Centrifuge modelling of deformation of a multi-layered sequence ...

Centrifuge modelling of deformation of a multi-layered sequence ...

Centrifuge modelling of deformation of a multi-layered sequence ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

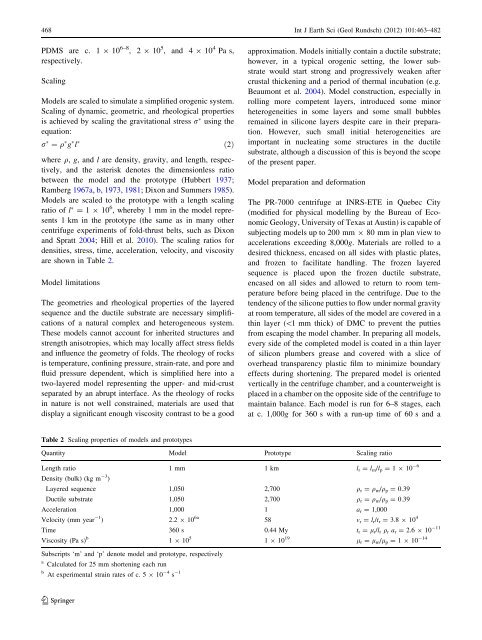

468 Int J Earth Sci (Geol Rundsch) (2012) 101:463–482PDMS are c. 1 9 10 6–8 , 2 9 10 5 , and 4 9 10 4 Pa s,respectively.ScalingModels are scaled to simulate a simplified orogenic system.Scaling <strong>of</strong> dynamic, geometric, and rheological propertiesis achieved by scaling the gravitational stress r using theequation:r ¼ q g l ð2Þwhere q, g, and l are density, gravity, and length, respectively,and the asterisk denotes the dimensionless ratiobetween the model and the prototype (Hubbert 1937;Ramberg 1967a, b, 1973, 1981; Dixon and Summers 1985).Models are scaled to the prototype with a length scalingratio <strong>of</strong> l = 1 9 10 6 , whereby 1 mm in the model represents1 km in the prototype (the same as in many othercentrifuge experiments <strong>of</strong> fold-thrust belts, such as Dixonand Spratt 2004; Hill et al. 2010). The scaling ratios fordensities, stress, time, acceleration, velocity, and viscosityare shown in Table 2.Model limitationsThe geometries and rheological properties <strong>of</strong> the <strong>layered</strong><strong>sequence</strong> and the ductile substrate are necessary simplifications<strong>of</strong> a natural complex and heterogeneous system.These models cannot account for inherited structures andstrength anisotropies, which may locally affect stress fieldsand influence the geometry <strong>of</strong> folds. The rheology <strong>of</strong> rocksis temperature, confining pressure, strain-rate, and pore andfluid pressure dependent, which is simplified here into atwo-<strong>layered</strong> model representing the upper- and mid-crustseparated by an abrupt interface. As the rheology <strong>of</strong> rocksin nature is not well constrained, materials are used thatdisplay a significant enough viscosity contrast to be a goodapproximation. Models initially contain a ductile substrate;however, in a typical orogenic setting, the lower substratewould start strong and progressively weaken aftercrustal thickening and a period <strong>of</strong> thermal incubation (e.g.Beaumont et al. 2004). Model construction, especially inrolling more competent layers, introduced some minorheterogeneities in some layers and some small bubblesremained in silicone layers despite care in their preparation.However, such small initial heterogeneities areimportant in nucleating some structures in the ductilesubstrate, although a discussion <strong>of</strong> this is beyond the scope<strong>of</strong> the present paper.Model preparation and <strong>deformation</strong>The PR-7000 centrifuge at INRS-ETE in Quebec City(modified for physical <strong>modelling</strong> by the Bureau <strong>of</strong> EconomicGeology, University <strong>of</strong> Texas at Austin) is capable <strong>of</strong>subjecting models up to 200 mm 9 80 mm in plan view toaccelerations exceeding 8,000g. Materials are rolled to adesired thickness, encased on all sides with plastic plates,and frozen to facilitate handling. The frozen <strong>layered</strong><strong>sequence</strong> is placed upon the frozen ductile substrate,encased on all sides and allowed to return to room temperaturebefore being placed in the centrifuge. Due to thetendency <strong>of</strong> the silicone putties to flow under normal gravityat room temperature, all sides <strong>of</strong> the model are covered in athin layer (\1 mm thick) <strong>of</strong> DMC to prevent the puttiesfrom escaping the model chamber. In preparing all models,every side <strong>of</strong> the completed model is coated in a thin layer<strong>of</strong> silicon plumbers grease and covered with a slice <strong>of</strong>overhead transparency plastic film to minimize boundaryeffects during shortening. The prepared model is orientedvertically in the centrifuge chamber, and a counterweight isplaced in a chamber on the opposite side <strong>of</strong> the centrifuge tomaintain balance. Each model is run for 6–8 stages, eachat c. 1,000g for 360 s with a run-up time <strong>of</strong> 60 s and aTable 2 Scaling properties <strong>of</strong> models and prototypesQuantity Model Prototype Scaling ratioLength ratio 1 mm 1 km l r = l m /l p = 1 9 10 -6Density (bulk) (kg m -3 )Layered <strong>sequence</strong> 1,050 2,700 q r = q m /q p = 0.39Ductile substrate 1,050 2,700 q r = q m /q p = 0.39Acceleration 1,000 1 a r = 1,000Velocity (mm year -1 ) 2.2 9 10 6a 58 v r = l r /t r = 3.8 9 10 4Time 360 s 0.44 My t r = l r /l r q r a r = 2.6 9 10 -11Viscosity (Pa s) b 1 9 10 5 1 9 10 19 l r = l m /l p = 1 9 10 -14Subscripts ‘m’ and ‘p’ denote model and prototype, respectivelya Calculated for 25 mm shortening each runb At experimental strain rates <strong>of</strong> c. 5 9 10 -4 s -1123