product data - StonCor Africa

product data - StonCor Africa

product data - StonCor Africa

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

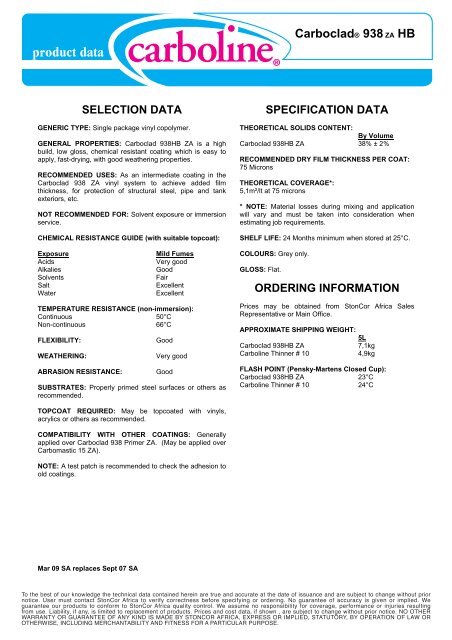

<strong>product</strong> <strong>data</strong>Carboclad® 938 ZA HBSELECTION DATAGENERIC TYPE: Single package vinyl copolymer.GENERAL PROPERTIES: Carboclad 938HB ZA is a highbuild, low gloss, chemical resistant coating which is easy toapply, fast-drying, with good weathering properties.RECOMMENDED USES: As an intermediate coating in theCarboclad 938 ZA vinyl system to achieve added filmthickness, for protection of structural steel, pipe and tankexteriors, etc.NOT RECOMMENDED FOR: Solvent exposure or immersionservice.CHEMICAL RESISTANCE GUIDE (with suitable topcoat):ExposureAcidsAlkaliesSolventsSaltWaterMild FumesVery goodGoodFairExcellentExcellentTEMPERATURE RESISTANCE (non-immersion):Continuous 50°CNon-continuous 66°CFLEXIBILITY:WEATHERING:ABRASION RESISTANCE:GoodVery goodGoodSUBSTRATES: Properly primed steel surfaces or others asrecommended.SPECIFICATION DATATHEORETICAL SOLIDS CONTENT:By VolumeCarboclad 938HB ZA 38% ± 2%RECOMMENDED DRY FILM THICKNESS PER COAT:75 MicronsTHEORETICAL COVERAGE*:5,1m²/lt at 75 microns* NOTE: Material losses during mixing and applicationwill vary and must be taken into consideration whenestimating job requirements.SHELF LIFE: 24 Months minimum when stored at 25°C.COLOURS: Grey only.GLOSS: Flat.ORDERING INFORMATIONPrices may be obtained from <strong>StonCor</strong> <strong>Africa</strong> SalesRepresentative or Main Office.APPROXIMATE SHIPPING WEIGHT:5LCarboclad 938HB ZA7,1kgCarboline Thinner # 104,9kgFLASH POINT (Pensky-Martens Closed Cup):Carboclad 938HB ZA 23°CCarboline Thinner # 10 24°CTOPCOAT REQUIRED: May be topcoated with vinyls,acrylics or others as recommended.COMPATIBILITY WITH OTHER COATINGS: Generallyapplied over Carboclad 938 Primer ZA. (May be applied overCarbomastic 15 ZA).NOTE: A test patch is recommended to check the adhesion toold coatings.Mar 09 SA replaces Sept 07 SATo the best of our knowledge the technical <strong>data</strong> contained herein are true and accurate at the date of issuance and are subject to change without priornotice. User must contact <strong>StonCor</strong> <strong>Africa</strong> to verify correctness before specifying or ordering. No guarantee of accuracy is given or implied. Weguarantee our <strong>product</strong>s to conform to <strong>StonCor</strong> <strong>Africa</strong> quality control. We assume no responsibility for coverage, performance or injuries resultingfrom use. Liability, if any, is limited to replacement of <strong>product</strong>s. Prices and cost <strong>data</strong>, if shown , are subject to change without prior notice. NO OTHERWARRANTY OR GUARANTEE OF ANY KIND IS MADE BY STONCOR AFRICA, EXPRESS OR IMPLIED, STATUTORY, BY OPERATION OF LAW OROTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

APPLICATION INSTRUCTIONSThese instructions are not intended to show <strong>product</strong> recommendations for specific service. They are issued as an aid in determining correct surfacepreparation, mixing instructions and application procedure. It is assumed that the proper <strong>product</strong> recommendations have been made. Theseinstructions should be followed closely to obtain the maximum service from the materials.SURFACE PREPARATION: Remove any oil and grease fromsurface to be coated.STEEL: Apply over clean, dry recommended primers.MIXING: Power-mix to a smooth consistency before thinning.Thin up to 12% by volume with Carboline Thinner # 10.NOTE: Use of thinners other than those supplied or approvedby <strong>StonCor</strong> <strong>Africa</strong> may adversely affect <strong>product</strong> performanceand void <strong>product</strong> warranty, whether expressed or implied.APPLICATION TEMPERATURES:MaterialSurfacesNormal 16-32°C 18-29°CMinimum 4°C 4°CMaximum 38°C 43°CAmbientHumidityNormal 13-38°C 10-85%Minimum 4°C 0%Maximum 43°C 95%Do not apply when the surface temperature is less than 2°Cabove the dew point.Special thinning and application techniques may be requiredabove or below normal conditions.SPRAY: Use sufficient air volume for correct operation ofequipment.Use a 50% overlap with each pass of the gun. On irregularsurfaces, coat the edges first, making an extra pass later.NOTE: The following equipment has been found suitable,however, equivalent equipment may be substituted.CONVENTIONAL: Use a 10mm minimum I.D. materialhose. Hold gun 300 to 350mm from the surface and at aright angle to the surface.Mfr & Gun Fluid Tip Air CapBinks # 18 or # 62 66 63PBDeVilbiss P-MBC or JGA E (app. 0.070” I.D) 704AIRLESS: Use a 10mm minimum I.D. material hose.Hold gun approximately 450-500mm from the surfaceand at a right angle to the surface.Mfr & GunPump*De Vilbiss JGN-502 QFA-514 or QFA-519Graco 205-591 President 30:0 or Bulldog 30:1Binks Model 700 B5-18 29:1 or B8-36 37:1* Teflon packings are recommended and are availablefrom pump manufacturer. Use a .017” to .021” tip with2000 psi (138 bar).Use a .017” to .021” tip with 2000 psi (138 bar).BRUSH: Use natural bristle brush applying with fullstrokes. Avoid rebrushing.ROLLER: Not recommended.DRYING TIMES:Recoat or to HandleTemperature24 Hours 4°C18 Hours 10°C10 Hours 16°C5 Hours 25°C3 Hours 32°CCLEAN UP: Use Carboline Thinner # 2.STORAGE CONDITIONS (Store indoors):Temperature:4-43°CHumidity: 0-100%CAUTION: MAY CONTAIN FLAMMABLE SOLVENTS. KEEP AWAY FROM SPARKS AND OPEN FLAMES. IN CONFINED AREAS WORKMEN MUST WEARFRESH AIRLINE RESPIRATORS. HYPERSENSITIVE PERSONS SHOULD WEAR GLOVES OR USE PROTECTIVE CREAM. ALL ELECTRONICEQUIPMENT AND INSTALLATIONS SHOULD BE MADE AND GROUNDED IN ACCORDANCE WITH THE NATIONAL ELECTRICAL CODE. IN AREASWHERE EXPLOSION HAZARDS EXIST, WORKMEN SHOULD BE REQUIRED TO USE NONFERROUS TOOLS AND TO WEAR CONDUCTIVEAND NONSPARKING SHOES.AnCompany<strong>Africa</strong><strong>StonCor</strong> <strong>Africa</strong> (Pty) LtdCo. Reg. No.: 1996/01848/07Tel No : +27 11 254 5500Website: www.stoncor.co.zaE-mail: stoncorsa@stoncor.com