Machinery Protection Devices - British Automation & Robot ...

Machinery Protection Devices - British Automation & Robot ...

Machinery Protection Devices - British Automation & Robot ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

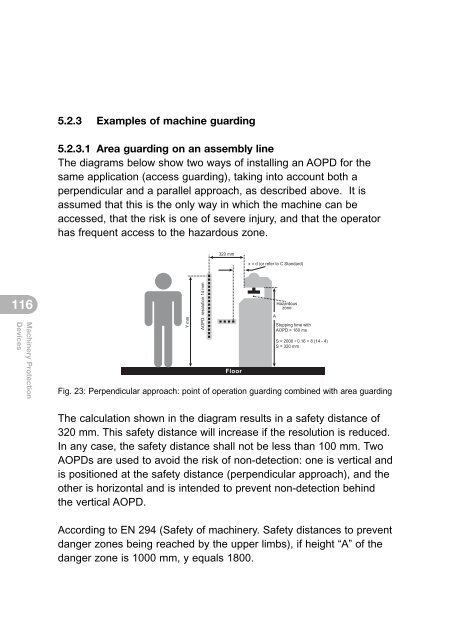

5.2.3 Examples of machine guarding5.2.3.1 Area guarding on an assembly lineThe diagrams below show two ways of installing an AOPD for thesame application (access guarding), taking into account both aperpendicular and a parallel approach, as described above. It isassumed that this is the only way in which the machine can beaccessed, that the risk is one of severe injury, and that the operatorhas frequent access to the hazardous zone.320 mmx = d (or refer to C Standard)116<strong>Machinery</strong> <strong>Protection</strong><strong>Devices</strong>Y mmAOPD: resolution 14 mmFig. 23: Perpendicular approach: point of operation guarding combined with area guardingThe calculation shown in the diagram results in a safety distance of320 mm. This safety distance will increase if the resolution is reduced.In any case, the safety distance shall not be less than 100 mm. TwoAOPDs are used to avoid the risk of non-detection: one is vertical andis positioned at the safety distance (perpendicular approach), and theother is horizontal and is intended to prevent non-detection behindthe vertical AOPD.FloorHazardouszoneAStopping time withAOPD = 160 msS = 2000 * 0.16 + 8 (14 - 4)S = 320 mm21According to EN 294 (Safety of machinery. Safety distances to preventdanger zones being reached by the upper limbs), if height “A” of thedanger zone is 1000 mm, y equals 1800.