model fsd-af-fa-212 combination fire / smoke damper - NCA ...

model fsd-af-fa-212 combination fire / smoke damper - NCA ...

model fsd-af-fa-212 combination fire / smoke damper - NCA ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

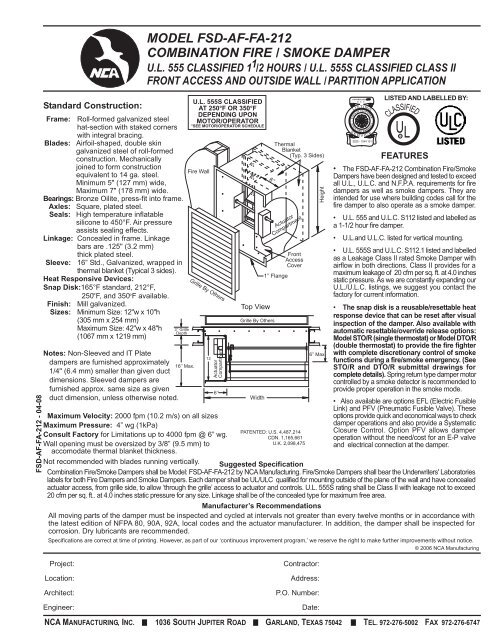

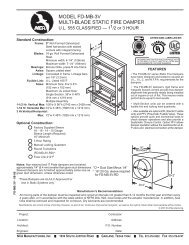

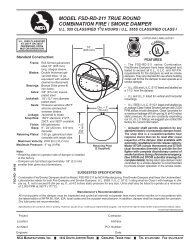

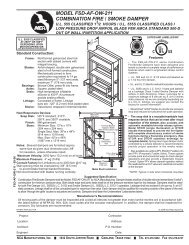

FSD-AF-FA-<strong>212</strong> - 04-08Standard Construction:Frame: Roll-formed galvanized steelhat-section with staked cornerswith integral bracing.Blades: Airfoil-shaped, double skingalvanized steel of roll-formedconstruction. Mechanicallyjoined to form constructionequivalent to 14 ga. steel.Minimum 5" (127 mm) wide,Maximum 7" (178 mm) wide.Bearings: Bronze Oilite, press-fit into frame.Axles:Seals:Square, plated steel.High temperature inflatablesilicone to 450°F. Air pressureassists sealing effects.Linkage: Concealed in frame. Linkagebars are .125" (3.2 mm)thick plated steel.Sleeve:16” Std., Galvanized, wrapped inthermal blanket (Typical 3 sides).Heat Responsive Devices:Snap Disk:165°F standard, <strong>212</strong>°F,250 ° F, and 350 ° F available.Finish: Mill galvanized.Sizes: Minimum Size: 12"w x 10"h(305 mm x 254 mm)Maximum Size: 42"w x 48"h(1067 mm x 1219 mm)Notes: Non-Sleeved and IT Plate<strong>damper</strong>s are furnished approximately1/4" (6.4 mm) smaller than given ductdimensions. Sleeved <strong>damper</strong>s arefurnished approx. same size as givenduct dimension, unless otherwise noted.Maximum Velocity: 2000 fpm (10.2 m/s) on all sizesMaximum Pressure: 4” wg (1kPa)Consult Factory for Limitations up to 4000 fpm @ 6” wg.Wall opening must be oversized by 3/8” (9.5 mm) toaccomodate thermal blanket thickness.MODEL FSD-AF-FA-<strong>212</strong>COMBINATION FIRE / SMOKE DAMPERU.L. 555 CLASSIFIED 1 1 /2 HOURS / U.L. 555S CLASSIFIED CLASS IIFRONT ACCESS AND OUTSIDE WALL / PARTITION APPLICATION3’’ GrilleDepth16’’ Max.U.L. 555S CLASSIFIEDAT 250°F OR 350°FDEPENDING UPONMOTOR/OPERATOR*SEE MOTOR/OPERATOR SCHEDULEFire WallGrille By Others12ActuatorCompartment6’’Top ViewWidthPATENTED: U.S. 4,487,214CDN. 1,165,661U.K. 2,098,475FEATURES• The FSD-AF-FA-<strong>212</strong> Combination Fire/SmokeDampers have been designed and tested to exceedall U.L., U.L.C. and N.F.P.A. requirements for <strong>fire</strong><strong>damper</strong>s as well as <strong>smoke</strong> <strong>damper</strong>s. They areintended for use where building codes call for the<strong>fire</strong> <strong>damper</strong> to also operate as a <strong>smoke</strong> <strong>damper</strong>.• U.L. 555 and U.L.C. S112 listed and labelled asa 1-1/2 hour <strong>fire</strong> <strong>damper</strong>.• U.L.and U.L.C. listed for vertical mounting.• U.L. 555S and U.L.C. S112.1 listed and labelledas a Leakage Class II rated Smoke Damper withairflow in both directions. Class II provides for amaximum leakage of 20 cfm per sq. ft. at 4.0 inchesstatic pressure. As we are constantly expanding ourU.L./U.L.C. listings, we suggest you contact the<strong>fa</strong>ctory for current information.• The snap disk is a reusable/resettable heatresponse device that can be reset <strong>af</strong>ter visualinspection of the <strong>damper</strong>. Also available withautomatic resettable/override release options:Model STO/R (single thermostat) or Model DTO/R(double thermostat) to provide the <strong>fire</strong> fighterwith complete discretionary control of <strong>smoke</strong>functions during a <strong>fire</strong>/<strong>smoke</strong> emergency. (SeeSTO/R and DTO/R submittal drawings forcomplete details). Spring return type <strong>damper</strong> motorcontrolled by a <strong>smoke</strong> detector is recommended toprovide proper operation in the <strong>smoke</strong> mode.• Also available are options EFL (Electric FusibleLink) and PFV (Pneumatic Fusible Valve). Theseoptions provide quick and economical ways to check<strong>damper</strong> operations and also provide a SystematicClosure Control. Option PFV allows <strong>damper</strong>operation without the need/cost for an E-P valveand electrical connection at the <strong>damper</strong>.Not recommended with blades running vertically. Suggested SpecificationCombination Fire/Smoke Dampers shall be Model: FSD-AF-FA-<strong>212</strong> by <strong>NCA</strong> Manu<strong>fa</strong>cturing. Fire/Smoke Dampers shall bear the Underwriters' Laboratorieslabels for both Fire Dampers and Smoke Dampers. Each <strong>damper</strong> shall be UL/ULC qualified for mounting outside of the plane of the wall and have concealedactuator access, from grille side, to allow ‘through the grille’ access to actuator and controls. U.L. 555S rating shall be Class II with leakage not to exceed20 cfm per sq. ft.. at 4.0 inches static pressure for any size. Linkage shall be of the concealed type for maximum free area.Manu<strong>fa</strong>cturer’s RecommendationsAll moving parts of the <strong>damper</strong> must be inspected and cycled at intervals not greater than every twelve months or in accordance withthe latest edition of NFPA 80, 90A, 92A, local codes and the actuator manu<strong>fa</strong>cturer. In addition, the <strong>damper</strong> shall be inspected forcorrosion. Dry lubricants are recommended.Specifications are correct at time of printing. However, as part of our ‘continuous improvement program,’ we reserve the right to make further improvements without notice.© 2006 <strong>NCA</strong> Manu<strong>fa</strong>cturing6’’Grille By OthersThermalBlanket(Typ. 3 Sides)ActuatorCompartment1’’ FlangeFrontAccessCoverHeight6’’ Max.LISTINGSTATE OF CALIFORNIASTATEFIRES E R VM A R S H A L LIC ELISTED AND LABELLED BY:CLASSIFIEDU L RProject:Location:Architect:Engineer:Contractor:Address:P.O. Number:Date:<strong>NCA</strong> MANUFACTURING, INC. 1036 SOUTH JUPITER ROAD GARLAND, TEXAS 75042 TEL. 972-276-5002 FAX 972-276-6747

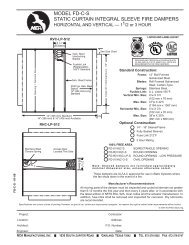

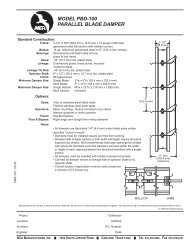

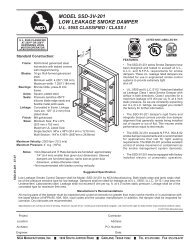

MODEL FSD-AF-FA-<strong>212</strong>COMBINATION FIRE / SMOKE DAMPERU.L. 555 CLASSIFIED 1 1 /2 HOURS / U.L. 555S CLASSIFIED CLASS IIFRONT ACCESS AND OUTSIDE WALL / PARTITION APPLICATIONPERFORMANCE DATA© 2006 <strong>NCA</strong> Manu<strong>fa</strong>cturingPressure drop testing was done by an independent laboratory to the AMCA Standard 500-D, Fig. 5.3ductwork upstream & downstream.PRESSURE DROP - INCHES OF WATER (In. W.C.)1.0.9.8.7.6.5.4.3.25.2.15.1.09.08.07.06.05.04.03.025.02.015.01DAMPER SIZE 36 x 36100 150 200 300 400 500 700 900 1500 2000 3000 4000 60001000VELOCITY THROUGH FACE AREA2.5DAMPER SIZE 24 x 242.5DAMPER SIZE 12 X 1222FSD-AF-FA-<strong>212</strong> - 09-06PRESSURE DROP - INCHES OF WATER (In. W.C.)1.51.0.9.8.7.6.5.4.3.25.2.15.1.09.08.07.06.05.04.03.025.02.015PRESSURE DROP - INCHES OF WATER (In. W.C.)1.51.0.9.8.7.6.5.4.3.25.2.15.1.09.08.07.06.05.04.03.025.02.015.01100 150 200 300 400 500 700 900 1500 2000 3000 4000 60001000VELOCITY THROUGH FACE AREA.01100 150 200 300 400 500 700 900 1500 2000 3000 4000 60001000VELOCITY THROUGH FACE AREA<strong>NCA</strong> MANUFACTURING, INC. 1036 SOUTH JUPITER ROAD GARLAND, TEXAS 75042 TEL. 972-276-5002 FAX 972-276-6747