Cat. 3 Custom Made Chain - Tsubaki Europe

Cat. 3 Custom Made Chain - Tsubaki Europe

Cat. 3 Custom Made Chain - Tsubaki Europe

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

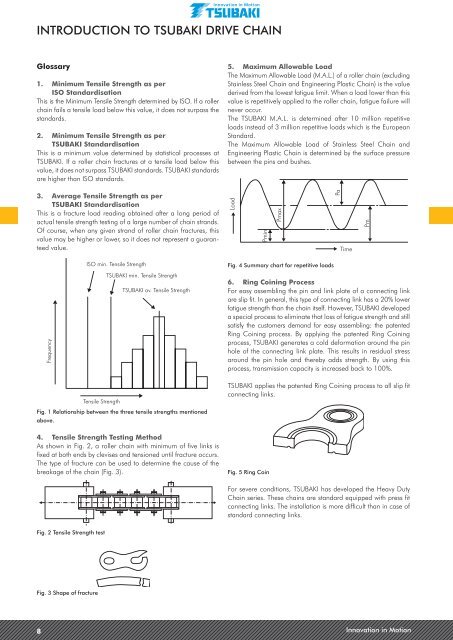

INTRODUCTION TO TSUBAKI DRIVE CHAINGlossary1. Minimum Tensile Strength as perISO Standar disationThis is the Minimum Tensile Strength determined by ISO. If a rollerchain fails a tensile load below this value, it does not surpass thestandards.2. Minimum Tensile Strength as perTSUBAKI StandardisationThis is a minimum value determined by statistical processes atTSUBAKI. If a roller chain fractures at a tensile load below thisvalue, it does not surpass TSUBAKI standards. TSUBAKI standardsare higher than ISO standards.5. Maximum Allowable LoadThe Maximum Allowable Load (M.A.L.) of a roller chain (excludingStainless Steel <strong>Chain</strong> and Engineering Plastic <strong>Chain</strong>) is the valuederived from the lowest fatigue limit. When a load lower than thisvalue is repetitively applied to the roller chain, fatigue failure willnever occur.The TSUBAKI M.A.L. is determined after 10 million repetitiveloads instead of 3 million repetitive loads which is the <strong>Europe</strong>anStandard.The Maximum Allowable Load of Stainless Steel <strong>Chain</strong> andEngineering Plastic <strong>Chain</strong> is determined by the surface pressurebetween the pins and bushes.3. Average Tensile Strength as perTSUBAKI StandardisationThis is a fracture load reading obtained after a long period ofactual tensile strength testing of a large number of chain strands.Of course, when any given strand of roller chain fractures, thisvalue may be higher or lower, so it does not represent a guaranteedvalue.LoadPminPmaxPaTimePmFrequencyISO min. Tensile StrengthTSUBAKI min. Tensile StrengthTSUBAKI av. Tensile StrengthFig. 4 Summary chart for repetitive loads6. Ring Coining ProcessFor easy assembling the pin and link plate of a connecting linkare slip fit. In general, this type of connecting link has a 20% lowerfatigue strength than the chain itself. However, TSUBAKI developeda special process to eliminate that loss of fatigue strength and stillsatisfy the customers demand for easy assembling: the patentedRing Coining process. By applying the patented Ring Coiningprocess, TSUBAKI generates a cold deformation around the pinhole of the connecting link plate. This results in residual stressaround the pin hole and thereby adds strength. By using thisprocess, transmission capacity is increased back to 100%.Tensile StrengthFig. 1 Relationship between the three tensile strengths mentionedabove.TSUBAKI applies the patented Ring Coining process to all slip fitconnecting links.4. Tensile Strength Testing MethodAs shown in Fig. 2, a roller chain with minimum of five links isfixed at both ends by clevises and tensioned until fracture occurs.The type of fracture can be used to determine the cause of thebreakage of the chain (Fig. 3).Fig. 5 Ring CoinFor severe conditions, TSUBAKI has developed the Heavy Duty<strong>Chain</strong> series. These chains are standard equipped with press fitconnecting links. The installation is more difficult than in case ofstandard connecting links.Fig. 2 Tensile Strength testFig. 3 Shape of fracture8 Innovation in Motion