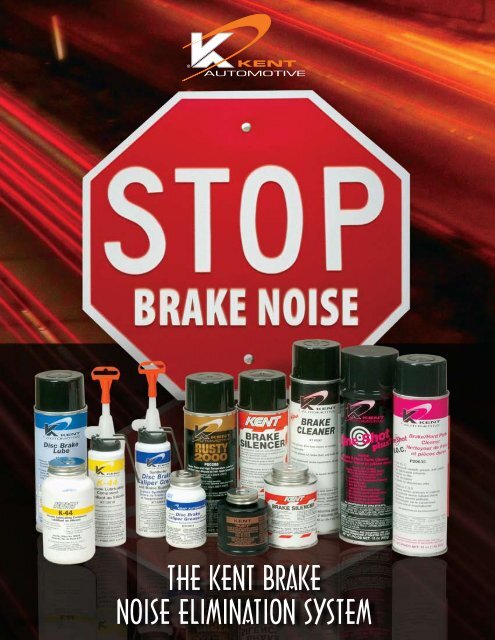

the kent brake noise elimination system - Kent-Automotive.com

the kent brake noise elimination system - Kent-Automotive.com

the kent brake noise elimination system - Kent-Automotive.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

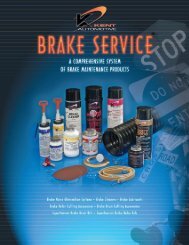

THE KENT BRAKENOISE ELIMINATION SYSTEM

THE KENT BRAKE NOISE ELIMINATION SYSTEM1Disassemblyand Cleaning3Brake HardwareLubricationPiston Rubber4LubricationONE SHOT V.O.C.Part Nos. P20635* and KT14372ONE SHOTPLUSPart No. P20100ONE SHOTBRAKECLEANERPart No.KT12267*BRAKE ANDPARTS CLEANERPart No. KT14126*A. Remove pads/linings fromcaliper/ <strong>brake</strong> assembly.B. Sand pad/lining surface usinga light to medium sandpaper oremery cloth. This will remove <strong>the</strong>glaze (on used pads/linings).RUSTY 2000Part No.P50258RUSTYBRAKEPLATE LUBEPart No.P50155DISC BRAKECALIPERGREASEPart No. KT13611,KT13614, KT13620While <strong>the</strong> treated pads are drying,clean <strong>the</strong> following areas with <strong>Kent</strong>'sOne Shot Brake Cleaners and lubricatewith Brake Plate Lube, Rusty 2000 or DiscBrake Caliper Grease.E. MOUNTING BOLTBUSHINGK-44Part No. P50015,KT13610DISCBRAKECALIPERGREASEPart No.KT13611,KT13614,KT13620A. Check fordeterioration.B. If serviceable, cleanwith <strong>Kent</strong>'s OneShot Brake Cleaner.C. Lubricate piston sealand rubber boot usingK-44 100% Silicone Pasteor Disc Brake Caliper Grease.BOOTPISTON SEALBLEEDER VALVEA. CALIPERSLEEVEC. PISTONReassembly

Spray (clean) pad/lining surfaceliberally with <strong>Kent</strong>’s One Shot Plus.This removes contaminants from<strong>the</strong> pad surface. Let dry <strong>com</strong>pletely,approximately 1-2 minutes.*Available in bulk sizes. See <strong>the</strong> <strong>Kent</strong> catalog or ask your<strong>Kent</strong> representative for more details.2Brake SilencerApplicationBRAKESILENCERPart No. P51216BRAKESILENCERPart No. P51153A. For disc <strong>brake</strong>pads, apply two(2) medium/wetcoats, allow todry thoroughly.B. For drum <strong>brake</strong>shoes, apply one(1) medium/wetcoat, allow todry thoroughly.Note: Metal backing plates can bewarmed to promote faster drying.F. RETAINER SPRINGB. CALIPER HOUSINGSEALBOOTPAD D. BACKING PLATEDisc Brake AssemblyA. Metal to metal contact points on <strong>the</strong>caliper assembly (points where backingplates hang on caliper assembly).B. Caliper housing (check cylinder wall forscoring)C. Piston face (rim) and piston shaft underrubber boot.D. Backing plate (back of pads at pointwhere piston makes contact).E. Mounting bolt and sleeve.F. Retaining spring (anti-rattle spring).A. ANCHOR PINB. BACKING PLATEC. WHEEL CYLINDERD. RETURN SPRINGC. HOLD DOWN SPRINGSECONDARY SHOEPRIMARY SHOEB. BRAKE ADJUSTING SCREWG. AUTOMATIC ADJUSTER SPRINGDrum or Conventional BrakesA. Anchor pin.B. Brake adjustment screw.C. Hold down springs.D. Return springs (at attaching point).E. Backing plate platforms (raised ledges).F. Wheel cylinder kit piston fork(both ends).G. Automatic adjuster spring(at attaching points).H. All o<strong>the</strong>r metal to metal contact points.5and InstallationWhen pad surfaces are <strong>com</strong>pletely dry,assembly and reinstall <strong>brake</strong>s.6Testing <strong>the</strong>BrakesA. Make five (5) or six (6) hard test stops(panic stops) in forward motion. (Thecar should be driven at approximately10 mph.)B. Make two (2) or three (3) panic stopsin reverse.C. Make one (1) or two (2) regular stops atnormal driving speed. The car is nowready for delivery to <strong>the</strong> customer.Note: It should be noted that <strong>the</strong> <strong>brake</strong>swill grab and groan during <strong>the</strong> first two orthree stops– this is normal. By <strong>the</strong> fifth orsixth stops, <strong>the</strong>y will return to normal.www.<strong>kent</strong>-automotive.<strong>com</strong>1.888.YES.KENT1666 E. Touhy Ave. • Des Plaines, IL 60018Printed in USA • Rev. 8/07 • E-315K

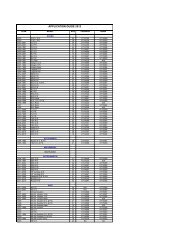

Brake NoiseElimination AssortmentsFeatures a step-by-step sequence utilizing a<strong>com</strong>bination of high-performance cleaners,lubricants and o<strong>the</strong>r <strong>brake</strong> protection products.Brake Noise Elimination System applicationchart included in each kit.DescriptionPartNo.Pkg.Qty.Introductory System P6001 1Introductory Kitwith One ShotPlus AerosolsIntroductory Kitwith Low VOC AerosolsP6875 1P6876 1Brake La<strong>the</strong> CuttingBits, Parts andAccessories• Supertanium Cutting Bits and Tool Holdersfor most bench mounted andon-<strong>the</strong>-car la<strong>the</strong>s.• Disc and Drum Silencer Bands• Swirl Grinder Pads• Spindle Boots• Chip Deflectors• Brake La<strong>the</strong> Tune-Up KitsDescription P6001 P6875 P6876One Shot Plus Aerosol, P20100 – 12 –Low VOC Aerosol, P20635 12 – 12Rusty Brake PlateLube Brush Top, P501553 1 1Rusty Brake PlateLube Aerosol, P50251 1 1K-44 Silicone LubeBrush Top, P500152 1 1Brake SilencerBrush Top, P512162 1 1Brake Silencer Aerosol, P51153 1 1 1Carrying Case, PA5706 1 1 1Application Chart 1 1 1Our <strong>com</strong>mitment to our customers is seenthrough our broad product offering, superiorcustomer service, highly trained technical staffand value added services that increase ourcustomer’s profitability. It’s what we like to call<strong>the</strong> <strong>Kent</strong> Difference!www.<strong>kent</strong>-automotive.<strong>com</strong> • 1.888.YES.KENT1666 E. Touhy Ave. • Des Plaines, IL 60018Printed in USA • Rev. 8/07 • E-315K