Dynaform® Fiberglass Structural Shapes

Dynaform® Fiberglass Structural Shapes

Dynaform® Fiberglass Structural Shapes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

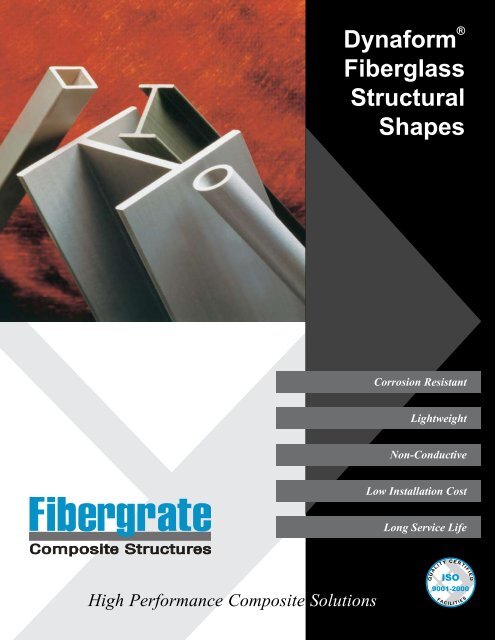

Dynaform ®<strong>Fiberglass</strong><strong>Structural</strong><strong>Shapes</strong>Corrosion ResistantLightweightNon-ConductiveLow Installation CostLong Service LifeHigh Performance Composite SolutionsQUALITYCERTIFIEDISO9001-2000F A CI LI TI E S

Dynaform ® <strong>Structural</strong> <strong>Shapes</strong>Dynaform ® pultruded fiberglass structural shapes from Fibergrate Composite Structures Inc.are used in a wide range of applications, providing a unique combination of corrosionresistance, high strength, dimensional stability and light weight, along with thermal andelectric non-conductivity. Durable Dynaform shapes provide years of low maintenanceservice in areas where steel, aluminum or wood components were traditionally specified.Today, these shapes are often used in highly corrosive applications where stainless steel andother expensive components were once required.Dynaform structural shapes are produced from the highest quality materials, providingdurability and years of low maintenance service. All shapes have been tested for physicalproperties according to standardized ASTM procedures. For test results showing the superior characteristics ofthe full range of Dynaform structural shapes, see the Typical Coupon Properties tables on page 7. For more designinformation consult our Dynaform Design Guide or Guidelines for the Engineer and Designer.A leading manufacturer of fiberglass products, Fibergrate offers pultruded shapes that exceed the requirementsof even the most demanding applications. Dynaform shapes are typically used in a large number of industriesincluding:• Chemical Processing • Pulp and Paper Manufacturing • Transportation• Utility/Power • Petroleum Refining • Telecommunications• Food and Beverage Processing • Water and Wastewater Treatment • Metals and MiningDynaform ® Resin Systems• ISO (olive green) — an excellent isophthalicpolyester resin offering resistance to a wide range ofchemicals, ISO is particularly suited for highly acidicconditions.• ISOFR (dark gray) — an isophthalic polyester resinformulation which exhibits the same characteristics asISO, while also providing a low flame-spread rating of25 or less (when tested according to ASTM E-84).• VEFR (beige) — a vinyl ester resin system whichoffers proven chemical resistance. VEFR is alsocapable of accommodating higher temperature servicewhile providing a low flame-spread of 25 or less (whentested according to ASTM E-84).Phone: 800-527-4043www.fibergrate.com

• Corrosion Resistance - the use of premiumgrade, isophthalic polyester or vinyl ester resinsystems and a synthetic surfacing veil maintainsstructural integrity providing long life inaggressive acidic or caustic environments• Light Weight and High Strength -allowing for dependable support of applied loadsand delivering a higher strength-to-weight ratiothan steel. The light weight also allows foreasier installation with no heavy equipment andless manpower required• Dimensional Stability - maintaining thecross-section of structural shapes based on a lowcoefficient of thermal expansion• Non-Conductivity - adding to personnelsafety• Electromagnetic Transparency - providingno impediment to the transmission of radio andmicrowave frequenciesStandard Dynaform structural shapes include I beams, wide flange beams, round tubes, square tubes, squareand round bars, flat sheets, channels, angles, concrete embedment angles, toe plates, threaded rods andnuts. Each shape is available in a number of sizes to accommodate a wide range of design and applicationrequirements. For special uses, custom shapes are also available.Angle Channel I-Beam Wide Flange BeamRound Tube Square Tube Round and Square Bar Concrete Embedment AnglesPhone: 800-527-4043www.fibergrate.com

Dynaform Quality and VersatilityContinuous fiber rovings and mat aredrawn through a resin bath and shapedthrough a series of forming guides, then mechanicallypulled through a heated die to form the Dynaform shape.A Commitment To QualityWith more than 30 years of experience, Fibergrate offers customersunparalleled expertise in the design and manufacture of quality fiberglassproducts. All phases involved in the development of Dynaform ®products are housed in the company’s modern manufacturingfacility of more than 105,000 covered square feet in Stephenville,Texas. Guiding this operation, from design to testing of finalproduct, is Fibergrate’s Total Quality Management (TQM) program.Critical to the production of Fibergrate’s quality shapes is the pultrusionprocess. <strong>Fiberglass</strong> and other reinforcements are drawn through a bathof thermosetting resin. The immersed fibers are then shaped through aseries of forming guides and mechanically pulled through a heated dieto produce the specific structural shape. Using this pultrusion process,continuous cross-section parts can be made to virtually any length.Dynaform structural shapes combine fiberglass and specially developedresins in a polymer matrix designed to meet the most demandingchemical, flame retardant, electrical, strength and environmentalstandards. Fibergrate’s thermosetting polyester or vinyl ester resin systemssupply the exceptional corrosion resistance of these structural shapes,while strategically placed fiberglass rovings and mat add structuralintegrity. In addition, all exterior surfaces of Dynaform shapes are coveredby a synthetic veil for added protection against ultraviolet ray exposure.Fabricated Dynaform columns ready for shipment.A completed Dynaform shape exits the pultrusion process.Phone: 800-527-4043www.fibergrate.com

Building With Dynaform <strong>Shapes</strong>The unique qualities of Dynaform structural shapes make themideal for use in areas where conventional materials have beentraditionally employed. Combining high strength-to-weight ratioand dimensional stability with exceptional corrosion resistance,Dynaform shapes have become the structural component of choicefor a wide range of industrial and commercial applications. Theseshapes have provided a high level of structural integrity in theconstruction of:• Walkways and Bridges• Handrail and Ladders• Trash and Bar Screens• Mezzanines• Maintenance Platforms• Tank Loading Platforms• Access Platforms• Helidecks• Tank Covers and Supports• Buildings and Sheds• Pipe and Equipment Racks• Wellbay PlatformsABOVE - As the chosen product for a highly corrosive batterymanufacturing facility, this Dynaform platform will provideyears of service.LEFT - Dynaform support structure and square tube handrailprovide a high level of corrosion resistance for this offshoreplatform.ABOVE - Square tube handrail manufactured with Dynaformcomponent products offer long life in the corrosive environmentof this wastewater treatment plant.LEFT - Advanced design and engineering of Dynaform structuralshapes provide a light weight, high strength support structure forthis Northern Ohio plating facility.Phone: 800-527-4043www.fibergrate.com

Dynaform <strong>Shapes</strong> AvailabilityISO = Isophthalic Polyester Resin/Olive GreenISOFR = Isophthalic Polyester Fire Retartdant Resin/Dark GrayVEFR = Vinyl Ester Fire Retardant Resin/BeigeNote: Special colors are availableProfile Size (inches) ISO ISOFR VEFR Wt/FtEqualLegAngleChannelI BeamWideFlangeBeamRoundTube1 x 1/8 ● ● ● 0.211-1/4 x 1/8 0.231-1/2 x 3/16 ● ● 0.371-1/2 x 1/4 ● ● ● 0.512 x 1/4 ● ● ● 0.683 x 1/4 ● ● ● 1.043 x 3/8 ● ● ● 1.654 x 1/4 ● ● ● 1.414 x 3/8 ● ● ● 2.234 x 1/2 ● ● ● 2.926 x 3/8 ● ● 3.446 x 1/2 ● ● ● 4.502 x 9/16 x 1/8 ● ● 0.253 x 7/8 x 1/4 ● ● 0.773 x 1 x 1/4 ● ● ● 0.874 x 1-1/8 x 1/4 ● ● 1.114 x 1-3/8 x 3/16 ● ● 0.866 x 1-5/8 x 1/4 ● ● ● 1.646 x 1-11/16 x 3/8 ● ● 2.528 x 2-3/16 x 3/8 ● ● ● 3.4010 x 2-3/4 x 1/2 ● ● ● 5.653 x 1-1/2 x 1/4 1.114 x 2 x 1/4 ● ● 1.466 x 3 x 1/4 ● ● 2.246 x 3 x 3/8 3.298 x 4 x 3/8 ● ● ● 4.468 x 4 x 1/2 5.8510 x 5 x 3/8 5.7810 x 5 x 1/2 7.4112 x 6 x 1/2 8.9718 x 3/8 x 4-1/2 x 1/2 8.4824 x 3/8 x 7-1/2 x 3/4 16.473 x 3 x 1/4 ● ● ● 1.694 x 4 x 1/4 ● ● ● 2.106 x 6 x 1/4 ● ● ● 3.416 x 6 x 3/8 ● ● ● 5.058 x 8 x 3/8 ● ● ● 6.808 x 8 x 1/2 8.9710 x 10 x 3/8 8.7810 x 10 x 1/2 11.3112 x 12 x 1/2 13.651 x 1/8 ● ● 0.251-1/4 x 1/8 0.321-1/2 x 1/8 ● ● 0.451-1/2 x 1/4 ● 0.791-3/4 x 1/8 0.471-3/4 x 1/4 0.942 x 1/4 ● ● ● 1.123 x 1/4 1.68● Stocked Item Stocked in Yellow† ISO stocked in white, VEFR in dark grayProfile Size (inches) ISO ISOFR VEFR Wt/Ft1-1/8 ● ● 0.321-1/4 x 1/8 0.411-1/4 x 1/4 0.681-1/2 x 1/8 ● ● ● 0.541-1/2 x 1/4 ● 0.981-3/4 x 1/8 0.63SquareTubeRound RodSquareRodFlat SheetConcreteEmbedmentAngle1-3/4 x 1/4 ● 1.102 x 1/8 ● ● ● 0.692 x 1/4 ● ● ● 1.402-1/8 x 3/16 1.142-1/4 x 1/8 ● ● 0.882-1/2 x 1/4 1.793 x 1/8 1.123 x 1/4 ● ● ● 2.154 x 1/4 ● ● 2.931/4† ● 0.043/8 † ● ● 0.091/2 † ● ● 0.175/8 † ● ● 0.273/4 † ● ● 0.3913/16 0.461 † ● ● 0.661-1/4 † ● 1.081-1/2 † ● 1.561 x 1 ● 0.871-1/4 x 1-1/4 1.311-1/2 x 1-1/2 ● ● 1.981/8 x 48 x 96 ● ● ● 1.143/16 x 48 x 96 ● ● ● 1.711/4 x 48 x 96 ● ● ● 2.343/8 x 48 x 96 ● ● ● 3.541/2 x 48 x 96 ● ● ● 4.685/8 x 48 x 96 5.793/4 x 48 x 96 6.941 x 48 x 96 7.271 x 1-1/2 x 1/4 ● 1.001-1/2 x 1-1/2 x 1/4 ● 1.102 x 1-1/2 x 1/4 ● 1.201 x 1-1/2 ● 0.952 x 1-1/2 ● 1.00Toe Plate 4 x 1/2 x 1/8 ● 0.49ThreadedRods andNuts3/8 - 16 UNC ● 0.091/2 - 13 UNC ● 0.145/8 - 11 UNC ● 0.233/4 - 10 UNC ● 0.331 - 8 UNC ● 0.50Phone: 800-527-4043www.fibergrate.com

Typical Coupon PropertiesBelow are the test results for typical coupon properties of Dynaform structural fiberglass shapes and threaded rods and nuts.Properties are derived per the ASTM test method shown. Synthetic surfacing veil and ultraviolet inhibitors are standard.Dynaform <strong>Shapes</strong>Mechanical Properties ASTM Units ValueTensile Stress, LW D - 638 psi 30,000Tensile Stress, CW D - 638 psi 7,000Tensile Modulus, LW D - 638 10 6 psi 2.5Tensile Modulus, CW D - 638 10 6 psi 0.8Compressive Stress, LW D - 695 psi 30,000Compressive Stress, CW D - 695 psi 15,000Compressive Modulus, LW D - 695 10 6 psi 2.5Compressive Modulus, CW D - 695 10 6 psi 1.0Flexural Stress, LW D - 790 psi 30,000Flexural Stress, CW D - 790 psi 10,000Flexural Modulus, LW D - 790 10 6 psi 1.8Flexural Modulus, CW D - 790 10 6 psi 0.8Modulus of Elasticity Full Section 10 6 psi 2.8Shear Modulus — 10 6 psi 0.450Short Beam Shear D - 2344 psi 4,500Punch Shear D - 732 psi 10,000Notched Izod Impact, LW D - 256 ft. - lbs./in. 25Notched Izod Impact, CW D - 256 ft. - lbs./in. 4(1) Excludes Round Rod and Square BarPhysical Properties ASTM Units ValueBarcoal D - 495 — 4524 Hour Water Absorption D - 570 % max 0.45Density D - 792 lbs./in. 3 0.062 - 0.070Coefficient of Thermal Expansion, LW D - 696 10 -6 in./in./°C 8Flammability Properties ASTM Units ValueTunnel Test* E - 84 Flame Spread 25 maxFlammability* D - 635 — Non-BurningElectrical Properties ASTM Units ValueArc Resistance, LW D - 495 seconds 120Dielectric Strength, LW D - 149 kv./in. 35Dielectric Strength, PF D - 149 volts/mil 200Dielectric Constant, PF D - 150 @60hz 5LW = Lengthwise, CW = Crosswise, PF = Perpendicular to Laminate Face*Pertains to ISOFR and VEFR onlyDynaform Threaded Rods and NutsDiameter - Threads Per Inch ASTM Units 3/8 - 16 UNC 1/2 - 13 UNC 5/8 - 11 UNC 3/4 - 10 UNC 1 - 8 UNCUltimate thread shear using standard fiberglass nut — lbs. 1,200 2,400 3,600 4,000 7,000Ultimate transverse shear-double shear B - 565 lbs. 4,200 7,400 11,600 17,200 27,400Max design transverse shear-double shear — lbs. 2,100 3,300 4,500 7,500 13,500Ultimate compressive strength-longitudinal D - 695 psi 47,000 50,000 50,000 50,000 65,000Ultimate flexural strength D - 790 psi 66,000 66,000 66,000 66,000 66,000Flexural Modulus D - 790 psi 2.0 2.0 2.0 2.5 2.75Ultimate torque strength using fiberglass nutlubricated with SAE 10W-30 motor oil— ft./lbs. 12 18 30 75 100Dielectric Strength D - 149 kv/in. 80 80 80 80 80Water Absorption, 24 hour immersion-threaded D - 570 % max 0.3 0.3 0.3 0.3 0.3Coefficient of thermal expansion-longitudinal — in./in./°F 6 x 10 -6 6 x 10 -6 6 x 10 -6 6 x 10 -6 6 x 10 -6Max recommended operating temp. based on50% retention of ultimate thread shear strength— °F 212 212 212 212 212Stud weight — ft./lbs. 0.087 0.143 0.227 0.333 0.500Flammability D - 635 — Self-extinguishing for allColor — — Gray Gray Gray Gray GrayAppropriate safety factor must be applied to all ultimate values.Dynaform threaded rods and nuts are Class 1 flame retardant vinyl ester. Standard length of threaded rod is 48”.Phone: 800-527-4043www.fibergrate.com

Fibergrate Products and Services©Fibergrate Inc. 2002 883102-10/05-7.5Made in the USAFibergrate ® Molded GratingFibergrate molded gratings are designed to provide the ultimate in reliable performance,even in the most demanding conditions. Fibergrate offers the widest selection in the marketwith more than ten resins and more than twenty grating configurations available in manypanel sizes and surfaces.Safe-T-Span ® Pultruded Industrial and Pedestrian GratingsCombining corrosion resistance, long-life and low-maintenance designs, Safe-T-Spanprovides unidirectional strength for industrial and pedestrian pultruded grating applications.RIGIDEX ® Moltruded ® GratingRIGIDEX moltruded gratings are the first fiberglass gratings to combine the corrosionresistance of molded grating with the longer span capacity of pultruded grating, all at thelow cost of metal gratings.Dynarail ® HandrailEasily assembled from durable prefabricated components or engineered to yourspecifications, Dynarail handrail meets or exceeds OSHA and strict building coderequirements for safety and design.Dynarail ® Safety Ladder SystemEasily assembled on site, Dynarail safety ladder systems meet or exceed OSHArequirements. Though less costly than prefabricated ladder systems, these safety laddersprovide a custom fit to the supporting structure.Dynaform ® <strong>Structural</strong> <strong>Shapes</strong>Fibergrate offers a wide range of pultruded structural components for industrial use,including bars, rods, tubes, beams, channels, leg angles and plates.Stair SolutionsFibergrate offers a wide range of slip-resistant products to meet your stair safety needs.These durable products which include treads, tread covers and covered stair treads are along-term, cost-efficient solution for your facility.Grating PedestalsUniquely designed adjustable single and quad head pedestals for square mesh moldedgrating are manufactured to provide safe and economical support for elevated flooring.Fabrication ServicesCombining engineering expertise with an understanding of fiberglass applications,Fibergrate provides turnkey design and fabrication of fiberglass structures, includingplatforms, catwalks, stairways and test racks.Fibergrate Composite Structures Inc. believes the information contained here to be trueand accurate. Fibergrate makes no warranty, expressed or implied based on thisliterature and assumes no responsibility for consequential or incidental damages in theuse of these products and systems described, including any warranty of merchantability orfitness. Information contained here is for evaluation only.Fibergrate Composite Structures Inc.Phone: 800-527-4043 • Fax: 972-250-1530www.fibergrate.com • Email: info@fibergrate.com