Material Properties_V115 (FKM)_GEAE Spec. A50TF327x - Simrit

Material Properties_V115 (FKM)_GEAE Spec. A50TF327x - Simrit

Material Properties_V115 (FKM)_GEAE Spec. A50TF327x - Simrit

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

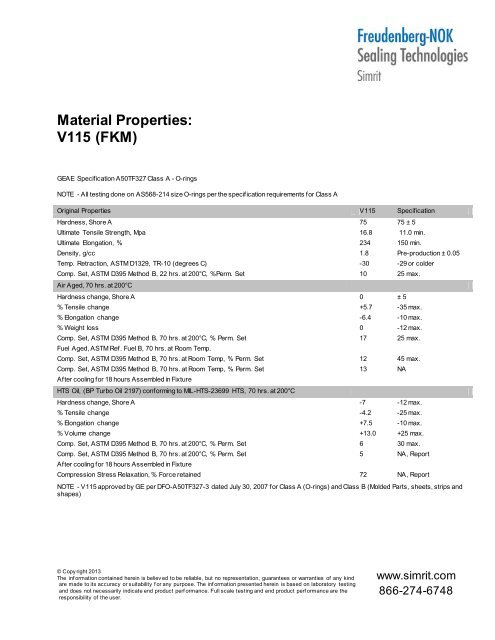

<strong>Material</strong> <strong>Properties</strong>:<strong>V115</strong> (<strong>FKM</strong>)<strong>GEAE</strong> <strong>Spec</strong>ification A50TF327 Class A - O-ringsNOTE - All testing done on AS568-214 size O-rings per the specification requirements for Class AOriginal <strong>Properties</strong> <strong>V115</strong> <strong>Spec</strong>ificationHardness, Shore A 75 75 ± 5Ultimate Tensile Strength, Mpa 16.8 11.0 min.Ultimate Elongation, % 234 150 min.Density, g/cc 1.8 Pre-production ± 0.05Temp. Retraction, ASTM D1329, TR-10 (degrees C) -30 -29 or colderComp. Set, ASTM D395 Method B, 22 hrs. at 200°C, %Perm. Set 10 25 max.Air Aged, 70 hrs. at 200°CHardness change, Shore A 0 ± 5% Tensile change +5.7 -35 max.% Elongation change -6.4 -10 max.% Weight loss 0 -12 max.Comp. Set, ASTM D395 Method B, 70 hrs. at 200°C, % Perm. Set 17 25 max.Fuel Aged, ASTM Ref. Fuel B, 70 hrs. at Room Temp.Comp. Set, ASTM D395 Method B, 70 hrs. at Room Temp, % Perm. Set 12 45 max.Comp. Set, ASTM D395 Method B, 70 hrs. at Room Temp, % Perm. Set 13 NAAfter cooling for 18 hours Assembled in FixtureHTS Oil, (BP Turbo Oil 2197) conforming to MIL-HTS-23699 HTS, 70 hrs. at 200°CHardness change, Shore A -7 -12 max.% Tensile change -4.2 -25 max.% Elongation change +7.5 -10 max.% Volume change +13.0 +25 max.Comp. Set, ASTM D395 Method B, 70 hrs. at 200°C, % Perm. Set 6 30 max.Comp. Set, ASTM D395 Method B, 70 hrs. at 200°C, % Perm. Set 5 NA, ReportAfter cooling for 18 hours Assembled in FixtureCompression Stress Relaxation, % Force retained 72 NA, ReportNOTE - <strong>V115</strong> approved by GE per DFO-A50TF327-3 dated July 30, 2007 for Class A (O-rings) and Class B (Molded Parts, sheets, strips andshapes)© Copy right 2013The inf ormation contained herein is believ ed to be reliable, but no representation, guarantees or warranties of any kindare made to its accuracy or suitability f or any purpose. The inf ormation presented herein is based on laboratory testingand does not necessarily indicate end product perf ormance. Full scale testing and end product perf ormance are theresponsibility of the user.www.simrit.com866-274-6748

<strong>GEAE</strong> <strong>Spec</strong>ification A50TF327 Class A - O-ringsNOTE - All testing done on AS568-214 size O-rings per the specification requirements for Class AHTS Oil, (BP Turbo Oil 2197) conforming to MIL-HTS-23699 HTS, 168 hrs. at 200°CHardness change, Shore A -11 -15 max.% Tensile change -7.1 -30 max.% Elongation change +4.2 -10 max.% Volume change +30 max.Comp. Set, ASTM D395 Method B, 168 hrs. at 200°C, % Perm. Set 5 35 max.Comp. Set, ASTM D395 Method B, 168 hrs.at 200°C, % Perm. Set 4 NA, ReportAfter cooling for 18 hours Assembled in FixtureCompression Stress Relaxation, % Force retained 76 NA, ReportHTS Oil, (BP Turbo Oil 2197) conforming to MIL-HTS-23699 HTS, 336 hrs. at 200°C <strong>V115</strong> <strong>Spec</strong>ificationHardness change, Shore A -11 NAUltimate Tensile Strength, Mpa 8.8 7.6 min.Ultimate Elongation, % 241 200 min.% Volume change +13.1 +27 max.Comp. Set, ASTM D395 Method B, 336 hrs. at 200°C, % Perm. Set 12 22 max.Comp. Set, ASTM D395 Method B, 336 hrs. at 200°C, % Perm. Set 13 32 max.After cooling for 18 hours Assembled in FixtureCompression Stress Relaxation, % Force retained 74 NA, ReportHTS Oil, (BP Turbo Oil 2197) conforming to MIL-HTS-23699 HTS, 1,000 hrs. at 200°CHardness change, Shore A -12 NAUltimate Tensile Strength, Mpa 3.9 3.3 min.Ultimate Elongation, % 102 80 min.% Volume change +17.0 +35 max.Comp. Set, ASTM D395 Method B, 336 hrs. at 200°C, % Perm. Set 28 50 max.Comp. Set, ASTM D395 Method B, 336 hrs. at 200°C, % Perm. Set 28 50 max.After cooling for 18 hours Assembled in FixtureCompression Stress Relaxation, % Force retained 67 NA, ReportNOTE - <strong>V115</strong> approved by GE per DFO-A50TF327-3 dated July 30, 2007 for Class A (O-rings) and Class B (Molded Parts, sheets, strips andshapes)© Copy right 2013The inf ormation contained herein is believ ed to be reliable, but no representation, guarantees or warranties of any kindare made to its accuracy or suitability f or any purpose. The inf ormation presented herein is based on laboratory testingand does not necessarily indicate end product perf ormance. Full scale testing and end product perf ormance are theresponsibility of the user.www.simrit.com866-274-6748

<strong>GEAE</strong> <strong>Spec</strong>ification A50TF327 Class A - O-RingsNOTE - All testing done on AS568-214 size O-rings per the specification requirements for Class AHTS Oil, (BP Turbo Oil 2197) conforming to MIL-HTS-23699 HTS, 2,000 hrs. at 200°CHardness change, Shore A 0 NA, ReportUltimate Tensile Strength, Mpa 2.2 NA, ReportUltimate Elongation, % 68 NA, Report% Volume change +22 NA, ReportComp. Set, ASTM D395 Method B, 336 hrs. at 200°C, % Perm. Set 38 NA, ReportComp. Set, ASTM D395 Method B, 336 hrs. at 200°C, % Perm. Set After cooling for 18 hours Assembled in Fixture 37 NA, ReportCompression Stress Relaxation, % Force retained 49 NA, Report© Copy right 2013The inf ormation contained herein is believ ed to be reliable, but no representation, guarantees or warranties of any kindare made to its accuracy or suitability f or any purpose. The inf ormation presented herein is based on laboratory testingand does not necessarily indicate end product perf ormance. Full scale testing and end product perf ormance are theresponsibility of the user.www.simrit.com866-274-6748