅12×2/∅14×2 (P) 20/200 9014.560 APPSU fitting∅18×2,5/∅14×2/∅14×2 (P) 10/80 9018.730 A∅18×2,5/∅14×2/∅18×2,5 (P) 10/80 9018.720 A∅18×2,5/∅25×3,5/∅18×2,5 (P) 5/40 9018.240 A∅25×3,5/∅14×2/∅18×2,5 (P) 5/40 9018.760 A∅25×3,5/∅14×2/∅25×3,5 (P) 5/40 9018.740 A∅25×3,5/∅14×2/∅25×3,5 (MN) 5/60 9013.42B A∅25×3,5/∅18×2,5/∅18×2,5 (P) 5/40 9018.070 A∅25×3,5/∅18×2,5/∅18×2,5 (MN) 5/60 9006.67B A∅25×3,5/∅18×2,5/∅25×3,5 (P) 5/40 9018.080 A∅25×3,5/∅18×2,5/∅25×3,5 (MN) 5/60 9006.66B A∅32×4,4/∅18×2,5/∅25×3,5 (P) 2/20 9018.510 A∅32×4,4/∅18×2,5/∅32×4,4 (P) 2/20 9018.530 A∅32×4,4/∅25×3,5/∅25×3,5 (P) 2/20 9018.500 A∅32×4,4/∅25×3,5/∅32×4,4 (P) 2/20 9018.520 A(P) - PPSU fitting, (MN) - brass fitting, nickel platedbrass fitting<strong>KAN</strong> -<strong>therm</strong> Push elbowSize Pcs. in one bag/box Code Price €/pcs. Group∅14×2/∅14×2 (P) 20/300 9018.170 A∅14×2/∅14×2 (MN) 20/400 9006.11B A∅18×2,5/∅18×2,5 (P) 20/200 9018.190 A∅18×2,5/∅18×2,5 (MN) 20/200 9006.13B A∅25×3,5/∅25×3,5 (P) 5/60 9018.200 A∅25×3,5/∅25×3,5 (MN) 10/80 9006.15B A∅32×4,4/∅32×4,4 (P) 5/30 9018.560 A(P) - PPSU fitting, (MN) - brass fitting, nickel platedPPSU fittingbrass fitting<strong>KAN</strong> -<strong>therm</strong> Push male elbow (for connection to copper pipes ∅15)Size Pcs. in one bag/box Code Price €/pcs. Group** ∅14×2/15Cu - G½" 20/200 9013.220 A* ∅14×2/15Cu - G½" (MN) 20/200 9013.22B A∅14×2/15Cu - G½" 20/200 9029.12 A(MN) - brass fitting, nickel platedTo connect these male tees to copper pipes use: eurocone adapter for copper pipe ∅15, G½”, code K-609010 (see ). p. 58* stock-out goods catalog net prices - no discount** on request (delivery date about 2 weeks) Push sliding sleeve not included- 15 -

<strong>KAN</strong>-<strong>therm</strong> Push System - for water and heating systems up to 10 bar 4<strong>KAN</strong> -<strong>therm</strong> Push tee for radiator connection with dia 15 copper pipe L min = 300 mm, nickel platedSized 1/d 2 Pcs./packing Code Price €/pcs. Group∅14×2/∅14×2 50 9013.14 A∅18×2,5/∅18×2,5 50 9006.310 A∅25×3,5/∅25×3,5 40 9003.700 A∅32×4,4/∅32×4,4 25 9019.150 A<strong>KAN</strong> -<strong>therm</strong> Push reducing tee for radiator connection with dia 15 copper pipe L min = 300 mm, nickelplatedSized 1/d 2 Pcs./packing Code Price €/pcs. Group∅18×2,5/∅14×2 LH 50 9013.500 A∅18×2,5/∅14×2 RH 50 9013.510 A∅25×3,5/∅18×2,5 LH 40 9013.270 A∅25×3,5/∅18×2,5 RH 40 9013.280 A∅32×4,4/∅25×3,5 LH 30 9019.090 A∅32×4,4/∅25×3,5 RH 30 9019.100 A<strong>KAN</strong> -<strong>therm</strong> Push tee for radiator connection with dia 15 copper pipe L min = 750 mm, nickel platedSized 1/d 2 Pcs./packing Code Price €/pcs. Group∅14×2/∅14×2 25 9013.15 A∅18×2,5/∅18×2,5 25 9006.320 A∅25×3,5/∅25×3,5 15 9003.710 A∅32×4,4/∅32×4,4 10 9019.160 AL mind 1d 2<strong>KAN</strong> -<strong>therm</strong> Push reducing tee for radiator connection with dia 15 copper pipe L min = 750 mm, nickelplatedSized 1/d 2 Pcs./packing Code Price €/pcs. Group∅18×2,5/∅14×2 LH 25 9013.520 A∅18×2,5/∅14×2 RH 25 9013.530 A∅25×3,5/∅18×2,5 LH 20 9013.290 A∅25×3,5/∅18×2,5 RH 20 9013.300 A∅32×4,4/∅25×3,5 LH 15 9019.110 A∅32×4,4/∅25×3,5 RH 15 9019.140 AAll fittings are nickel plated.Other length L min on request.Use RH and LH reduction tees to connect radiators. RH tee identification: looking at bigger diameter the copper pipe bow should be at the right side. Drawingshows LH reduction tee.Various connection options for the fittings with nickel plated tubes with all kinds of fittings are described in the technical part of the catalog - "Screwconnections for pipe PE-RT and PE-Xc".<strong>KAN</strong> -<strong>therm</strong> Push coupling for radiator connection with dia 16 multilayer pipe L min = 500 mmSized 2/d 1 Pcs./packing Code Price €/pcs. Group∅16×2/∅14×2 50 9027.160 A∅16×2/∅18×2,5 50 9027.180 Ad 1 d 2L min- 16 -* stock-out goods catalog net prices - no discount** on request (delivery date about 2 weeks) Push sliding sleeve not included

4 <strong>KAN</strong>-<strong>therm</strong> Push System - for water and heating systems up to 10 bar<strong>KAN</strong> -<strong>therm</strong> Push fixed elbow for radiator connection with dia 15 copper pipe, nickel platedSize Pcs./packing Code Price €/pcs. Group∅12×2 L min = 210 mm 60 9016.230 A∅14×2 L min = 210 mm 60 9014.450 A∅14×2 L min = 300 mm 60 9016.000 A∅14×2 L min = 750 mm 25 9016.010 A∅18×2,5 L min = 210 mm 60 9015.230 A∅18×2,5 L min = 300 mm 60 9016.020 A∅18×2,5 L min = 750 mm 25 9016.030 AVarious connection options for the fittings with nickel plated tubes with all kinds of fittings are described in the technical part of the catalog - "Screwconnections for pipe PE-RT and PE-Xc".L min<strong>KAN</strong> -<strong>therm</strong> Push double fixed elbow for radiator connection with dia 15 copper pipe, nickel platedSize Pcs./packing Code Price €/pcs. Group∅12×2 L min = 200 mm 20 9016.240 A∅14×2 L min = 200 mm 20 9014.460 A∅14×2 L min = 300 mm 15 9015.250 A∅18×2,5 L min = 200 mm 20 9015.240 A∅18×2,5 L min = 300 mm 15 9015.270 APipes to be cut using minicutter (see p. 33)Various connection options for the fittings with nickel plated tubes with all kinds of fittings are described in the technical part of the catalog - "Screwconnections for pipe PE-RT and PE-Xc".50 mmL min + 25 mmL min<strong>KAN</strong> -<strong>therm</strong> Push U-shaped elbow for radiator connection with dia 15 copper pipe, nickel platedSize Pcs./packing Code Price €/pcs. Group** ∅14×2 L=120 30 9016.30 AL=160 30 9016.36 AL=180 30 9016.38 AL=200 20 9016.40 A** ∅18×2,5 L=120 30 9016.420 AL=160 30 9016.430 AL=180 30 9016.440 AL=200 20 9016.450 AVarious connection options for the fittings with nickel plated tubes with all kinds of fittings are described in the technical part of the catalog - "Screwconnections for pipe PE-RT and PE-Xc".225 mmL* stock-out goods catalog net prices - no discount** on request (delivery date about 2 weeks) Push sliding sleeve not included- 17 -

<strong>KAN</strong>-<strong>therm</strong> Push System - for water and heating systems up to 10 bar 4<strong>KAN</strong> -<strong>therm</strong> Push PPSU wallplate elbow with short plastic plugSize Pcs. in one bag/box Code Price €/pcs. Group14×2 G½" 5/60 9017.000 A18×2,5 G½" 5/60 9017.020 APPSU Wallplate elbow is sold with M8 nut and short plastic plug in a set.Plastic short plug is used to make a pressure test only and it shouldn’t be used to blank off the installation permanently.Sealing compounds like adhesives which are chemical aggressive should not be used.To seal the thread use tow with sealing compound (avoid using excessive amount of tow).It is not allowed to connect brass fittings with female pipe cylindrical thread (e.g. G½'') with out-of-the system elements with male pipe conical thread(e.g. R½'').a<strong>KAN</strong> -<strong>therm</strong> Push wallplate elbow with short plastic plugSize Pcs. in one bag/box Code Price €/pcs. Group∅14×2 G½" (K) 5/70 9017.030 A∅18×2,5 G½" (K) 5/70 9017.050 A∅18×2,5 G½" (D) 5/60 9017.070 A(K) short version: a = 41 mm; b = 20 mm(D) long version: a = 52,5 mm; b = 31,5 mmbTo fix the wallplate elbow to the wall use the mountig plate. Battery connections can be used in central heating systems in connections of a radiator with walloutputs (by cables in a wall chase) by angle valve.It is not allowed to connect brass fittings with female pipe cylindrical thread (e.g. G½'') with out-of-the system elements with male pipe conical thread (e.g. R½'').PPSU Wallplate elbow is sold with fixing bolt and short plastic plug in a set.Plastic short plug is used to make a pressure test only and it shouldn’t be used to blank off the installation permanently.<strong>KAN</strong> -<strong>therm</strong> Push wallplate angle tee with short plastic plugSize Pcs. in one bag/box Code Price €/pcs. Group*∅18×2,5/∅18×2,5 G½" (MN) 5/60 9017.090 A(MN) - brass fitting, nickel platedTo fix the wallplate elbow to the wall use the mountig plate.To seal the thread use tow with sealing compound (avoid using excessive amount of tow).Sealing compounds like adhesives which are chemical aggressive should not be used.PPSU Wallplate elbow is sold with fixing bolt and short plastic plug in a set.Plastic short plug is used to make a pressure test only and it shouldn’t be used to blank off the installation permanently.*<strong>KAN</strong> -<strong>therm</strong> Push PPSU wallplate elbowSize Pcs. in one bag/box Code Price €/pcs. Group14×2 G½" 10/80 9018.660 A18×2,5 G½" 10/80 9018.680 APlastic short plug is used to make a pressure test only and it shouldn’t be used to blank off the installation permanently. <strong>KAN</strong>-<strong>therm</strong> plastic plug code6095.33.To seal the thread use tow with sealing compound (avoid using excessive amount of tow).Sealing compounds like adhesives which are chemical aggressive should not be used.It is not allowed to connect brass fittings with female pipe cylindrical thread (e.g. G½'') with out-of-the system elements with male pipe conical thread(e.g R½'').a*<strong>KAN</strong> -<strong>therm</strong> Push wallplate elbowSize Pcs. in one bag/box Code Price €/pcs. Group∅14×2 G½" (K) 10/100 9029.08 A∅18×2,5 G½" (K) 10/100 9029.07 A∅18×2,5 G½" (D) 10/80 9029.10 A(K) short version: a = 41 mm; b = 20 mm(D) long version: a = 52,5 mm; b = 31,5 mmbTo fix the wallplate elbow to the wall use the mountig). Battery connections can be used in central heating systems in connections of a radiator with walloutputs (by cables in a wall chase) by angle valve.It is not allowed to connect brass fittings with female pipe cylindrical thread (e.g. G½'') with out-of-the system elements with male pipe conical thread(e.g. R½'')..Plastic short plug is used to make a pressure test only and it shouldn’t be used to blank off the installation permanently. <strong>KAN</strong>-<strong>therm</strong> plastic plug code6095.33.*<strong>KAN</strong> -<strong>therm</strong> Push wallplate angle teeSize Pcs. in one bag/box Code Price €/pcs. Group∅18×2,5/∅18×2,5 G½" 10/60 9006.53 A∅18×2,5/∅18×2,5 G½" (MN) 10/60 9006.53B A(MN) - brass fitting, nickel platedTo fix the wallplate elbow to the wall use the mountig plate.It is not allowed to connect brass fittings with female pipe cylindrical thread (e.g. G½'') with out-of-the system elements with male pipe conical thread(e.g. R½'').Plastic short plug is used to make a pressure test only and it shouldn’t be used to blank off the installation permanently. <strong>KAN</strong>-<strong>therm</strong> plastic plug code6095.33.- 18 -* stock-out goods catalog net prices - no discount** on request (delivery date about 2 weeks) Push sliding sleeve not included

4 <strong>KAN</strong>-<strong>therm</strong> Push System - for water and heating systems up to 10 bar<strong>KAN</strong> -<strong>therm</strong> plastic plug for pressure test - short - service partSize Pcs. in one bag/box Code Price €/pcs. GroupG½" 20/300 6095.33 AIt may be repeatedly use (has O-Ring seal) and should be used for all <strong>KAN</strong>-<strong>therm</strong> wallplate elbows and wallplate tees.Plastic short plug is used only to make the pressure test and it cannot be use to blank off the installation permanently.<strong>KAN</strong> -<strong>therm</strong> mounting bolt - service partPcs. in one bag/box New code Code Price €/pcs. Group100/2000 K-505100 6096.02 AUse for wallplate elbow and tee to fix to the mounting plate.<strong>KAN</strong> -<strong>therm</strong> Push sliding sleeveSize Pcs. in one bag/box Code Price €/pcs. Group∅12×2A 50/700 9014.490 A∅14×2A 50/700 9006.01 A∅18×2,5A 50/500 9001.80 A∅25×3,5A 20/200 9006.78 A∅32×4,4A 10/100 9019.07 ASize with A letter means use of sleeve for pipes PE-Xc or PE-RT with EVOH layer only.When assembling Push connections use assembly tools for PE-RT and PE-Xc pipes with appropriate inserts (purchase or rental of tools available in <strong>KAN</strong>branches).NOTES* stock-out goods catalog net prices - no discount** on request (delivery date about 2 weeks) Push sliding sleeve not included- 19 -

<strong>KAN</strong>-<strong>therm</strong> Push System - for water and heating systems up to 6 bar 5<strong>KAN</strong> -<strong>therm</strong> pipe PE-Xc acc. to DIN 16892/93 with EVOH layer acc. to DIN 4726 - for Push and screw fittingsSize Pipe length in coil/on palette Code Price €/m Group∅12×2 200/4000 0.2144 C∅14×2 200/4000 0.2145 C∅18×2 200/3000 0.2148 C∅25×3,5 50/1000 0.9127 C∅32×4,4 25/500 0.9133 C<strong>KAN</strong> -<strong>therm</strong> pipe PE-RT with EVOH layer acc. to DIN 4726Size Pipe length in coil/on palette Code Price €/m Group∅12×2 200/4000 0.2174 C∅14×2 200/4000 0.2175 C∅18×2 200/3000 0.2178 C∅25×3,5 50/1000 0.9226 C<strong>KAN</strong> -<strong>therm</strong> Push straight male connectorSize Pcs. in one bag/box Code Price €/pcs. Group∅12×2 G½" 10/150 9014.580 A∅14×2 G½" 10/150 9006.37K A** ∅14×2 G½" (MN) 10/150 9006.37KC A∅18×2 G½" 10/150 9006.89K A** ∅18×2 G½" (MN) 10/150 9006.89KC A∅25×3,5 G½" 10/100 9014.98 A** ∅25×3,5 G½" (MN) 10/100 9014.98C A∅25×3,5 G¾" 10/100 9014.220 A** ∅25×3,5 G¾" (MN) 10/100 9014.220C A∅32×4,4 G1'' 5/50 9019.030 A** ∅32×4,4 G1'' (MN) 5/50 9019.030C A(MN) - brass fitting, nickel plated<strong>KAN</strong> -<strong>therm</strong> Push straight female connectorSize Pcs. in one bag/box Code Price €/pcs. Group∅12×2 G½" 10/150 9014.590 A∅14×2 G½" 10/150 9014.270 A** ∅14×2 G½" (MN) 10/150 9014.270C A∅18×2 G½" 10/150 9014.280 A** ∅18×2 G½"(MN) 10/150 9014.280C A∅25×3,5 G¾" 5/70 9014.300 A** ∅25×3,5 G¾" (MN) 5/70 9014.300C A∅32×4,4 G1'' 5/50 9019.040 A** ∅32×4,4 G1'' (MN) 5/50 9019.040C A(MN) - brass fitting, nickel platedDon't join them with conical external threads (e.g. R½").<strong>KAN</strong> -<strong>therm</strong> Push eurocone adapterSize Pcs. in one bag/box Code Price €/pcs. Group∅18×2 G½" 20/200 9014.240 A** ∅18×2 G½" (MN) 20/200 9014.240C A(MN) - brass fitting, nickel platedPush eurocone adapter can be used for manifold type 40 (see p. 62) or male tees and elbows.<strong>KAN</strong> -<strong>therm</strong> Push couplingSize Pcs. in one bag/box Code Price €/pcs. Group∅12×2/∅12×2 50/700 9014.610 A∅14×2/∅14×2 50/500 9006.06 A** ∅14×2/∅14×2 (MN) 50/500 9006.06C A∅18×2/∅18×2 20/300 9001.86 A** ∅18×2/∅18×2 (MN) 20/300 9001.86C A∅25×3,5/∅25×3,5 10/100 9006.10 A** ∅25×3,5/∅25×3,5 (MN) 10/100 9006.10C A∅32×4,4/∅32×4,4 5/60 9019.050 A** ∅32×4,4/∅32×4,4 (MN) 5/60 9019.050C A(MN) - brass fitting, nickel plated<strong>KAN</strong> -<strong>therm</strong> Push reducing couplingSize Pcs. in one bag/box Code Price €/pcs. Group∅14×2/∅12×2 50/500 9016.250 A∅18×2/∅12×2 20/400 9016.260 A∅18×2/∅14×2 20/400 9006.060R A** ∅18×2/∅14×2 (MN) 20/400 9006.06RC A∅25×3,5/∅18×2 20/200 9023.06 A** ∅25×3,5/∅18×2 (MN) 20/200 9023.06C A∅32×4,4/∅25×3,5 5/70 9019.120 A** ∅32×4,4/∅25×3,5 (MN) 5/70 9019.120C A(MN) - brass fitting, nickel platedThis coupler is used for repair purposes (re-boring faults) as well as for joining of long pipe sections.- 20 -* stock-out goods catalog net prices - no discount** on request (delivery date about 2 weeks) Push sliding sleeve not included

5 <strong>KAN</strong>-<strong>therm</strong> Push System - for water and heating systems up to 6 bar<strong>KAN</strong> -<strong>therm</strong> Push male teeSize Pcs. in one bag/box Code Price €/pcs. Group∅12×2/∅12×2/∅12×2 (P) 20/200 9014.650 A∅14×2/∅14×2/∅14×2 (P) 10/100 9018.250 A∅14×2/∅14×2/∅14×2 (MN) 20/200 9006.16B A∅18×2/∅18×2/∅18×2 (P) 10/80 9018.010 A∅18×2/∅18×2/∅18×2 (MN) 10/150 9001.79B A∅25×3,5/∅25×3,5/∅25×3,5 (P) 5/40 9018.030 A∅25×3,5/∅25×3,5/∅25×3,5 (MN) 5/60 9006.20B A∅32×4,4/∅32×4,4/∅32×4,4 (P) 2/20 9018.69 A(P) - PPSU fitting, (MN) - brass fitting, nickel plated<strong>KAN</strong> -<strong>therm</strong> Push reducing teeSize Pcs. in one bag/box Code Price €/pcs. Group∅14×2/∅12×2/∅12×2 (P) 20/200 9014.570 A∅14×2/∅12×2/∅14×2 (P) 20/200 9014.560 A∅14×2/∅18×2/∅14×2 (P) 10/100 9018.700 A∅14×2/∅18×2/∅14×2 (MN) 10/150 9013.39B APPSU fitting∅18×2/∅14×2/∅14×2 (P) 10/80 9018.220 A∅18×2/∅14×2/∅14×2 (MN) 10/150 9013.10B A∅18×2/∅14×2/∅18×2 (P) 10/80 9018.210 A∅18×2/∅14×2/∅18×2 (MN) 10/150 9013.11B A∅18×2/∅25×3,5/∅18×2 (P) 5/40 9018.230 A∅18×2/∅25×3,5/∅18×2 (MN) 5/60 9013.12B A∅25×3,5/∅14×2/∅18×2 (P) 5/40 9018.750 A∅25×3,5/∅14×2/∅18×2 (MN) 5/60 9013.43B A∅25×3,5/∅14×2/∅25×3,5 (P) 5/40 9018.740 A∅25×3,5/∅14×2/∅25×3,5 (MN) 5/60 9013.42B A∅25×3,5/∅18×2/∅18×2 (P) 5/40 9018.050 A∅25×3,5/∅18×2/∅18×2 (MN) 5/60 9006.22B A∅25×3,5/∅18×2/∅25×3,5 (P) 5/40 9018.060 A∅25×3,5/∅18×2/∅25×3,5 (MN) 5/60 9006.21B A∅32×4,4/∅18×2/∅25×3,5 (P) 2/20 9018.540 A∅32×4,4/∅18×2/∅32×4,4 (P) 2/20 9018.550 A∅32×4,4/∅25×3,5/∅25×3,5 (P) 2/20 9018.500 A∅32×4,4/∅25×3,5/∅32×4,4 (P) 2/20 9018.520 A(P) - PPSU fitting, (MN) - brass fitting, nickel platedbrass fitting<strong>KAN</strong> -<strong>therm</strong> Push male branch teeSize Pcs. in one bag/box Code Price €/pcs. Group*∅18×2/15Cu - G½" 10/120 9006.64 A∅18×2/15Cu - G½" (MN) 10/120 9006.64B A(MN) - brass fitting, nickel platedTo connect these male tees to copper pipes use: eurocone adapter for copper pipe ∅15, G½”, code K-609010 (see ). p. 58<strong>KAN</strong> -<strong>therm</strong> Push elbowSize Pcs. in one bag/box Code Price €/pcs. Group∅14×2/∅14×2 (P) 20/300 9018.170 A∅14×2/∅14×2 (MN) 20/400 9006.11B A∅18×2/∅18×2 (P) 20/200 9018.180 A∅18×2/∅18×2 (MN) 20/200 9001.78B A∅25×3,5/∅25×3,5 (P) 5/60 9018.200 A∅25×3,5/∅25×3,5 (MN) 10/80 9006.15B APPSU fitting∅32×4,4/∅32×4,4 (P) 5/30 9018.560 A(P) - PPSU fitting, (MN) - brass fitting, nickel platedbrass fitting<strong>KAN</strong> -<strong>therm</strong> Push male elbow (for connection to copper pipes ∅15)Size Pcs. in one bag/box Code Price €/pcs. Group** ∅14×2/15Cu - G½" 20/200 9013.220 A* ∅14×2/15Cu - G½" (MN) 20/200 9013.22B A∅14×2/15Cu - G½" 20/200 9029.12 A* ∅18×2/15Cu - G½" 20/200 9006.65 A∅18×2/15Cu - G½" (MN) 20/200 9006.65B A(MN) - brass fitting, nickel platedTo connect these male tees to copper pipes use: eurocone adapter for copper pipe ∅15, G½”, code K-609010 (see ). p. 58* stock-out goods catalog net prices - no discount** on request (delivery date about 2 weeks) Push sliding sleeve not included- 21 -

<strong>KAN</strong>-<strong>therm</strong> Push System - for water and heating systems up to 6 bar 5<strong>KAN</strong> -<strong>therm</strong> Push tee for radiator connection with dia 15 copper pipe L min = 300 mm, nickel platedSized 1/d 2 Pcs./packing Code Price €/pcs. Group∅14×2/∅14×2 50 9013.14 A∅18×2/∅18×2 60 9001.770 A∅25×3,5/∅25×3,5 40 9003.700 A∅32×4,4/∅32×4,4 25 9019.150 A<strong>KAN</strong> -<strong>therm</strong> Push reducing tee for radiator connection with dia 15 copper pipe L min = 300 mm, nickelplatedSized 1/d 2 Pcs./packing Code Price €/pcs. Group∅18×2/∅14×2 LH 60 9013.16 A∅18×2/∅14×2 RH 50 9013.17 A∅25×3,5/∅18×2 LH 40 9003.130 A∅25×3,5/∅18×2 RH 40 9003.720 A∅32×4,4/∅25×3,5 LH 30 9019.090 A∅32×4,4/∅25×3,5 RH 30 9019.100 A<strong>KAN</strong> -<strong>therm</strong> Push tee for radiator connection with dia 15 copper pipe L min = 750 mm, nickel platedSized 1/d 2 Pcs./packing Code Price €/pcs. Group∅14×2/∅14×2 25 9013.15 A∅18×2/∅18×2 25 9001.830 A∅25×3,5/∅25×3,5 15 9003.710 A∅32×4,4/∅32×4,4 10 9019.160 AL mind 1 d 2<strong>KAN</strong> -<strong>therm</strong> Push coupling for radiator connection with dia 16 multilayer pipe L min = 500 mm<strong>KAN</strong> -<strong>therm</strong> Push reducing tee for radiator connection with dia 15 copper pipe L min = 750 mm, nickelplatedSized 1/d 2 Pcs./packing Code Price €/pcs. Group∅18×2/∅14×2 LH 25 9013.18 A∅18×2/∅14×2 RH 25 9013.19 A∅25×3,5/∅18×2 LH 20 9003.140 A∅25×3,5/∅18×2 RH 20 9003.730 A∅32×4,4/∅25×3,5 LH 15 9019.110 A∅32×4,4/∅25×3,5 RH 15 9019.140 AAll fittings are nickel plated.Other length L min on request.Use RH and LH reduction tees to connect radiators. RH tee identification: looking at bigger diameter the copper pipe bow should be at the right side. Drawingshows LH reduction tee.Various connection options for the fittings with nickel plated tubes with all kinds of fittings are described in the technical part of the catalog - "Screwconnections for pipe PE-RT and PE-Xc".Sized 2/d 1 Pcs./packing Code Price €/pcs. Group∅16×2/∅14×2 50 9027.160 A∅16×2/∅18×2 50 9027.170 Ad 1 d 2L min- 22 -* stock-out goods catalog net prices - no discount** on request (delivery date about 2 weeks) Push sliding sleeve not included

5 <strong>KAN</strong>-<strong>therm</strong> Push System - for water and heating systems up to 6 bar<strong>KAN</strong> -<strong>therm</strong> Push fixed elbow for radiator connection with dia 15 copper pipe, nickel platedSize Pcs./packing Code Price €/pcs. Group∅12×2 L min = 210 mm 60 9016.230 A∅14×2 L min = 210 mm 60 9014.450 A∅14×2 L min = 300 mm 60 9016.000 A∅14×2 L min = 750 mm 25 9016.010 AL min∅18×2 L min = 210 mm 60 9014.470 A∅18×2 L min = 300 mm 60 9016.580 A∅18×2 L min = 750 mm 25 9016.590 AVarious connection options for the fittings with nickel plated tubes with all kinds of fittings are described in the technical part of the catalog - "Screwconnections for pipe PE-RT and PE-Xc".<strong>KAN</strong> -<strong>therm</strong> Push double fixed elbow for radiator connection with dia 15 copper pipe, nickel platedSize Pcs./packing Code Price €/pcs. Group∅12×2 L min = 200 mm 20 9016.240 A∅14×2 L min = 200 mm 20 9014.460 A∅14×2 L min = 300 mm 15 9015.250 A∅18×2 L min = 200 mm 20 9014.480 A∅18×2 L min = 300 mm 15 9015.260 APipes to be cut using minicutter, code 210416.Various connection options for the fittings with nickel plated tubes with all kinds of fittings are described in the technical part of the catalog - "Screwconnections for pipe PE-RT and PE-Xc".50 mmL min + 25 mmL min<strong>KAN</strong> -<strong>therm</strong> Push U-shaped elbow for radiator connection with dia 15 copper pipe, nickel platedSize Pcs./packing Code Price €/pcs. Group** ∅14×2 L=120 30 9016.30 AL=160 30 9016.36 AL=180 30 9016.38 AL=200 20 9016.40 A** ∅18×2 L=120 30 9016.31 AL=160 30 9016.37 AL=180 30 9016.39 AL=200 20 9016.41 AVarious connection options for the fittings with nickel plated tubes with all kinds of fittings are described in the technical part of the catalog - "Screwconnections for pipe PE-RT and PE-Xc".225 mmL<strong>KAN</strong> -<strong>therm</strong> Push PPSU wallplate elbow with short plastic plugSize Pcs. in one bag/box Code Price €/pcs. Group14×2 G½" 5/60 9017.000 A18×2 G½" 5/60 9017.010 APPSU Wallplate elbow is sold with M8 nut and short plastic plug in a set.Plastic short plug is used to make a pressure test only and it shouldn’t be used to blank off the installation permanently.Sealing compounds like adhesives which are chemical aggressive should not be used.To seal the thread use tow with sealing compound (avoid using excessive amount of tow).It is not allowed to connect brass fittings with female pipe cylindrical thread (e.g. G½'') with out-of-the system elements with male pipe conical thread(e.g. R½'').<strong>KAN</strong> -<strong>therm</strong> Push wallplate elbow with short plastic plugSize Pcs. in one bag/box Code Price €/pcs. Group∅14×2 G½" (K) 5/70 9017.030 A∅18×2 G½" (K) 5/70 9017.040 A∅18×2 G½" (D) 5/60 9017.060 Aa(K) short version: a = 41 mm; b = 20 mm(D) long version: a = 52,5 mm; b = 31,5 mmTo fix the wallplate elbow to the wall use the mountig plate. Battery connections can be used in central heating systems in connections of a radiator with walloutputs (by cables in a wall chase) by angle valve.It is not allowed to connect brass fittings with female pipe cylindrical thread (e.g. G½'') with out-of-the system elements with male pipe conical thread(e.g. R½'').PPSU Wallplate elbow is sold with fixing bolt and short plastic plug in a set.Plastic short plug is used to make a pressure test only and it shouldn’t be used to blank off the installation permanently.b<strong>KAN</strong> -<strong>therm</strong> Push wallplate angle tee with short plastic plugSize Pcs. in one bag/box Code Price €/pcs. Group∅18×2/∅18×2 G½" (MN) 5/60 9017.080 A(MN) - brass fitting, nickel platedTo fix the wallplate elbow to the wall use the mountig plate.It is not allowed to connect brass fittings with female pipe cylindrical thread (e.g. G½'') with out-of-the system elements with male pipe conical thread(e.g. R½'').PPSU Wallplate elbow is sold with fixing bolt and short plastic plug in a set.Plastic short plug is used to make a pressure test only and it shouldn’t be used to blank off the installation permanently.* stock-out goods catalog net prices - no discount** on request (delivery date about 2 weeks) Push sliding sleeve not included- 23 -

<strong>KAN</strong>-<strong>therm</strong> Push System - for water and heating systems up to 6 bar 5*<strong>KAN</strong> -<strong>therm</strong> Push PPSU wallplate elbowSize Pcs. in one bag/box Code Price €/pcs. Group14×2 G½" 10/80 9018.660 A18×2 G½" 10/80 9018.670 AFor pressure test use <strong>KAN</strong>-<strong>therm</strong> plastic plug code 6095.33.To seal the thread use tow with sealing compound (avoid using excessive amount of tow).Sealing compounds like adhesives which are chemical aggressive should not be used.It is not allowed to connect brass fittings with female pipe cylindrical thread (e.g. G½'') with out-of-the system elements with male pipe conical thread(e.g R½'').Plastic short plug is used to make a pressure test only and it shouldn’t be used to blank off the installation permanently.ba*<strong>KAN</strong> -<strong>therm</strong> Push wallplate elbowSize Pcs. in one bag/box Code Price €/pcs. Group∅14×2 G½" (K) 10/100 9029.08 A∅18×2 G½" (K) 10/100 9029.06 A∅18×2 G½" (D) 10/80 9029.09 A(K) short version: a = 41 mm; b = 20 mm(D) long version: a = 52,5 mm; b = 31,5 mmTo fix the wallplate elbow to the wall use the mountig plate. Battery connections can be used in central heating systems in connections of a radiator with walloutputs (by cables in a wall chase) by angle valve.It is not allowed to connect brass fittings with female pipe cylindrical thread (e.g. G½'') with out-of-the system elements with male pipe conical thread(e.g. R½'').Plastic short plug is used to make a pressure test only and it shouldn’t be used to blank off the installation permanently.For pressure test use <strong>KAN</strong>-<strong>therm</strong> plastic plug code 6095.33.*<strong>KAN</strong> -<strong>therm</strong> Push wallplate angle teeSize Pcs. in one bag/box Code Price €/pcs. Group∅18×2/∅18×2 G½" 10/60 9006.51 A∅18×2/∅18×2 G½" (MN) 10/60 9006.51B A(MN) - brass fitting, nickel platedTo fix the wallplate elbow to the wall use the mountig plate.It is not allowed to connect brass fittings with female pipe cylindrical thread (e.g. G½'') with out-of-the system elements with male pipe conical thread(e.g. R½'').For pressure test use <strong>KAN</strong>-<strong>therm</strong> plastic plug code 6095.33.Plastic short plug is used to make a pressure test only and it shouldn’t be used to blank off the installation permanently.<strong>KAN</strong> -<strong>therm</strong> plastic plug for pressure test - short - service partSize Pcs. in one bag/box Code Price €/pcs. GroupG½" 20/300 6095.33 AIt may be repeatedly use (has O-Ring seal) and should be used for all <strong>KAN</strong>-<strong>therm</strong> wallplate elbows and wallplate tees.Plastic short plug is used only to make the pressure test and it cannot be use to blank off the installation permanently.<strong>KAN</strong> -<strong>therm</strong> mounting bolt - service partPcs. in one bag/box New code Code Price €/pcs. Group100/2000 K-505100 6096.02 AUse for wallplate elbow and tee to fix to the mounting plate.<strong>KAN</strong> -<strong>therm</strong> Push sliding sleeveSize Pcs. in one bag/box Code Price €/pcs. Group∅12×2A 50/700 9014.490 A∅14×2A 50/700 9006.01 A∅18×2A 50/500 9001.80 A∅25×3,5A 20/200 9006.78 A∅32×4,4A 10/100 9019.07 ASize with A letter means use of sleeve for pipes PE-Xc or PE-RT with EVOH layer only.When assembling Push connections use assembly tools for PE-RT and PE-Xc pipes with appropriate inserts (purchase or rental of tools available in <strong>KAN</strong>branches).NOTES- 24 -* stock-out goods catalog net prices - no discount** on request (delivery date about 2 weeks) Push sliding sleeve not included

6 <strong>KAN</strong>-<strong>therm</strong> Push System - for water systems under pressure of 10 bar<strong>KAN</strong> -<strong>therm</strong> pipe, PE-Xc acc. to DIN 16892/93 without EVOH layer - for Push fittings and screw fittingsSize Pipe length in coil/on palette Code Price €/m Group∅12×2 (1) 200/4000 0.2144 C∅14×2 (1) 200/4000 0.2145 C∅18×2,5 200/3000 0.9118 C∅25×3,5 50/1000 0.9125 C∅32×4,4 25/500 0.9132 C1)PE-Xc pipe ∅12×2 and ∅14×2 with antidiffusion barrier can be used for water systems under pressure of 10 bar<strong>KAN</strong> -<strong>therm</strong> pipe, PE-RT with EVOH layer acc. to DIN 4726 - for Push fittigs and screw fittingsSize Pipe length in coil/on palette Code Price €/m Group∅12×2 (1) 200/4000 0.2174 C∅14×2 (2) 200/4000 0.9214 C∅18×2,5 200/3000 0.9218 C∅25×3,5 50/1000 0.9225 C∅32×4,4 25/500 0.9232 C1)PE-Xc pipe ∅12×2 with antidiffusion barrier can be used for water systems under pressure of 10 bar. For assembly the brass sliding Push ring should beused – code 9014.4902)for assembly the connection with Push connectors the brass sliding Push ring should be used – code 9006.0<strong>KAN</strong> -<strong>therm</strong> Push straight male connectorSize Pcs. in one bag/box Code Price €/pcs. Group∅12×2 G½" 10/150 9014.580 A∅14×2 G½" 10/150 9006.37K A** ∅14×2 G½" (MN) 10/150 9006.37KC A∅18×2,5 G½" 10/150 9006.39K A** ∅18×2,5 G½" (MN) 10/150 9006.39C A∅25×3,5 G½" 10/100 9014.98 A** ∅25×3,5 G½" (MN) 10/100 9014.98C A∅25×3,5 G¾" 10/100 9014.220 A** ∅25×3,5 G¾" (MN) 10/100 9014.220C A∅32×4,4 G1'' 5/50 9019.030 A** ∅32×4,4 G1'' (MN) 5/50 9019.030C A(MN) - brass fitting, nickel plated<strong>KAN</strong> -<strong>therm</strong> Push straight female connectorSize Pcs. in one bag/box Code Price €/pcs. Group∅12×2 G½" 10/150 9014.590 A∅14×2 G½" 10/150 9014.270 A** ∅14×2 G½" (MN) 10/150 9014.270C A∅18×2,5 G½" 10/150 9014.290 A** ∅18×2,5 G½" (MN) 10/150 9014.290C A∅25×3,5 G¾" 5/70 9014.300 A** ∅25×3,5 G¾" (MN) 5/70 9014.300C A∅32×4,4 G1'' 5/50 9019.040 A** ∅32×4,4 G1'' (MN) 5/50 9019.040C A(MN) - brass fitting, nickel platedDon't join them with conical external threads (e.g. R½").<strong>KAN</strong> -<strong>therm</strong> Push eurocone adapterSize Pcs. in one bag/box Code Price €/pcs. Group∅18×2,5 G½" 20/200 9014.250 A** ∅18×2,5 G½" (MN) 20/200 9014.250C A(MN) - brass fitting, nickel platedPush eurocone adapter can be used for manifold type 40 (see p. 62 ) or male tees and elbows.<strong>KAN</strong> -<strong>therm</strong> Push couplingSize Pcs. in one bag/box Code Price €/pcs. Group∅12×2/∅12×2 50/700 9014.610 A∅14×2/∅14×2 50/500 9006.06 A** ∅14×2/∅14×2 (MN) 50/500 9006.06C A∅18×2,5/∅18×2,5 20/400 9006.08 A** ∅18×2,5/∅18×2,5 (MN) 20/400 9023.07 A∅25×3,5/∅25×3,5 10/100 9006.10 A** ∅25×3,5/∅25×3,5 (MN) 10/100 9006.10C A∅32×4,4/∅32×4,4 5/60 9019.050 A** ∅32×4,4/∅32×4,4 (MN) 5/60 9019.050C A(MN) - brass fitting, nickel plated<strong>KAN</strong> -<strong>therm</strong> Push reducing couplingSize Pcs. in one bag/box Code Price €/pcs. Group∅14×2/∅12×2 50/500 9016.250 A∅18×2,5/∅14×2 20/400 9019.130 A** ∅18×2,5/∅14×2 (MN) 20/400 9019.130C A∅25×3,5/∅18×2,5 20/200 9006.11CN A** ∅25×3,5/∅18×2,5 (MN) 20/200 9006.11C A∅32×4,4/∅25×3,5 5/70 9019.120 A** ∅32×4,4/∅25×3,5 (MN) 5/70 9019.120C A(MN) - brass fitting, nickel platedCoupling is used for repair purposes (re-boring faults) as well as for joining of long pipe sections.* stock-out goods catalog net prices - no discount** on request (delivery date about 2 weeks) Push sliding sleeve not included- 25 -

<strong>KAN</strong>-<strong>therm</strong> Push System - for water systems under pressure of 10 bar 6<strong>KAN</strong> -<strong>therm</strong> Push male teeSize Pcs. in one bag/box Code Price €/pcs. Group∅12×2/∅12×2/∅12×2 (P) 20/200 9014.650 A∅14×2/∅14×2/∅14×2 (P) 10/100 9018.250 A∅14×2/∅14×2/∅14×2 (MN) 20/200 9006.16B A∅18×2,5/∅18×2,5/∅18×2,5 (P) 10/80 9018.020 A∅18×2,5/∅18×2,5/∅18×2,5 (MN) 10/150 9006.18B A∅25×3,5/∅25×3,5/∅25×3,5 (P) 5/40 9018.030 A∅25×3,5/∅25×3,5/∅25×3,5 (MN) 5/60 9006.20B A∅32×4,4/∅32×4,4/∅32×4,4 (P) 2/20 9018.69 A(P) - PPSU fitting, (MN) - brass fitting, nickel platedPPSU fitting<strong>KAN</strong> -<strong>therm</strong> Push reducing teeSize Pcs. in one bag/box Code Price €/pcs. Group∅14×2/∅12×2/∅12×2 (P) 20/200 9014.570 A∅14×2/∅12×2/∅14×2 (P) 20/200 9014.560 A∅18×2,5/∅14×2/∅14×2 (P) 10/80 9018.730 A∅18×2,5/∅14×2/∅18×2,5 (P) 10/80 9018.720 A∅18×2,5/∅25×3,5/∅18×2,5 (P) 5/40 9018.240 A∅25×3,5/∅14×2/∅18×2,5 (P) 5/40 9018.760 A∅25×3,5/∅14×2/∅25×3,5 (P) 5/40 9018.740 A∅25×3,5/∅14×2/∅25×3,5 (MN) 5/60 9013.42B A∅25×3,5/∅18×2,5/∅18×2,5 (P) 5/40 9018.070 A∅25×3,5/∅18×2,5/∅18×2,5 (MN) 5/60 9006.67B A∅25×3,5/∅18×2,5/∅25×3,5 (P) 5/40 9018.080 A∅25×3,5/∅18×2,5/∅25×3,5 (MN) 5/60 9006.66B Abrass fitting∅32×4,4/∅18×2,5/∅25×3,5 (P) 2/20 9018.510 A∅32×4,4/∅18×2,5/∅32×4,4 (P) 2/20 9018.530 A∅32×4,4/∅25×3,5/∅25×3,5 (P) 2/20 9018.500 A∅32×4,4/∅25×3,5/∅32×4,4 (P) 2/20 9018.520 A(P) - PPSU fitting, (MN) - brass fitting, nickel plated<strong>KAN</strong> -<strong>therm</strong> Push elbowSize Pcs. in one bag/box Code Price €/pcs. Group∅14×2/∅14×2 (P) 20/300 9018.170 A∅14×2/∅14×2 (MN) 20/400 9006.11B APPSU fitting∅18×2,5/∅18×2,5 (P) 20/200 9018.190 A∅18×2,5/∅18×2,5 (MN) 20/200 9006.13B A∅25×3,5/∅25×3,5 (P) 5/60 9018.200 A∅25×3,5/∅25×3,5 (MN) 10/80 9006.15B A∅32×4,4/∅32×4,4 (P) 5/30 9018.560 A(P) - PPSU fitting, (MN) - brass fitting, nickel platedbrass fitting<strong>KAN</strong> -<strong>therm</strong> Push male elbow (for connection to copper pipes ∅15)Size Pcs. in one bag/box Code Price €/pcs. Group** ∅14×2/15Cu - G½" 20/200 9013.220 A* ∅14×2/15Cu - G½" (MN) 20/200 9013.22B A∅14×2/15Cu - G½" 20/200 9029.12 A(MN) - brass fitting, nickel platedTo connect these male tees to copper pipes use: eurocone adapter for copper pipe ∅15, G½”, code K-609010 (see ). p. 58d 1d 2L min<strong>KAN</strong> -<strong>therm</strong> Push coupling for radiator connection with dia 16 multilayer pipe L min = 500 mmSized 2/d 1 Pcs./packing Code Price €/pcs. Group∅16×2/∅14×2 50 9027.160 A∅16×2/∅18×2,5 50 9027.180 A- 26 -225 mmL<strong>KAN</strong> -<strong>therm</strong> Push U-shaped elbow for radiator connection with dia 15 copper pipe, nickel platedSize Pcs./packing Code Price €/pcs. Group** ∅14×2 L=120 30 9016.30 AL=160 30 9016.36 AL=180 30 9016.38 AL=200 20 9016.40 A** ∅18×2,5 L=120 30 9016.420 AL=160 30 9016.430 AL=180 30 9016.440 AL=200 20 9016.450 AVarious connection options for the fittings with nickel plated tubes with all kinds of fittings are described in the technical part of the catalog - "Screwconnections for pipe PE-RT and PE-Xc".* stock-out goods catalog net prices - no discount** on request (delivery date about 2 weeks) Push sliding sleeve not included

6 <strong>KAN</strong>-<strong>therm</strong> Push System - for water systems under pressure of 10 bar<strong>KAN</strong> -<strong>therm</strong> Push fixed elbow for radiator connection with dia 15 copper pipe, nickel platedSize Pcs./packing Code Price €/pcs. Group∅12×2 L min = 210 mm 60 9016.230 A∅14×2 L min = 210 mm 60 9014.450 A∅14×2 L min = 300 mm 60 9016.000 A∅14×2 L min = 750 mm 25 9016.010 A∅18×2,5 L min = 210 mm 60 9015.230 A∅18×2,5 L min = 300 mm 60 9016.020 A∅18×2,5 L min = 750 mm 25 9016.030 AL minVarious connection options for the fittings with nickel plated tubes with all kinds of fittings are described in the technical part of the catalog - "Screwconnections for pipe PE-RT and PE-Xc".<strong>KAN</strong> -<strong>therm</strong> Push double fixed elbow for radiator connection with dia 15 copper pipe, nickel platedSize Pcs./packing Code Price €/pcs. Group∅12×2 L min = 200 mm 20 9016.240 A∅14×2 L min = 200 mm 20 9014.460 A∅14×2 L min = 300 mm 15 9015.250 A∅18×2,5 L min = 200 mm 20 9015.240 A∅18×2,5 L min = 300 mm 15 9015.270 APipes to be cut using minicutter (see p. 33).Various connection options for the fittings with nickel plated tubes with all kinds of fittings are described in the technical part of the catalog - "Screwconnections for pipe PE-RT and PE-Xc".50 mmL min + 25 mmL min<strong>KAN</strong> -<strong>therm</strong> Push tee for radiator connection with dia 15 copper pipe L min = 300 mm, nickel platedSized 1/d 2 Pcs./packing Code Price €/pcs. Group∅14×2/∅14×2 50 9013.14 A∅18×2,5/∅18×2,5 50 9006.310 A∅25×3,5/∅25×3,5 40 9003.700 A∅32×4,4/∅32×4,4 25 9019.150 A<strong>KAN</strong> -<strong>therm</strong> Push reducing tee for radiator connection with dia 15 copper pipe L min = 300 mm, nickelplatedSized 1/d 2 Pcs./packing Code Price €/pcs. Group∅18×2,5/∅14×2 LH 50 9013.500 A∅18×2,5/∅14×2 RH 50 9013.510 A∅25×3,5/∅18×2,5 LH 40 9013.270 A∅25×3,5/∅18×2,5 RH 40 9013.280 A∅32×4,4/∅25×3,5 LH 30 9019.090 A∅32×4,4/∅25×3,5 RH 30 9019.100 A<strong>KAN</strong> -<strong>therm</strong> Push tee for radiator connection with dia 15 copper pipe L min = 750 mm, nickel platedSized 1/d 2 Pcs./packing Code Price €/pcs. Group∅14×2/∅14×2 25 9013.15 A∅18×2,5/∅18×2,5 25 9006.320 A∅25×3,5/∅25×3,5 15 9003.710 A∅32×4,4/∅32×4,4 10 9019.160 A<strong>KAN</strong> -<strong>therm</strong> Push reducing tee for radiator connection with dia 15 copper pipe L min = 750 mm, nickelplatedSized 1/d 2 Pcs./packing Code Price €/pcs. Group∅18×2,5/∅14×2 LH 25 9013.520 A∅18×2,5/∅14×2 RH 25 9013.530 A∅25×3,5/∅18×2,5 LH 20 9013.290 A∅25×3,5/∅18×2,5 RH 20 9013.300 A∅32×4,4/∅25×3,5 LH 15 9019.110 A∅32×4,4/∅25×3,5 RH 15 9019.140 AAll fittings are nickel plated.Other length L min on request.Use RH and LH reduction tees to connect radiators. RH tee identification: looking at bigger diameter the copper pipe bow should be at the right side. Drawingshows LH reduction tee.Various connection options for the fittings with nickel plated tubes with all kinds of fittings are described in the technical part of the catalog - "Screwconnections for pipe PE-RT and PE-Xc".L mind 1* stock-out goods catalog net prices - no discount** on request (delivery date about 2 weeks) Push sliding sleeve not included- 27 -

<strong>KAN</strong>-<strong>therm</strong> Push System - for water systems under pressure of 10 bar 6<strong>KAN</strong> -<strong>therm</strong> Push PPSU wallplate elbow with short plastic plugSize Pcs. in one bag/box Code Price €/pcs. Group14×2 G½" 5/60 9017.000 A18×2,5 G½" 5/60 9017.020 APPSU Wallplate elbow is sold with M8 nut and short plastic plug in a set.Sealing compounds like adhesives which are chemical aggressive should not be used.To seal the thread use tow with sealing compound (avoid using excessive amount of tow).Plastic short plug is used to make a pressure test only and it shouldn’t be used to blank off the installation permanently.It is not allowed to connect brass fittings with female pipe cylindrical thread (e.g. G½'') with out-of-the system elements with male pipe conical thread(e.g. R½'').a<strong>KAN</strong> -<strong>therm</strong> Push wallplate elbow with short plastic plugSize Pcs. in one bag/box Code Price €/pcs. Group∅14×2 G½" (K) 5/70 9017.030 A∅18×2,5 G½" (K) 5/70 9017.050 A∅18×2,5 G½" (D) 5/60 9017.070 A(K) short version: a = 41 mm; b = 20 mm(D) long version: a = 52,5 mm; b = 31,5 mmbTo fix the wallplate elbow to the wall use the mountig plate. Battery connections can be used in central heating systems in connections of a radiator with walloutputs (by cables in a wall chase) by angle valve.It is not allowed to connect brass fittings with female pipe cylindrical thread (e.g. G½'') with out-of-the system elements with male pipe conical thread(e.g. R½'').PPSU Wallplate elbow is sold with fixing bolt and short plastic plug in a set.Plastic short plug is used to make a pressure test only and it shouldn’t be used to blank off the installation permanently.<strong>KAN</strong> -<strong>therm</strong> Push wallplate angle tee with short plastic plugSize Pcs. in one bag/box Code Price €/pcs. Group∅18×2,5/∅18×2,5 G½" (MN) 5/60 9017.090 A(MN) - brass fitting, nickel platedTo fix the wallplate elbow to the wall use the mountig plate.It is not allowed to connect brass fittings with female pipe cylindrical thread (e.g. G½'') with out-of-the system elements with male pipe conical thread(e.g. R½'').PPSU Wallplate elbow is sold with fixing bolt and short plastic plug in a set.Plastic short plug is used to make a pressure test only and it shouldn’t be used to blank off the installation permanently.*<strong>KAN</strong> -<strong>therm</strong> Push PPSU wallplate elbowSize Pcs. in one bag/box Code Price €/pcs. Group14×2 G½" 10/80 9018.660 A18×2,5 G½" 10/80 9018.680 AFor pressure test use <strong>KAN</strong>-<strong>therm</strong> plastic plug code 6095.33.Plastic short plug is used to make a pressure test only and it shouldn’t be used to blank off the installation permanently.To seal the thread use tow with sealing compound (avoid using excessive amount of tow).Sealing compounds like adhesives which are chemical aggressive should not be used.It is not allowed to connect brass fittings with female pipe cylindrical thread (e.g. G½'') with out-of-the system elements with male pipe conical thread(e.g R½'').a*<strong>KAN</strong> -<strong>therm</strong> Push wallplate elbowSize Pcs. in one bag/box Code Price €/pcs. Group∅14×2 G½" (K) 10/100 9029.08 A∅18×2,5 G½" (K) 10/100 9029.07 A∅18×2,5 G½" (D) 10/80 9029.10 A(K) short version: a = 41 mm; b = 20 mm(D) long version: a = 52,5 mm; b = 31,5 mmbTo fix the wallplate elbow to the wall use the mountig plate. Battery connections can be used in central heating systems in connections of a radiator with walloutputs (by cables in a wall chase) by angle valve.It is not allowed to connect brass fittings with female pipe cylindrical thread (e.g. G½'') with out-of-the system elements with male pipe conical thread(e.g. R½'').For pressure test use <strong>KAN</strong>-<strong>therm</strong> plastic plug code 6095.33.Plastic short plug is used to make a pressure test only and it shouldn’t be used to blank off the installation permanently.*<strong>KAN</strong> -<strong>therm</strong> Push wallplate angle teeSize Pcs. in one bag/box Code Price €/pcs. Group∅18×2,5/∅18×2,5 G½" 10/60 9006.53 A∅18×2,5/∅18×2,5 G½" (MN) 10/60 9006.53B A(MN) - brass fitting, nickel platedTo fix the wallplate elbow to the wall use the mountig plate.It is not allowed to connect brass fittings with female pipe cylindrical thread (e.g. G½'') with out-of-the system elements with male pipe conical thread(e.g. R½'').For pressure test use <strong>KAN</strong>-<strong>therm</strong> plastic plug code 6095.33.Plastic short plug is used to make a pressure test only and it shouldn’t be used to blank off the installation permanently.- 28 -* stock-out goods catalog net prices - no discount** on request (delivery date about 2 weeks) Push sliding sleeve not included

6 <strong>KAN</strong>-<strong>therm</strong> Push System - for water systems under pressure of 10 bar<strong>KAN</strong> -<strong>therm</strong> plastic plug for pressure test - short - service partSize Pcs. in one bag/box Code Price €/pcs. GroupG½" 20/300 6095.33 AIt may be repeatedly use (has O-Ring seal) and should be used for all <strong>KAN</strong>-<strong>therm</strong> wallplate elbows and wallplate tees.Plastic short plug is used only to make the pressure test and it cannot be use to blank off the installation permanently.<strong>KAN</strong> -<strong>therm</strong> mounting bolt - service partUse for wallplate elbow and tee to fix to the mounting plate.Pcs. in one bag/box New code Code Price €/pcs. Group100/2000 K-505100 6096.02 A<strong>KAN</strong> -<strong>therm</strong> Push sliding sleeveSize Pcs. in one bag/box Code Price €/pcs. Group∅12×2A 50/700 9014.490 A∅14×2A 50/700 9006.01 A∅18×2,5 50/500 9006.76 A∅25×3,5 20/200 9006.05 A∅32×4,4 10/100 9019.06 ASize with A letter means use of sleeve for pipes PE-Xc or PE-RT with EVOH layer only.When assembling Push connections use assembly tools for PE-RT and PE-Xc pipes with appropriate inserts (purchase or rental of tools available in <strong>KAN</strong>branches).NOTES* stock-out goods catalog net prices - no discount** on request (delivery date about 2 weeks) Push sliding sleeve not included- 29 -

<strong>KAN</strong>-<strong>therm</strong> System - screw fittings for pipes PE-Xc and PE-RT 7<strong>KAN</strong> -<strong>therm</strong> pipe PE-Xc acc. to DIN 16892/93 with EVOH layer acc. to DIN 4726 - for Push and screwfittingsSize Pipe length in coil/on palette Code Price €/m Group∅12×2 200/4000 0.2144 C∅14×2 200/4000 0.2145 C∅18×2 200/3000 0.2148 C∅18×2,5 200/3000 0.9119 C∅25×3,5 50/1000 0.9127 C∅32×4,4 25/500 0.9133 C<strong>KAN</strong> -<strong>therm</strong> pipe PE-Xc acc. to DIN 16892/93 with EVOH layer acc. to DIN 4726 - for screw fittings onlySize Pipe length in coil/on palette Code Price €/m Group∅16×2 200/3000 0.2146 C<strong>KAN</strong> -<strong>therm</strong> pipe, PE-Xc acc. to DIN 16892/93 without EVOH layer - for Push fittings and screw fittingsSize Pipe length in coil/on palette Code Price €/m Group∅18×2,5 200/3000 0.9118 C∅25×3,5 50/1000 0.9125 C∅32×4,4 25/500 0.9132 C<strong>KAN</strong> -<strong>therm</strong> pipe, PE-RT with EVOH layer acc. to DIN 4726 - for Push fittigs and screw fittingsSize Pipe length in coil/on palette Code Price €/m Group∅12×2 200/4000 0.2174 C∅14×2 200/4000 0.2175 C∅18×2 200/3000 0.2178 C∅25×3,5 50/1000 0.9226 C<strong>KAN</strong> -<strong>therm</strong> pipe, PE-RT with EVOH layer acc. to DIN 4726 - for screw fittings onlySize Pipe length in coil/on palette Code Price €/m Group∅16×2 200/3000 0.2176 C<strong>KAN</strong> -<strong>therm</strong> pipe, PE-RT without EVOH layer - for Push fittings and screw fittingsSize Pipe length in coil/on palette Code Price €/m Group∅18×2,5 200/3000 0.9218 C∅25×3,5 50/1000 0.9225 C∅32×4,4 25/500 0.9232 C- 30 -catalog net prices - no discountPE-Xc and PE-RT tubes have technical approval and positive hygienic assessment

7 <strong>KAN</strong>-<strong>therm</strong> System - screw fittings for pipes PE-Xc and PE-RT<strong>KAN</strong> -<strong>therm</strong> compression straight male connectorSize Pcs. in one bag/box Code Price €/pcs. Group∅12×2 G½" 10/150 9014.23 A** ∅12×2 G½" (MN) 10/150 9014.23C A∅14×2 G½" 10/150 9006.42 A** ∅14×2 G½" (MN) 10/150 9006.42C A∅16×2 G½" 10/150 9006.43 A** ∅16×2 G½" (MN) 10/150 9006.43C A∅18×2 G½" 10/150 9001.94 A** ∅18×2 G½"(MN) 10/150 9001.94C A∅18×2,5 G½" 10/150 9006.44 A** ∅18×2,5 G½" (MN) 10/150 9006.00 A∅25×3,5 G½" 10/80 9014.310 A** ∅25×3,5 G½" (MN) 10/80 9014.310C A∅25×3,5 G¾" 10/80 9001.90 A** ∅25×3,5 G¾" (MN) 10/80 9001.00 A∅32×4,4 G1" 5/30 9019.000 A** ∅32×4,4 G1" (MN) 5/30 9019.000C A(MN) - brass fitting, nickel platedConnection with general purpose fittings possible.<strong>KAN</strong> -<strong>therm</strong> compression straight female connectorSize Pcs. in one bag/box Code Price €/pcs. Group∅12×2 G½" 10/150 9014.320 A** ∅12×2 G½" (MN) 10/150 9014.320C A∅14×2 G½" 10/150 9014.330 A** ∅14×2 G½" (MN) 10/150 9014.330C A∅16×2 G½" 10/150 9014.340 A** ∅16×2 G½" (MN) 10/150 9014.340C A∅18×2 G½" 10/150 9014.350 A** ∅18×2 G½" (MN) 10/150 9014.350C A∅18×2,5 G½" 10/150 9014.360 A** ∅18×2,5 G½" (MN) 10/150 9014.360C A∅25×3,5 G¾" 10/80 9014.370 A** ∅25×3,5 G¾" (MN) 10/80 9014.370C A∅32×4,4 G1" 5/30 9019.010 A** ∅32×4,4 G1" (MN) 5/30 9019.010C A(MN) - brass fitting, nickel platedConnection with general purpose fittings possible.Don't join them with conical external threads (e.g. R½'').<strong>KAN</strong> -<strong>therm</strong> compression couplingSize Pcs. in one bag/box Code Price €/pcs. Group∅12×2 10/120 9014.16 A** ∅12×2 (MN) 10/120 9014.16C A∅14×2 10/120 9014.13 A** ∅14×2 (MN) 10/120 9014.13C A∅16×2 10/150 9014.14 A** ∅16×2 (MN) 10/150 9014.14C A∅18×2 10/120 981 A** ∅18×2 (MN) 10/120 981C A∅18×2,5 10/120 9014.17 A** ∅18×2,5 (MN) 10/120 9014.17C A∅25×3,5 5/60 9014.19 A** ∅25×3,5 (MN) 5/60 9014.19C A∅32×4,4 2/30 9019.02 A** ∅32×4,4 (MN) 2/30 9019.02C A(MN) - brass fitting, nickel platedThis coupler is used for repair purposes (re-boring faults) as well as for joining of long pipe sections.<strong>KAN</strong> -<strong>therm</strong> eurocone adapter (nickel plated nut)Size Pcs. in one bag/box Code Price €/pcs. Group∅12×2 G½" 15/300 9012.91 A∅12×2 G¾" 15/150 9012.92 A∅14×2 G½" 15/300 9003.47 A∅14×2 G¾" 15/150 9006.56 A∅16×2 G¾" 15/150 9006.57 A∅18×2 G¾" 15/150 9006.59 A∅18×2,5 G¾" 15/150 9006.48 A∅25×3,5 G1" 10/80 9003.67 AIt can make possible connections with manifolds with male nipples and fittings.<strong>KAN</strong> -<strong>therm</strong> special spanner for eurocone adaptersSize Code Price €/pcs. Group30 mm K-501900 AThe spanner intended for eurocone adapter G¾" montage.<strong>KAN</strong> -<strong>therm</strong> compression ring - service part for screw fittingsSize Pcs. in one bag/box Code Price €/pcs. Group∅12 100/1000 9012.913 A∅14 100/1000 9006.95 A∅16 100/1000 9006.97 A∅18 100/1000 9001.96 A∅25 50/500 9001.92 AFor fittings acc. to (see p. 31).* stock-out goods catalog net prices - no discount** on request (delivery date about 2 weeks) Push sliding sleeve not included- 31 -

<strong>KAN</strong>-<strong>therm</strong> System - Push tools 8<strong>KAN</strong> -<strong>therm</strong> hydraulic Push tool with foot drive - KPPN setCode Price €/pcs. GroupKPPN- P PSUKIt consists of the following items: PN01, PT8471, PT8469, PT8468, PT8467, P8471 (2 pcs.), P8469 (2 pcs.), P8468 (2 pcs.), P8467 (2 pcs.), 84550, Z-P12,Z-P14, Z-P18, Z-P185, Z-P25, Z-P32, 002.001.003, 0.2125.<strong>KAN</strong> -<strong>therm</strong> hydraulic Push tool with foot drive (for Push fittings from ∅14 to ∅32)For connection PE-Xc and PE-RT pipes with Push fittings couplings (see Chapter 1, 2, 3).Code Price €/pcs. GroupPN01K<strong>KAN</strong> -<strong>therm</strong> mechanical hand Push tool - KPPR setCode Price €/pcs. GroupKPPR-PPSU/NKIt consists of the following items: PR01/N, MZH1418 (set), MZH2532 (set), PT8471, PT8469, PT8468, PT8467, P8471 (2 pcs.), P8469 (2 pcs.), P8468(2 pcs.), P8467 (2 pcs.), 84550, Z-P12, Z-P14, Z-P18, Z-P185, Z-P25, Z-P32, 002.001.002, 0.2125.<strong>KAN</strong> -<strong>therm</strong> manual mechanical Push tool<strong>KAN</strong> -<strong>therm</strong> jaw for manual mechanical Push toolCode Price €/pcs. GroupPR01/NKSize Code Price €/set Group∅12-∅18 (set - 2pcs.) MZH1418 K∅25-∅32 (set - 2pcs.) MZH2532 KFor connection PE-Xc and PE-RT pipes with sliding Push fittings (see Chapter 1, 2, 3).<strong>KAN</strong> -<strong>therm</strong> insert for hydraulic and manual mechanical Push tool (for PPSU Push tees and elbows)Size Code Price €/pcs. Group∅12×2 PT8471 K∅14×2 PT8469 K∅18×2 (∅18×2,5) PT8468 K∅25×3,5 PT8467 KCan be used together with hydraulic with foot drive or mechanical or electric-hydraulic Push tool.For mounting of elbows and tees made of PPSU from fitting side following inserts are to be used: PT8471 for diameter 12 (black insert), PT8469 for diameter 14 (black insert) PT8468 for diameter 16 (black insert) PT8467 for diameter 25 (black insert) P8467 for diameter 32 (nickel plated insert)For PPSU body never use inserts for brass elbows and tees P8466, P8464 or inserts for wallplate elbows P8470.<strong>KAN</strong> -<strong>therm</strong> insert for hydraulic and manual mechanical Push tool (for Push coupling or Push sliding sleeve)Size Code Price €/pcs. Group∅12×2 P8471 K∅14×2 P8469 K∅18×2 (∅18×2,5) P8468 K∅25×3,5 (∅32×4,4 PPSU) P8467 KCan be used together with hydraulic with foot drive or mechanical or electric-hydraulic Push tool.<strong>KAN</strong> -<strong>therm</strong> insert for hydraulic and manual mechanical Push tool (for brass Push tees and elbows)Size Code Price €/pcs. Group∅14×2 P8465 K∅18×2 (∅18×2,5) P8463 K∅25×3,5 (∅32×4,4) P8464 KCan be used together with hydraulic with foot drive or mechanical or electric-hydraulic Push tool.<strong>KAN</strong> -<strong>therm</strong> insert for hydraulic and manual mechanical Push tool (for Push brass wallplate elbows)Size Code Price €/pcs. Group∅18×2 P8470 KCan be used together with hydraulic with foot drive or mechanical or electric-hydraulic Push tool.- 32 -catalog net prices - no discount

8 <strong>KAN</strong>-<strong>therm</strong> System - Push tools<strong>KAN</strong> -<strong>therm</strong> expanding tool for pipes PE-Xc and PE-RTCode Price €/pcs. Group84550 KUsed with Z-P... expanding head.<strong>KAN</strong> -<strong>therm</strong> expanding headSize Code Price €/pcs. Group∅12×2 Z-P12 K∅14×2 Z-P14 K∅18×2 Z-P18 K∅18×2,5 Z-P185 K∅25×3,5 Z-P25 K∅32×4,4 Z-P32 KUsed with expanding tool 84550.<strong>KAN</strong> -<strong>therm</strong> tool case for hydraulic Push tool with foot driveCode Price €/pcs. Group002.001.003 KFor hydraulic Push tool with foot drive PN01, inserts, expanding tool 84550, expanding head, cutter for pipes PE-Xc and PE-RT, code 02125.<strong>KAN</strong> -<strong>therm</strong> tool case for manual mechanical Push toolCode Price €/pcs. Group002.001.002 KFor manual mechanical Push tool PR01/N, inserts, expanding tool 84550, expanding head, cutter for pipes PE-Xc and PE-RT, code 02125.<strong>KAN</strong> -<strong>therm</strong> cutter for Ø12-32 pipes PE-Xc and PE-RTPcs. in one bag/box Code Price €/pcs. Group1/25 0.2125 K<strong>KAN</strong> -<strong>therm</strong> replacement blade for cutter for Ø12-32 pipes PE-Xc and PE-RTCode Price €/pcs. Group0.2125-OK<strong>KAN</strong> -<strong>therm</strong> minicutter for Ø15 copper pipes 4-16 mmCode Price €/pcs. Group210416 Kcatalog net prices - no discount- 33 -

<strong>KAN</strong>-<strong>therm</strong> Press SystemISO 9001 : 2000TECHNOLOGYOF SUCCESS