Centrifuge modelling of deformation of a multi-layered sequence ...

Centrifuge modelling of deformation of a multi-layered sequence ...

Centrifuge modelling of deformation of a multi-layered sequence ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

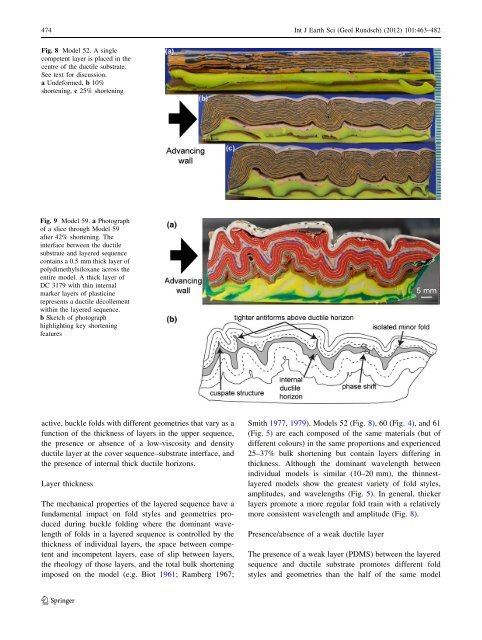

474 Int J Earth Sci (Geol Rundsch) (2012) 101:463–482Fig. 8 Model 52. A singlecompetent layer is placed in thecentre <strong>of</strong> the ductile substrate.See text for discussion.a Undeformed, b 10%shortening, c 25% shorteningFig. 9 Model 59. a Photograph<strong>of</strong> a slice through Model 59after 42% shortening. Theinterface between the ductilesubstrate and <strong>layered</strong> <strong>sequence</strong>contains a 0.5 mm thick layer <strong>of</strong>polydimethylsiloxane across theentire model. A thick layer <strong>of</strong>DC 3179 with thin internalmarker layers <strong>of</strong> plasticinerepresents a ductile décollementwithin the <strong>layered</strong> <strong>sequence</strong>.b Sketch <strong>of</strong> photographhighlighting key shorteningfeaturesactive, buckle folds with different geometries that vary as afunction <strong>of</strong> the thickness <strong>of</strong> layers in the upper <strong>sequence</strong>,the presence or absence <strong>of</strong> a low-viscosity and densityductile layer at the cover <strong>sequence</strong>–substrate interface, andthe presence <strong>of</strong> internal thick ductile horizons.Layer thicknessThe mechanical properties <strong>of</strong> the <strong>layered</strong> <strong>sequence</strong> have afundamental impact on fold styles and geometries producedduring buckle folding where the dominant wavelength<strong>of</strong> folds in a <strong>layered</strong> <strong>sequence</strong> is controlled by thethickness <strong>of</strong> individual layers, the space between competentand incompetent layers, ease <strong>of</strong> slip between layers,the rheology <strong>of</strong> those layers, and the total bulk shorteningimposed on the model (e.g. Biot 1961; Ramberg 1967;Smith 1977, 1979). Models 52 (Fig. 8), 60 (Fig. 4), and 61(Fig. 5) are each composed <strong>of</strong> the same materials (but <strong>of</strong>different colours) in the same proportions and experienced25–37% bulk shortening but contain layers differing inthickness. Although the dominant wavelength betweenindividual models is similar (10–20 mm), the thinnest<strong>layered</strong>models show the greatest variety <strong>of</strong> fold styles,amplitudes, and wavelengths (Fig. 5). In general, thickerlayers promote a more regular fold train with a relativelymore consistent wavelength and amplitude (Fig. 8).Presence/absence <strong>of</strong> a weak ductile layerThe presence <strong>of</strong> a weak layer (PDMS) between the <strong>layered</strong><strong>sequence</strong> and ductile substrate promotes different foldstyles and geometries than the half <strong>of</strong> the same model123